|

Re: Rod bolt stretch - nuthin' but frustration

[Re: Hemi_Joel]

#2944841

Re: Rod bolt stretch - nuthin' but frustration

[Re: Hemi_Joel]

#2944841

07/19/21 01:41 PM

07/19/21 01:41 PM

|

Joined: Aug 2019

Posts: 9,388

Super Spudsville

Mr PotatoHead

Half Baked

|

Half Baked

Joined: Aug 2019

Posts: 9,388

Super Spudsville

|

I was reading that and found it interesting enough to look into it. More then one way to skin a rod bolt cat. Here is how I do it. I apply pressure with my thumb. It works fine and is consistent.

STOP POTATO HATE!

|

|

|

Re: Rod bolt stretch - nuthin' but frustration

[Re: Hemi_Joel]

#2946204

Re: Rod bolt stretch - nuthin' but frustration

[Re: Hemi_Joel]

#2946204

07/22/21 10:35 PM

07/22/21 10:35 PM

|

Joined: Jan 2003

Posts: 1,753

Windsor, ON, Canada

Diplomat360

OP

OP

top fuel

|

OP

OP

top fuel

Joined: Jan 2003

Posts: 1,753

Windsor, ON, Canada

|

Yeah, that's what I thought you meant.

I cannot do that as neither one of my higher precision gauges is mechanical, they are both digital.

Having said that, replacing the inner spring to a higher rate one did address the issue I was seeing. The plunger is a lot harder to move now and stays pretty steady. I still ended up tossing a different tip on the other side of the stretch gauge since I found that these bolts didn't have a precisely and smoothly machined recess in the head of the bolt itself. That caused the pointed end to slide around on that irregular surface, enough so that I could see the readings jumping a tad.

Now that brings me to another topic, which is: what is a safe torque to build up to as I attempt to reach the bolt stretch?

These Eagle bolts are meant to go 0.0064-8 at the recommende 75 ft-lbs of torque with the ARP lube. Well, that's nice and dandy but I only see 0.0048 streatch and it only climbs to 0.0051 at 85 ft-lbs. So things are barely moving!

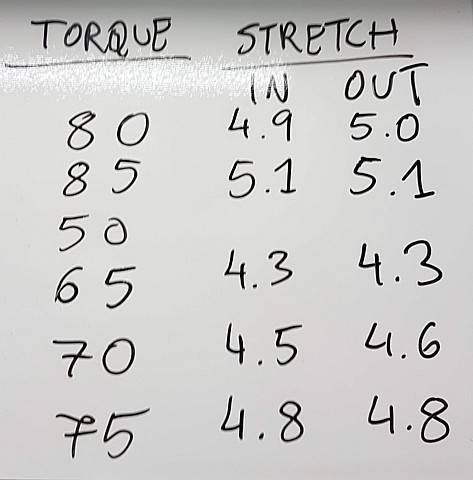

Take a look at the attached chart...start at 65 (half-way through) and wrap around back to the top for the 80 and 85 readings.

I don't know what to make of this, can try to go higher but I'm thinking the recommended 0.0064 is still some ways away.

I used both of my torque wrenches to spot check, digital and the click type, both matched, so I think the torque being applied is true.

Last edited by Diplomat360; 07/22/21 10:36 PM. Reason: IN and OUT shows the both bolts

|

|

|

Re: Rod bolt stretch - nuthin' but frustration

[Re: Diplomat360]

#2946223

Re: Rod bolt stretch - nuthin' but frustration

[Re: Diplomat360]

#2946223

07/22/21 11:15 PM

07/22/21 11:15 PM

|

Joined: Aug 2019

Posts: 9,388

Super Spudsville

Mr PotatoHead

Half Baked

|

Half Baked

Joined: Aug 2019

Posts: 9,388

Super Spudsville

|

I start mine at 65 and when im where you are and im not sure the "book"way but I use my long arm clicker and right after the click I gently pull just a hair like I hit the mark and wanted a bolt snug. Im sure the bolt moves just a few degrees. You might try that on your current #65 ever so slightly and see how much you add. I shoot for just above the min, spec and ive never go over. I generally can hit it the first or second bump. (not really a bump a gentle pull) Here is a good read... it says add more tq. at the end of the article. It does not say in what manner. Im sure there is a tq value you could add but I just bang it out. But in the end all that really matters is you get the stretch needed. https://www.cpgnation.com/how-to-measure-bolt-stretch-for-proper-torque/

STOP POTATO HATE!

|

|

|

Re: Rod bolt stretch - nuthin' but frustration

[Re: Mr PotatoHead]

#2946302

Re: Rod bolt stretch - nuthin' but frustration

[Re: Mr PotatoHead]

#2946302

07/23/21 10:13 AM

07/23/21 10:13 AM

|

Joined: May 2005

Posts: 1,960

Apollo, PA.

