Moparts

WHY??

Things just keep going down hill with this dart. I installed the new street dominator intake on my 440. Did it like ive always done, new valley pan and GOOD sealer, and it wont idle because its leaking along both sides so bad! I mocked the thing up and the bolts went right in and all, but its leaking..I can spray carb cleaner along the sides of it and it will rev a little. Ive sure know my share of people that have put aftermarket intakes on with no issues, so i dont understand this..

Posted By: ratroaster

Re: WHY?? - 06/09/19 07:45 PM

Has the intake been milled off?

Some aluminum intakes need the paper gaskets along with the valley pan.

Posted By: mopower440

Re: WHY?? - 06/09/19 08:59 PM

Some aluminum intakes need the paper gaskets along with the valley pan.

Wonder why? Wont that throw the bolt holes off? Guess i can try. What side of the valley tray do the gaskets go, or do they go on BOTH sides?

both sides & have your machinist check it for flatness but I would get the .015" ones first & mockup/measure & have him mill as needed which'll take care of the fitment & the flatness. Good luck on it.

Posted By: Dave Hall

Re: WHY?? - 06/09/19 09:13 PM

Both sides? At least the intake side if there lies the problem. The Right Stuff. Schmooie it over the top of the mating surfaces if you have to.

Posted By: mopower440

Re: WHY?? - 06/09/19 10:24 PM

both sides & have your machinist check it for flatness but I would get the .015" ones first & mockup/measure & have him mill as needed which'll take care of the fitment & the flatness. Good luck on it.

Do you guys noramlly have to mill new aluminum intakes everytime you buy one?

Posted By: elmor353

Re: WHY?? - 06/09/19 10:40 PM

No, unless the heads have been milled. I always use paper gaskets on both sides of the valley pan when using aluminum intakes. I've had several aluminum big block intakes leak so bad that they didn't want to run. The paper gaskets won't throw the holes off by much. I've never had a problem with lining up the bolt holes using them. If the bolt holes line up through the valley pan, they should line up through the paper.

Posted By: mopower440

Re: WHY?? - 06/09/19 10:49 PM

No, unless the heads have been milled. I always use paper gaskets on both sides of the valley pan when using aluminum intakes. I've had several aluminum big block intakes leak so bad that they didn't want to run. The paper gaskets won't throw the holes off by much. I've never had a problem with lining up the bolt holes using them. If the bolt holes line up through the valley pan, they should line up through the paper.

Wonder what the deal is with aluminum leaking so bad without the gaskets? Are they just not machined as well as the chrysler originals or what? If thats the case, its a damn shame for the price you have to pay for them! Ok, do i need to use RTV along with the paper gaskets to be sure the dang thing will seal this time?

Be sure the front and rear corners of the manifold aren't touching the cross bars that hold down the bathtub gasket at the front and rear.

Posted By: 469runner

Re: WHY?? - 06/09/19 11:26 PM

I think that Aluminum moves around so much more with heat cycling than the OEM Iron intakes did. Chrysler did use the paper gaskets in addition to the valley pan when the 440 six packs came out using the Edelbrock sourced manifolds.

Posted By: topside

Re: WHY?? - 06/09/19 11:33 PM

Could be that the angles are off slightly due to a set-up error when manufactured, or the end rails on your bathtub are holding the intake up off the heads a slight amount.

I've used .015 paper gaskets glued to both sides of the tub for decades, because I don't want to chance an air/oil leak and have to do the job twice.

Sure, a lot of guys get away with even re-using an old bathtub, but my luck's never been that casual

Posted By: mopower440

Re: WHY?? - 06/10/19 11:58 AM

should I use sealant along with the paper gaskets?

I would. Permatex 99MA "high tack" the thin red spray works good.

Posted By: DaveRS23

Re: WHY?? - 06/10/19 01:30 PM

should I use sealant along with the paper gaskets?

May not be necessary, but sure won't hurt. What's the chances that you will want to pull the intake back off in the future? There are a number of good sealers for this job. Which one to use depends on how big a gap needs filled and how difficult it will be to remove the intake in the future.

Right Stuff is probably the best gasket maker I have ever seen. It will fill big gaps and, as the name implies, doesn't even need the paper gaskets. But you may need a crane to pull the intake back off. It is that good. Personally, this is what I use on things that I don't expect to need to come back apart.

