Moparts

Cooling Issue Solved & Some Tuning Questions

Posted By: Crazy68Dart

Cooling Issue Solved & Some Tuning Questions - 07/28/15 03:32 AM

I had been having issues with the Dart getting warm in traffic. I had a jag clutch / fan that never seemed to pull a lot of air. I replaced it with the following, and a 1" spacer.

http://www.summitracing.com/parts/sum-g4917Am running the stock 318 radiator, re-cored to 3 rows. Engine is stock/rebuilt 68' 383, with carb, headers, intake.

I have the initial timing set at 18 degrees, only the light spring, and total timing at 38. I have the vacuum advance hooked up adding 18 more degrees of timing. Hooked to manifold/lower port on Holley DP. I am thinking this might be too much timing as the car seems to be hesitating/breaking up from 2-3k RPM at light throttle. The exhaust is somewhat loud, I have looked at number 1 and 8 plugs, and no signs of detonation. I doubt I could hear it if it was. Plugs are a lightish tan in color. Carb is stock, stock jets, etc. etc.

If I get on the car it wakes up, and I am wondering if this is because vacuum drops and all that timing goes away.

I am going to mess with the vacuum advance, try it disconnected, see if the car acts different, etc. It won't idle as clean. Right now I have around 20" of dead steady vacuum with the can hooked up at about 950 RPM.

Anyone think I am hurting anything cruising around? Only way I know to dial this thing in...

Thanks

Posted By: RapidRobert

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 03:48 AM

with all that timing it sure ain't retarded! & if no pinging you are OK in that regard. plug descrip sounds OK & unleaded burns with less color anyway. You might unplug the can & see if that miss goes away (might be too much timing) & the can capped will change timing and alter rotor phasing

Posted By: ahy

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 03:48 AM

Not sure on the part throttle hesitation... that said, ported vacuum for the vacuum advance generally seems to do best. No vacuum advance at idle = steady timing at idle which is usually good Also, 18 degrees initial plus manifold vacuum advance could be a lot of timing at idle/low speed.

No short term harm in disconnecting and plugging vacuum advance for a test run. After doing that, suggest you hook it to ported vacuum for another test.

Posted By: Pacnorthcuda

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 03:57 AM

Put a timing light on the damper while you rev it up till it starts missing/running ruff. I bet you will see spark scatter. Then disco the vacuum and recheck, probably smooth, but if not, you have at least determined its either mechanical or vacuum advance

I went through the same thing and cured it with a new MP distributor.

BTW, I just put the same Summit fan (18" version) for the same reason.

GOOD flex fans rock!

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 04:02 AM

Thanks guys. I really don't want to give up the additional advance that I am getting at idle, helps with cooling, etc. Connecting to port vacuum will only make the can operate at cruise, which is where I am currently having the issue. Either way, to your point, I am going to fool around and see if disconnecting helps, that will at least tell me it is an ignition timing issue and not a carb issue. The vacuum at idle is stead and solid 19-20", so no worries of the timing jumping around. The car jumps to life off the starter (starts really easy), and now with the cooling issues solved I am feeling better about everything.

Is there a way to limit the advance from the can? I know you can adjust the "on off point" with an allen wrench, but is there a way to limit the amount of advance?

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 04:06 AM

Put a timing light on the damper while you rev it up till it starts missing/running ruff. I bet you will see spark scatter. Then disco the vacuum and recheck, probably smooth, but if not, you have at least determined its either mechanical or vacuum advance

I went through the same thing and cured it with a new MP distributor.

BTW, I just put the same Summit fan (18" version) for the same reason.

GOOD flex fans rock!

Thanks. This distributor is brand new. FWIW, I have had it for years, and didn't pay near what it is going for now.

http://www.amazon.com/ACCEL-59302-Performance-Replacement-Distributor/dp/B000CIE64QI had another thread on what I did to curve it over the weekend.

Agree on the fan -- this thing is really nicely made. Very pleased so far.

Posted By: RapidRobert

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 04:17 AM

Is there a way to limit the advance from the can? I know you can adjust the "on off point" with an allen wrench, but is there a way to limit the amount of advance?

yes, epoxy strips of feeler gauge on either side of the "notch" in the arm to limit its travel into the can but just me I think you have way too much timing being on manifold. keep us updated

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 01:01 PM

Thanks, will let you know.

Posted By: DaveRS23

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 03:34 PM

Is there a way to limit the advance from the can? I know you can adjust the "on off point" with an allen wrench, but is there a way to limit the amount of advance?

yes, epoxy strips of feeler gauge on either side of the "notch" in the arm to limit its travel into the can but just me I think you have way too much timing being on manifold. keep us updated

Another thing you can do is to tighten the advance can spring down enough to where the beginning point is way late so that the vacuum advance is not "full on" at your cruise vacuum. Using one of those hand vacuum pumps is the easiest way to establish how much advance your combo likes. But trial and error with the allen wrench will get you there too. It will just take a bit longer to figure out.

And your mechanical advance does sound a bit much. How did you establish that as the best for your combo?

As a starting point, I use 32* mechanical advance and about 42* total with vacuum and tune from there. On the vacuum advance, I start a little low and add a couple of degrees at a time until the car starts to "surge" at cruise and then back it off until the "surge" is out of it.

Posted By: lewtot184

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 03:37 PM

run the vacuum advance to the timed port at the metering block.

Posted By: krautrock

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 04:09 PM

i had a very light miss at part throttle on my truck, sounds similar to your miss.

i jetted the carb up a step and it solved it.

Posted By: autoxcuda

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 05:38 PM

I had been having issues with the Dart getting warm in traffic. I had a jag clutch / fan that never seemed to pull a lot of air. I replaced it with the following, and a 1" spacer.

http://www.summitracing.com/parts/sum-g4917Am running the stock 318 radiator, re-cored to 3 rows. Engine is stock/rebuilt 68' 383, with carb, headers, intake.

