Posted By: 6packattk

Oil System Mods For Big Block Refresher Course Please - 12/04/09 07:29 PM

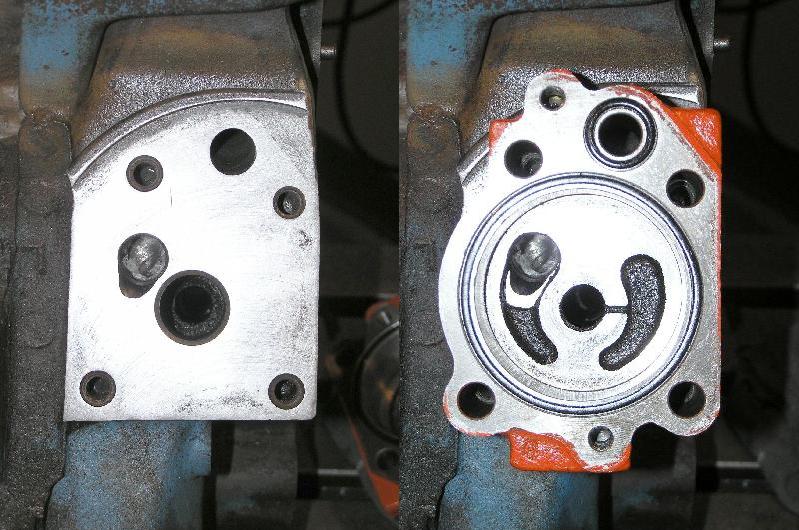

