Moparts

Come on ... BE HONEST...what do you properly TORQUE... ?

Posted By: dOrk !

Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 02:49 AM

... I’ve built a few motors and done lots of mechanical work ... BUT NOT LIKE SOME HERE !

Me ? ... rod and mains.. head bolts ... most times INTAKE BOLTS ...,

BUTTTT ... oil pan and water pump bolts ? ... etc ?? !!

Posted By: Guitar Jones

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 03:19 AM

Pretty much just cam sprockets, bearing caps and head bolts. But with over 45 years as an auto mechanic I have a pretty good feel for things.

Posted By: Jim_Lusk

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 03:22 AM

On an engine, pretty much everything EXCEPT some intake bolts that there is no way to get a torque wrench on (middle bolts on a 340 come to mind). I also torque lug nuts and some suspension nuts (ball joints, tie rods).

Posted By: Uberpube

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 04:14 AM

If I can get a torque wrench on it, I'll do it to spec.

Posted By: Ramrod39

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 06:05 AM

Important stuff. Engine internals, things like that. Beyond that, I am pretty well calibrated and can feel what is right.

Posted By: Stanton

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 02:01 PM

Anything that specifies more than 30 foot pounds.

Posted By: 6PakBee

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 02:51 PM

I torque everything that has a specification. I find that even after decades I tend to over tighten smaller fasteners (< 3/8" or so) and under tighten larger fasteners (> 3/8" or so). I've gone to grade 8 on any 1/4" bolt as I pop the stock fasteners like candy. Intake gasket end rails on a BB as one example. The only notable exception is the oil pan. That I use gasket compression to know when to stop.

Posted By: Sniper

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 02:54 PM

Everything.

Even the inner intake bolts

Posted By: 5thAve

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 03:57 PM

Engine internals, heads and intake gasket. Other then that I mostly only do something if it's hard to get to once everything is fully assembled or if it's a part I don't want to take off again or gasket failure might have been part of the original problem.

Posted By: MarkZ

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 04:57 PM

Head bolts, rod bolts, main caps, rockers shaft bolts, etc. Don't think I've ever torqued intake bolts, oil pan bolts or anything on the front of the motor for that matter. I'm anal about the tightening sequence though.

Posted By: moparjim79

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 05:05 PM

Here's a thought too-- is it not just as important to follow the steps/procedure/sequences incrementally as it is to torque to "value"? Example: (generic) lets say head bolts need 110 ftlbs., who feels ok just jammin' them away to said torque spec following the sequence? Or do you go incrementally (20ftlbs, 40 ftlbs, etc)?

Posted By: Guitar Jones

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 06:37 PM

Incremental is the way it should be done and the way I like to do it, but let 's face it, unless this is a high performance car it probably isn't going to matter. There is a difference between a race engine and a stock daily driver. For instance, for a driver just torquing rod bolts is fine, for a race engine, the bolt stretch method should be mandatory.

Posted By: Kern Dog

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 07:09 PM

Head bolts, Rod bearings, main bearings, flywheel bolts, lug nuts. That is about it.

Posted By: John_Kunkel

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 07:47 PM

Since the OP wasn't engine-specific, don't forget lug nuts.

Posted By: Hemi_Joel

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/20/21 08:35 PM

I torque everything that has a specification. I find that even after decades I tend to over tighten smaller fasteners (< 3/8" or so) and under tighten larger fasteners (> 3/8" or so). I've gone to grade 8 on any 1/4" bolt as I pop the stock fasteners like candy. Intake gasket end rails on a BB as one example. The only notable exception is the oil pan. That I use gasket compression to know when to stop.

About the same here plus I use a torque wrench on the air cleaner wing nut, hose clamps, and trim screws.

Posted By: A727Tflite

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 12:30 AM

I torque everything that has a specification. I find that even after decades I tend to over tighten smaller fasteners (< 3/8" or so) and under tighten larger fasteners (> 3/8" or so). I've gone to grade 8 on any 1/4" bolt as I pop the stock fasteners like candy. Intake gasket end rails on a BB as one example. The only notable exception is the oil pan. That I use gasket compression to know when to stop.

