Posted By: clemford

727 front clutch orifice restriction size - 05/26/23 11:44 PM

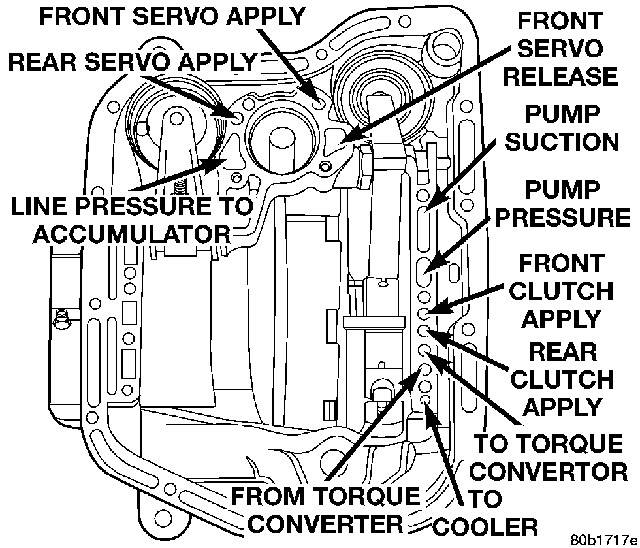

Im wondering what size to reduce the front clutch because of the hard thumping into 3rd at light throttle and overlap on manually 1-2 shift for the last 48 years.

I removed the shuttle rod and put back in the d pocket ball bearing. I might even put the accumulator spring back in after seeing the cheap fairbanks (plate kit) didnt even have an accumulator blocker rod, but it was still in straight. I'll use the fairbanks separator plate.

This still has the stock original line psi spring. A&A told me maybe go a turn more over stock 1 5/16 inches. ,spring is much weaker than b&M, etc.

y07a66 here said .093 was good size for him a few years back but he had a transgo 2 spring really cranked up so im thinking my weak spring psi will need a bigger hole, at least 100 . A&A thought might be good. the b&m were .140 which wasnt small enough with big spring. Any guesses as these headers and sore back make vb removing miserable. I can put up with manual shift overlap and 3rd gear clunk rather than downshift flare up. Its just a guessing game.

Also i put a a&a part throttle kit in . That will be interesting. Also pulling tailshaft tomorrow to do the rear pin o .ring. It would have been easier to have pulled tranny out. Thanks in advance.

I removed the shuttle rod and put back in the d pocket ball bearing. I might even put the accumulator spring back in after seeing the cheap fairbanks (plate kit) didnt even have an accumulator blocker rod, but it was still in straight. I'll use the fairbanks separator plate.

This still has the stock original line psi spring. A&A told me maybe go a turn more over stock 1 5/16 inches. ,spring is much weaker than b&M, etc.

y07a66 here said .093 was good size for him a few years back but he had a transgo 2 spring really cranked up so im thinking my weak spring psi will need a bigger hole, at least 100 . A&A thought might be good. the b&m were .140 which wasnt small enough with big spring. Any guesses as these headers and sore back make vb removing miserable. I can put up with manual shift overlap and 3rd gear clunk rather than downshift flare up. Its just a guessing game.

Also i put a a&a part throttle kit in . That will be interesting. Also pulling tailshaft tomorrow to do the rear pin o .ring. It would have been easier to have pulled tranny out. Thanks in advance.