Posted By: IROC78

8.75 question - 07/27/22 11:49 PM

So I ran into an issue I was hoping someone may be able to shed some light on. I recently went to buy a 8.75 third member from Dr Diff. It turns out he is short staffed and not doing any assembling right now. So he sold me all the parts and I dropped them off to a reputable local shop that specializes in differentials.

I got a call from the shop today and was told the third member would not go together.

I was told the ring gear and bolts are hitting the case. The gears are 3.91's, and when the shop owner called Yukon he was told that with that ratio there should be no grinding to the case necessary to assemble the unit. The shop owner estimated 2-3 hours labor to clearance the new Yukon case to get things to fit. He has another OEM gearset on hand and that ring gear measures slightly smaller. The Dr Diff Sure Trac II unit measured out spot on. Cass sold me the parts for $1310 I believe, and he sells the assembled third members for $1425. I have a hard time believing he's spending an additional 2-3 hours to clearance a brand new case on top of time to set the unit up all for $115.00. If anyone out there could shed some light on this for me it would be much appreciated.

My first move was to get in touch with Cass, but he is on vacation until next Thursday. Thank you for any and all help, it is much appreciated.

Posted By: TJP

Re: 8.75 question - 07/28/22 01:10 AM

I would suggest a visit to the shop as your description is confusing (No offense meant). The ring gear and bolts are hitting which case? The Housing or the differential itself? and which bolts? the Ring gear?

How can that be? The ring gear goes on one side, the bolts on the other.

the ring gear bolts are on a much smaller radius than the OD of the gear.

I am totally confused ( which is not unusual LOL)

Further more I would not allow him to start HACKING on things until the issue is identified and corrected PROPERLY.

Keep us posted

Posted By: slantzilla

Re: 8.75 question - 07/28/22 01:49 AM

I just put together a 4.86 with a spool. Before the backlash was set the ring gear bolts were very close to the inside of the housing. IIRC, the housings that Doc sells are heavier than stock, the bolts might be close.

But yeah, go there in person to see what is going on. He might be trying to put the carrier in upside down.

Posted By: PhillyRag

Re: 8.75 question - 07/28/22 02:29 AM

I just put together a 4.86 with a spool. Before the backlash was set the ring gear bolts were very close to the inside of the housing. IIRC, the housings that Doc sells are heavier than stock, the bolts might be close.

But yeah, go there in person to see what is going on. He might be trying to put the carrier in upside down.

I would hope that isn't the case (no pun intended)

Posted By: IROC78

Re: 8.75 question - 07/28/22 11:31 AM

Thank you for the replies. When I used the word "case" what I was referring to was the housing. When the shop told me the ring gear and bolts were making contact with it, I assumed the bolts he was talking about the ring gear bolts but I did not specifically ask. I will be sure to let you guys know what the situation was/is once I lay eyes on it myself. Thanks again !

Posted By: TJP

Re: 8.75 question - 07/28/22 03:17 PM

Thank you for the replies. When I used the word "case" what I was referring to was the housing. When the shop told me the ring gear and bolts were making contact with it, I assumed the bolts he was talking about the ring gear bolts but I did not specifically ask. I will be sure to let you guys know what the situation was/is once I lay eyes on it myself. Thanks again !

Take a pic or two for posting and Yukon, Dr. Diff etc.

Again I would not start hacking on things as it usually leads to other problems.

Posted By: topside

Re: 8.75 question - 07/28/22 03:26 PM

This sounds pretty weird to me: I've had 2 8.75" diff cases/housings/whatever with 3.91s swapped for 3.23s and none of them were modified.

Parts were from Dr. Diff, too.

One was a 742 & the other a 489 casting.

Posted By: moparx

Re: 8.75 question - 07/28/22 05:22 PM

this will be interesting to find out what is going on.

as was said, if possible, please post a couple of pictures showing what the problem is.

Posted By: CMcAllister

Re: 8.75 question - 07/28/22 05:40 PM

Never heard of it. Would like to see it.

Ring gear bolts hitting the housing at the faceplate?

Posted By: GomangoCuda

Re: 8.75 question - 07/28/22 11:05 PM

First thing is you described them as a reputable differential shop. Do they normally work on car differentials or is their business working on semis, school buses, dump trucks and bull dozers. Maybe the guy working on yours normally sweeps the floor and he is learning to work on your 8 3/4 by watching youtube videos.

Can we assume that the ring and pinion are actually a set and were not mixed up at the factory? For example a pinion for a 3.23 is not going to work with a 3.91 ring. Has the pinion depth been properly set? Do they have the proper shims and tools to do that? Maybe the pinion bearing is not all the way on the pinion or maybe the cup is not all the way in the housing bore. Since this a new aftermarket housing (China?) it is certainly possible that it was not machined properly.

