Moparts

Science behind Mopar cooling??

Posted By: Montclaire

Science behind Mopar cooling?? - 12/29/20 11:28 PM

Hello, I have a 74 Barracuda with a transplanted 440. This is a factory non-AC car so it has a 22" radiator (newer stock-style replacement for the 1974 factory 19" unit). I'm going through the cooling system and will be replacing the water pump. As I understand it, non-AC cars got a 22" radiator, the larger pulley and an 8 blade pump. AC cars got a larger radiator, the smaller pulley and 6 blade pump. The net effect was a slightly under-driven pump on the non-AC cars and an over-driven pump with AC (around 140%).

I have both pulleys to choose from but haven't decided on a pump yet. I am not running AC, just want to cool the 440. Now, some subscribe to the theory that a faster pump is always better but I can't see how that would be accurate. The factory obviously had a reason for two different setups. My guess would be to give the coolant enough time to properly do its job with the smaller radiator. The AC cars probably got a 6 blade pump to reduce cavitation and the smaller pulley to increase pressure in the system. What did non-AC police package cars use?

Thanks in advance

Posted By: SportF

Re: Science behind Mopar cooling?? - 12/30/20 01:57 AM

Can't give you a reason why the facotory did what they did, but the more/faster the water moves through the system the more heat transfer/cooling you get. The old wives tale of water going too fast is just that, a tale.

Of course, the University of Minnesota heat transfer lab could be wrong too, but since they have been at it since 1880, probably not.

Posted By: dragon slayer

Re: Science behind Mopar cooling?? - 12/30/20 02:05 AM

Faster with wrong impeller does not mean faster water if cavitation occurs. Hard to really know what they were doing unless an engineer has the notes. Proper cooling, not too much power loss, versus AC with more power loss and heat generation at higher idle speed. I guess it all depends what you want to do with the car, but once you have sufficient cooling rate, getting more is not a benefit. Is car going to idle a lot in city driving, or cruising at higher rpm, or spend most time at high rpm doing the 1/4 mile.

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 12/30/20 02:46 AM

It's running hot at lower speeds (as is steam, not just high on the gauge). I'll be adding a shroud and a 5-blade viscous fan to replace the mickey mouse flex fan that's on it now, along with new cap, thermostat, cooler plugs, checking the advance, etc. It already has an overflow tank and runs cool enough at speed so I'm assuming it's not blocked up otherwise.

I came across this thread:

http://www.dodgecharger.com/forum/index.php?PHPSESSID=qdp6mreo87eglkba11hdrim0o0&topic=60599.0There's a lot to read there but starting on page 8 there is a comparison of water pumps. Pump #1 is a motor home piece with an 8 blade impeller measuring 4.375" across that has really good flow numbers at low speed. So not only is there a difference in the number of fins, but also the diameter of the impeller, and I'm assuming the pitch of the fins determines the curve of the flow.

It looks like I am better off with an 8-blade pump so long as the impeller is big enough. NAPA makes a stock looking one. I can always speed it up with the smaller pulley I guess, which will give more flow at lower rpms. This is just a street car, it may see a bigger cam as the motor feels pretty tame right now but nothing wild. It's going to see a lot of low speed city driving under 40mph so it'll have to run a little cooler to be happy. The last owner also opened up the hood scoops which doesn't do much on the Barracuda hoods (may actually hurt) so they'll get plugged back up, too.

Posted By: topside

Re: Science behind Mopar cooling?? - 12/30/20 03:14 AM

The shroud alone will pay big dividends.

Colder spark plugs won't affect cooling, and open E 'Cuda scoops has no appreciable effect.

Posted By: AndyF

Re: Science behind Mopar cooling?? - 12/30/20 03:17 AM

For a street car the faster you can spin the water pump the better. If you start driving at high speeds then you'll have to rethink the drive ratio. The factory engineers changed the ratio for the engines that were capable of higher speeds since they were most likely worried about cavitation. For a street car I'd duplicate the HD cooling package that you could get with the tow package. I think police cars and taxi cabs also got the HD cooling package. It should be spelled out in the master parts book for your make and model.

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 12/30/20 03:18 AM

NAPA shows two pumps, TFW 42032 and WP 58173. The 42032 pump impeller measures 3.84", haven't found a measurement on the other one yet. The smaller 6-blade impeller probably frees up some HP on a drag car but I'm going in the other direction.

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 12/30/20 03:21 AM

For a street car I'd duplicate the HD cooling package that you could get with the tow package.

Andy, I'd love to but it's got the narrow yoke and I'm not cutting it for a bigger rad. Chrysler built a lot of big blocks with 22" radiators so I'm sure it'll be ok if the parts are matched.

Posted By: DaytonaTurbo

Re: Science behind Mopar cooling?? - 12/30/20 03:36 AM

If you're cooling well at cruising speed but poorly at low speeds the shroud and proper fan will make a big difference. Also the rubber seal at the front of the hood so air is forced through the rad at speed.

Posted By: Twostick

Re: Science behind Mopar cooling?? - 12/30/20 06:25 AM

I read somewhere that they used the smaller impeller pump on the A/C cars because they overcooled with the big pump at idle which was caused by the higher idle speed spec. This was likely a concern for emissions and in town fuel mileage.

Kevin

Posted By: A39Coronet

Re: Science behind Mopar cooling?? - 12/30/20 01:24 PM

Less vanes so less total drag when the AC compressor is on?

Posted By: mrob

Re: Science behind Mopar cooling?? - 12/30/20 02:16 PM

If you're using the A/C pulleys, your fan will also spin faster than crank rpm which will help at idle and low speeds. Don't know if that's an issue for you, but wanted to mention it.

Posted By: Gtxxjon

Re: Science behind Mopar cooling?? - 12/30/20 03:49 PM

There is no one answer to this I bet?

Every big block car I have ever owned always needed a 26 inch radiator!

No engine driven fan was ever good enough to ‘draw out heat’ in a traffic jam.

So it’s twin electric fans if you wannabe safe!

On the whole it will not be needed, in slow traffic one fan will suffice.

In heavy traffic both fans will deffo be needed and a good charging system to cope too.

Water pump selection is a difficult choice but an all Ali set-up, pump and housing is a must.

The pump blades must have a backing plate as this reduces cavitation and the Chevy spiral style pumps are useless...

Posted By: RapidRobert

Re: Science behind Mopar cooling?? - 12/30/20 04:28 PM

It's running hot at lower speeds (as is steam, not just high on the gauge). runs cool enough at speed so I'm assuming it's not blocked up otherwise.

as said you need more air and or water flow. after the fan/shroud I would get the 8 blader & tack weld an anticav plate behind the vanes (cut the round piece in two & weld on each half

Posted By: John_Kunkel

Re: Science behind Mopar cooling?? - 12/30/20 05:06 PM

The reason for overdriving the pump was to turn the fan faster, more cooling airflow at low speeds. Turning the pump faster could cause cavitation, thus the smaller impeller.

Posted By: moparx

Re: Science behind Mopar cooling?? - 12/30/20 06:46 PM

what cavitation could one expect with a spiral [chevy style] pump impeller ?

i know this style is not widely accepted, but i am curious. especially used with a small pump pulley.

Posted By: GODSCOUNTRY340

Re: Science behind Mopar cooling?? - 12/30/20 07:03 PM

Chrysler used the 6 vain pumps on AC cars for this reason, remember there was an AC condenser in front of the radiator that isn't there with non AC cars. The condenser is not only restricting airflow through the radiator but it's transferring it's heat to the radiator so, Chrysler slowed the flow through the radiator to give the fluid more time to cool.

Posted By: Sniper

Re: Science behind Mopar cooling?? - 12/30/20 07:29 PM

Chrysler slowed the flow through the radiator to give the fluid more time to cool.

Not how that works at all. If the water spends more time in the radiator to "cool", then it also spends more time in the engine getting "hot". So, at best, it would be a wash.

The biggest factor in thermodynamics the the temperature differential not the time in the radiator.

Posted By: Pacnorthcuda

Re: Science behind Mopar cooling?? - 12/30/20 07:33 PM

Chrysler used the 6 vain pumps on AC cars for this reason, remember there was an AC condenser in front of the radiator that isn't there with non AC cars. The condenser is not only restricting airflow through the radiator but it's transferring it's heat to the radiator so, Chrysler slowed the flow through the radiator to give the fluid more time to cool.

Nope. As Kunkel stated above, it’s to increase airflow while not increasing the opportunity for cavitation.

