Posted By: patrick

re-ringing a short block, cast or moly rings? - 07/06/09 04:50 PM

short block in question is a 1986 vintage 318, 76k miles on it.

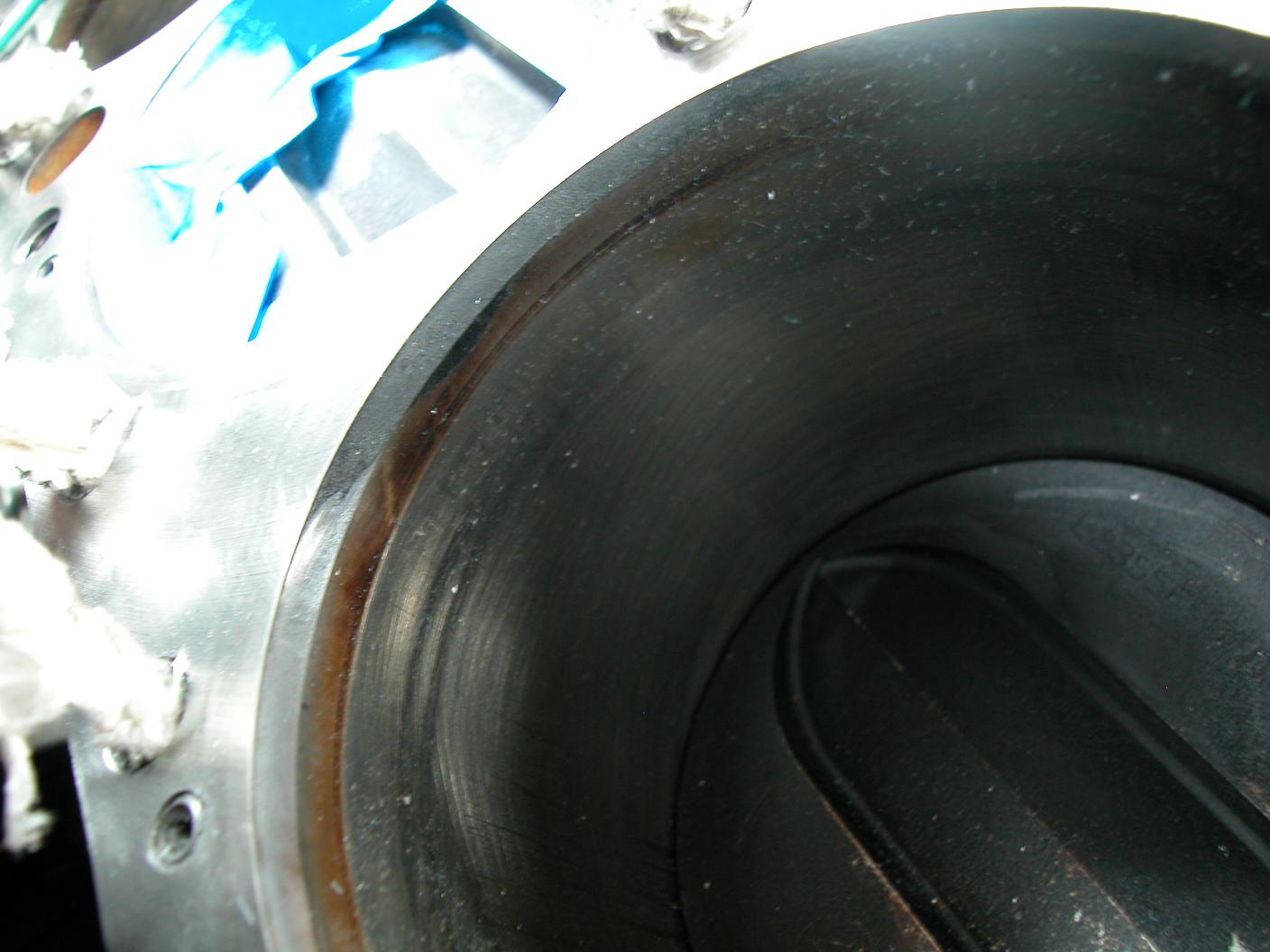

there is no ridge detectable with a fingernail, and you can still see the cross hatching

I wasn't really planning on even touching the rings, but last year I sold the '302 heads off the motor, and apparently I didn't do a super job cleaning things up after I took them off and there was a little bit of coolant sitting in the #4 and #6 cyls. I can't feel anything with my finger/fingernail, but there is some slight discoloration in the cylinders, that's why I'm thinking of tossing new rings in.

should I leave it as is, or toss some new rings in it while I have it apart?

I have one of those 3 finger, spring loaded hone/deglazers that I can run through the bores to clean it up, or I know someone with a ball hone that I can borrow. which would be better? also, if I toss new rings in, should I get plain cast, or plasma moly coated?

thanks in advance.

there is no ridge detectable with a fingernail, and you can still see the cross hatching

I wasn't really planning on even touching the rings, but last year I sold the '302 heads off the motor, and apparently I didn't do a super job cleaning things up after I took them off and there was a little bit of coolant sitting in the #4 and #6 cyls. I can't feel anything with my finger/fingernail, but there is some slight discoloration in the cylinders, that's why I'm thinking of tossing new rings in.

should I leave it as is, or toss some new rings in it while I have it apart?

I have one of those 3 finger, spring loaded hone/deglazers that I can run through the bores to clean it up, or I know someone with a ball hone that I can borrow. which would be better? also, if I toss new rings in, should I get plain cast, or plasma moly coated?

thanks in advance.

the wife won't like it if I have to bore w/pistons

the wife won't like it if I have to bore w/pistons