High Tack is a good sealant to use on the gaskets. But since it is gasoline resistant, it is a real mess to clean up if you ever need to pull the intake. Have some lacquer thinner or acetone handy for clean-up.

Hylomar A/F is the best sealant if you think that the intake will need to come back off. While it is very good at sealing, it releases the part rather easily. But it is pretty expensive and can be difficult to find. This is what I use on anything that I think may need to come back apart.

And finally grease. Of course grease is not really a sealant, but it softens and helps keep soft paper gaskets and sure makes taking things apart very easy and often allows the re-use of the gasket. For example, I always use grease on my carburetor base gaskets.

Be sure the front and rear corners of the manifold aren't touching the cross bars that hold down the bathtub gasket at the front and rear.

John has a good point here. The crossbars are only tapered on one side, it they're installed upside down the taper is now on the bottom and the intake could be held up by the non-tapered side.

Posted By: mopower440

Re: WHY?? - 06/11/19 01:56 AM

Be sure the front and rear corners of the manifold aren't touching the cross bars that hold down the bathtub gasket at the front and rear.

John has a good point here. The crossbars are only tapered on one side, it they're installed upside down the taper is now on the bottom and the intake could be held up by the non-tapered side.

I will be sure to check this on this install! I didnt pay any attention to that last time! Thanks for bringing this up! I know you use RTV, the right stuff, etc in the 4 corners, but do you also use it along the whole rail on both ends or just the valley tray alone?

Just use it along the whole rail under the tray, you don't need any on top of the valley tray at the crossbars.

Posted By: Cab_Burge

Re: WHY?? - 06/11/19 02:12 AM

Just use it along the whole rail under the tray, you don't need any on top of the valley tray at the crossbars.

There is no way I would use the "Right Stuff all the way across the bottom of the stock lifter valley pan

Especially if you wanted to try and reuse it again later

I do use a small dab of adhesive silicone RTV in the corners under the stock valley pan under retaining bars in the corners to seal them up

This is about 5 times in about a week of guys with intake sealing questions.

Many or most aftermarket intake castings need to be ground where they go over the end rails, this is very likely the cause of many non sealing intakes.

I use old/used valley trays with crushed sealing ridges. This adds a bit more clearance for the thin gaskets on both sides of the tray

Posted By: mopower440

Re: WHY?? - 06/11/19 11:53 AM

This is about 5 times in about a week of guys with intake sealing questions.

Many or most aftermarket intake castings need to be ground where they go over the end rails, this is very likely the cause of many non sealing intakes.

I use old/used valley trays with crushed sealing ridges. This adds a bit more clearance for the thin gaskets on both sides of the tray

I will be watching to see if this may be a problem! Thanks for the heads up!