....

Are you running a fan shroud?

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 07:14 PM

Is there a way to limit the advance from the can? I know you can adjust the "on off point" with an allen wrench, but is there a way to limit the amount of advance?

yes, epoxy strips of feeler gauge on either side of the "notch" in the arm to limit its travel into the can but just me I think you have way too much timing being on manifold. keep us updated

Another thing you can do is to tighten the advance can spring down enough to where the beginning point is way late so that the vacuum advance is not "full on" at your cruise vacuum. Using one of those hand vacuum pumps is the easiest way to establish how much advance your combo likes. But trial and error with the allen wrench will get you there too. It will just take a bit longer to figure out.

And your mechanical advance does sound a bit much. How did you establish that as the best for your combo?

As a starting point, I use 32* mechanical advance and about 42* total with vacuum and tune from there. On the vacuum advance, I start a little low and add a couple of degrees at a time until the car starts to "surge" at cruise and then back it off until the "surge" is out of it.

How I got here -- I am at 18 initial (not centrifugal) based on vacuum reading and adjusting the dizzy. Once that was set, I knew I wanted to be around 38 total (initial+centrifugal), so I pulled the dizzy apart and adjusted the centrifugal advance down to 20 degrees (10 degrees in the dizzy). While I was in there, I removed the heavy spring, leaving the light spring to help bring the advance in a little quicker. This is a stock build 383 with 906 heads, so not the most combustion-efficient setup, so I think it can take a little more timing. Vacuum reading with the can hooked up is about 20". I got this point after the initial timing was set, hooked the can up, and tweaked the idle mixture screws.

I have a mighty vac pump, and will play with the can next.

What I think might be happening, my cruise is 2-2.5k at 45-50 MPH (not exact) but close. So I am getting pretty close to full advance at this RPM, with the light spring only it was all in by 2500, so 38 degrees. Add another 18 on top of that with the can hooked to manifold and that is 56 degrees of timing at cruise. Might be a tad too much. I think low 50s is what to shoot for baseline and tweak per your surging adjustment comment.

A few options -- bring the initial timing down some, and readjust centrifugal to get back to 38 total. Attack can to port vacuum so that it does nothing at idle (which I want more timing at idle to help with cooling tooling around in traffic), or adjust some of the overall timing out of the can with the shims.

Either way, removing the can and/or trying port timing should tell me something. Either the car behaves the same way (which would mean it is likely carb related) or something changes (which should tell me it is timing related).

The other part of this is I am getting a whistling sound from time to time at idle/950 RPM. Vacuum leak? Not sure, vacuum signal is very steady at idle. Tracking that down too.

All part of the fun.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 07/28/15 07:17 PM

I am yes. It is the A-body shroud from mancinis. The lower holes did not align, so I had to modify, but it is on there. As you know this is a very shallow shroud and I really wonder if it does a whole lot of good. The closest point of the fan blade is 1.5" from the radiator core. Blades are about 1/2 in 1/2 out. I can grab a pic if you want later?

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 08/02/15 03:04 AM

Well disconnected and plugged vacuum advance... didn't really make much of a difference with this hesitation/miss issue.

I am wondering if I should tune the hesitation issue out with the can connected or disconnected. Connected seems to make sense, since that is how I am planning to run it?

The carb has the stock jets (and everything else) 70s front 80s rear.

What to you guys suggest as a starting point for jets, pump cam (30cc), etc?

Posted By: RapidRobert

Re: Cooling Issue Solved & Some Tuning Questions - 08/02/15 05:22 AM

Does it miss all the time? If not when? hot cold what RPM and in hg does it start to miss at? reluctor gap. rotor phasing. plugs. plug wires. less likely (vac leak/lean jetting). I wouldn't think 70's is in danger of being lean but bumping up 4 sizes for a 1 hour test would be easy to elim that & might partly compensate for a vac leak just for diagnostic purposes.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 08/02/15 02:59 PM

RPM is 2-2.5k through 3-3.5k RPM at light throttle. I think there are some carb issues. If I take up to 3500 and jump on it, it stumbles and then pulls hard.

Would need to check reluctor gap. I am beginning to think this is more of a carb issue than a timing issue (at the moment).

Going to baseline the carb when I get some hours to mess around. Idle, transition slots/blades, fuel level, check for vacuum leaks, etc. etc. I know where the ignition timing is, so that is good.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 03/09/19 02:08 PM

Hey all. Its been a long time. I am re-baselining things on the Dart. I am running the billet Accel distributor. Anyone have any idea how much mechanical advance this distributor will provide with the slots opened up the whole way? My previous tune is listed above. 18 initial, about 20 mechanical, one, light spring, and then with the vacuum can hooked up around 18 more.

I've used a piston stop to verify TDC on the harmonic damper, insulating and rerouting some fuel lines, and a insulation plate to hopefully take care of the vapor lock issue I've had a few times.

Any suggestions on a baseline tune (lets start with ignition timing for now) for a pretty much stock 383 would be helpful too. 150 PSI cranking compression, stock cam, RPM intake, headers. After I get this set, I'll focus on the carb.

Thanks!