About the same here plus I use a torque wrench on the air cleaner wing nut, hose clamps, and trim screws.

Just like the vehicle assembly plants - they use DC nut runners on everything.

And the manufacturing plants use them too along with “multiples”.

Posted By: cudaman1969

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 12:53 AM

45 years ago couldn’t keep oil pan bolts from coming lose or falling out on the race car, on a whim I looked in a service manual, used the torque and never came lose again. Long story short I torque EVERYTHING I can get to at factory spec.

Posted By: moparjim79

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 01:27 AM

[/quote]

About the same here plus I use a torque wrench on the air cleaner wing nut, hose clamps, and trim screws.

[/quote]

That was awesome

Posted By: mopars4ever

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 02:43 AM

Pretty much everything I can get a torque wrench on. I don`t torque valve cover and oil pan bolts as I do them by feel. As a side note, I remember when I was young I asked a mechanic at the local dealer what was the torque spec for main caps bolts and head bolts for a small block mopar. He said I don`t know I just use my air gun and crank them down. I laughed as I thought he was joking. He said I`m not joking I work flat rate and I don`T have time for that. He added that he never has any come backs.

Posted By: Sniper

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 02:54 AM

I find a correlation between the lack of using a torque wrench and leaky valve covers and oil pans.

I am lazy, I prefer to do the job once.

Posted By: 3hundred

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 02:59 AM

45 years ago couldn’t keep oil pan bolts from coming lose or falling out on the race car, on a whim I looked in a service manual, used the torque and never came lose again. Long story short I torque EVERYTHING I can get to at factory spec.

I used to have trouble with transmission pans. After I found we had an inch pound wrench I used the spec, typically 12 in lbs, found it took several rounds to get them all tight at once, no more leaks.

Posted By: poorboy

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 04:55 AM

About 30 years ago I lost the ability to be able to know how tight bolts were by hand tightening. Torquing everything is a royal pain. Over the last 15 or so years, I don't do much stuff that requires specific torque anymore. Just one of several reasons I became a welder. Gene

Posted By: Cab_Burge

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 06:55 AM

I remember a older Service station mechanic telling me that he had calibrated elbows on most tightening he did on cars in that stations bays.

I will use a inch lb. torque wrench and convert the lighter ft. lbs. into inch lbs. like using 23 Ft. Lbs. on 5/16 bolts, 23x12=276 inch lbs. 20x12=240 + 3x12=36. 36+240= 276

Posted By: Mcode69

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 10:47 AM

Heads, rods and mains here down under !

Posted By: 6PakBee

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 01:27 PM

I torque everything that has a specification. I find that even after decades I tend to over tighten smaller fasteners (< 3/8" or so) and under tighten larger fasteners (> 3/8" or so). I've gone to grade 8 on any 1/4" bolt as I pop the stock fasteners like candy. Intake gasket end rails on a BB as one example. The only notable exception is the oil pan. That I use gasket compression to know when to stop.

What is the torque spec on an air cleaner wing nut, hose clamps, and trim screws? After all, you said you used a torque wrench to tighten them, you must know.

Posted By: dOrk !

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 02:15 PM

I’m surprised....

NO one mentions the critical torque spec of the ......

Muffler bearing

Maybe the

from Bend oVeR can check in

Posted By: mopars4ever

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 02:19 PM

I find a correlation between the lack of using a torque wrench and leaky valve covers and oil pans.

Quite the opposite for me. They are the only ones I have found that needed hand tightening instead of a torque wrench. All seemed to be too loose.

Posted By: dOrk !

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 02:22 PM

Oil pan bolts?

Did you

THROW OUT the special nyLock bolts

Posted By: 19swinger70

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 03:57 PM

I use a torque wrench on all mechanical assemblies where I can actually gain enough clearence to do so. When I can't, it bothers me!

Posted By: Dcuda69

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 04:29 PM

I think you need to be more specific. Putting together older iron is completely different than the late model stuff. Not following specific torque specs/sequences on late model stuff(especially TTY bolts) will guarantee failures.

