You are so wrong. Anyone that wires these old cars off the alternator stud with old wiring and connections is a hack.

Two conditions to get it right.

Once you add accesories as an upgrade on your car, i.e. electric fans, the alternator must be upgraded accordingly. Stock configuration for a correct ammeter reading is everything must be sourced from alt side. You need just to check a factory diagram to prove this is a must.

So the conditions if keeping ammeter on car to be correctly sourced are:

-Everything must be sourced from alt side

-alt must be upgraded accordingly to the new accesories to keep the right reading and the loads going throught the correct side.

Several reasons why wiring on Mopars are a weak spot and this is on 70% of times owners/mechanics fault by the unkownledgement of how the system works.

The alt provides what the car and its accesories requires to work and tries to keep the batt fully charged, nothing more, but less is not capable.

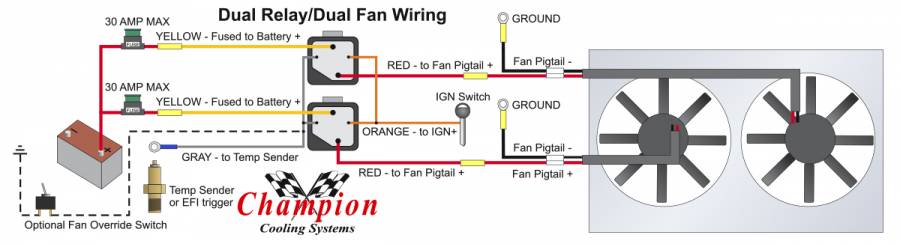

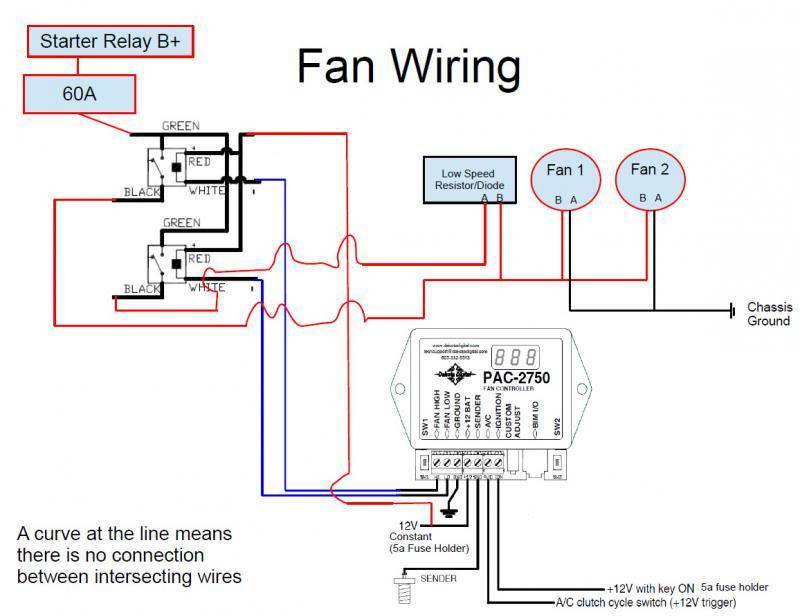

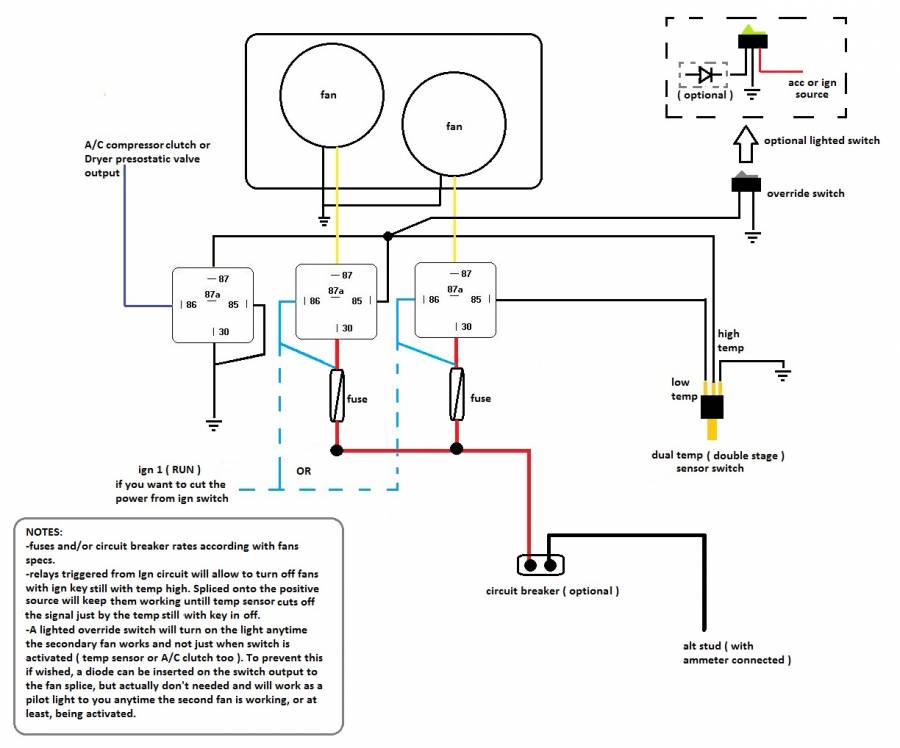

If you source anything on batt side, more load will go through the stock wiring, bulkhead, ammeter etc… like if the batt will never get fully charged. So if you source, on this case, electric fans correctly on alt stud, the load the alt will supply to source them, WON’T EVER RUN through the stock wiring but straight from alt to the fans relay setup. BUT if you source them on batt side the required load to feed them will be stressing unnecessarily throught the stock system and amm will be constantly on CHARGE side.

Which is true, bulkhead is a weak spot, and stock alts are tipically unable to keep the batt charged at iddle, hence why when revving up the engine, the ammeter senses CHARGE. This is increased with loads hooked up on batt side as mentioned.

