Posted By: Red383

Grinding weld on patch panel - 06/19/20 10:30 PM

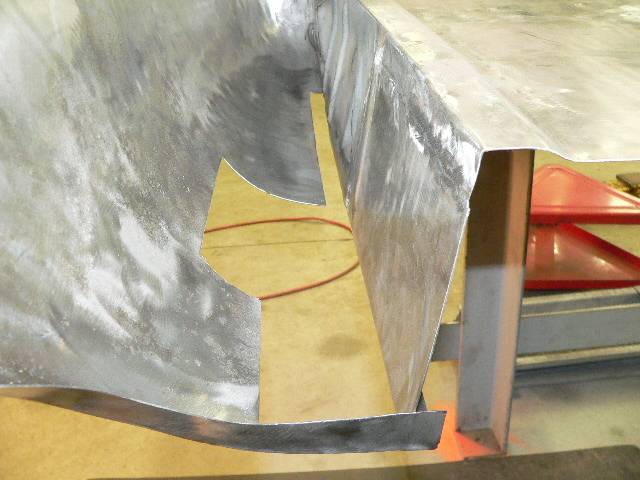

After welding in a patch panel, at what point am I doing more damage than good when grinding the weld down? Does it have to be completely smooth before applying filler?

Thanks

Thanks