|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: NachoRT74]

#2713587

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: NachoRT74]

#2713587

11/07/19 08:47 AM

11/07/19 08:47 AM

|

Joined: Aug 2007

Posts: 6,095

Valencia, España

NachoRT74

master

|

master

Joined: Aug 2007

Posts: 6,095

Valencia, España

|

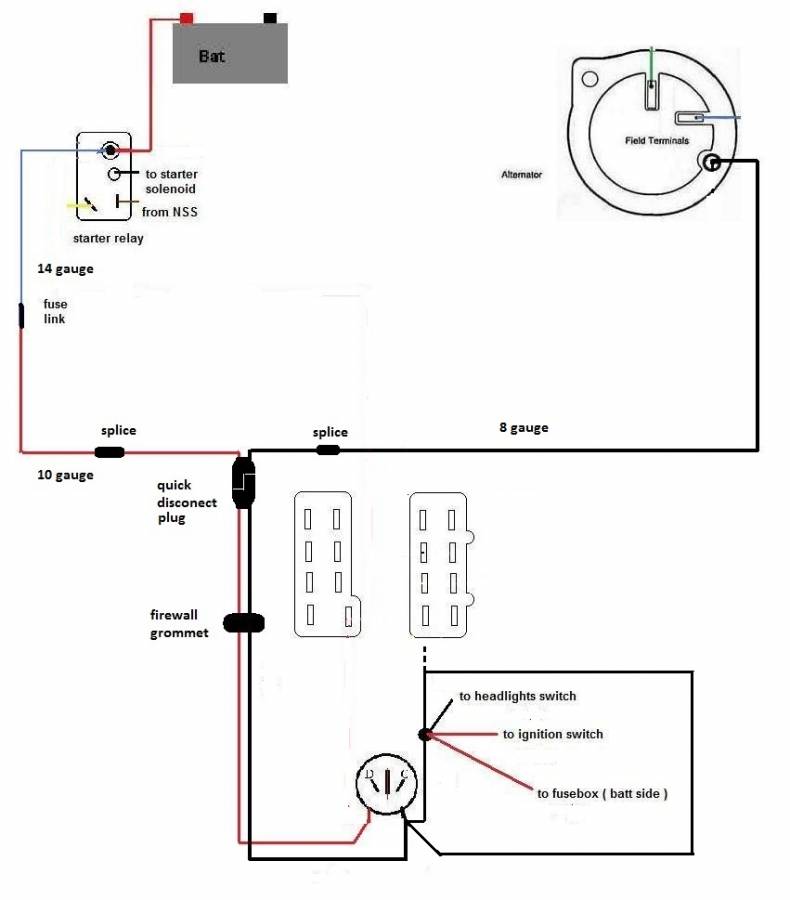

ok, the idea about the 16 fuse link running to feed the splice into the cab even is not bad, will be actually just protecting in case of a short the ign system and MAYBE headlights ( just headlights, not even interior or parking ones ). I have heard the light switch gets a breaker inside, never have dissasembled one, but if that's true, then not even the light system is actually down the fuse link protection sicne got its own one. For the rest of parts, you already got the fuse box. now, if you actually wanna remove the charging system completelly out of the bulkhead and still keep all the paths capabilities.... what about try this ? -8 gauge wire up to amm -The 12 wire originally running between splice and bulkhead now run between splice and amm stud, doubling the existant path between amm and splice. This will still feed the splice with TWO wires. Would be great of course the wire lenght between bulkhead and splice is long enough to also reach the ammeter. On this way you won't have to deal and work on the main splice, which usually is electrically welded, and is a better job that any splice home made. and I still would use a quick disconect link, like this loop, to be able to conect and disconect anytime thiis ( for any reason ), cutting one side long to attach eyelet terminals reaching the ammeter, and the other side splicing into the engine bay wires ![[Linked Image]](https://cdn11.bigcommerce.com/s-lamnh677/images/stencil/1280x1280/products/12102/15619/WORKMAN-TP_TN__89220.1490044355.jpg)

Last edited by NachoRT74; 11/07/19 09:54 AM.