The only moments weakness of the stock system becomes critical sourcing CORRECTLY the added accesories on alt side is when the alt is unable to source most of the required loads (or engine is off, so does the alt ) and battery becomes on the constant main source. This is the moment when the ammeter becomes on a dancing gauge going back and forward along with engine revs. The more load going back and forth along the charging system, the more heat is able to get and this is the moment becomes on a dangerous stage.

Since the beginning EVERYONE began to source added accesories on batt side. This along with the weak bulkhead spot (which is true) and the unneficient stock alts at iddle is what got our Mopars burning wiring along the years. Add to this, ppl “upgrading” batteries with more reserve capacity to hold added accesories, which it took MORE time to keep them charged by the uneficient stock alts… so more stress to the system.

So in conclusion:

Hook up the fans on alt stud and upgrade the alternator are the correct way to proceed to keep safe the wiring and ammeter and EVEN THE BULKHEAD conector, because bulkhead won’t get ever this load correctly soorcing the fans. But is true some easy wiring mods are advice just in case, like save the bulkhead connections with some paths and wiring upgrades… which has been already shown and discussed in the past on several threads when talking about alt upgrades and those who thinks the ammeter bypass ( or the jumpong wire between alt and batt ) is the solution. No need to jump out batt with alt, which bypasses the amm reading. And with the correct procedures, the ammeter will be still safe and reading strong and correctly

Being there done that, on a driver ( A REAL DRIVER ) 74 Mopar on a heavy transit city.

Which is also true is when proceeding with any add on or upgrade, the related system must be correctly checked to be sure if will survive to the new part or upgrade.

![[Linked Image]](https://board.moparts.org/ubbthreads/ubbthreads.php/ubb/download/Number/328217/filename/Main%20charging%20wires-system.jpg)

![[Linked Image]](https://board.moparts.org/ubbthreads/ubbthreads.php/ubb/download/Number/328217/filename/Main%20charging%20wires-system.jpg)