We Need Pictures

Posted By: IROC78

Re: 8.75 question - 07/28/22 11:10 PM

No I'm definitely not going to have them grind on anything and I'm glad they called me instead of "making it work". The shop is strictly high performance differentials and does all of the work for the hot rod shop where my buddy works and came highly recommended by him as well as several local Mopar guys. Granted most of the stuff they work on is Ford nine inch, he said they do plenty of 8 3/4 and Dana rears as well. While the shop is "local" to me it is still over an hour ride each way so at this point I will probably wait for Dr Diff to get back in next Thursday and see what he has to say. I'm hoping that it was just a bad/wrong part that got sent, and thought maybe it was a common issue someone else had run into. One issue is the gear set is Dr Diff brand, and without knowing who makes it for him, the guy at the shop can't talk to the manufacturer. I will also have him send me a picture when he gets a chance and I will be sure to post whatever I get picture wise. Thanks again everyone,

I put a set of 4.10's in a Yukon case a few years back and it was problem free. I was installing a spool but they are the same size from the carrier bearings to the ring gear flange.

The only thing I can add to look at is make sure the bearings are pressed completely on the carrier. That would be the only thing that would cause the carrier to interfere with the case

Gus

Posted By: IROC78

Re: 8.75 question - 08/13/22 11:22 PM

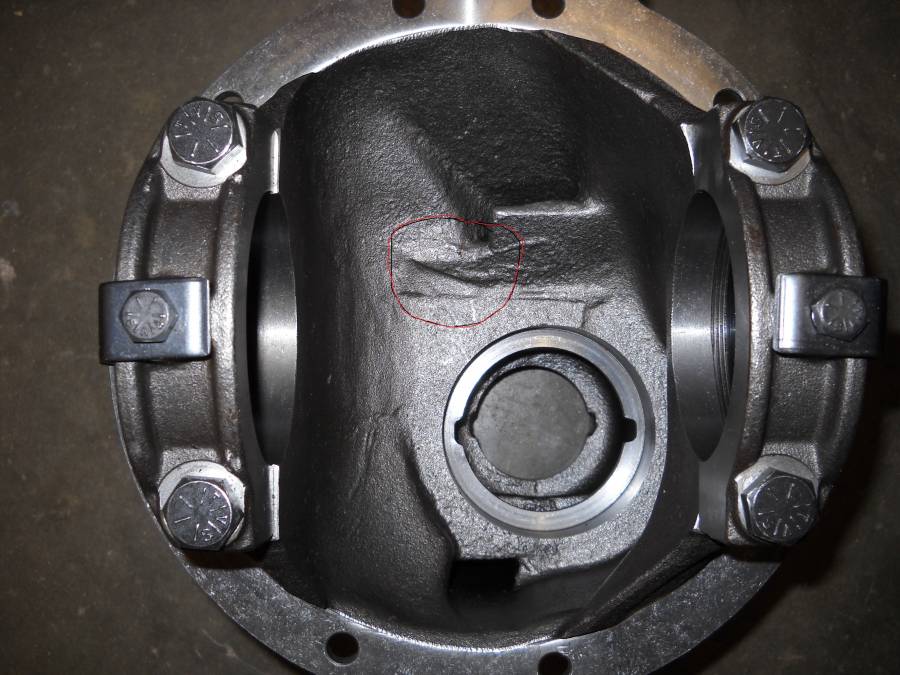

Sorry for not updating this sooner, but I figured it wasn't a good idea to post again until I had pictures. After talking to Cass at DoctorDiff he told me the problem is casting shift when these Yukon nodular 489 housings are made. He was very helpful as always, and told me where the housing would need to be clearanced. The shop I was working with was hesitant to remove as much material as would be necessary from the housing, so I just ended up bringing them a shock one to use as I really didn't need the added strength of the nodular case for this particular project. Cass also stated that occasionally he heeds to clearance the side of the housing and cap in order for the ring gear bolts to clear. Here are a couple of pictures. The first is one the shop took to show me the carrier wouldn't sit all the way down in the case, and the second is one I took and circled the hump in the casting that was the culprit. Thank you again to everyone who replied trying to help, it is greatly appreciated. Hopefully this will help someone else out in the future if they encounter the same problem.

Posted By: TJP

Re: 8.75 question - 08/14/22 02:01 AM

I would call that housing a REJECT / bad part that should have been caught during QA. Where are these being made dare I ask?

Not that it really matters as a bad part is a bad part

Posted By: carnut68

Re: 8.75 question - 08/14/22 07:51 AM

I bought a 489 housing from DR Diff and spool with all parts needed ,it was assembled by a friend with 4.30 gears no issues. He tried it in his ride and it made a 9.65 pass or 4.