With a Charger born in Chrysler assembly plant in Valencia, Venezuela

|

|

|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: jcruse64]

#2713719

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: jcruse64]

#2713719

11/07/19 03:11 PM

11/07/19 03:11 PM

|

Joined: Aug 2007

Posts: 6,095

Valencia, España

NachoRT74

master

|

master

Joined: Aug 2007

Posts: 6,095

Valencia, España

|

If using same quick disconect link I'm using remember you won't find diff gauge wires for red and black, so you will have to stuck with 8 or 10 gauge on both sides. You can still use the 8 gauge wire and splice in it a 10 gauge running to batt and of course the 14 fuse link. That's JUST an idea about this, being clean, but there are a dozen of ways to make this. You can even install junction points to get power from there anytime you want. I.E. on black side at firewall to get power there from the correct side of the ammeter for a correct reading and feed accesories. This could replace the quick disconect link and the splice for the quick disconect link loop. I'm using quick disconect link because I don't want to drill my firewall or anything on engine bay to install junction points ![[Linked Image]](https://images-na.ssl-images-amazon.com/images/I/419GO-pti1L.jpg) You can even use a dual side stud installed on firewall and not use a grommet. Something like this: ![[Linked Image]](https://www.getfast1.com/assets/images/Electrical/47204_47205.jpg) Althought I like these better ( but is bigger than needed ) ![[Linked Image]](https://www.picclickimg.com/d/l400/pict/273997158653_/Feeder-Through-Terminal-Junction-Firewall-Battery-Studs-Bulkhead.jpg)

Last edited by NachoRT74; 11/07/19 04:33 PM.

With a Charger born in Chrysler assembly plant in Valencia, Venezuela

|

|

|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: jcruse64]

#2713751

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: jcruse64]

#2713751

11/07/19 04:16 PM

11/07/19 04:16 PM

|

Joined: Aug 2007

Posts: 6,095

Valencia, España

NachoRT74

master

|

master

Joined: Aug 2007

Posts: 6,095

Valencia, España

|

well, the stud on the round ones is 3/8" while the others are 5/16", so there is a difference. Eyelet terminals must be big, which makes a difference attaching small wires wire in them. I had once those in my hands and I recall the hole to be drilled on firewall must be something like 7/8" or so.

Last edited by NachoRT74; 11/07/19 04:20 PM.

With a Charger born in Chrysler assembly plant in Valencia, Venezuela

|

|

|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: NachoRT74]

#2713754

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: NachoRT74]

#2713754

11/07/19 04:23 PM

11/07/19 04:23 PM

|

Joined: Aug 2007

Posts: 6,095

Valencia, España

NachoRT74

master

|

master

Joined: Aug 2007

Posts: 6,095

Valencia, España

|

Now, I don't get why would you need a dual stud for firewall like these to hook up a switched source into the cab... unless you want a switched source on both sides of firewall

With a Charger born in Chrysler assembly plant in Valencia, Venezuela

|

|

|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: jcruse64]

#2713755

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: jcruse64]

#2713755

11/07/19 04:23 PM

11/07/19 04:23 PM

|

Joined: Feb 2010

Posts: 1,645

Phila. Pa.

Mattax

top fuel

|

top fuel

Joined: Feb 2010

Posts: 1,645

Phila. Pa.

|

A 16 gage fusible link is needed when there are wires and connections12 gage or smaller before a fuse or breaker. If you have a crimper, then you can make your own in-line connectors. Advantage would be if you wanted to change wire diameters or have one wire connecting to two wires out. You can do the same with the ring terminals and a stud. Parallel is convenient if the original bulkhead connector is OK. If its toasted like Krautrock's '79 truck, then not so much so. Parallel is similar to what Nacho shows above, and would be same as the optional Dart wiring if the original alternator feed was left in place. (The one with the ?) https://board.moparts.org/ubbthread...6198/filename/1973-60Amp-Dart-color2.pngBut there is a related strategy that is interesting to mention. This is where the power into the cabin split before entering. One power lead goes to the key switch. The other power lead is for all the systems that don't use the switch. In other words, are always hot. A version of this is used on the '76 A-bodies and probably other cars in that time frame. One thing I like about the '79 truck ignition column wiring is that there are two hot wires. So this reduces the loads on the terminals.