Posted By: RapidRobert

Re: Cooling Issue Solved & Some Tuning Questions - 03/09/19 06:10 PM

You might (1) set the initial with the "vacuum gauge method", (max vac in drive/idling then back off the INITIAL till the VACUUM drops 1 in hg & this is what the eng will see stoplight to stoplight & if it dont balk when cranking when hot you are good on the initial then (2) set the total (initial+springs) to 36 (38 in some cases), (the $25 FBO plate is the best deal in the house for this on a "regular" dist then (3) mix/match springs so that you are just under the pinging point at WOT up thru the gears on your hottest/driest (most likely to ping) day & peoples' hearing varies so give it a cushion, you want to be close to the pinging point but NEVER/EVER over it then (4) plug in the can to ported & adj the tip in with a 3/32 allen wrench till you are just under the pinging point in everyday driving under varying RPM/load conditions. there are manifold tuning afficionados but I ain't never tried it but some swear by it as opposed to ported. "Quicker/close" would be to set the initial to 20 then the total to 36 then work with the springs then plug in the can. First I would have the carb somewhat "close", at least not too lean

Posted By: Mattax

Re: Cooling Issue Solved & Some Tuning Questions - 03/09/19 07:08 PM

Interesting.

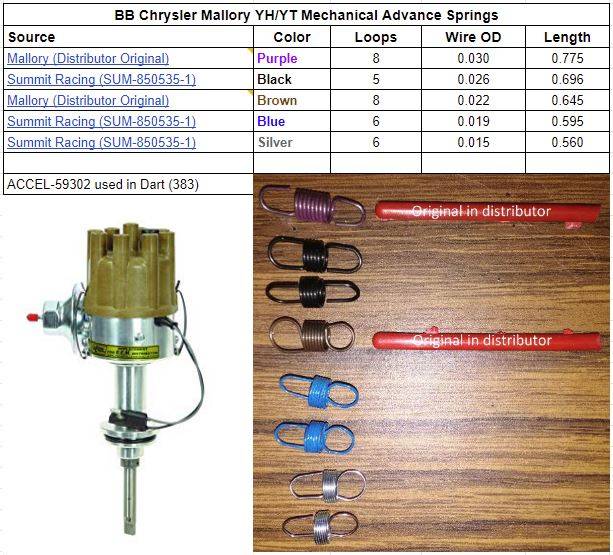

That photo shows a Mallory YH advance mechanism.

There are three adjustments that can be made internally.

Timing for your engine should be close to stock since its a stock engine. It can be tweaked from there but that's a good baseline.

Since yours is slightly hot rodded, looking at non-CAP '67 Plymouth specs, the initial timing should be 12.5* BTC. It should advance 6 to 10* by 1500 rpm.

After that it depends on whether it was the 2 bbl or 4 bbl version, and if we look at '68 specs 4bbl w/ (CAP) manual and automatic are different. What did your '68 start life as?

Posted By: crackedback

Re: Cooling Issue Solved & Some Tuning Questions - 03/09/19 07:23 PM

With only one spring the timing is going to be all in RIGHT NOW off idle is my guess.

Posted By: Mattax

Re: Cooling Issue Solved & Some Tuning Questions - 03/09/19 08:18 PM

nah. As long as its primary spring, which is looks like. The black spring is a reasonable starting point.

The total advance is set almost maxed out. That will also increase the intial tension on the primary spring.

So idle to maybe 1500 will be OK. Above that it will advance way too quick and too much.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 01:36 AM

The engine started life as a 68 2bbl. However, it was rebuilt along the way, and before I got it. The important things, 150 cranking PSI within 5% of each other in every cylinder. I had to put a rear sump pan on it to clear the AlterKtion (also adding a windage tray, yeah somewhat pointless at this RPM level, but didn't cost me much), cross hatch in the bores and bottom end was clean. Top side the valley and under valve covers super clean. It pulls really strong and steady vacuum at idle (with vacuum can on manifold vacuum) as well. I'm not sure what cam is in it, but with that kind of vacuum at idle it is pretty tame.

If you look up towards the top of the thread (from a few years ago), that is what I measured. That was with my dialback light. Now that I have confirmed TDC (and have added timing tape), I might just put it back together and make sure everything is where I think it is. But a few years ago, initial was 18 degrees and adding 20 degrees of mechanical advance all in by around 2500. Seems like a lot of initial timing, but with this and the vacuum can attached it pulls 18-20 inches of vacuum, and has a clean idle. I keep reading that the engines like more initial with the newer/ethanol fuel.

I'm going to get a jet kit for the carb and richen the primaries (after I verify ignition timing). Maybe 74 or 76 (has stock 70s in it right now) and see if that changes anything. Setting idle mixture works fine, transfer slots are not over-exposed, and blades are closed. Put new 30cc pump diaphrams in it a few years ago, with the red cam (forget which hole it is mounted in), but it pumps with even the slightest movement of the throttle.

Posted By: Cab_Burge

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 03:21 AM

What is the Holley List # and dash cast into the choke horn ? I would look up the original stock specs. for that carb dash number, IE 4779-6 and jet it back to stock unless your more than 1500 Ft above sea level, if so then try one Holley # size smaller. for every 1000 Ft above sea level to get you in the ball park.

If your 4000 Ft above sea level and the stock primary jet was suppose to be a # 76 I would try a 72,73 or maybe even a 71.

Leave the secondary jetting alone until you get the primary side jetting and air bleeds and spark plug heat range and ignition timing set up exactly the way you love it!

Posted By: Mattax

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 04:14 AM

Sounds like good advice.

The engine started life as a 68 2bbl. However, it was rebuilt along the way, and before I got it.

What I was looking forwith respect to timing was which cam is in it? I guess from what you know, we don't know. That's OK. The curves aren't that far apart.

a few years ago, initial was 18 degrees and adding 20 degrees of mechanical advance all in by around 2500. Seems like a lot of initial timing, but with this and the vacuum can attached it pulls 18-20 inches of vacuum, and has a clean idle. I keep reading that the engines like more initial with the newer/ethanol fuel.

It is alot. That amount of initial is needed on relatively radical cams, maybe around 240* at 0.050 in 383.