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 12/30/20 08:18 PM

The reason for overdriving the pump was to turn the fan faster, more cooling airflow at low speeds. Turning the pump faster could cause cavitation, thus the smaller impeller.

Now that makes a lot of sense. The iron pumps do not seem to need the anti-cavitation plate as they have a flat backing surface for the impeller. The aluminum pumps usually have a cavity so they would require the plate. I'll be using an iron 8-blade pump with an impeller over 4". Right now the car has the larger pulley on it. If I pull the pump and find it's an 8-blade, I'll swap to the smaller pulley with the shroud and clutch fan and see how it does.

Posted By: mopars4ever

Re: Science behind Mopar cooling?? - 12/30/20 08:23 PM

Is it a 2 row core radiator? If so, why not just go with a 3 row core? I did that on my Charger and I had no more issues.

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 12/30/20 08:33 PM

Is it a 2 row core radiator? Is so, why not just go with a 3 row core? I did that on my Charger and I had no more issues.

To be honest I haven't checked yet. I know the rad is newer and doesn't have a lot of miles on it so I was going to try all of the basics before swapping radiators. The engine has a mix-match of parts on it (pulleys, brackets, etc) so I am going back to all stock pieces and assess from there. Can I ask where you bought yours? Thanks

Posted By: mopars4ever

Re: Science behind Mopar cooling?? - 12/30/20 08:39 PM

Can`t help with that as I had my original re cored.

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 12/30/20 08:44 PM

Ah, ok. Another reason I wasn't looking to swap rads just yet - I know the chicom jobbers have smaller tubes than original so it might have to end up being a factory 22" rad with a new, proper dia core.

Posted By: mopars4ever

Re: Science behind Mopar cooling?? - 12/30/20 08:59 PM

Mine was re cored about 15 years ago so maybe they were different then.

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 12/30/20 09:49 PM

As an example: OER makes a 22", 3-row radiator for 70-72 small block E-body (I have the later style water pump housing with the pass side discharge). It's listed as 1/2" tubes on 9/16" centers. Compare this to factory rads which are 9/16" tubes on 9/16" centers. Max cooling was even bigger - 5/8" tubes on 7/16" centers.

From Glen Ray:

Posted By: GODSCOUNTRY340

Re: Science behind Mopar cooling?? - 12/31/20 01:27 AM

Chrysler used the 6 vain pumps on AC cars for this reason, remember there was an AC condenser in front of the radiator that isn't there with non AC cars. The condenser is not only restricting airflow through the radiator but it's transferring it's heat to the radiator so, Chrysler slowed the flow through the radiator to give the fluid more time to cool.

Nope. As Kunkel stated above, it’s to increase airflow while not increasing the opportunity for cavitation.

Come on now, the number of vanes on the pump have absolutely NOTHING to do with airflow. The water pump is pushing coolant, not air. Dirt track racers discovered many years ago that removing the thermostat actually caused engines to quickly overheat, the remedy was and still is, install a restrictor plate in place of the thermostat to SLOW DOWN coolant flow giving the radiator more time to cool the fluid.

Posted By: ek3

Re: Science behind Mopar cooling?? - 12/31/20 02:34 AM

Hello, I have a 74 Barracuda with a transplanted 440. This is a factory non-AC car so it has a 22" radiator (newer stock-style replacement for the 1974 factory 19" unit). I'm going through the cooling system and will be replacing the water pump. As I understand it, non-AC cars got a 22" radiator, the larger pulley and an 8 blade pump. AC cars got a larger radiator, the smaller pulley and 6 blade pump. The net effect was a slightly under-driven pump on the non-AC cars and an over-driven pump with AC (around 140%).

I have both pulleys to choose from but haven't decided on a pump yet. I am not running AC, just want to cool the 440. Now, some subscribe to the theory that a faster pump is always better but I can't see how that would be accurate. The factory obviously had a reason for two different setups. My guess would be to give the coolant enough time to properly do its job with the smaller radiator. The AC cars probably got a 6 blade pump to reduce cavitation and the smaller pulley to increase pressure in the system. What did non-AC police package cars use?

Thanks in advance

its really simple . the thermostat is what gives "time to cool" ..... you need good speed/flow from -both- the pump and fan/ air at no- to slow speeds....

Posted By: AndyF

Re: Science behind Mopar cooling?? - 12/31/20 05:02 AM

As an example: OER makes a 22", 3-row radiator for 70-72 small block E-body (I have the later style water pump housing with the pass side discharge). It's listed as 1/2" tubes on 9/16" centers. Compare this to factory rads which are 9/16" tubes on 9/16" centers. Max cooling was even bigger - 5/8" tubes on 7/16" centers.

From Glen Ray:

Yeah the internal construction of the radiator can make a big difference in how well it works. Cheap radiators look just like expensive ones on the outside but they don't flow as much so they don't cool as much. The more water you can flow thru the radiator the more heat you can pull out of the engine.

Posted By: sthemi

Re: Science behind Mopar cooling?? - 12/31/20 05:18 AM

AC cars have smaller pulley, turning the fan and water pump faster, water pump have fewer blades to ensure no cavitation at high speeds. At idle, fan spins faster and the water stays in radiator longer...more cooling. And don't forget the shroud is required to be sure the fan is efficient.

Posted By: 360view

Re: Science behind Mopar cooling?? - 12/31/20 10:08 AM

The disagreements here are at root about cavitation, and the root of cavitation understanding is that the boiling point of water depends on BOTH temperature and pressure. The next important point is that the design of the pump impellor affects where on the blades a steam bubble meets a high enough pressure to suddenly collapse back into liquid water in an extremely violent event that human beings have a hard time imagining because it is the opposite of an explosion.

Posted By: jlatessa

Re: Science behind Mopar cooling?? - 12/31/20 01:46 PM

One thing to keep in mind about all pumps is how close the impeller is to the housing surface.

I've tried a few pumps that had too much clearance for optimum water flow.

The flow rate is something I never could figure out how to measure,

but I would imagine the closer the impeller is to the housing surface, the better.

Joe

Posted By: dragon slayer

Re: Science behind Mopar cooling?? - 12/31/20 01:47 PM

This is a more complex issue then just flow or cavitation. Misapplication of principles. What does radiator flow mean? Water flow or air flow? Flow alone does not control heat transfer rate. Surface area, material, Temp difference of air and water, design all factor in for radiator heat transfer coefficient to maximize the cooling of the water at the radiator. Contact time in both the radiator and the engine do matter. Cavitation is not only the material damage to the impeller, it changes the efficiency of the pump and you lose flow volume. Capacity of the system matter too, with regard to equilibrium of the system.

Time matters. Take a frozen radiator, and 200 degree water and push it through the radiator in 1sec. What is outlet temp of water. How about after 5 sec, one minute? Same with the block.

If the radiator was cooling incoming 210 degree water and dropping it to 150 at outlet what would happen as the water temp in the engine started to drop to 175. The thermostat would close and reduce the flow to help keep the motor water temp at the optimum temp so the block would be at the correct temp for combustion and operating design. At that point, what good would this high capacity radiator, fan, and water pump do if the system is causing the thermostat to cycle closed trying to keep the the motor at the correct operating temperature. North Dakota in the winter with no thermostat. What would max engine temp be under those conditions.

Look at service manual, race manual, and the Chrysler training material, and everything was a trade off. The hemi and the small impeller was a performance move to save HP loss. Same with the centrifical fan for hemi versus thermostatic one for AC cars. I think Superbirds where having cooling issues and the recommendation was to go to a fixed fan blade. This would be a HP loss at high speed though. Look at all the combinations of fan types, blade lengths and pitch, impeller types and your head will spin.

If you are have a cooling issue, I would look at the block and head cleanliness and your radiator. A good cleaning flush. You can use a temp sensor gun to see if you have hot spot on the engine, head, manifold causing excess heat generation. A good solid fan will maximize air flow at idle. I think the pump impeller would be the last thing I would look at unless some thing wrong internally with the housing and the water is not flowing properly.