B1MAXX

top fuel

|

top fuel

Joined: May 2005

Posts: 1,960

Apollo, PA.

|

Torque them to the recommended value, and forget it.

I have been through this many times. The bolts are never stretched to the recommended length at the recommended torque. You can go to 10% more in ft- lbs on the bolts but don't chase the stretch number you will ruin you bolts.

I torque them, record the stretch. and watch for any abnormalities.

Your numbers are exactly what I would expect to see.

Last edited by B1MAXX; 07/23/21 10:14 AM.

|

|

|

Re: Rod bolt stretch - nuthin' but frustration

[Re: B1MAXX]

#2946307

Re: Rod bolt stretch - nuthin' but frustration

[Re: B1MAXX]

#2946307

07/23/21 10:42 AM

07/23/21 10:42 AM

|

Joined: Aug 2019

Posts: 9,388

Super Spudsville

Mr PotatoHead

Half Baked

|

Half Baked

Joined: Aug 2019

Posts: 9,388

Super Spudsville

|

This will confuse you more. About the 2000 series bolts. https://www.speed-talk.com/forum/viewtopic.php?f=1&t=34381 I will add ive one motor ive never checked stretch, apart each winter with the entry level eagle arp bolts. #63 and never look back. I really dont know how I got stuck on the stretch thing, sorta like the op, years ago I just wanted to do "better" and that goes back to why I wrote that many think at our power levels we can be semi close and never have a rod bolt issue. But if the torque value was the best way, why do so many use the stretch?

STOP POTATO HATE!

|

|

|

Re: Rod bolt stretch - nuthin' but frustration

[Re: moparx]

#2946362

Re: Rod bolt stretch - nuthin' but frustration

[Re: moparx]

#2946362

07/23/21 01:37 PM

07/23/21 01:37 PM

|

Joined: May 2005

Posts: 1,960

Apollo, PA.

B1MAXX

top fuel

|

top fuel

Joined: May 2005

Posts: 1,960

Apollo, PA.

|

what would be a good tolerance guideline to follow for stretch ? all being within +/- .000? trying to learn here.  My gauge reads in 1/2 thous. so I would expect to see between .005 and .006 as an example.

|

|

|

Re: Rod bolt stretch - nuthin' but frustration

[Re: moparx]

#2946371

Re: Rod bolt stretch - nuthin' but frustration

[Re: moparx]

#2946371

07/23/21 01:51 PM

07/23/21 01:51 PM

|

Joined: May 2005

Posts: 1,960

Apollo, PA.

B1MAXX

top fuel

|

top fuel

Joined: May 2005

Posts: 1,960

Apollo, PA.

|

5 & 6 thousandths or do you mean .0005-.0006 [ten thousandths] ? you wouldn't believe how many engines a buddy and i "built" back in my junkyard ownership days outside on a windy day in the dirt "yard".  they ran reasonably well, considering how ignorant/stupid we were. the older i get, the dumber i realize i truly am.........  5-6 thousandths. My gauge is only graduated in .0005. Not necessarily, sometimes we overthink things and create problems.

|

|

|

Re: Rod bolt stretch - nuthin' but frustration

[Re: B1MAXX]

#2946382

Re: Rod bolt stretch - nuthin' but frustration

[Re: B1MAXX]

#2946382

07/23/21 02:25 PM

07/23/21 02:25 PM

|

Joined: Apr 2006

Posts: 4,220

West Plains, MO

DrCharles

master

|

master

Joined: Apr 2006

Posts: 4,220

West Plains, MO

|

and if more torque is needed to get the desired stretch, why not just up the torque value, say 10, 15# , or whatever extra ? wouldn't that basically "average out" the desired stretch ? [provided the correct lube in the correct amount is used]   In my experience if you do that and chase the stretch, you end up putting a lot more pounds on the fastener than the recommended torque. But isn't the recommended torque selected to give you (approximately) the proper stretch? Stretch is all about the clamping force which keeps your rod cap on as the piston reverses at TDC...  I put my 451 together with Eagle rods and ARP bolts... there was a surprisingly large spread in the amount of torque required to reach .0063" stretch. I think it was something like 15 or even 20 ft-lb between the loosest and the tightest (it's been a number of years and I didn't write it down). That was after one cycle for trial assembly. The torque required to reach proper stretch has a lot to do with the amount of lube used, the machined finish of the washer, nut, threads and rod cap on each fastener

|

|

|

Re: Rod bolt stretch - nuthin' but frustration

[Re: DrCharles]