18-20 " of vacuum is a good indicator that the cam is quite strong at idle and should be fine with stock initial timing (pre-CAP). It probably could be made to work with the emmissions specs but that's just a headache for what your doing and hurts economy.

You can't really use vacuum to guide setting initial timing with a manual transmission. Out of gear, all engines love lots of timing and lean mixtures. Life's easy. Too easy. Start to put any load on and there's no power.

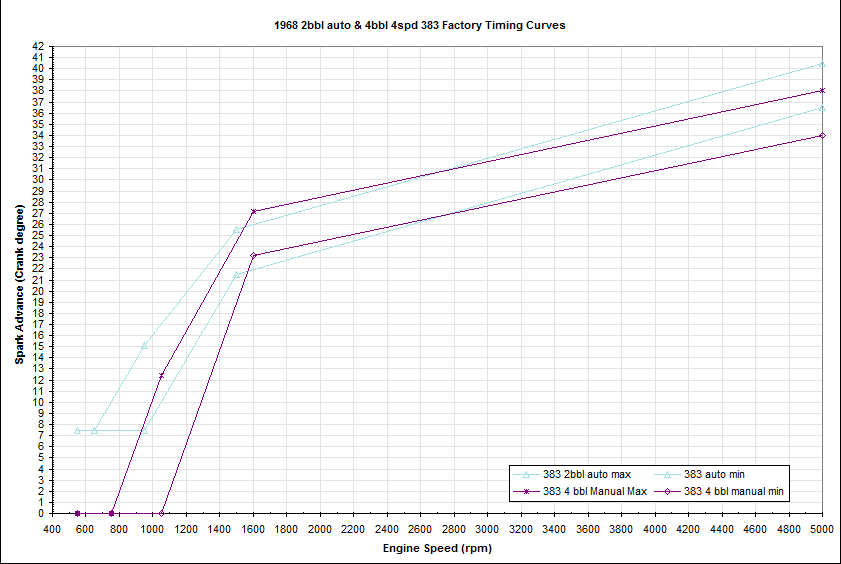

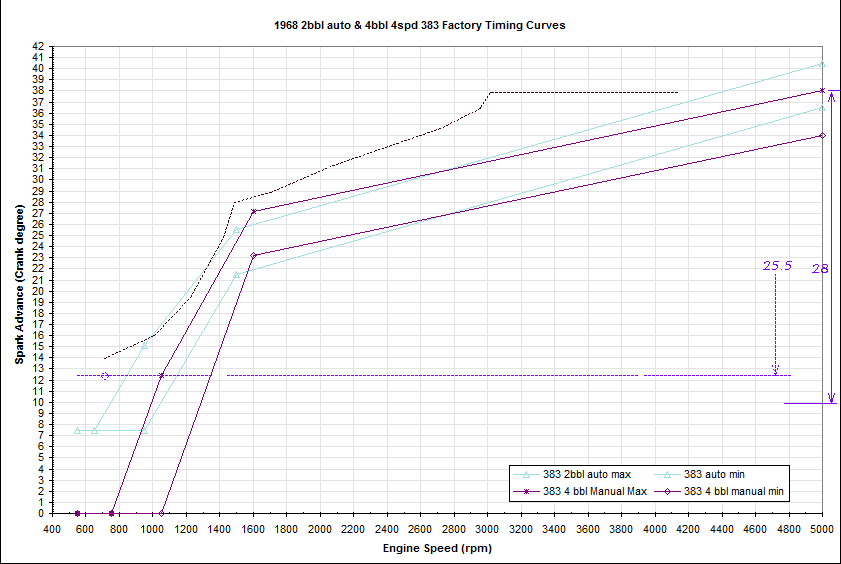

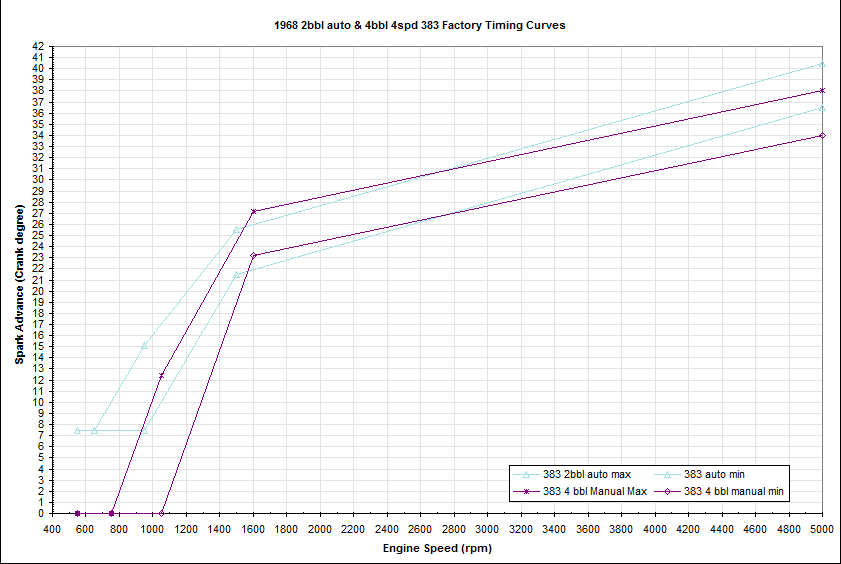

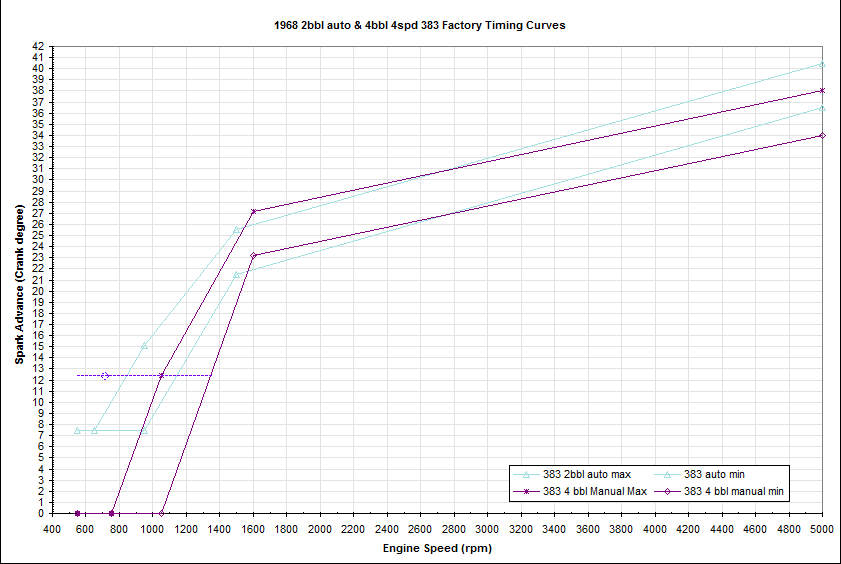

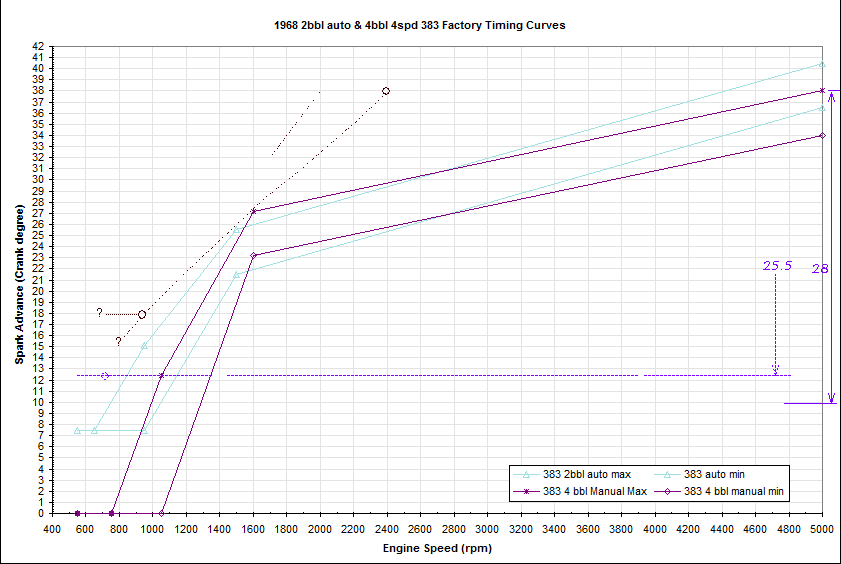

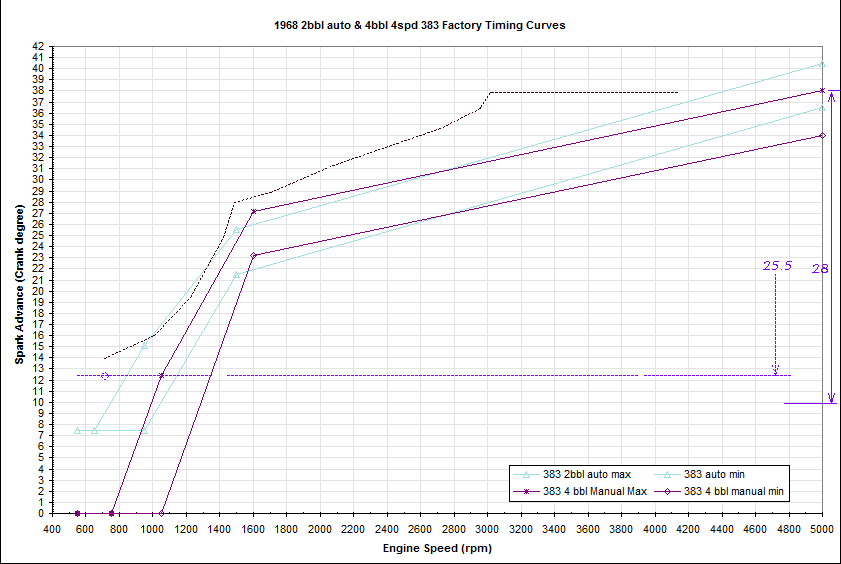

My suggestion is to go for timing curve based off the 1968 curves for a 2 bbl automatic and a 4 bbl 4 speed, but use the '67 initial.

Initial timing for all 383s in 1968 was reduced to reduce certain emmissions. Just use 12 - 15* BTC and try to get the idle speed down. Factory was 650 rpm with emmissions. You should be able to get in that ballpark.

Try the black or orange spring on the one side, and the secondary spring should have an long loop so it doesn't engage until the rpms are up around 1500 -2000.

If you don't do that, my experience (small block) is that on longer trips the engine will ping at part throttle load.

With the YH advance it is very difficult to slow down upper end of the advance the way the factory distributors did. Just do the best you can. If you can keep it from hitting 38* until after 3000 rpm you'll have done well. You can then use vacuum advance, and tweak it to provide around 56* when crusiing on the highway and it shouldn't ping at part throttle. 56 is what Direct Connection recommended as a target for b/RB engines and guess what? Shop manual shows a 383 4 bbl vac advance can add 24* at 15"Hg. Add that to factory curve which shows 32* at 3000 rpm and its 56*. There seems to be a pattern here.

Description: 1968 2 bbl auto Timing specs overlayed with 4 bbl 4-speed specs

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 11:16 AM

Cab, the carb is a 4779-5. Its got stock jets 70s/80s. I am in NE Ohio, think we are around 800-1000ft above sea level here. I cannot remember which plugs I have in the car. I'll look today.