Last edited by Mattax; 11/07/19 04:41 PM.

|

|

|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: Mattax]

#2713764

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: Mattax]

#2713764

11/07/19 04:44 PM

11/07/19 04:44 PM

|

Joined: Aug 2007

Posts: 6,095

Valencia, España

NachoRT74

master

|

master

Joined: Aug 2007

Posts: 6,095

Valencia, España

|

Parallel is convenient if the original bulkhead connector is OK.

If its toasted like Krautrock's '79 truck, then not so much so.

sure and I mentioned. If terminals &/or bulkhead can't be or don't want to be saved, better simply run new paths out of bulkhead. Myself I rebuilt my electrical systems to original conditions THEN I made the upgrades ( parallel ), but that´s just because I wanted to keep/rebuilt the factory setup and keep it in working order. I got a good conditions bulkhead conector and new harness plugs to rebuilt my wiring. I made by myself the wiring, didn't buy the harnesses made.

This is where the power into the cabin split before entering.

One power lead goes to the key switch.

The other power lead is for all the systems that don't use the switch. In other words, are always hot.

A version of this is used on the '76 A-bodies and probably other cars in that time frame.

I think ( unless I'm missing something ) you are getting confused about shunted charging systems, where yes, in fact, the power got spliced before entering into the cab, for the main splice on 12 or 10 gauge, as long for the ammeter on 16 gauge form ( at both ends of the engine bay shunt ). So the bulkhead gets 3 wires entering from that wiring area. I think B and M/F bodies got couple more, but I don't think A bodies. Althought A bodies got a 32 circuit bulkhead panel for 76, but maybe also wiring the fuel pace system and some other stuff more at teh same time than the new Charging wiring network Be best to find ones with a cover or shroud like was used on many of the alternator Batt terminals. agreed, there are many options for these firewall junctions. I just posted couple of them. To each own choose which one. Making a google search will find them

Last edited by NachoRT74; 11/07/19 04:48 PM.

With a Charger born in Chrysler assembly plant in Valencia, Venezuela

|

|

|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: Mattax]

#2713862

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: Mattax]

#2713862

11/07/19 11:28 PM

11/07/19 11:28 PM

|

Joined: Jan 2003

Posts: 2,094

central texas

krautrock

top fuel

|

top fuel

Joined: Jan 2003

Posts: 2,094

central texas

|

Just added fusible links to my wiring. Soldered both FL’s to a single connector so they can bolt to b+ on the relay. One FL for the alt wire, one going into the cab feeding the wiring harness in there.

First ran the truck without bolting the connector to the starter relay, so factory original routing but bypassing the bulkhead. Ammeter showed heavy charging for about 20 seconds, then went down to very slight charging. Headlights and all the cab electrics were strong, much better than before..thankfully.

Since i already wired it to connect to the relay, i wired it up that way, everything is good but i am getting a pulsing intensity through the lights, headlights and dash lights too. Like a metronome, slightly brighter then dimmer. About two pulses per second, don’t think it does it at idle but as soon as rpms go up it starts, doesn’t change frequency at all though.

Kinda weird. Wonder if its coming from the alternator or the modified wiring path.

|

|

|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: krautrock]

#2713870

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: krautrock]

#2713870

11/07/19 11:44 PM

11/07/19 11:44 PM

|

Joined: Nov 2003

Posts: 36,040

Lincoln Nebraska

RapidRobert

Circle Track

|

Circle Track

Joined: Nov 2003

Posts: 36,040

Lincoln Nebraska

|

from the alt, check the brushes. EDIT (I'm assuming no electromechanical reg)

Last edited by RapidRobert; 11/07/19 11:49 PM.

live every 24 hour block of time like it's your last day on earth

|

|

|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: Mattax]

#2714319

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: Mattax]

#2714319

11/09/19 06:50 PM

11/09/19 06:50 PM

|

Joined: Feb 2010

Posts: 1,645

Phila. Pa.