Posted By: moparx

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 06:15 PM

Posted By: IMGTX

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 11:32 PM

Rod, main, & head bolts - yes

Lug nuts on any import or an American car newer than mid 80's. Yes

Exotic unfamiliar engine parts like Cam Phasers or some other unusual item that looks like it could warp under too much pressure, I look up and torque to spec too.

Anything else I will torque with experience and the industry standard spiral sequence.

I never thought of anything else having a torque spec until I watched a terminator movie and Arnold used a torque wrench on a starter. I thought that's weird and then it hit me, oh yeah there is probably a spec for everything. LOL

I also only use Red threadlocker (Permanent) and never blue (Temporary). Especially on cam bolts, even if it isn't required.

I also incrementally torque nearly everything and never tighten any one bolt until all the bolts are started and run most of the way in. I can not tell you how many newbie mechanics just start popping in bolts & tighten away, and then they have to loosen them all to get the last few in.

Posted By: Sniper

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/21/21 11:44 PM

I find a correlation between the lack of using a torque wrench and leaky valve covers and oil pans.

Quite the opposite for me. They are the only ones I have found that needed hand tightening instead of a torque wrench. All seemed to be too loose.

I'm thinking of the ones reefed down so hard that they warp the rails and never seal. Both ends of the spectrum are bad.

Posted By: justinp61

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/22/21 02:18 PM

I used to have trouble with transmission pans. After I found we had an inch pound wrench I used the spec, typically 12 in lbs, found it took several rounds to get them all tight at once, no more leaks.

Same here, oil pans and valve covers too.

Posted By: MarkZ

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/22/21 02:48 PM

I used to have trouble with transmission pans. After I found we had an inch pound wrench I used the spec, typically 12 in lbs, found it took several rounds to get them all tight at once, no more leaks.

Same here, oil pans and valve covers too.

Type of pan/cover and gasket probably matters as well. If you're using a cork gasket with a stamped steel cover, then torque spec is crucial. I've been using cast aluminum covers/pans with anti-crush gaskets now for years and don't have any issues with hand tightening. Still using a stamped oil pan, but for that I bought Andy's pan reinforcements.

Posted By: IMGTX

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/22/21 07:42 PM

I used to have trouble with transmission pans. After I found we had an inch pound wrench I used the spec, typically 12 in lbs, found it took several rounds to get them all tight at once, no more leaks.

Same here, oil pans and valve covers too.

#1 important thing for pans and covers is clean and check them with a straight edge. Too many gorillas work on the car before me and think tighten it until it bends the wrench and the pan.

For trans/oil/valve covers I do not use anything bigger than a 1/4" drive ratchet. Same thing with plastic intakes.

I do follow the gasket manufacturers recommendation about sealant but if it doesn't have specs I do this.

Trans pans I oil both sides of the gasket and snug repeatedly in a crisscross pattern until it feels good or the gasket starts to just barely squeeze out.

Oil pan I spread a thin thin smear of sealant on both sides of the gasket and snug repeatedly in a crisscross pattern until it feels good or the gasket starts to just barely squeeze out.

Valve covers, I use sealant on the valve cover side of the gasket and oil on the bottom of the gasket then snug then repeatedly in a crisscross pattern until it feels good or the gasket starts to just barely squeeze out.

If I have a leak I snug a little more but that doesn't happen often and it is usually when a center bolt valve cover has been bent in the middle.

The most important thing is to do what works best for you.

Posted By: volaredon

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/22/21 09:30 PM

Pffft.... not much. usually just internal engine bolts. Head, rod, main, sometimes manifolds.

Posted By: 360view

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/22/21 10:15 PM

Keep a “fisherman’s scale” in your tool box and every wrench becomes a torque wrench.

Posted By: Pacnorthcuda

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/22/21 10:18 PM

Keep a “fisherman’s scale” in your tool box and every wrench becomes a torque wrench.

IF you factor the length of the wrench into the calculation!

Posted By: dOrk !

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/22/21 10:20 PM

i m a GORILLA is not uncorrect...

Those damn pan rails are a bummer

Posted By: NANKET

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/25/21 09:52 PM

How about the front suspension bolts. Anybody concerned with these?

When you turn bolts everyday for a career you can get really good at getting bolts to proper torque by hand it you pay attention.