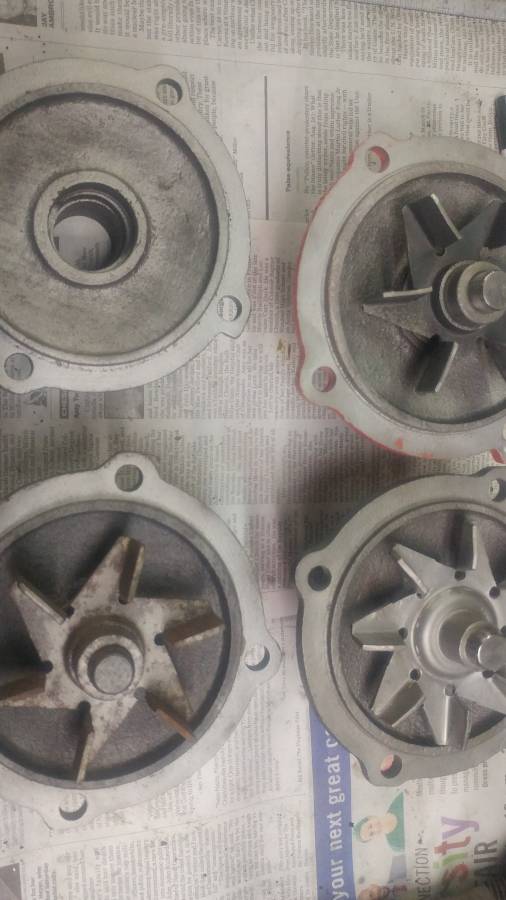

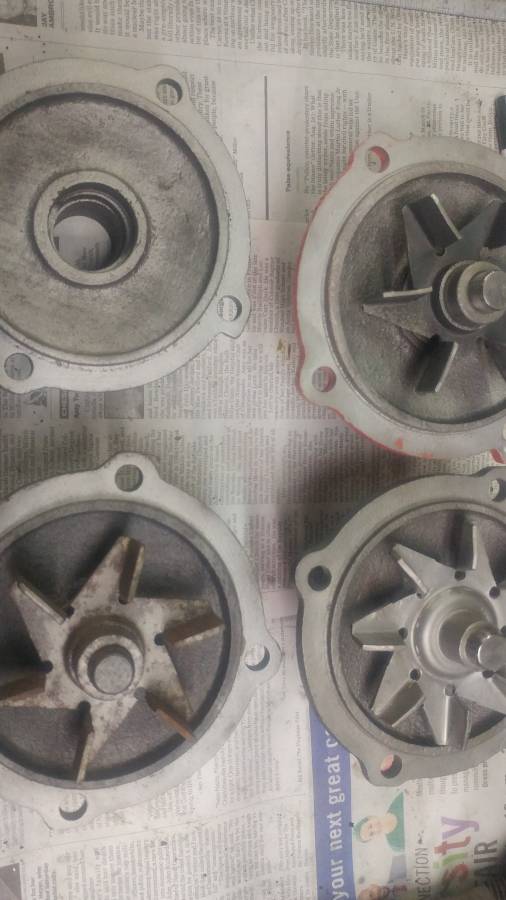

That test the RV guys did was interesting reading as it was hard to come to solid conclusions on what is best for cooling if I remember right. Which impeller do you want to use? Notice the orientation and size difference, and this doesn't even include the turbine style plastic and cast blades used in the mid 60s.

Posted By: Sniper

Re: Science behind Mopar cooling?? - 12/31/20 03:25 PM

Time matters. Take a frozen radiator, and 200 degree water and push it through the radiator in 1sec. What is outlet temp of water. How about after 5 sec, one minute? Same with the block.

In a closed system like an engine, the time in the radiator spent cooling is also the time in the engine spent getting hotter, then microboiling starts to happen and your plan to spend more time in the radiator cooling the water off just got it's butt handed to it. Last thing you want to do is slow water flow. Max flow short of cavitation works best. Same with air flow. No one ever says " we need to slow the flow of air thru the radiator so the air has more time to cool it" wonder why?

Posted By: moparx

Re: Science behind Mopar cooling?? - 12/31/20 07:40 PM

several times it has been stated a .040 distance needs to be kept from the pump to the housing to prevent cavitation.

that is from the blade tips to the housing casting, correct ?

Posted By: dragon slayer

Re: Science behind Mopar cooling?? - 12/31/20 07:44 PM

Time matters. Take a frozen radiator, and 200 degree water and push it through the radiator in 1sec. What is outlet temp of water. How about after 5 sec, one minute? Same with the block.

In a closed system like an engine, the time in the radiator spent cooling is also the time in the engine spent getting hotter, then microboiling starts to happen and your plan to spend more time in the radiator cooling the water off just got it's butt handed to it. Last thing you want to do is slow water flow. Max flow short of cavitation works best. Same with air flow. No one ever says " we need to slow the flow of air thru the radiator so the air has more time to cool it" wonder why?

There is an optimum flow point in any system. The water is a confined unit, the air is not. It is an unlimited source so of course you want to cycle it through as fast as possible. If the air was part of a closed system and getting hotter each cycle you would rethink air flow velocity.

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 12/31/20 08:17 PM

The big takeaway from the RV pump comparison is the difference in flow at low rpm between the impeller designs. The first pump with the large 8-blade impeller seems to move the most coolant at idle or near idle. Since I apparently need to increase either or both coolant and air flow at low speed I will be using a remanned 8-blade iron pump with the large pulley, unless I find an 8-blade pump already on the engine, in which case I will swap to the smaller AC pulley. There is also a “compromise” Hemi pulley that falls around 120%.

If these changes do not work I will look deeper - radiator upgrade, internal blockage, etc. I had the car out for a while in November on a 50’ day and it stayed reasonably cool so I am optimistic that putting some things back to stock will get me where I have to go. The crank pulley is not stock so it could just be a drastically under driven 6-blade pump providing poor coolant flow combined with a lack of shroud and aftermarket fan causing poor air flow.

Posted By: AndyF

Re: Science behind Mopar cooling?? - 12/31/20 08:42 PM

You are on the correct path. For you application you want to move as much water as possible thru the system. Other applications have different requirements but your application is going to work best with a lot of water flow. You'll also want to have a shroud and a clutch fan and then just keep an eye on the radiator. The one you have might be fine, if not you might need to get a 3 core or one with bigger tubes.

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 12/31/20 09:28 PM

That’s the plan. I bought a reproduction 22” shroud and a Mopar 5-blade fan with clutch. I also have a factory 7-blade fan to try if the 5-blade doesn’t move enough air, assuming it clears the shroud. It’s off a 1973 small block AC car.

Posted By: Gtxxjon

Re: Science behind Mopar cooling?? - 01/01/21 10:31 AM

Happy New Year to all who care about Mopars and cooling lol...

If Wingcar owners can keep their Mighty Mopars cool with the 'airflow' they have, then there is hope for all Mopar owners.

Modern cars work on very tight cooling margins, small rad, small hoses, high power efficient electric fans and everything working as good as poss!

Mopars with 22 inch rads, built from old copper/tin/brass combo's are always gonna be at a loss.

My Moparmate runs a 512ci motor in his 66 Polara, and it still has overheating problems after 3 different rads and 25-pumps...

It started out as a 'never hot' 383ci engine with a 22 inch original rad. and working Air CON!

Once we put a 440ci motor in the rad would not keep up in heavy traffic.

So we got a new rebuilt 26 inch Fury rad from a 71 car and tried that.

Better but still not right in the summer months...

On to the new 512ci with Edelbrocks and TTI full 2.5 system

Eventually we removed the Air-con system (that was still working fine) and it made very little difference at ALL!

Next on the list was all the possible water pumps available from 'Tom, Dick and Harry', the worst being '440 source'...

The housing has very small and restricted waterways and the impeller was deffo Chevy!

So he took the plunge and bought a new 'two row' extra cooling 26 inch ALI rad (same width as a 4 row) and guess what?

It was worse...

Just in case you was wondering, yep it always had a rad specific 'fan shroud' and clutch fan.

We think the opening in the 'rad support area' is a little small for a Bigblock car, but cutting is Not an option...

The Polara ran 13.20secs 'in drive' at Santa pod raceway, she did get a little hot, but nothing horrendous...

Not bad for a 'stock car' in full trim with street tyres 'weighing in' (with driver and passenger) @ TWO TONS...

The plan is to run a 12sec pass (in drive) and put the 383 back in, how boring...

Covid has a lot to answer for...

Posted By: 360view

Re: Science behind Mopar cooling?? - 01/01/21 12:19 PM

The big takeaway from the RV pump comparison is the difference in flow at low rpm between the impeller designs. The first pump with the large 8-blade impeller seems to move the most coolant at idle or near idle. Since I apparently need to increase either or both coolant and air flow at low speed I will be using a remanned 8-blade iron pump with the large pulley, unless I find an 8-blade pump already on the engine, in which case I will swap to the smaller AC pulley. There is also a “compromise” Hemi pulley that falls around 120%.