Mattax

top fuel

|

top fuel

Joined: Feb 2010

Posts: 1,645

Phila. Pa.

|

Nothing to apologize for IMO. I thought they were all Packard 56 - that's what I saw posted on jeep forums, here, Forabodiesonly etc. Someone mentioned there were different types, but only when I was working on my '67's harness did I see that most (all?) of the '67 harness female terminals had the rolled edges for spring tension. Then when I replaced a terminal on the M&H repop engine harness, I found out for myself the Chrysler type (Packard 58 style) didn't stay in the connector housing for the Packard 56.  Then I compared the terminals and fortunately I had saved the original harness. So I was able to use the original plastic terminal cover and all was well. Chrysler also used 'twin locks' (steering column wiring connectors) and others which I don't know the names of. PS. Slightly off topic, but related to the project. Inside the firewall connectors, there is a foam seal on the half with the male terminals. Detroit Muscle Technologies makes those. For the truck might have to contact Jim to see what he has or can make.

|

|

|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: NachoRT74]

#2714500

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: NachoRT74]

#2714500

11/10/19 12:27 PM

11/10/19 12:27 PM

|

Joined: Aug 2007

Posts: 6,095

Valencia, España

NachoRT74

master

|

master

Joined: Aug 2007

Posts: 6,095

Valencia, España

|

Now, I don't get why would you need a dual stud for firewall like these to hook up a switched source into the cab... unless you want a switched source on both sides of firewall I'm still thinking on this... why using this junctions for a keyed source being they really constant ?... maybe you meant using a relay activated by the ign switch but sourced from this junction? Ammeter studs are also junction points if needed. Sure the firewall juntion is easier to reach and harder to beat. Need to say NOTHING OF THIS will work propperly if you don't get the right alternator! The right alternator is what will save the ammeter! and some other parts of the electrical network And, better if you dissasemble the cluster to check the ammeter conditions being tight to the internal shunt. Remember it got 50 year of stress and a badly balanced charging system from factory. If they began to be loosen, they are called to a problem when loads go throught. I fixed a 70 Charger ammeter solding the studs to the shunt with lead just like solding wires. This consistent good contact will save from misscontact causing heat so won't melt the lead when load go through ( if happens ) Some ppl is about more radical electrical welding these studs LOL, even replacing studs. read this ( I don't think being that extreme is really needed LOL) https://www.dodgetalk.com/forums/showthread.php?t=252130last time I read this, images floated on, not I can't see them anymore, dunno if you.

Last edited by NachoRT74; 11/10/19 12:42 PM.

With a Charger born in Chrysler assembly plant in Valencia, Venezuela

|

|

|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: NachoRT74]

#2714553

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: NachoRT74]

#2714553

11/10/19 03:19 PM

11/10/19 03:19 PM

|

Joined: May 2014

Posts: 206

Paducah, KY USA Earth

jcruse64

OP

OP

enthusiast

|

OP

OP

enthusiast

Joined: May 2014

Posts: 206

Paducah, KY USA Earth

|

Nacho, what I had been thinking was to run the blue Accy wire from the ignition harness to a stud or buss (NOT the alternator or battery double sided stud), to allow to power something like a USB plug, on key on/Ign off circumstances. I'd have to take the other side of that stock blue wire in the connector, which goes to the fuse box to power fused accessories, to that stud or boss, so it would have power also, if I interrupt the connection at the ignition harness connector. Just thinking about it, and after a response about this idea on another forum, it would probably be better to go through relays, with power to the relays coming off the new firewall stud for the alternator.

I have the dash all the way apart already. This all started with wanting to clean the dash up and picking up some bulb holders to replace missing ones, and changing to LED bulbs. One thing keeps leading to another here as I find more stuff to do to the wiring and dash. I'm taking contact cleaner and steel wool and cleaning the posts on all the gauges, and the amp gauge is in good shape still. Also gently cleaning the back of the circuit board, first with a pencil eraser, and then with contact cleaner on the head of a Q-tip. Also painting the needles on the gauges.

What do you believe is a good upgrade over the stock alternator? Even though this truck used to have a snow plow and wrecker boom, it did not come from factory with either of those, so it is likely the original 60 or 65 amp alternator.

Joe

|

|

|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: jcruse64]

#2714558

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: jcruse64]