#2946388

Re: Rod bolt stretch - nuthin' but frustration

[Re: DrCharles]

#2946388

07/23/21 03:14 PM

07/23/21 03:14 PM

|

Joined: Jan 2003

Posts: 1,753

Windsor, ON, Canada

Diplomat360

OP

OP

top fuel

|

OP

OP

top fuel

Joined: Jan 2003

Posts: 1,753

Windsor, ON, Canada

|

...But isn't the recommended torque selected to give you (approximately) the proper stretch? Stretch is all about the clamping force which keeps your rod cap on as the piston reverses at TDC...  ... Aha!!! ...and that right there is where I'm stuck today, at least mentally that is. You expect a bolt to stretch by a given amount provided that you apply a certain amount of force that causes the bolt to get elongated. That force being defined and measured as torque. I haven't had a chance yet to try other rod/bolt combos, which I will tonight. In the meantime though I did get a pretty quick response (a couple actually) from Eagle regarding my follow up questions, basically the matters we have been discussion in this thread here. My 1st email to Eagle:

Alright sir, so here is the situation I have and I'm wondering what I should do at this point in time.

What is a safe torque to build up to as I attempt to reach the bolt stretch?

These bolts are meant to go 0.0064-8 at the recommended 75 ft-lbs of torque with the ARP lube. Good stuff, but I only see 0.0048 streatch and it only climbs to 0.0051 at 85 ft-lbs. So things are barely moving!

Here is what I'm actually seeing starting at the 65 ft-lbs mark:

TORQUE INNER-BOLT OUTER-BOLT

65 4.3 4.3

70 4.5 4.6

75 4.8 4.8

80 4.9 5.0

85 5.1 5.1

So I am still quite some ways away from the recommended 6.4-8 stretch, but having already gone up to 85 ft-lbs I am extremely uncomfortable going any higher.

The tightening torque has been checked with two torque wrenches: one digital, the 2nd one a click-type, they both match.

The bolts are using a good measure of the ARP lube, not overkill, just well coated, both the bolt threads as well as the under-head.

I have not tried any other bolt/connecting rod sets yet, only this 1st one.

Thanks,

-Dariusz

Eagle's 1st response:

Hey Dariusz

The proper way to do stretch is closed in wrench and install gauge and pull to the stretch your looking for. Do look at torque. Now if you want to torque it, dont look at stretch. We use the torque method here. So pick one and go with it, Both work.

They will never match.

My 2nd email to Eage:

Ah, so let me clarify.

I actually have the rod installed in a rod vise. I get both bolts torqued to 25 ft-lbs before I start the final tightening sequence up to the 75 ft-lbs recommended value.

Prior to doing this I check the free bolt length, and I check it afterwards as well. So far there is not stretch that I am able to detect. So this should be good news and implies the bolt returns (springs) back quite fine.

Based on what you wrote below though it does not sound like you are providing a max torque to get that recommended 0.0064-8 stretch though...man, I can go up further, but is there a realistic point of "no-return"? Meaning, I've stretched the bolt too far using just the TORQUE approach?

Thanks,

-Dariusz

Eagle's 2nd response:

Your correct, we don't offer a max torque, Torque will be lower than stretch always. So just pick one and go with it. Again I use torque on my motors and never had a failure do to the bolt torque. Both processes work. Just don't look at the torque is your doing stretch.

Man...if I felt frustration initially while attempting to get me a good measure of bolt stretch, that literally pales in comparison to what I'm feeling right now. Keep in mind I'm an overall newbie in the bigger scheme of things, but I am clearly reading, watching, hearing people out there talk about rod bolt stretch and the bolts having a defined yield value. And here I have a manufacturer that's literally telling me to ignore either one, never combine the two and instead just pick one!!! My God...so having caughed up the extra cash for a better engineering solution I get to pick the fashion in which I will grenade the motor? (yes, I'm overplaying this, but holy [censored], all of a sudden I miss my stock rods with the ARP wavelock bolts and a simpleton 48 ft-lbs of torque LOL): 1) pick the 75 ft-lbs and never mind that only stretches the bolt to 0.00051 and from an engineering perspective doesn't put it into a state where the bolt will be impart enough clamping force to deal with the dynamics of engine operation??? 2) Or on the other hand ignore the measure of torque being applied to a bolt and just bloody yank on the thing until I see the bolt-stretch I aim to see??? ....somebody shoot me now!!! LOL

|

|

|

Re: Rod bolt stretch - nuthin' but frustration

[Re: B1MAXX]