Posted By: RealWing

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/26/21 03:08 AM

I can usually tell what torque to apply after many many years of experience as well, however, every one of the front suspension bolts on my current '69 Barracuda restoration are torqued to spec.

Jim

Posted By: Sniper

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/26/21 01:35 PM

Anyone that thinks they can tell how tight something is torqued "by hand" is fooling themselves.

Posted By: jlatessa

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/26/21 02:29 PM

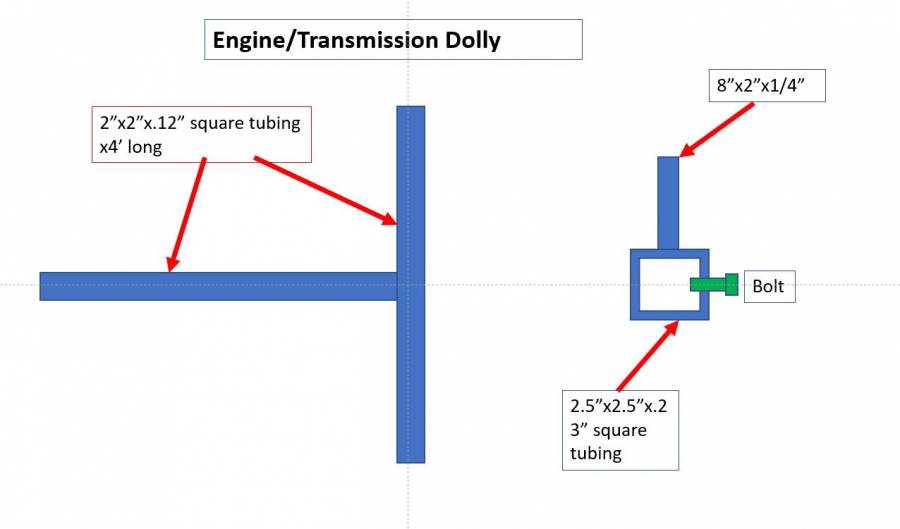

Realwing, is that a home made roll around under you eng./trans?

Looks good, care to share how you fabbed it?

The furniture movers we have aren't going to cut it for mobility.

Thanks, Joe

Posted By: 6PakBee

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/26/21 02:40 PM

Anyone that thinks they can tell how tight something is torqued "by hand" is fooling themselves.

I'm not so sure that applies to all people. When I was going to college I worked part time at the local Chrysler dealer. One thing I did was new car pre-delivery preparation (dealer prep). One of the items on the checklist was to make sure the front wheel bearings were adjusted properly, So I was working on a new car and had the torque wrench out adjusting the front wheel bearings as per the FSM procedure. The senior mechanic walked over and asked me what I was doing. Told him, he laughed that you could do that by hand, didn't need a torque wrench. This is 1974 and I'm young, dumb, and headstrong so I proceed to tell him it can't be done. Now this is a guy that has worked on Mopars since 1947 and has done it all. So it ended up in a challenge. I'd do it by the book and he'd do it his way and we'd compare. So I set one side and make a small dimple on the nut so you could tell position. Loosened it up and he had a go at it (I covered the dimple with a bit of grease) and......he ended up in EXACTLY the same spot. I never questioned him again and over the next year I learned a lot from that old fart. Passed away about 20 years go. Great loss of talent. Sometime I'll tell the story about replacing the casting plug in the end of a 383 head...with the engine in the car....on the end that faces the firewall...without removing the head.

Posted By: IMGTX

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/26/21 05:17 PM

Anyone that thinks they can tell how tight something is torqued "by hand" is fooling themselves.

Sometime I'll tell the story about replacing the casting plug in the end of a 383 head...with the engine in the car....on the end that faces the firewall...without removing the head.

I'm about to do that on a 440 Chrysler 300. My plan was a plumbing bar clamp. I would be very interested in his way.

Posted By: Dcuda69

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/26/21 06:17 PM

Anyone that thinks they can tell how tight something is torqued "by hand" is fooling themselves.