Mattax, this is great info. Thank you. I'm not sure how much mechanical advance this distributor will give me? But, it sounds like I should open the slots the whole way (to give me full mechanical advance) and I'll bring my initial back to not overshoot all of the mechanical being added. At the moment I closed the slots down some to stop the mechanical advance at 20 degrees since my current initial is 18, for 38 total.

I'll have to see what springs I have. I don't recall having more than came with the distributor, but I'll look. If not, I'll pick up a spring kit.

650 RPM idle speed with a manual, or was that auto with auto trans?

Thanks again.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 01:29 PM

The spring that I removed from the mechanical advance...

Posted By: Mattax

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 02:06 PM

I'm not sure how much mechanical advance this distributor will give me? But, it sounds like I should open the slots the whole way (to give me full mechanical advance) and I'll bring my initial back to not overshoot all of the mechanical being added. At the moment I closed the slots down some to stop the mechanical advance at 20 degrees since my current initial is 18, for 38 total.

I'll have to see what springs I have. I don't recall having more than came with the distributor, but I'll look. If not, I'll pick up a spring kit.

LOL. I see you were ahead of me while typing!

I found your other thread. You wrote it was the secondary spring was purple. That's certainly OK to start with. I wouldn't rush out to buy the kit. They've gotten pricey last I checked.

There is a silver secondary spring that

may have a slightly higher rate. I say may because I have two different measurements for purple springs.

Assuming the YH advance your Accel is the same as all the others, the total advance possible is at probably 28*, maybe 30*.

In the kits with extra springs are keys to assist in setting the advance. They're plastic spacers of different thickness. You might be able to make your own and they'd be just as accurate. I've seen the thickness measurements posted on the interweb, but if we can't find, I'll measure the set I have.

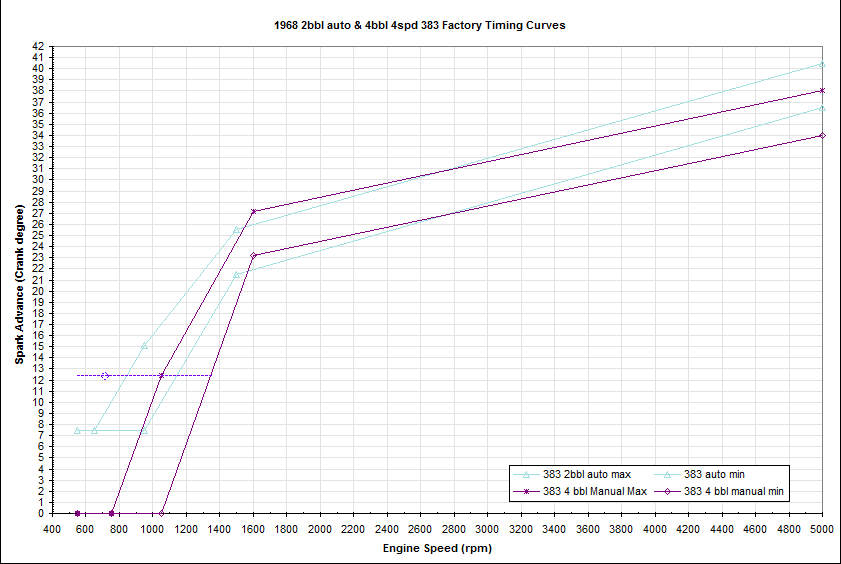

My guess from eyeballing the photo above is there is 20 - 24* degrees advance where you have it set. I know you measured 20* advance from 950 rpm to around 2400 rpm. But could there be a few degrees more below 950 rpm? In other words if you slowed the engine, does the timing stay steady or go down?

Posted By: Mattax

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 02:22 PM

The purple spring you have is 8 coils. The one I have that has 8 coils was made with .035" diameter wire. The other one I have was made with .032" diameter wire and has 9 coils so you probably have the stronger one.

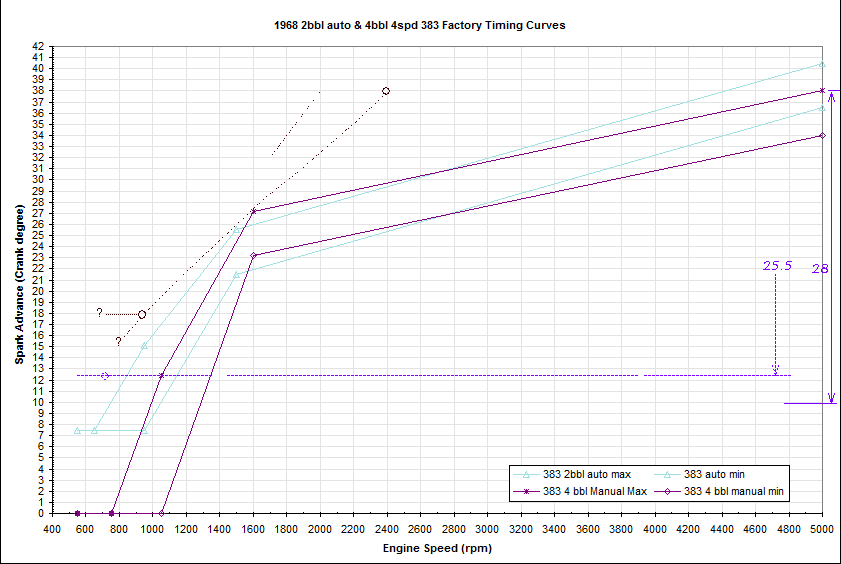

Instructions with the kit confirmed the advance adjustment available is 28* max.

I think if you start with it adjusted around 24 to 25* that would be good.