Posted By: jlatessa

Re: WHY?? - 06/11/19 12:51 PM

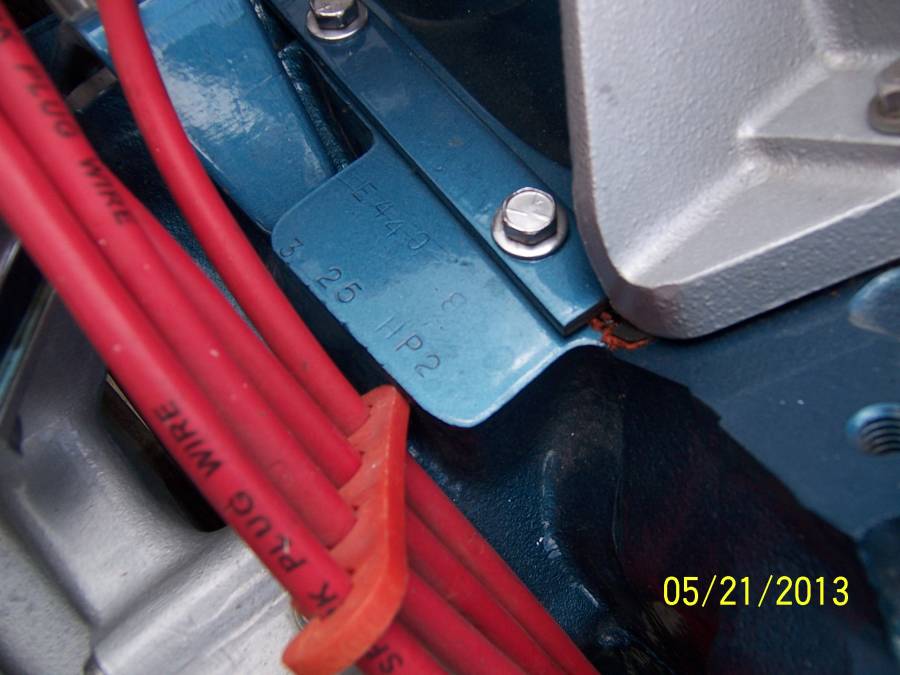

Jeez Modelmakerinc, that is one hospital grade sanitary engine!

Joe

Jeez Modelmakerinc, that is one hospital grade sanitary engine!

well thanks but the picture was taken just after its installation, I assure you it does not look as sanitary now.

Posted By: jbc426

Re: WHY?? - 06/11/19 03:50 PM

Hughes Engines sells a kit that allows you to figure out exactly what's going on between the two surfaces, manifold and heads. It consists of a small thread of crushable "Wax Wire" that doesn't spring back once crushed.

The posts above on this thread contain a wealth of information on how to do an effective install once you've figured out the issue, or to skip the proper way and simply overcome the sealing issue with added sealant.

Either way once your intake is effectively sealed, it doesn't really matter how you got there as long as it stays sealed.

One step forward, two steps back seems to be a continuing theme with my Mopars. I just keep pushing forward, sometimes after a good pause.

http://www.hughesengines.com/Upload/TechArticles/INTAKE_MANIFOLD_SEALINGJULY2015.pdf

both sides & have your machinist check it for flatness but I would get the .015" ones first & mockup/measure & have him mill as needed which'll take care of the fitment & the flatness. Good luck on it.

Do you guys noramlly have to mill new aluminum intakes everytime you buy one?

It’s the only way to ensure it’s perfectly flat.

Posted By: dOrk !

Re: WHY?? - 06/11/19 09:38 PM

Post a pic of the port face of the intake.... the SD intake has a special pattern on it

Posted By: mopower440

Re: WHY?? - 06/13/19 01:24 AM

I give up guys! I just give up! I put gaskets on both sides of the tray, made sure the intake wasnt hitting the hold down straps and STILL, same thing! Its better this time because before it wouldnt even stay running part throttle, where it will now, but it will NOT idle below about 1800 rpm..still leaking along the drivers side ports..maybe passenger also, i was too upset to even check. You know, ive been wanting an intake for the 25 years ive owned the damn car and finally get one and it refuses to work! Is there anyone on here that ports stock iron intakes? Thats about my only choice i guess if i choose to keep the car.

Posted By: 469runner

Re: WHY?? - 06/13/19 03:42 AM

Oh boy, I know this is frustrating. Has the engine ever been rebuilt? I had one with exactly the issue you are describing. The shop that decked the block not only screwed up the dimensions front to back, but side to side as well. A few thousands of an inch may not seem like much, but when all the tolerances stacked up it made for an intake that would never seal. I had given up on this ever running again. I had a friend look at it and knew right away what was going on. I got another block and got another machine shop. Lay the intake on the heads and check all around with feeler gauges. That will tell the tale.

Posted By: mopower440

Re: WHY?? - 06/13/19 10:17 AM

I rebuilt it but had no machining done besides boring the cylinders. I had no problem with the stock intake sealing with nothing but the valley tray, but this aluminum will not!

Posted By: bonefish

Re: WHY?? - 06/13/19 01:29 PM

i know this may sound crazy but did you alternate the tightening pattern side to side back to front.prob wont help but its easy to try

Posted By: mopower440

Re: WHY?? - 06/13/19 01:47 PM

i know this may sound crazy but did you alternate the tightening pattern side to side back to front.prob wont help but its easy to try

I did. I wish that was all it was. I REALLY wanted this intake.

You said the the engine has been rebuilt. The heads if they have had a valve job, more than likely the heads have been surfaced and many shops when they bore an engine they will surface the deck. there is really no way of knowing from the computer what is going on with your application but maybe a few pictures of it apart and of the parts you are using could shed some light. or find the local MoPar guy and pick his brain or pay him to look at it.