Yep! Our Snap on guy did a demo for our classes at school. None, I mean NONE of us were right on and that includes a few of us with 30+ years turning wrenches. Like I said earlier....new stuff is WAY different than stuff built 50 years ago. If you're not torquing stuff you're begging for come backs.

Posted By: Sniper

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/26/21 06:20 PM

Anyone that thinks they can tell how tight something is torqued "by hand" is fooling themselves.

I'm not so sure that applies to all people. When I was going to college I worked part time at the local Chrysler dealer. One thing I did was new car pre-delivery preparation (dealer prep). One of the items on the checklist was to make sure the front wheel bearings were adjusted properly, So I was working on a new car and had the torque wrench out adjusting the front wheel bearings as per the FSM procedure. The senior mechanic walked over and asked me what I was doing. Told him, he laughed that you could do that by hand, didn't need a torque wrench. This is 1974 and I'm young, dumb, and headstrong so I proceed to tell him it can't be done. Now this is a guy that has worked on Mopars since 1947 and has done it all. So it ended up in a challenge. I'd do it by the book and he'd do it his way and we'd compare. So I set one side and make a small dimple on the nut so you could tell position. Loosened it up and he had a go at it (I covered the dimple with a bit of grease) and......he ended up in EXACTLY the same spot. I never questioned him again and over the next year I learned a lot from that old fart. Passed away about 20 years go. Great loss of talent. Sometime I'll tell the story about replacing the casting plug in the end of a 383 head...with the engine in the car....on the end that faces the firewall...without removing the head.

Maybe you need to go back and reread how to set front wheel bearing preload. Having just converted my 51 from the original style setup to the later style, such as used in 74, there is no torque on the bearings when you are done.

Posted By: 6PakBee

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/26/21 06:27 PM

Anyone that thinks they can tell how tight something is torqued "by hand" is fooling themselves.

Sometime I'll tell the story about replacing the casting plug in the end of a 383 head...with the engine in the car....on the end that faces the firewall...without removing the head.

I'm about to do that on a 440 Chrysler 300. My plan was a plumbing bar clamp. I would be very interested in his way.

IIRC what Vern did was use a bar and a block of wood against the firewall. Took a punch and, in combination with the bar, pressed on a side of the plug to turn it sideways. He then pulled it out with a smaller bar. Cleaned the bore up with some abrasive cloth (as I remember this was the worst part), then used a socket and the bar/wood combo to press the plug in. He was leveraging everything off the firewall using the wood block as a spreader. I can't remember him disconnecting the kickdown linkage or the throttle linkage but he must have as this was the driver's side head. This was a mid 60's Chrysler wagon if my memory isn't totally crap today.

Posted By: Pacnorthcuda

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/26/21 06:30 PM

Anyone that thinks they can tell how tight something is torqued "by hand" is fooling themselves.

I'm not so sure that applies to all people. When I was going to college I worked part time at the local Chrysler dealer. One thing I did was new car pre-delivery preparation (dealer prep). One of the items on the checklist was to make sure the front wheel bearings were adjusted properly, So I was working on a new car and had the torque wrench out adjusting the front wheel bearings as per the FSM procedure. The senior mechanic walked over and asked me what I was doing. Told him, he laughed that you could do that by hand, didn't need a torque wrench. This is 1974 and I'm young, dumb, and headstrong so I proceed to tell him it can't be done. Now this is a guy that has worked on Mopars since 1947 and has done it all. So it ended up in a challenge. I'd do it by the book and he'd do it his way and we'd compare. So I set one side and make a small dimple on the nut so you could tell position. Loosened it up and he had a go at it (I covered the dimple with a bit of grease) and......he ended up in EXACTLY the same spot. I never questioned him again and over the next year I learned a lot from that old fart. Passed away about 20 years go. Great loss of talent. Sometime I'll tell the story about replacing the casting plug in the end of a 383 head...with the engine in the car....on the end that faces the firewall...without removing the head.

Maybe you need to go back and reread how to set front wheel bearing preload. Having just converted my 51 from the original style setup to the later style, such as used in 74, there is no torque on the bearings when you are done.

The procedure still involves a torque spec to arrive at the desired result. Unless you are good at doing it without, and many people are.