If these changes do not work I will look deeper - radiator upgrade, internal blockage, etc. I had the car out for a while in November on a 50’ day and it stayed reasonably cool so I am optimistic that putting some things back to stock will get me where I have to go. The crank pulley is not stock so it could just be a drastically under driven 6-blade pump providing poor coolant flow combined with a lack of shroud and aftermarket fan causing poor air flow.

That is a good plan of action

but you have left out:

a) Having instruments to measure the temperatures of air entering and leaving the radiator, and water entering and leaving the radiator. Good quality calibrate-able IR gun AND Thermometer with thin metal probes are worth the money. Lay out a grid of spots to measure on the radiator to take measurements to find potential cold sections that may indicate poor water flow or hot areas indicating poor airflow.

b) Knowing exactly what Brand and Design Thermostat you have and testing that thermostat yourself to see what temperature it starts opening, what temperature it is fully open at. Also decide what bypass holes you should give it. Similarly consider whether you should try a “Balanced Flow” design.

For those posters thinking time in radiator is the same as time in engine block, think again.

Gallons of flow is equal in the two

but internal cross sectional area of the radiator and block are vastly different.

The speed of the internal flows varies greatly. Liquid flow can zip or linger in different block passages but liquid flow speed through radiator tubes ought to be much more consistent even though no side tank design is perfect, there will be “eddies” that keep tube flow from being perfectly equal.

For airflow, the fins are never exactly spaced right, even before bug collisions do their number on the fin gaps.

Posted By: cudaman1969

Re: Science behind Mopar cooling?? - 01/01/21 03:19 PM

Never had a problem cooling any of my cars if the system stayed as it came from the factory. The only exception was my race car, built totally by me (long story) the engine I bought, 499 Indy headed McCandless built. Radiator was a VW Sciroco. Temp would climb to over 220-230 degrees after a run (5.60 in the 1/8) had a big fan on the radiator plus the little external motor to turn pump. A buddy gave me the VW factory ran housing setup that was used on that radiator, not expecting it to help I was surprised big time. Idle all day - 160 top, make a run in the heat - 180 top. Factory guys are paid the big bucks to figure this junk out, follow it. AC friend (went to college to study this) told me the higher the radiator temp the faster it will cool, temp deferential I think he said. IMO if you have a factory stock radiator figure out why the engine’s running hot, not why the radiator isn’t cooling.

Posted By: TJP

Re: Science behind Mopar cooling?? - 01/01/21 06:19 PM

Never had a problem cooling any of my cars if the system stayed as it came from the factory. The only exception was my race car, built totally by me (long story) the engine I bought, 499 Indy headed McCandless built. Radiator was a VW Sciroco. Temp would climb to over 220-230 degrees after a run (5.60 in the 1/8) had a big fan on the radiator plus the little external motor to turn pump. A buddy gave me the VW factory ran housing setup that was used on that radiator, not expecting it to help I was surprised big time. Idle all day - 160 top, make a run in the heat - 180 top. Factory guys are paid the big bucks to figure this junk out, follow it. AC friend (went to college to study this) told me the higher the radiator temp the faster it will cool, temp deferential I think he said. IMO if you have a factory stock radiator figure out why the engine’s running hot, not why the radiator isn’t cooling.

I will agree to a point with your first statement. However I have had several 22 inch equipped big block cars through the shop that experienced heating issues with new cores in the radiator. Most were under low speed conditions on 75+ degree days. After verifying all was as it should be. I have sent several of these "problem radiators with new cores" to Glen Ray. They came back and the cooling problems magically go away. His explanation is, the efficiency of replacement cores that are being produced today and the majority of them are not equal to what was used back in the day. One customer who had lived with the issue for several years has not experienced an issue in seven or so years since the Glen ray radiator was installed. All measurements were taken with using a

thermocouple probe next as close to the t/stat as possible and laboratory grade meter.

The second statement is dead on the money. I was taught, the factory boys are not stupid and to ask oneself what are you trying to gain by changing something and would that money be better spent elsewhere ? Example: stock vs aftermarket valve covers, air cleaners etc.

Posted By: moparx

Re: Science behind Mopar cooling?? - 01/01/21 06:32 PM

one thing about overheating that makes me a little different from most is, at 200 or 210, i am not concerned in the least.

220, if not for too long [like stuck in traffic], makes me notice, but if it cools back to the 200ish range back on the road all is ok.

it also depends on where the reading is coming from and the accuracy of the gauge involved. most gauges are far from accurate, mechanical or electric.

a good IFR gun helps tremendously.

running too cold is bad in my book. in the past i was a "cool" engine advocate, but have since changed my mind and have had very good results running hotter than most.

however, at these temperatures, your cooling system MUST be in top shape or you will have problems.

just my opinion and experience, your mileage will vary.

Posted By: AndyF

Re: Science behind Mopar cooling?? - 01/01/21 06:57 PM

I agree. Just because a radiator is new doesn't mean it is any good. The Chinese build a lot of junk that looks good but doesn't work. They tend to cut corners on anything that the buyer doesn't see such as the tubing size inside the core. Anytime a person buys aftermarket parts they have to carefully examine them to verify that they will actually work. If the part comes from China it is best to assume that it is crap and work from there rather than assume it is good. Lots of radiator mfgs in the world, some are great, some aren't.

Posted By: mopower440

Re: Science behind Mopar cooling?? - 01/02/21 12:41 AM

I will tell you what id did. I have a 1972 dart with a mild 440/727. I built it many years ago and used the original to the car 22" 318 radiator and shroud. used a 6 blade flex fan, no thermostat, and the 4 groove pulley that was on the 440 when i got it from the junkyard to build. It NEVER would stay cool. It would take a good while to get hot, but would eventually creep on up to 220 and keep going so i would always have to just shut it off. It would creep up a lot quicker when sitting still and would TRY and drop when moving but would still just keep trying to climb. Couldnt figure it out because if i took the radiator cap off, the coolant was really moving and if i revved it up, the coolant would really flow! I got to looking at radiators and the only one i really was interested in was the 'cold case' brand as it has 2 rows of 1.25 inch tubes! SO, i bought the 22" cold case radiator, used the original shroud again, a stock 7 bladed chrysler fan, a high flow miloden 180 degree thermostat, and a factory 8 bladed pump. Guess what..it does NOT get hot anymore and i love it! It will idle all day long at 180 degrees no matter how miserably hot it is here in TN. and as soon as i start moving, it drops to about 175 degrees. It never even tries to go past 180 ever! After 20 years of dealing with this, i can finally ride around and not have to worry about stopping to let it cool down. This cold case radiator is still only a 22" like the original that was in it but it sure does cool better. i also do believe the thermostat and factory fan helped a lot too.I debated for months on whether to get a 26" or 22" and talked to Chris at cold case and he thought the 22" would do just fine and it is a direct bolt in. Im glad i got the 22" because its all that is needed.

https://www.coldcaseradiators.com/

Posted By: TJP

Re: Science behind Mopar cooling?? - 01/02/21 01:26 AM

it also depends on where the reading is coming from and the accuracy of the gauge involved. most gauges are far from accurate, mechanical or electric.

a good IFR gun helps tremendously.

not reying to start a peeing contest but just state the facts

1: I agree and will say I question the accuracy of any gauge and have found some new BRAND NAME gauges to be way out of whack and normally at the hot end. I have also found that the warmer the motor gets the farther out of range they usually go. Worst i can remember read 260+ at 200 degrees. Typically electric gauges are calibrated at both ends Cold and Hot. But the pivot point is not in the middle. (think off a see saw that does not pivot in the middle.) Poor connections to voltage and ground will affect accuracy

2: IR guns should only be used as an indicator as they need to be calibrated for the surface(s) they are readin.

3: Thermocouples do not lie and are normally accurate to within 2 degrees or better on a calibrated meter. Their accuracy can easily be checked by using Ice water (32 degees, and water, that boils at 212) In addition their response is almost instant.

Posted By: ProStDodge

Re: Science behind Mopar cooling?? - 01/02/21 03:19 AM

OK, I may be a little out in left field here, but by chance have you checked total ignition timing?

Too much timing and todays poor quality gas will create heat. You might be surprised how much timing you can get at 1800rpm and no load (full mechanical advance and full vacuum advance). This is especially true if someone advanced the timing to get the car to idle a little better (bigger carb and/or bigger cam).

If you don"t have a timing light handy, just pull the hose off the vacuum advance, plug the hose to eliminate the vacuum leak, then take a drive.

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 01/02/21 06:44 AM

OK, I may be a little out in left field here, but by chance have you checked total ignition timing?