#2946469

Re: Rod bolt stretch - nuthin' but frustration

[Re: B1MAXX]

#2946469

07/23/21 08:15 PM

07/23/21 08:15 PM

|

Joined: Aug 2003

Posts: 43,097

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,097

Bend,OR USA

|

If you go after that stretch number your bolt won't return to it original free length....trust me.

Your numbers look correct . pick a torque and look for an oddball with the gauge, you likley won't find one. and move on. I wouldn't take them to 100ft trying to get the stretch. Iam balancing a set of scat h-beams right now so I just opened the box, they have arp 2000's, the card says torque to 75lbs and in red "do not exceed .006 stretch." I always check the stretch on the rods I test in a rod vice, if they don't return to zero after loosening they don't get used, I remember having to stretch, tighten, torque, the stock type ARP replacement bolts 3 times before using them. The instruction where to use a certain torque value and then measure the stretch if they didn't return to .000 return then to ARP for replacement  I have had ARP 2000 bolts made for one of the better known Hi Po rod makers over stretch at 55 Ft. Lbs. on a 7/16 bolt   I called ARP and they said to call the rod makers as they had made them to his engineering specs. and he would have to stand behind it, he didn't  His recommendations were torque them to 30 ft. lbs. and then rotate them 60 degrees more  I refuse to use that method without a stretch spec which was not furnish with those rods  Hence me starting at 50 Lbs. or less on stretching rod bolts for the first time from then on

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Rod bolt stretch - nuthin' but frustration

[Re: Diplomat360]

#2946540

Re: Rod bolt stretch - nuthin' but frustration

[Re: Diplomat360]

#2946540

07/24/21 03:05 AM

07/24/21 03:05 AM

|

Joined: Apr 2006

Posts: 4,220

West Plains, MO

DrCharles

master

|

master

Joined: Apr 2006

Posts: 4,220

West Plains, MO

|

...But isn't the recommended torque selected to give you (approximately) the proper stretch? Stretch is all about the clamping force which keeps your rod cap on as the piston reverses at TDC...  ... Aha!!! ...and that right there is where I'm stuck today, at least mentally that is. You expect a bolt to stretch by a given amount provided that you apply a certain amount of force that causes the bolt to get elongated. That force being defined and measured as torque. The "gotcha" is that the force elongating the bolt is only approximated by torque on the nut. As I mentioned, the relationship between the force and the torque is affected by quite a few variables. But the stretch is directly related to the force by the elastic strength of the bolt material. I'm getting out of my depth here (I was an EE, not an ME)  My understanding is that torque is easier to measure, so it's more commonly used. Without measuring the stretch, you have no idea exactly how much clamping force is present. On the other hand, millions of engines have been built with a torque wrench and not a stretch gauge, and they don't seem to blow up any more often...  Pick your poison, I guess.

|

|

|

Re: Rod bolt stretch - nuthin' but frustration

[Re: Cab_Burge]

#2946598

Re: Rod bolt stretch - nuthin' but frustration

[Re: Cab_Burge]

#2946598

07/24/21 11:37 AM

07/24/21 11:37 AM

|

Joined: Apr 2006

Posts: 4,220

West Plains, MO

DrCharles

master

|

master

Joined: Apr 2006

Posts: 4,220

West Plains, MO

|

I

X number of degrees of rotation is ALWAYS .xxx" of stretch no matter the friction, the tool or the operator.

Kevin Unless you have a defective or harder than the other bolts  Been there done that with the ARP 2000 bolts in those race rods I talked about  No one or company makes the exact same after market parts now unless it is the high dollar multi tested space program parts    Defective threads in the nut or bolt would be a problem for sure. But you'd feel that while tightening it. And if the bolt is "soft" you will have the correct .xxx" of stretch, but below-spec clamping force  But if the bolt is harder, it will take more torque to achieve the same angle rotation (and therefore more clamping force). This wouldn't necessarily be a bad thing as long as it wasn't SO excessive it pulls the end out of round  I guess the conclusion is that angle torquing bolts is a good thing, as long as a minimum torque spec is also met. If not, the fastener is defective...

|

|

|

|

|