Posted By: mopower440

Re: WHY?? - 06/13/19 04:33 PM

You said the the engine has been rebuilt. The heads if they have had a valve job, more than likely the heads have been surfaced and many shops when they bore an engine they will surface the deck. there is really no way of knowing from the computer what is going on with your application but maybe a few pictures of it apart and of the parts you are using could shed some light. or find the local MoPar guy and pick his brain or pay him to look at it.

But if the heads or block got milled, how does the stock intake still work..no sealant or gaskets, just the tray? I never gave the machine shop the intake when they did my heads and block..

Here's what I've had to do on one Edelbrock intake that wouldn't seal. I used Ultimate Black RTV, put it on about 1/8" thick, let it set up overnight before installing intake. I had to push down on the intake to get the bolts to start but once I did it went on with no more vacuum leaks. Some intakes get through quality control that should never have gone out, but things happen. Give this a try, I think you'll have your intake sealed up.

Posted By: mopower440

Re: WHY?? - 06/13/19 05:22 PM

Here's what I've had to do on one Edelbrock intake that wouldn't seal. I used Ultimate Black RTV, put it on about 1/8" thick, let it set up overnight before installing intake. I had to push down on the intake to get the bolts to start but once I did it went on with no more vacuum leaks. Some intakes get through quality control that should never have gone out, but things happen. Give this a try, I think you'll have your intake sealed up.

do I still use the paper gaskets? Also, which side of the tray do I use the bead of RTV because I'm not sure which side of the tray it's leaking on..?

I'd still use the paper gaskets with a light coating under the pan, then put a light coating on top of pan and place the top gasket onto that. Then apply the 1/8" completely around the port openings and the heat crossover. Let this set up over night and drop the intake on, push it down and tighten from the center out. Make sure you alternate from side to side as you tighten it down. If this doesn't work, I hope you're not trying to put a 383 intake onto a 440. (just joking).

Posted By: mopower440

Re: WHY?? - 06/13/19 05:53 PM

I'd still use the paper gaskets with a light coating under the pan, then put a light coating on top of pan and place the top gasket onto that. Then apply the 1/8" completely around the port openings and the heat crossover. Let this set up over night and drop the intake on, push it down and tighten from the center out. Make sure you alternate from side to side as you tighten it down. If this doesn't work, I hope you're not trying to poh

put a 383 intake onto a 440. (just joking).

haha, nah, it's got the 440 part number.ok, I have the paper gaskets glued to the tray already, so you think I should just do the 1/8 bead between the intake and gasket only, not between the head and gasket? Also, what sealant do you recommend for the 1/8 bead, the right stuff?

Posted By: ZIPPY

Re: WHY?? - 06/13/19 07:15 PM

Be advised, RTV is not resistant to gasoline.

I'd pull it apart, clean it all up, lay the manifold on the heads dry and start checking with feeler gauges all around.

Nice thing about it...you can reach underneath the intake and check for gaps with feeler gauges as well as on top.

If it seems there is an impossible-to-see issue still, you can also reach underneath the intake (without the valley pan)

with a flashlight, in total darkness, and you may be able to detect a gap somewhere by shining the light on it and

observing from different angles.

If something is cut at the wrong angle or what not, you might be able to find it doing this.

You can try this, too.

http://www.hughesengines.com/Upload/TechArticles/INTAKE_MANIFOLD_SEALINGJULY2015.pdf

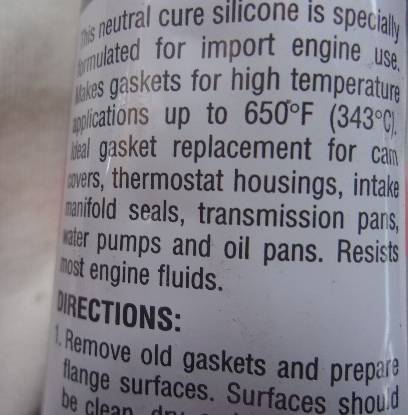

That's strange, it states right on the package good for intake manifold seals.

Posted By: mopower440

Re: WHY?? - 06/13/19 10:30 PM

well, i brought home a can of 'The right stuff" and a tube of ultimate black RTV.. NOW, which to use.....?