Too much timing and todays poor quality gas will create heat. You might be surprised how much timing you can get at 1800rpm and no load (full mechanical advance and full vacuum advance). This is especially true if someone advanced the timing to get the car to idle a little better (bigger carb and/or bigger cam).

If you don"t have a timing light handy, just pull the hose off the vacuum advance, plug the hose to eliminate the vacuum leak, then take a drive.

As I said on the first page, ignition timing is on the list. It has a mopar performance distributor which should have the adjustable advance. I believe these are Mallory units and can be improved with a spring change, some are better than others. I have a copy of Mopar Action around here somewhere that goes into detail on dialing one in.

Posted By: ruderunner

Re: Science behind Mopar cooling?? - 01/02/21 01:09 PM

Times whatever on the shroud. And honestly I wouldn't expect to need anything else.

There's only 2 times in the 30 years I've owned it that it ever started getting hot, once when first put together no shroud and poorly tuned. The second was last summer, parked in traffic on fresh blacktop and 100 degrees ambient. It got up to 220 and a few more rpm cooled it right down. 26 inch radiator of unknown application, poorly fitting shroud from unknown application and 5 blade flex fan.

You need to get air over the core at low speed, this is what a shroud is for.

Posted By: moparx

Re: Science behind Mopar cooling?? - 01/02/21 03:48 PM

YES SIR !

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 03/23/21 10:34 PM

A little update here, I pulled the pump and it’s an aftermarket aluminum 8 blade. I don’t see any markings on it, anyone recognize it? The vane spread is about 4-3/8”. The radiator is a 3-row, but a few of the tubes are partially blocked. Looks like rust or sand, maybe stop leak. The coolant drained clear.

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 03/23/21 10:39 PM

Oh, and I made the same mistake that I made 20 years ago - the smaller water pump pulley only lines up with the AC crank pulley. So I’ll be keeping the stock non-AC piece.

Posted By: cudaman1969

Re: Science behind Mopar cooling?? - 03/24/21 03:31 AM

Can't give you a reason why the facotory did what they did, but the more/faster the water moves through the system the more heat transfer/cooling you get. The old wives tale of water going too fast is just that, a tale.

Of course, the University of Minnesota heat transfer lab could be wrong too, but since they have been at it since 1880, probably not.

Doing some welding the other day and dunked the piece in the water tank, got me thinking of what you said. So used the torch to get a piece red hot, dipped it real fast and out, didn’t cool it much, got it red hot again dipped it for 15 seconds and it cooled down to touch. My thoughts are if the water is slow enough it’ll transfer the heat better, it needs time. After heating and dipping a few times that water got hot and it took much longer to cool to touch.

Posted By: AndyF

Re: Science behind Mopar cooling?? - 03/24/21 04:25 AM

I don't recognize it but it looks like someone pop riveted a flat plate to the impeller so maybe that is a Flow Kooler? I think that is what they used to look like. These days Flow Kooler has a neat looking CNC aluminum impeller design. I don't know how well it works but it sure looks cool.

https://flowkoolerwaterpumps.com/co...r-dodge-plymouth-hemi-hi-flow-water-pump

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 03/24/21 05:10 AM

That's probably a good guess. I'll be switching to a remanned factory pump.

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 03/24/21 11:30 PM

Well I guess there's just some good old scale in the core. Not sure why, the engine was supposedly refreshed about 5 years ago and the rad doesn't look that old at all. I'm only seeing a little here and there but I have to assume that there's more hiding. It looks like the PO was chasing coolant leaks, could a lack of pressure in the system cause scale buildup? Maybe the system was open for a while.

I've been looking at new rads and anything stock looking with a 3 row core is $500 and up. I'm guessing I can get this one rodded out for $100 so that's the route I'm taking. If that still doesn't work then I need to find something with bigger tubes that will do the job. Everything these days is 1/2" tube and 2 row.

Posted By: Sniper

Re: Science behind Mopar cooling?? - 03/25/21 01:10 PM

Can't give you a reason why the facotory did what they did, but the more/faster the water moves through the system the more heat transfer/cooling you get. The old wives tale of water going too fast is just that, a tale.

Of course, the University of Minnesota heat transfer lab could be wrong too, but since they have been at it since 1880, probably not.

Doing some welding the other day and dunked the piece in the water tank, got me thinking of what you said. So used the torch to get a piece red hot, dipped it real fast and out, didn’t cool it much, got it red hot again dipped it for 15 seconds and it cooled down to touch. My thoughts are if the water is slow enough it’ll transfer the heat better, it needs time. After heating and dipping a few times that water got hot and it took much longer to cool to touch.

Some welder in his garage has just proven the world's thermodynamic experts across all areas and centuries wrong.

What's next? Gonna prove the theory of relativity is false?

Maybe you ought to go read up on how it works and then you'll understand the reason high flow is the key, here's a hint it has little to do with time.

Posted By: 83hurstguy

Re: Science behind Mopar cooling?? - 03/25/21 02:47 PM

Can't give you a reason why the facotory did what they did, but the more/faster the water moves through the system the more heat transfer/cooling you get. The old wives tale of water going too fast is just that, a tale.

Of course, the University of Minnesota heat transfer lab could be wrong too, but since they have been at it since 1880, probably not.

Doing some welding the other day and dunked the piece in the water tank, got me thinking of what you said. So used the torch to get a piece red hot, dipped it real fast and out, didn’t cool it much, got it red hot again dipped it for 15 seconds and it cooled down to touch. My thoughts are if the water is slow enough it’ll transfer the heat better, it needs time. After heating and dipping a few times that water got hot and it took much longer to cool to touch.

I have done several projects with industrial air to water heat exchangers that are copper/nickel material with a fan (e.g. a giant radiator), and the heat transfer continues to increase with water velocity up to the point the tubes actually start to erode from the turbulence. Turbulent water flow causes mixing and is good for heat transfer. There was a statement on a previous page that each system has an optimum flow point for heat transfer. That's incorrect - you can always increase cooling by increasing flow up to the point of material limitations, pumping cost (friction loss), or other physical limitations. There's no heat transfer coefficient that reverses at some flow condition and causes the heat transfer of the system to decrease.

In the bucket analogy, the heat transfer RATE between the hot part and the water is actually greater when you first immersed it, and that heat transfer RATE between the part and the water decreases as the difference in temperature between them decreases. If you wanted to cool the part even faster, you would have turbulent mixing in the bucket or the water exchanging itself out so there was no temperature rise of the cooling fluid. It's not a comparable analogy to an automotive cooling system, because the hot part isn't continuously generating its own heat either.

Posted By: AndyF

Re: Science behind Mopar cooling?? - 03/25/21 03:29 PM

Well I guess there's just some good old scale in the core. Not sure why, the engine was supposedly refreshed about 5 years ago and the rad doesn't look that old at all. I'm only seeing a little here and there but I have to assume that there's more hiding. It looks like the PO was chasing coolant leaks, could a lack of pressure in the system cause scale buildup? Maybe the system was open for a while.

I've been looking at new rads and anything stock looking with a 3 row core is $500 and up. I'm guessing I can get this one rodded out for $100 so that's the route I'm taking. If that still doesn't work then I need to find something with bigger tubes that will do the job. Everything these days is 1/2" tube and 2 row.

Cooling systems go south pretty quickly if there are air leaks so that could be the problem. If it was run with a leak or two then it could have developed some scaling issues. I think the rodding process will cost you more than $100 but you'll just have to check it out. If you have an old time radiator shop in your town you'll be okay. We used to have a couple of old time radiator shops with old guys who would fuss and fiddle with radiators until they were perfect but now they've all been replaced with new shops that just sell you off shore radiators. They don't know how to fix anything, they just charge you $600 for a cheap Chinese piece of garbage. So if you have an old time radiator shop use it while you can.

Posted By: jcc

Re: Science behind Mopar cooling?? - 03/25/21 05:08 PM

Can't give you a reason why the facotory did what they did, but the more/faster the water moves through the system the more heat transfer/cooling you get. The old wives tale of water going too fast is just that, a tale.

Of course, the University of Minnesota heat transfer lab could be wrong too, but since they have been at it since 1880, probably not.

Doing some welding the other day and dunked the piece in the water tank, got me thinking of what you said. So used the torch to get a piece red hot, dipped it real fast and out, didn’t cool it much, got it red hot again dipped it for 15 seconds and it cooled down to touch. My thoughts are if the water is slow enough it’ll transfer the heat better, it needs time. After heating and dipping a few times that water got hot and it took much longer to cool to touch.