Light dotted lines show where it might be at now.

Posted By: Mattax

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 02:40 PM

With the advance set to 24*, if the purple spring engages around 14* out, it will slow the timing and the curve should look something like shown with dark dashes if initial is 14* around 650 rpm.

See what you get and then we can figure out what is needed to adjust it as needed.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 02:49 PM

One of these:

https://www.summitracing.com/oh/parts/sum-850535-1/overview/Good point on the lower side of the RPM/advance. It is idling more than 650 at the moment and you are probably right that the mechanical is likely adding few degrees.

I'll start with 12 initial and with 24-26 that will put me at 36-38 total.

I'll put the purple spring back in and see what happens. I need to run to summit today anyway, so I'll probably pick up the curve kit above just so I have it.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 02:50 PM

Typing at same time again! Thanks, I'll start tweaking.

Posted By: Mattax

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 02:56 PM

OK. The nice thing about the curve kit is the extra springs.

If not. here's what crackedback posted about the keys.

Thickness of some keys from the mallory kit.

14*: .140"

16*: .155"

18*: .170"

And from FABO post

https://www.forabodiesonly.com/mopar/threads/mallory-29014-advance-curve-kit.351641/#post-197131432714° = .130” or 3.3mm or #30 drill

16° = .149” or #25 drill

18° = .167” or #19 drill

20° = .184” or #13 drill

22° = .202” or #7 drill

24° = .225” or 5.7mm or #1 drill

26° = .240” or 6.1mm or B drill

28° = .260” or 6.6 mm or G drill

Posted By: Mattax

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 03:15 PM

This is weird, looks like my first post this morning disappeared.

650 rpm was the idle speed for 4 bbl manual and automatic, and 2 bbl manual 383. 2 bbl automatic was 600 rpm. All '68 383s were CAP equiped

Non-CAP 1967 383s all had idle speeds spec of 550 rpm. (that's with A/C on if so equiped).

The reason for the higher idle speed was that CAP traded some power and efficiency at idle for big reductions in CO and HC (but worse NOx).

But the loss of even a little power at idle has a noticble impact so higher rpm was needed to keep them runnin smooth and handle the loads when A/C was on or the car put in gear.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 03:30 PM

Thanks. Yeah I didn't see that original post either. Hmm. I'll shoot for 650. Shouldn't be a problem.

A *master reference* on the advance springs would be nice. I'm sure one exists somewhere. Instructions that are included with advance kit I linked above:

https://static.summitracing.com/global/images/instructions/sum-850535-1.pdf

Posted By: Mattax

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 04:12 PM

Unfortunately there isn't one from the company. The Mopar Performance version of the kit had a partial list of spring rates.

That's why I measured all the springs and made my own spreadsheet with the calculated spring rates.

However as I learned the hard way, that's only part of the story.

Spring Rates control how quickly the advance increases (the slope of the graph).

But the advance starting RPM is controlled by the free length of the spring and how much it is stretched when installed.

For the long looped springs, the slack between free length and the spring perches determines the degrees out before it engages.

and that's what is misleading about the graphed advances in Mallory's instructions.

One of the flukes of the YH advance mechanism is changing the degrees of advance changes the spring perch positions.

This is where I and others with cammed up motors that need short advances easily get messed up.

Say we want 16 to 17* initial, and 32* max. So we set the mechanicsm for 15 to 16* advance.

The side effect of this is the first spring as very little tension on it, As a result the weight starts moving out at far less than 750 rpm.

The way to put tension back in it is to bend the spring perches out. But obviously that's something we don't want to bend so far and then back too many times.

Fortunately that's not your situation. You can still do the tab bending as needed to either put more tension in the first spring, or to get the secnd spring to engage earlier.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 04:28 PM

Yep totally agree. Over time as well, depending on QC, materials changing, etc. etc. it all requires some trial and error.

Posted By: Mattax

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 04:51 PM

I'm afraid who ever put together those Mallory instructions didn't fully understand the unit.

My timing experiments with the YH distributor where all done on the car, with high idle, not on a distributor machine. That's how I finally started to get hang of the relationships. So yes, especially with all the variables, its definately something that requires trials and adjustments.

Once you see where your at, if you don't like the slope, I can tell you what springs should get a steeper or shallower slope. We'll have to count the coils and if you have a caliper, measure the diameters and length the ones you have.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 03/10/19 05:18 PM

I have a set of calipers. I'll measure what I have, and what comes in the new kit and throw it in a spreadsheet. I want to get the car to run better and starting with something closer to factor spec probably makes sense so I'll work it that way, then carb/fuel system if necessary.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 03/16/19 07:28 PM

I am going to leave the brown and put the purple spring back in. This is how the distributor was setup out of the box. I never ran it this way, I pulled the purple spring from the get go. This will give the stock "two step" advance curve that is described here:

http://www.loco4fomoco.com/MalloryAdvanceCurveKit.pdfThe summit curve kit I linked to above was probably an unnecessary expense, but it was pretty cheap (20 bucks), and the keys are handy. We'll see how accurate they are.

I took some measurements and organized the data. That purple spring is really stiff! The above document says that all advance should be in by 3500 RPM. We'll see I guess. Hopefully this info is useful for someone.

Posted By: Mattax

Re: Cooling Issue Solved & Some Tuning Questions - 03/17/19 02:37 PM

Measure the coil outer diameters and you can calculate the spring rates.

From that you can figure tension at any given distance.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 05/06/19 11:47 AM

A few weeks ago I recurved the distributor back to the stock springs and set mechanical adv to 24 degrees total. Based on this I set initial to 14 degrees. I also have vacuum can hooked to full port vacuum (below butterflies). Reset the idle down to 700-750 idle mixture on the Holley using vacuum gauge and took the car for a spin. Felt much better off of idle whereas before with the single, light spring I could feel the mechanical advance making the car act very strange right off of idle releasing clutch to get the car moving. Bring RPMs up to not stall car, release clutch, drop RPMs slightly, etc. and it was causing timing fluctuation which I could feel in how the power was being applied. That issue is now gone!