Posted By: Kern Dog

Re: WHY?? - 06/13/19 11:25 PM

well, i brought home a can of 'The right stuff" and a tube of ultimate black RTV.. NOW, which to use.....?

Maybe I missed it....Did you do a DRY mock up with NO valley pan yet? Aftermarket stuff has slipped by with quality control mistakes before.

Seriously...To keep fiddling with different gaskets and sealers is totally pointless if the intake was cast or machined wrong.

Posted By: mopower440

Re: WHY?? - 06/14/19 01:19 AM

I think i got it straightened out and didnt have to pull the intake back off afterall... I found 2 things that i didnt like and fixed both so not sure which one fixed it. I told you about spraying carb cleaner along the rail and it revved up right? Well i got to thinking that maybe the gasket between the carb and intake was possibly leaking and sucking that carb cleaner in and not the intake..so i pulled the carb off and that thick gasket was pretty rough..been used a long time, so i found a thin gasket to put between this thick gasket and the intake because that side of the thick gasket was in bad shape. Next, i checked the torque on the intake and it was only at 20 ft. pds..so i tightened it up to 40..Fired it up and she idled on her own!! I ran it for over an hour and drove around and all seems fine thankfully! I do appreciate everyones help with this, thats for sure!!! Now my next problem is finding another thermoquad base plate..the throttle shaft bore on the primary side on mine is worn and it whistles to beat hell when idling and is very aggrevating! Also, i cant get the primaries to close all the way against the idle screw because of this so its wanting to idle at 1000 rpm's..I can pull it back with my hand but it wants to go back up on its own..I think with the throttle shaft bore worn that its binding the primary plates just enough to do this.. This is a big primary thermoquad, wondering if i can use the base plate off any thermoquad as long as it has the big primaries? I know the top plates and center sections vary, but not sure about the bottom plates..This one is a 9077S.

That was too easy (sorry bad joke!). I'm glad it worked out WO haveing to pull the intake. Enjoy.

Posted By: 469runner

Re: WHY?? - 06/14/19 01:59 AM

Glad it worked out. Especially appreciate the follow up. So many folks fix it and never share what was found. It helps the whole community of enthusiasts when one shares what fixes the problem. Now maybe I'll run out to the garage and look at my carburetor gasket.

Posted By: bonefish

Re: WHY?? - 06/14/19 02:25 AM

well, i brought home a can of 'The right stuff" and a tube of ultimate black RTV.. NOW, which to use.....?

if your goin to use the RIGHT STUFF you might as well just weld it on.

Posted By: Kern Dog

Re: WHY?? - 06/14/19 02:41 AM

This reminds me of the story about the Marine Biologist that spent a week on a boat listening to whales squeak and moan, trying to interpret what the noises meant. After 7 days, he was ready to write up his report...THEN noticed the door to the cabin was opening and closing making the same squeaky noise he had been hearing all week.

Posted By: dOrk !

Re: WHY?? - 06/14/19 05:07 AM

This reminds me of the story about the Marine Biologist that spent a week on a boat listening to whales squeak and moan, trying to interpret what the noises meant. After 7 days, he was ready to write up his report...THEN noticed the door to the cabin was opening and closing making the same squeaky noise he had been hearing all week.

Did that Marine proctologist STILL write up that report and bill the gov 500k$ ?

Posted By: mopower440

Re: WHY?? - 06/15/19 02:20 AM

Been playing around with it tonight..all is well except for a minor little thing..with this SD intake, it has this very slight stumble off idle when stabbing the throttle wide open from idle..Its very, very minor..but it wasnt there with the original intake..any reason this single plane would do that where the dual plane iron intake didnt? Im not sure if maybe the big single plane may require even more pump shot than the dual plane did possibly?

Posted By: Kern Dog

Re: WHY?? - 06/15/19 03:55 AM

The intake flows more air, the carburetor is the same. I say the pump shot needs to be increased. You are getting a momentary lean condition on tip in.

Some manifolds have bolt pattern for both types of carbs. If you are using a holley, that is the wide pattern. I have seen where one or more of the inner bolt pattern bolt hole, breaks through to the plenum. Huge vacuum leak and will make your engine run exactly as you are saying. I get a 5/16'x18 v1/2' set screw and put it in the leaking hole with red loctite.