Some welder in his garage has just proven the world's thermodynamic experts across all areas and centuries wrong.

What's next? Gonna prove the theory of relativity is false?

Maybe you ought to go read up on how it works and then you'll understand the reason high flow is the key, here's a hint it has little to do with time.

In all fairness, that "time" consideration has been common misunderstanding on this site since day one.

However, I have not seen and maybe missed the part mentioned here ( maybe earlier in the thread?) where rate does become a concern, when cavitation enters the picture, which is exacerbated by higher temps especially over boiling, but that is also mitigated by higher static operating pressures. All meaning, there are high flow rates where the coolant will absorb less heat intake as air bubbles form on the heated surfaces, and the coolant temp might actually start to show lower temps, as it loses liquid contact with the hot surfaces, and the surfaces create super hot spots of random boiling coolant. If I am just restating a topic already covered, sorry.

"Cavitation is a phenomenon in which the static pressure of the liquid reduces to below the liquid's vapour pressure, leading to the formation of small vapor-filled cavities in the liquid. When subjected to higher pressure, these cavities, called "bubbles" or "voids", collapse and can generate shock waves that may damage machinery" Wiki

Posted By: Sniper

Re: Science behind Mopar cooling?? - 03/25/21 05:59 PM

High flow rates tend to "wash away" any bubble formations which might insulate the part needing cooling. there are lots of papers out there on the issue.

One analogy to make the point was using a garden hose to cool then using a fire hose to cool. Which do you think did a better job?

the two key factors are high flow rate, which increases turbulence to "wash away" those bubbles as well as constantly exposes the cooling medium to the cooling process. The other is temperature differential, the larger the difference between the coolant and the air the larger the temperature drop.

Very distantly is time.

Now if our welder wanted to test that he'd put two equally hot pieces of metal, same mass and shape, into two different buckets. One bucket would just be standing water, the other would have some sort of stirrer in there to move the water. record the cooling rate of both and get back to us.

Further proof would be recording the cooling rate as you increase the stirring rate. You'll find your proof there.

Posted By: cudaman1969

Re: Science behind Mopar cooling?? - 03/25/21 10:07 PM

Can't give you a reason why the facotory did what they did, but the more/faster the water moves through the system the more heat transfer/cooling you get. The old wives tale of water going too fast is just that, a tale.

Of course, the University of Minnesota heat transfer lab could be wrong too, but since they have been at it since 1880, probably not.

Doing some welding the other day and dunked the piece in the water tank, got me thinking of what you said. So used the torch to get a piece red hot, dipped it real fast and out, didn’t cool it much, got it red hot again dipped it for 15 seconds and it cooled down to touch. My thoughts are if the water is slow enough it’ll transfer the heat better, it needs time. After heating and dipping a few times that water got hot and it took much longer to cool to touch.

Some welder in his garage has just proven the world's thermodynamic experts across all areas and centuries wrong.

What's next? Gonna prove the theory of relativity is false?

Maybe you ought to go read up on how it works and then you'll understand the reason high flow is the key, here's a hint it has little to do with time.

Exactly what I said dip sh!t TIME

Posted By: Sniper

Re: Science behind Mopar cooling?? - 03/25/21 10:41 PM

Can't give you a reason why the facotory did what they did, but the more/faster the water moves through the system the more heat transfer/cooling you get. The old wives tale of water going too fast is just that, a tale.

Of course, the University of Minnesota heat transfer lab could be wrong too, but since they have been at it since 1880, probably not.

Doing some welding the other day and dunked the piece in the water tank, got me thinking of what you said. So used the torch to get a piece red hot, dipped it real fast and out, didn’t cool it much, got it red hot again dipped it for 15 seconds and it cooled down to touch. My thoughts are if the water is slow enough it’ll transfer the heat better, it needs time. After heating and dipping a few times that water got hot and it took much longer to cool to touch.

Some welder in his garage has just proven the world's thermodynamic experts across all areas and centuries wrong.

What's next? Gonna prove the theory of relativity is false?

Maybe you ought to go read up on how it works and then you'll understand the reason high flow is the key, here's a hint it has little to do with time.

Exactly what I said dip sh!t TIME

Reading comprehension isn't your forte.

Posted By: dragon slayer

Re: Science behind Mopar cooling?? - 03/26/21 12:51 PM

Can't give you a reason why the facotory did what they did, but the more/faster the water moves through the system the more heat transfer/cooling you get. The old wives tale of water going too fast is just that, a tale.

Of course, the University of Minnesota heat transfer lab could be wrong too, but since they have been at it since 1880, probably not.

Doing some welding the other day and dunked the piece in the water tank, got me thinking of what you said. So used the torch to get a piece red hot, dipped it real fast and out, didn’t cool it much, got it red hot again dipped it for 15 seconds and it cooled down to touch. My thoughts are if the water is slow enough it’ll transfer the heat better, it needs time. After heating and dipping a few times that water got hot and it took much longer to cool to touch.

I have done several projects with industrial air to water heat exchangers that are copper/nickel material with a fan (e.g. a giant radiator), and the heat transfer continues to increase with water velocity up to the point the tubes actually start to erode from the turbulence. Turbulent water flow causes mixing and is good for heat transfer. There was a statement on a previous page that each system has an optimum flow point for heat transfer. That's incorrect - you can always increase cooling by increasing flow up to the point of material limitations, pumping cost (friction loss), or other physical limitations. There's no heat transfer coefficient that reverses at some flow condition and causes the heat transfer of the system to decrease.

In the bucket analogy, the heat transfer RATE between the hot part and the water is actually greater when you first immersed it, and that heat transfer RATE between the part and the water decreases as the difference in temperature between them decreases. If you wanted to cool the part even faster, you would have turbulent mixing in the bucket or the water exchanging itself out so there was no temperature rise of the cooling fluid. It's not a comparable analogy to an automotive cooling system, because the hot part isn't continuously generating its own heat either.

Was this a small closed loop system, or a large industrial set up with huge cooling tank? The turbulent flow that is generated will also result in turbulent flow at the pump which is part of the system on a car, followed by cavitation, air pockets, nucleate boiling, then reduced flow and steam pockets.

The car system is different. Air flow is an open system and you have a constant temp cooling air. Increase air flow, increase cooling effect in the radiator. Increase area of water and air contact increase cooling effect. Increase water flow through heat source and cooling source with internal pump part of small closed water system and effect can vary. There is a point when the coefficient of heat transfer can change an reduce effective heat transfer. Heat transfer is different for straight plate and a curved plate of same material.

Posted By: jcc

Re: Science behind Mopar cooling?? - 03/26/21 01:15 PM

High flow rates tend to "wash away" any bubble formations which might insulate the part needing cooling. there are lots of papers out there on the issue.

One analogy to make the point was using a garden hose to cool then using a fire hose to cool. Which do you think did a better job?

A simplistic but still slightly flawed analogy/example.

In your "wash away" comment above, that is true, and its likely equally true in that higher flow rate causes the bubbles/voids in the first place. I hope we both understand coolant flow in our context is not thru a straight uniform pipe, but thru a likely very coarse multiple direction changing path with many abrupt changes in coolant flow path in the engine block, heads, all precipitating cavitation concerns as flow rate increases.

Posted By: A12

Re: Science behind Mopar cooling?? - 03/26/21 01:26 PM

I know little or nothing about cooling systems, flow speeds, etc., the only thing I ever learned about liquid cooled internal combustion engines was "the engine is not cooled by liquid, the liquid is only the medium for moving the heat to a point where it can be dissipated by air. If the radiator was not in the system the engine would never be cooled by the liquid. Okay I hope that doesn't

more than what is being discussed.....................sure is a very interesting thread

.........I guess I'm learning more and more with each post

"Liquid assisted, air cooled"

Oh I did learn something about cooling systems.....the best way to handle the cavitation, flow speed (at all engine RPMs) coolant contact time is to use an electric water pump and electric radiator fan(s)....solves a lot of issues.

Posted By: 83hurstguy

Re: Science behind Mopar cooling?? - 03/26/21 02:50 PM

I have done several projects with industrial air to water heat exchangers that are copper/nickel material with a fan (e.g. a giant radiator), and the heat transfer continues to increase with water velocity up to the point the tubes actually start to erode from the turbulence. Turbulent water flow causes mixing and is good for heat transfer. There was a statement on a previous page that each system has an optimum flow point for heat transfer. That's incorrect - you can always increase cooling by increasing flow up to the point of material limitations, pumping cost (friction loss), or other physical limitations. There's no heat transfer coefficient that reverses at some flow condition and causes the heat transfer of the system to decrease.