Posted By: moparx

Re: 8.75 question - 08/14/22 06:30 PM

i worked with iron and steel castings a lot during my 45yr machinist career, and it was common to have to remove, or clearance, casting lumps.

these castings were for high pressure vessels, and were very high quality to begin with, but they still needed work at times to allow the internal parts to fit.

i wouldn't think twice about removing those lumps shown, unless it took a HUGE amount of material removal to make the guts fit.

just my personal experience working with castings. your mileage will vary.

Posted By: IROC78

Re: 8.75 question - 08/14/22 09:32 PM

I'm not sure where Yukon produces these, although from my experience unless it says "Made in USA", it is usually made elsewhere. I agree, after seeing things in person I wouldn't have worried about removing some material, but for some reason the shop was against it or seemed to think it would be a bigger issue than they wanted to deal with. I am sure the stock piece will be just fine for my application, as I imagine it would be pretty hard for me to hurt it as this is going in a street car with 215's in the back :-)

Posted By: poorboy

Re: 8.75 question - 08/15/22 01:57 AM

It probably really comes back to the casting process.

Both the top surface and the bottom surface (and often times a center mold) of a casting are produced by a sand mold (at least they were 30 years ago). Those sand casting molds that the melted steel or iron is poured into is nothing more then sand bonded together in a lined steel framework. The casting defect shown was simply a matter of some of the bonded sand has broken off, or was not present, on either the top, the bottom, or the inner molds.

The process to make a sand cast part is pretty fascinating to witness. The inner mold is formed by mixing sand with a bonding agent, then while its still moldable, it is pressed into a mold to make the desired shape of the inner opening with metal rods of enough strength and length to support the inner mold on the top and bottom casting housing, the metal rods became part of the casting. Hundreds of these inner casting molds are made daily (enough for each daily run), then set aside to fully cure. The top and bottom castings are often formed on the pouring floor conveyer system and is often automated. A steel sleeve it set on a wood platform that rides on a skid. Then the sand mixed with the bonding agent is added inside of the sleeve. The next station the bottom mold has the sand pressed into the desired shape by a machined mold. On an adjacent line the upper casting mold is made the same way, at the same time. At the next station, the inner mold in placed onto the top of the bottom mold in the proper position. At the next station, the top mold is inverted and sat on top of the bottom mold. The next step the molten metal that will be the cast housing is poured into the complete mold. The filled mold travels along a very long track until the poured metal cools to a specific temp. (the line at the foundry I worked at was a mile long conveyor and it took somewhere between a 1/2 hour to an hour or more for the metal to cool enough, the speed at which the skid moved was set dependent on the casting being made).

After the casting reached the proper temp, the mold was removed from the board and the skid it was riding on. the next step pushed the sand out of the steel sleeves and the sand and the casting was dumped onto a metal netting that shook and broke up the sand (the top, bottom, and often the inner castings). The castings rolled down a grade and were picked back up on the next step. While the sand and the casting were rolling down the grade, the skid, the base board and the steel sleeves were all returned to the beginning of the line for the next casting.

From this point the operation was mostly manual (back then) where the still hot casting was rotated by hoist to remove the inner sand casting, and the parts were set on steel pallets to be moved to a place to sit and cool for a day. After the cooling process, the castings were inspected mostly looking to be sure there were no unexpected holes, or defects in the castings. Then they were moved to the grinding station where the casting slag was removed, and future machining areas were ground basically flat. Actual machining may or may not have been done inhouse.. Any defective castings were returned to the melting pot and were recycled.

After machining, some areas around the machined locations (done in house) were checked with go/no go clearance devices. Some were sent back to the grinding area to be dressed up. (The people that set up your gears may not want the grinding dust or casting dust inside their facility.)

This is sort of an over view of the sand casting process, as it was 30 years ago. I worked maintenance on that main casting line, so some details may not be in the correct order, and certainly doesn't include every process. I watched the last couple hours of the pouring process on that machine every work day for 6 months before I got out of the sand box, and got a better job elsewhere. Gene

Posted By: GomangoCuda

Re: 8.75 question - 08/15/22 02:10 AM

I would not want to grind more than a superficial amount without sonic testing. Just send it back and tell them to send you a good one.

Posted By: IROC78

Re: 8.75 question - 08/15/22 01:00 PM

Thank you for the insight into how the casting process works as it helps provide a visual as to what happened with this piece during production. While I was initially surprised that there couldn't be better quality control, regardless of where it was produced, it seems that it is actually quite common. I installed the center chunk using the factory 489 housing yesterday and should be back on the road soon. The old one will either be sent back or sold to my friend who is in need of it with a full disclosure so they are not surprised like I was. Thanks again guys!

Posted By: JohnRR

Re: 8.75 question - 08/15/22 01:19 PM

but for some reason the shop was against it or seemed to think it would be a bigger issue than they wanted to deal with.

I'll go with the latter ....

Housing are more than likely cast offshore ... thank the EPA for destroying manufacturing in this country for the most part.

I was getting ready to throw a bunch of housings in my scrap pile , maybe I'm going to second guess that now ...