#2714558

11/10/19 03:47 PM

11/10/19 03:47 PM

|

Joined: Aug 2007

Posts: 6,095

Valencia, España

NachoRT74

master

|

master

Joined: Aug 2007

Posts: 6,095

Valencia, España

|

it could be a good idea get an acc or ign1 juntion for some functions depending on your plans for your truck, Dunno on trucks, but E bodies and 71/74 B ( and I think laters Mopars too ) got a buss ( male prong ) for Acc source embosed on fuse box but unfused. Also got a batt buss there, both visible here: ![[Linked Image]](https://www.picclickimg.com/d/l400/pict/152642745808_/Mopar-72-73-74-B-E-Body-Cuda.jpg) Otherwise also got a fused acc source hanging out on the harness on bullet kind terminals. About alternator, if you wanna go for cheap on stock form, no less than 80 amps alt used on mid 80s Mopars ( they use to source 45-50 amps iddling depending on pulley diameter ). They use to go into the $50-70 rate. Other options ( on stock form ) comes from TuffStuff guys. When I get money, I'd go for the 100 amps one, but they are rated on $200-250. Powermaster got a nice stockish option too claimmed to be able to source 65 amps while iddling. Then after that there are several nippondenso alternators what it works like originals, on same stock reg and wiring. about ammeter, since you have the cluster out, please take your time on check internally the ammeter just to be sure studs are tight INTO the ammeter shunt, not just at cluster housing,

Last edited by NachoRT74; 11/10/19 03:55 PM.

With a Charger born in Chrysler assembly plant in Valencia, Venezuela

|

|

|

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: jcruse64]

#2714566

Re: Safely Wiring Accessories/Amp Gauge Re-wire

[Re: jcruse64]

#2714566

11/10/19 04:33 PM

11/10/19 04:33 PM

|

Joined: Feb 2010

Posts: 1,645

Phila. Pa.

Mattax

top fuel

|

top fuel

Joined: Feb 2010

Posts: 1,645

Phila. Pa.

|

Even though this truck used to have a snow plow and wrecker boom, it did not come from factory with either of those, so it is likely the original 60 or 65 amp alternator.

It was probably better that way. Almost always those things are attached to connector at the battery terminal or relay stud. really not much difference in this respect. Here's why it might have been better he did not have a high output alternator. Lets say the alternator can produce a maximum of 210 Watts at idle rpm. With only engine load (field power and ignition) it can hold 14.5 Volts while supplying those needs. Lets say they add up to 5 amps. So 72.5 Watts. If the battery needs charging, there is a maximum of 137 Watts it can still produce at that voltage, providing just under 10 amps to the battery. Assuming that's all the battery wants, the ammeter and all the wires can easily handle 10 amps. Now lets have the engine idling when the tow rig is powered, and it wants 12 amps. Well even if the battery was fully charged, the alternator can't provide that at 14.5 Volts. But it can provide the 12 amps - or close to it, at less than 14.5 Volts. If my math is correct, 12 amps demanded by the motor and 5 amps provided by the engine = 17 amps 210 Watts divided by 17 = 12.4 Volts. Well the battery if fully charged will be around 12.8 Volts, so it takes over. Now the ammeter sees 5 amps discharge. Again the wiring is safe. But lets say John tow truck operator increases the alternator rpms with a different pulley, or had an alternator that could produce more power at idle. If it the alternator can now produce 420 Watts, what happens? From the 5 amps go to the engine and 12 amps go through the ammeter. This acceptable - although arguabley if the alternator can supply that much power at idle, why send it all the way through the cab, the ammeter and to the battery? This is getting to the crux of figuring out the best arrangement for the equipment., Really high draw equipment - like some winches - have to be placed on the battery. They can draw over 100 amps when loaded. With an alternator that produced a lot of power at idle, it might try to send 30 - 40 - 50 amps or more through the cab, main splice, ammeter and fusible link. Or, almost as bad, maybe worse, is an alternator that produces high power but only at speeds above idle. When the vehicle is driving down the road at 25 mph or better, its going to be able to produce close to its maximum. This is when a high output alternator can be a bad thing for a drained battery. The battery might try to suck 30, 40 or more amps from the alternator. On a stock alternator, it will max out and the voltage will drop and so would the battery demand. On the optional 60 amp alternator, the engineers knew this could be a problem, hence the heavier wiring. But still there are limitations in the ammeter and the battery itself. This is the balance to be struck, bith in how things are wired and the selection of alternators. It best for the alternator survival to have an alternator that is not maxed out very much. On the other hand, the maximum it can produce was a limiting factor helping protect the circuits and battery. My understanding is nowadays certain work trucks and motorhomes use a second battery and an 'isolator' for equipment that would otherwise stress the starting battery and alternator circuit.

Last edited by Mattax; 11/10/19 04:34 PM.

|

|

|

|

|