In the bucket analogy, the heat transfer RATE between the hot part and the water is actually greater when you first immersed it, and that heat transfer RATE between the part and the water decreases as the difference in temperature between them decreases. If you wanted to cool the part even faster, you would have turbulent mixing in the bucket or the water exchanging itself out so there was no temperature rise of the cooling fluid. It's not a comparable analogy to an automotive cooling system, because the hot part isn't continuously generating its own heat either.

Was this a small closed loop system, or a large industrial set up with huge cooling tank? The turbulent flow that is generated will also result in turbulent flow at the pump which is part of the system on a car, followed by cavitation, air pockets, nucleate boiling, then reduced flow and steam pockets.

The car system is different. Air flow is an open system and you have a constant temp cooling air. Increase air flow, increase cooling effect in the radiator. Increase area of water and air contact increase cooling effect. Increase water flow through heat source and cooling source with internal pump part of small closed water system and effect can vary. There is a point when the coefficient of heat transfer can change an reduce effective heat transfer. Heat transfer is different for straight plate and a curved plate of same material.

Turbulent flow in a localized area targeted for heat transfer doesn't necessarily equate to turbulent flow at the pump.

You're going to need to explain your last two sentences, as they are far too general - What input(s) changes the coefficient of heat transfer to reduce the effective heat transfer and what drives that change?

Also, using your postulated scenario, since air is assumed to be a constant temperature and unlimited heat sink, the faster you pump hot coolant to the radiator, the larger delta T you maintain between the radiator and atmospheric heat sink, therefore maximizing heat transfer rate between the two.

Posted By: dragon slayer

Re: Science behind Mopar cooling?? - 03/26/21 03:52 PM

It does cause cavitation at the pump for a car because the pump can generate extra heat, and pressure drop at the impeller. It is not an external pump with head tank to the pump input before flowing to the heat exchange such as in industrial set ups. That head prevents cavitation. The Pump is centered on the heat exchanger because the fan is connected to the pump. Heat exchanger outlet goes up to the pump, vice down like a head tank. Less input pressure, so as you increase water flow you increase risk for cavitation.

There are engineering studies that show how the heat transfer coefficient changes. It is not linear in all ranges with flow. Just like hp and torque curves fall off. It would be optimized in a system design. Heat transfer is a rate right? One molecule of water moving through the radiator at the speed of sound would cool less then one moving a 10mph. At higher speeds it is in the cool zone less. Of course the next molecule in would probably be hotter then the one in front because it is a closed loop. Obviously the goal is keeping the engine at the correct operating temp during various uncontrollable conditions like winter versus summer.

That 440 RV test had a lot of good info an unexpected results with many different impeller designs. Those that were larger did not always produce cooler engine temps. I think a lot of this is in the weeds if you get a good radiator and fan set up.

Posted By: jcc

Re: Science behind Mopar cooling?? - 03/26/21 06:16 PM

"One molecule of water moving through the radiator at the speed of sound would cool less then one moving a 10mph."

But we are not talking about one molecule, we are talking about is how many molecules over a period of time, ie rate, who cares what each molecule absorbs, its the overall result that is the issue I believe, and as noted, the more molecules the higher the T delta.

Posted By: dragon slayer

Re: Science behind Mopar cooling?? - 03/27/21 01:48 AM

In engineering you can break down systems to indiv components an analyze. I was just trying to explain. If folks don't get the principles and understand the thermodynamic laws then so be it. I think some are just talking past each other. Regardless, there was plenty of engineering that went into the cooling system if you want to use examples from other industries that do not apply to how a car works ok, but that doesn't mean that principle matter. My only point was you can raise flow higher to the point you short circuit the cooling and create hot spots in the block and even the radiator. Cavitation was an issue Chrysler worried about.

Posted By: 83hurstguy

Re: Science behind Mopar cooling?? - 03/27/21 03:28 AM

There are engineering studies that show how the heat transfer coefficient changes. It is not linear in all ranges with flow. Just like hp and torque curves fall off. It would be optimized in a system design. Heat transfer is a rate right? One molecule of water moving through the radiator at the speed of sound would cool less then one moving a 10mph. At higher speeds it is in the cool zone less. Of course the next molecule in would probably be hotter then the one in front because it is a closed loop. Obviously the goal is keeping the engine at the correct operating temp during various uncontrollable conditions like winter versus summer.

Just because something is non-linear, does not mean that it has an inflection point and decreases over a specific value. The rest of those analogies aren't even relevant.

This is probably some of the best compiled cooling system information on the internet; Stewart did a ton of testing on stock car/NASCAR engines and posted some of their findings, unfortunately only the summaries are still available.

https://www.stewartcomponents.com/index.php?route=information/information&information_id=14I never commented on the original post regarding why A/C cars are over-driven and non-A/C cars are under driven. It has everything to do with the fan speed. Due to the condenser being in front of the radiator (higher pressure drop through the stacked cores) and also the need to have airflow for the A/C to work at low car speeds (e.g., sitting in traffic), the water pump pulley was overdriven to spin the fan quicker.

Now... for using a 22" radiator to cool the big block. Hopefully cleaning this one out works, but if not, find a radiator that has the widest tubes possible and most tube-to-fin contact area. Unfortunately, this is where expensive radiators earn their keep over the cheaper ones. The hotter you keep the radiator fins due to their contact with the coolant tubes, the more heat will get transferred to the air stream. Aluminum is stronger than copper, so the AL radiators can run larger tubes and get significantly more fin contact area. For example... three rows of 9/16" tubes = 1-11/16" of tube/fin contact length. A radiator with two rows of 1" aluminum tubes likely fits in the same core spot and gets 2" of tube/fin contact. Radiator core design can be a bit tricky, because if you just increase thickness, the pressure drop across the air side increases, which then decreases fan flow and is counter productive... most of the expensive units have figured this out.

Posted By: dragon slayer

Re: Science behind Mopar cooling?? - 03/27/21 04:31 AM

"Just because something is non-linear, does not mean that it has an inflection point and decreases over a specific value. The rest of those analogies aren't even relevant."

Of course not, but with nucleate boiling it does occur.

Posted By: PhillyRag

Re: Science behind Mopar cooling?? - 03/27/21 05:58 AM

Who here believes Chrysler had a Thermodynamics Engineer/Scientist on staff during the late 60's, doing "Nucleate Boiling Analysis" before "finalizing" a coolant system.

Or was it Trial&Error as with many of the racers of that era?

They took it to an "acceptable" level & then rubber stamped it.

After all it was Chrysler & not NASA.

Guess that's why many of these cars are marginal at-best wrt cooling.

Posted By: ruderunner

Re: Science behind Mopar cooling?? - 03/27/21 10:19 AM

I don't get the constant claims of marginal cooling. Other than the wing cars, it's not like every Mopar was an unreliable overheating pile of junk.

Most problems I've seen are leaks or clogs(usually from excessive stpp leak)

Make sure the system works correctly, clean and leak free. Correct fan and shroud.

Heck, I ran my roadrunner without a fan for one summer. I've seen Dodge trucks with no pump blades run without overheating.

Posted By: SportF

Re: Science behind Mopar cooling?? - 03/27/21 12:01 PM

Can't give you a reason why the facotory did what they did, but the more/faster the water moves through the system the more heat transfer/cooling you get. The old wives tale of water going too fast is just that, a tale.

Of course, the University of Minnesota heat transfer lab could be wrong too, but since they have been at it since 1880, probably not.

It could be the physics in your radiator are different than the physics of other radiators in other parts of the universe. Not much chance, but if true, you should get a hold of the Mechanical lab at the U of M.

Posted By: dragon slayer

Re: Science behind Mopar cooling?? - 03/27/21 12:56 PM

Who here believes Chrysler had a Thermodynamics Engineer/Scientist on staff during the late 60's, doing "Nucleate Boiling Analysis" before "finalizing" a coolant system.

Or was it Trial&Error as with many of the racers of that era?

They took it to an "acceptable" level & then rubber stamped it.

After all it was Chrysler & not NASA.

Guess that's why many of these cars are marginal at-best wrt cooling.

Yes they did actually. Go read a few patent documents on any part of a car and come back and tell us that they were just trial and error like high school racers. There was engineering and science involved. They applied know thermodynamic principles/laws along with fluid mechanics taught at any mechanical engineering college.