Up through 2500-3000 RPM the car felt better, but putting it under load, up hill, and giving it some throttle cause a loss of power and cough up through the carb. Felt like a lean condition to me, so yesterday I had some time to play with the car some, and jetted up from the stock 70s to 73s. I left the secondaries alone (80s). Took the car for a drive and it now has a clean/strong transition under load and the cough is gone.

I've checked the float level a few times, and understand that the general recommendation is that fuel should dripple very slightly out of the bottom of sight plug with a rock of the car. This isn't very scientific... I need to rock the Dart fairly hard to get fuel to slosh out. I can see the top of the fuel level inside bowls (front and back are set the same) when letting sit/idle.

I'm thinking the float level might be a hair low, but what is the general concensus here? I was thinking of possibly raising it some and going from a 73 back to 72 on primary jets.

Progress!

Thanks!

Posted By: RapidRobert

Re: Cooling Issue Solved & Some Tuning Questions - 05/06/19 12:02 PM

I've checked the float level a few times, and understand that the general recommendation is that fuel should dripple very slightly out of the bottom of sight plug with a rock of the car.

I would go ahead & raise it to there.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 05/06/19 12:20 PM

I've checked the float level a few times, and understand that the general recommendation is that fuel should dripple very slightly out of the bottom of sight plug with a rock of the car.

I would go ahead & raise it to there.

Should I be looking for fuel to dribble out just when simply removing the sight plug, or only with a *slight* rock of the car?

Posted By: Get-X

Re: Cooling Issue Solved & Some Tuning Questions - 05/06/19 02:02 PM

I've checked the float level a few times, and understand that the general recommendation is that fuel should dripple very slightly out of the bottom of sight plug with a rock of the car.

I would go ahead & raise it to there.

Should I be looking for fuel to dribble out just when simply removing the sight plug, or only with a *slight* rock of the car?

It should start to dribble out running at idle with the plug removed. That being said, it should barely be weeping out, not pouring out in any way. If you rock the car then it should pour out a bit then stop when settling. Also, your primary jetting seems very light compared to where I've had my 383's in the past with the Holley 750, but those motors were not stock with stock cams. I wouldn't worry about what the number is, I'd just jet it where it wants to be.

Posted By: Crazy68Dart

Re: Cooling Issue Solved & Some Tuning Questions - 05/06/19 02:15 PM

I've checked the float level a few times, and understand that the general recommendation is that fuel should dripple very slightly out of the bottom of sight plug with a rock of the car.

I would go ahead & raise it to there.

Should I be looking for fuel to dribble out just when simply removing the sight plug, or only with a *slight* rock of the car?

It should start to dribble out running at idle with the plug removed. That being said, it should barely be weeping out, not pouring out in any way. If you rock the car then it should pour out a bit then stop when settling. Also, your primary jetting seems very light compared to where I've had my 383's in the past with the Holley 750, but those motors were not stock with stock cams. I wouldn't worry about what the number is, I'd just jet it where it wants to be.

Yeah, the 73s really helped, so it was lean. Its stock cam with RPM intake, headers, and the 750. Its running better and better the more I tweak it.

Okay, thanks. From what I have read from various tuning guides is that the lower threads just barely get wet / very light dribble of fuel. My floats are low. I'll adjust them up and keep tinkering.

Posted By: Mattax

Re: Cooling Issue Solved & Some Tuning Questions - 05/06/19 02:24 PM

I agree with the above. Somewhere around just dribbling out. Fine tune from there.

A few weeks ago I recurved the distributor back to the stock springs and set mechanical adv to 24 degrees total. Based on this I set initial to 14 degrees.

I'm sure that's what you meant. So its around 36 total on the engine.

When you get a chance, find out what rpm this happens.

And what is the timing advances to at 2500 and 3000.

I also have vacuum can hooked to full port vacuum (below butterflies).

Likely a source of the problem here.

Should be on ported. Only need or want around 12-16* at idle with a stockish engine. It's probably got 20* something and therefore runs nicer at with a lean mixture. But that lean mix is not providing power. With an automatic it would be more obvious, but its still true. Put it on ported, a little rich mix and it will burn faster and be good.

Up through 2500-3000 RPM the car felt better, but putting it under load, up hill, and giving it some throttle cause a loss of power and cough up through the carb. Felt like a lean condition to me, so yesterday I had some time to play with the car some, and jetted up from the stock 70s to 73s. I left the secondaries alone (80s). Took the car for a drive and it now has a clean/strong transition under load and the cough is gone.

Good.

I was thinking of possibly raising it some and going from a 73 back to 72 on primary jets.

Good plan.

The other thing you can experiment with is richening the idle circuit.

One change at time, so try this afterword.

Easy way will be to stick a wire in each idle air bleed. (primary side only) Some magazine writers say this will only effect transition. In my experience that's horsepucky. It will help most in the transition, but it will effect the entire idle. You may have to readjust the mix screws.

You can use one wire or two. In either case, stick it in the airbleed, then bend it over the choke tower and run it under the air cleaner gasket. That way they can't move.

The idle airbleeds will probably be between .073 and .076" diameter. Measure with the shank of a small drill.

Calculate the area. then come up with a wire or pair of wires to reduce bleed about .003" diameter.

In otherwords, if the bleeds are .076" diameter, restrict them to the equivalent of .073 or .074"

I wouldn't take them lower than .070 unless the idle feed restrictions are real small, and I doubt they are.