Posted By: 6PakBee

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/26/21 08:06 PM

Anyone that thinks they can tell how tight something is torqued "by hand" is fooling themselves.

I'm not so sure that applies to all people. When I was going to college I worked part time at the local Chrysler dealer. One thing I did was new car pre-delivery preparation (dealer prep). One of the items on the checklist was to make sure the front wheel bearings were adjusted properly, So I was working on a new car and had the torque wrench out adjusting the front wheel bearings as per the FSM procedure. The senior mechanic walked over and asked me what I was doing. Told him, he laughed that you could do that by hand, didn't need a torque wrench. This is 1974 and I'm young, dumb, and headstrong so I proceed to tell him it can't be done. Now this is a guy that has worked on Mopars since 1947 and has done it all. So it ended up in a challenge. I'd do it by the book and he'd do it his way and we'd compare. So I set one side and make a small dimple on the nut so you could tell position. Loosened it up and he had a go at it (I covered the dimple with a bit of grease) and......he ended up in EXACTLY the same spot. I never questioned him again and over the next year I learned a lot from that old fart. Passed away about 20 years go. Great loss of talent. Sometime I'll tell the story about replacing the casting plug in the end of a 383 head...with the engine in the car....on the end that faces the firewall...without removing the head.

Maybe you need to go back and reread how to set front wheel bearing preload. Having just converted my 51 from the original style setup to the later style, such as used in 74, there is no torque on the bearings when you are done.

I couldn't find a '74 manual online but this is the procedure from the '73 manual.

Posted By: 340SIX

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/26/21 11:38 PM

I just turn everything till it snaps off then back up 1 full measured turn

Posted By: RealWing

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/26/21 11:57 PM

Yes it is homemade. I attached a photo. If you need some measurements, let me know.

Jim

Posted By: Cab_Burge

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/27/21 01:53 AM

Posted By: jlatessa

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/27/21 02:13 AM

Yes, thanks, a couple of dimensions will save me some time.

Do the two tabs in front locate in the k frame?

Thanks again, Joe

Posted By: RealWing

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/27/21 02:36 AM

Yes, thanks, a couple of dimensions will save me some time.

Do the two tabs in front locate in the k frame?

Thanks again, Joe

The 2 vertical pieces fit alongside the oil pan and support the engine/K Frame on the oil pan flange. US Car tools has one which is somewhat similar and locates in the K Frame

http://store.uscartool.com/Mopar-K-Frame-Stand-Drivetrain-Restoration-Tool_p_84.html

Posted By: dvw

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/27/21 12:24 PM

I worked as a flat rate mechanic 35 plus years . In that scenario very few items were ever torqued. Can you feel the amount of torque? You can get pretty close. You get a pretty good feel for it. Even with power tools. Not everyone has this ability. Same as metal shaping, body work or anything else in life. It was obviously close enough. Stuff didn't break or fall off. Race stuff? I torque any thing I can.

Posted By: RealWing

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/27/21 08:02 PM

Posted By: jlatessa

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 02/27/21 09:39 PM

Thanks a bunch RealWing, I'm going to get started on it.

To the OP, sorry for the hijack, should have done a PM.

Joe

Posted By: Magnum

Re: Come on ... BE HONEST...what do you properly TORQUE... ? - 03/04/21 01:48 AM

Anyone that thinks they can tell how tight something is torqued "by hand" is fooling themselves.

I I'd do it by the book and he'd do it his way and we'd compare. So I set one side and make a small dimple on the nut so you could tell position. Loosened it up and he had a go at it (I covered the dimple with a bit of grease) and......he ended up in EXACTLY the same spot. I never questioned him again .

A front wheel bearing is unique. You are compressing 2 tapered wheel bearings. There IS a spot where they get tightened to and most of us can easily find it. Even the range from too loose there is backlash to too tight and it's hard to turn is pretty close to each other.

Anything that crushes a gasket like in the engine not only gets torqued to spec but a pattern is important. Rod bolts stretch when torqued properly, also important.

I always torque U bolts to rear housing too, it's not as tight as most of you "by feel" think it is. Every wheel and every suspension fastener and if it's crushing a sleeve, at ride height.