Go head take a closed car system with a 22 or 26" radiator and raise the water flow to the maximum you can and come back and tell us how much more it cooled the car. The water is either in the block and heads being heated or in the radiator being cooled. It comes to equilibrium based on the volume of the system, the heat source and the cooling source. Keep the open system airflow constant at let say 80degrees and constant flow. Just raise water flow rate

Posted By: 83hurstguy

Re: Science behind Mopar cooling?? - 03/27/21 01:20 PM

"Just because something is non-linear, does not mean that it has an inflection point and decreases over a specific value. The rest of those analogies aren't even relevant."

Of course not, but with nucleate boiling it does occur.

Aaaaand nucleate boiling occurs at lower flow rates because of increased coolant temperature rise, which decreases heat transfer coefficient.

From the EMP Stewart link: “Higher coolant flow will ALWAYS result in higher heat transfer. Coolant cannot absorb heat after it reaches it's pressure corrected vapor point. Furthermore, coolant absorbs heat at a progressively slower rate as it approaches this point.”

Thanks for proving my point, my work here is done.

Posted By: madscientist

Re: Science behind Mopar cooling?? - 03/27/21 01:58 PM

There are engineering studies that show how the heat transfer coefficient changes. It is not linear in all ranges with flow. Just like hp and torque curves fall off. It would be optimized in a system design. Heat transfer is a rate right? One molecule of water moving through the radiator at the speed of sound would cool less then one moving a 10mph. At higher speeds it is in the cool zone less. Of course the next molecule in would probably be hotter then the one in front because it is a closed loop. Obviously the goal is keeping the engine at the correct operating temp during various uncontrollable conditions like winter versus summer.

Just because something is non-linear, does not mean that it has an inflection point and decreases over a specific value. The rest of those analogies aren't even relevant.

This is probably some of the best compiled cooling system information on the internet; Stewart did a ton of testing on stock car/NASCAR engines and posted some of their findings, unfortunately only the summaries are still available.

https://www.stewartcomponents.com/index.php?route=information/information&information_id=14I never commented on the original post regarding why A/C cars are over-driven and non-A/C cars are under driven. It has everything to do with the fan speed. Due to the condenser being in front of the radiator (higher pressure drop through the stacked cores) and also the need to have airflow for the A/C to work at low car speeds (e.g., sitting in traffic), the water pump pulley was overdriven to spin the fan quicker.

Now... for using a 22" radiator to cool the big block. Hopefully cleaning this one out works, but if not, find a radiator that has the widest tubes possible and most tube-to-fin contact area. Unfortunately, this is where expensive radiators earn their keep over the cheaper ones. The hotter you keep the radiator fins due to their contact with the coolant tubes, the more heat will get transferred to the air stream. Aluminum is stronger than copper, so the AL radiators can run larger tubes and get significantly more fin contact area. For example... three rows of 9/16" tubes = 1-11/16" of tube/fin contact length. A radiator with two rows of 1" aluminum tubes likely fits in the same core spot and gets 2" of tube/fin contact. Radiator core design can be a bit tricky, because if you just increase thickness, the pressure drop across the air side increases, which then decreases fan flow and is counter productive... most of the expensive units have figured this out.

Thanks for the link. That was great to read.

Posted By: moparx

Re: Science behind Mopar cooling?? - 03/27/21 06:16 PM

an informative link, and i thank you for the posting !

and now the everlasting debate, what exactly is "hot" ?

many moons ago, i was of the opinion that 180 degrees was getting "too hot".

now, i like to see running temperatures of 195-205, and somewhat get concerned when seeing 220-230 in stop and go traffic on a 100 degree day.

am i way off base crazy ? [i have been told i am more than "nutz" quite a few times.

]

Posted By: Montclaire

Re: Science behind Mopar cooling?? - 03/27/21 08:29 PM

I ordered an aluminum radiator from Auto City Classics. It’s stock appearing and has 1” tubes. The plan was to get the one that’s in the car flushed and rodded but the more I thought about it, it seemed like throwing good money after bad. The guy I bought the car from said it needed a shroud - not that it needed to be flushed, making me think that it’s always run hot.

Every traditional brass/copper replacement radiator on the market under $600 has 1/2” tubes (actually slightly less due to the metric/standard conversion). Combine that with today’s crappy chicom copper and aluminum just made more and more sense. The unit that was already in the car was a three row, better than what I could buy in copper for the same price as the aluminum.

Posted By: jcc

Re: Science behind Mopar cooling?? - 03/28/21 03:01 AM

In engineering you can break down systems to indiv components an analyze. I was just trying to explain. If folks don't get the principles and understand the thermodynamic laws then so be it. I think some are just talking past each other. Regardless, there was plenty of engineering that went into the cooling system if you want to use examples from other industries that do not apply to how a car works ok, but that doesn't mean that principle matter. My only point was you can raise flow higher to the point you short circuit the cooling and create hot spots in the block and even the radiator. Cavitation was an issue Chrysler worried about.

Not sure if your comment is directed at me, or that we disagree much on this issue.

But now I have gone back and viewed EVERY reply here ( which I should have done at the onset), and which I had not done in my first reply when I first offhandedly mentioned cavitation. When others before me mention cavitation, it mostly seemed to be in reference to proper pump selection, design, and installation. All valid concerns. But it seems when pump based cavitation erupts, its hard for me to visualize any significant real flow increases, if any. Another member mentioned bubble formation on surfaces ( from heat?), but my cavitation concern was primarily from cavitation resulting from higher flows, or inertia cavitation, which is not a likely result with pump cavitation. High flow cavitation is for us likely extremely difficult to confirm or diagnose, other then if we make a change, that change explains all by itself the fix, an unscientific conclusion.

Posted By: dragon slayer

Re: Science behind Mopar cooling?? - 03/28/21 01:05 PM

I guess we are out in left field now with some of these discussions and none of it really helps the original poster. One of the earlier quotes is kind of funny as it is lifted from a paragraph called Common Misconceptions. It is also very vague. With a statement that increased flow increases cooling. Cooling of what? And under what conditions? I did spend some time looking at some engineering papers, mostly from Auto field.

Coolant flow is the item they seem to look at the least other than warm up phase. First, the biggest concern is proper engine temperature to improve emissions and conserve fuel. All the strategies are around warm up, and idle with a cooling system that can handle worst cooling condition WOT full load. But all the emission and fuel economy problems are at start up (warmup) and idle. So for our problems with our cars take what Chrysler did for a car with AC. They increased coolant capacity and surface area of the radiator. 22" to 26". Sure a lot has to do with making the AC work, but it also had to make the engine work too. Then they increased the speed of the fan and water pump by about 40% via pulley ratio. Then they increased the diameter of the fan, then they increased the pitch of the fan all to really increase dramatically the air flow through the radiator at (low speeds and idle); this with a constant input air temp because it is an open system. Unlimited air. But what about that increase in water flow? Well, instead of leaving impeller alone, they reduced the blades from 8 to 6. They reduced the diameter from 4.4" to 3.65" all to reduce impeller surface area and reduce the flow. Prevent cavitation I am sure. Is flow higher or lower then no AC car? Don't know. But I know they chose to offset the increased rpm of the pump with a smaller impeller.

As far as the engineering, it is not just cavitation, but also aeration that can cause problems with cooling rate when flow is increase too much. It is not nucleate boiling that cause loss of heat transfer rate, nucleate boiling is the peak of heat transfer flux. It is the departure from it and film boiling that insulates the metal heat source and dramatically reduces the heat transfer rate. You have no evidence that increasing flow dramatically in the engine block can prevent this film or steam boiling in certain pockets of the block and heads.

If you have modified your engine and increased it's heat output, your best to go increase the coolant capacity and cooling area with improved airflow. Not concentrate on increasing water flow through the system.

Do you really think if you are sitting in traffic with a moderate load on the engine and high air temp, watching coolant and oil temp rise, that if you had a booster water pump and turned it on to increase water flow that some how the system temp would just go down? Where did the heat go?

Posted By: A12

Re: Science behind Mopar cooling?? - 03/29/21 01:08 AM

What material is best for radiator construction for heat dissipation, is it aluminum?

Posted By: ruderunner

Re: Science behind Mopar cooling?? - 03/29/21 09:54 AM

Copper and brass are better thermo conducting. Given identical construction that would work better.

But aluminum can be built stronger and lighter, and cheaper, typically aluminum is built with a larger surface area to achieve better cooling.

Posted By: 360view

Re: Science behind Mopar cooling?? - 03/29/21 10:16 AM

When Howard Stewart was running his own Q&A board in the late 1990s it was the most informative source of automotive cooling information I have ever encountered.

I was just wondering if anyone who is limited on radiator area size and radiator depth

has disconnected the heater hoses