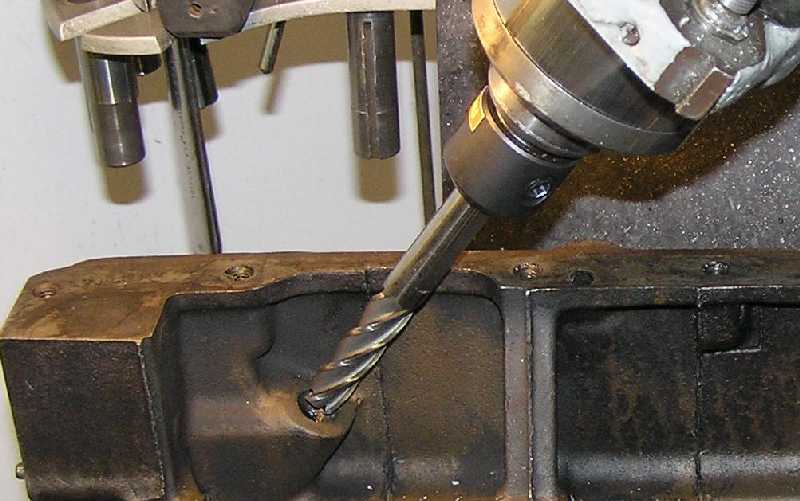

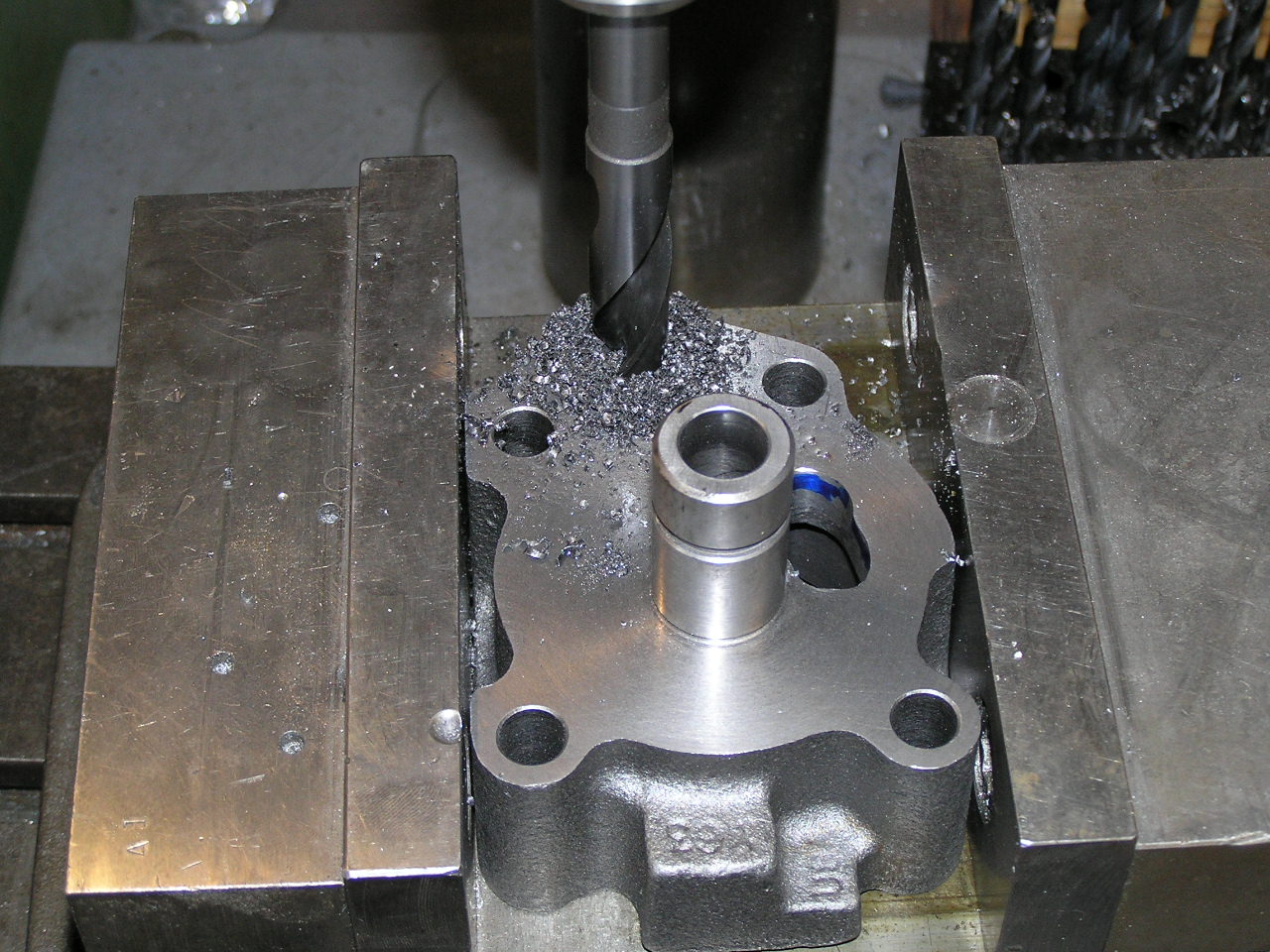

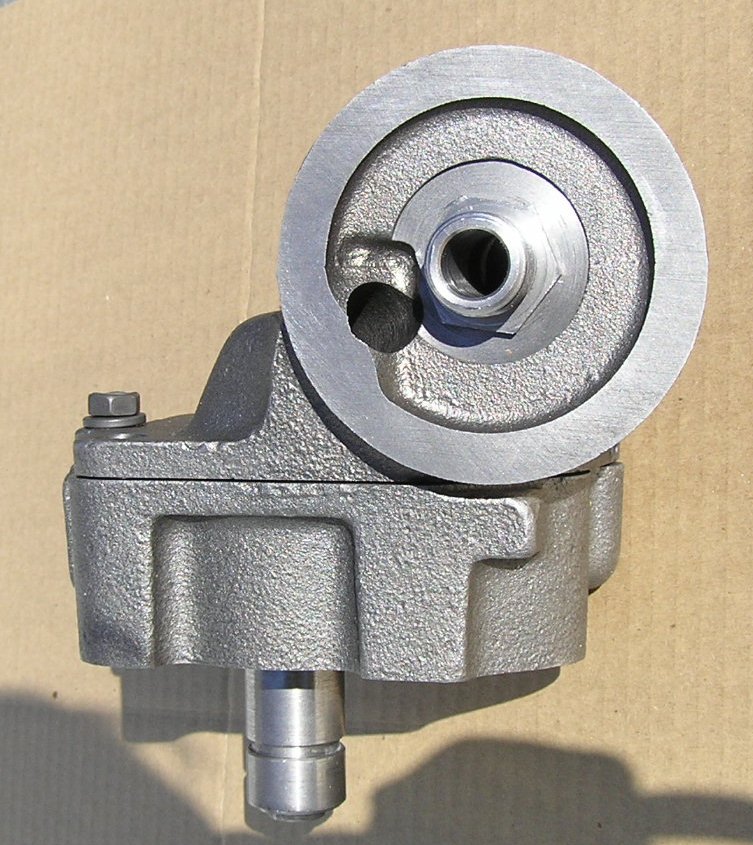

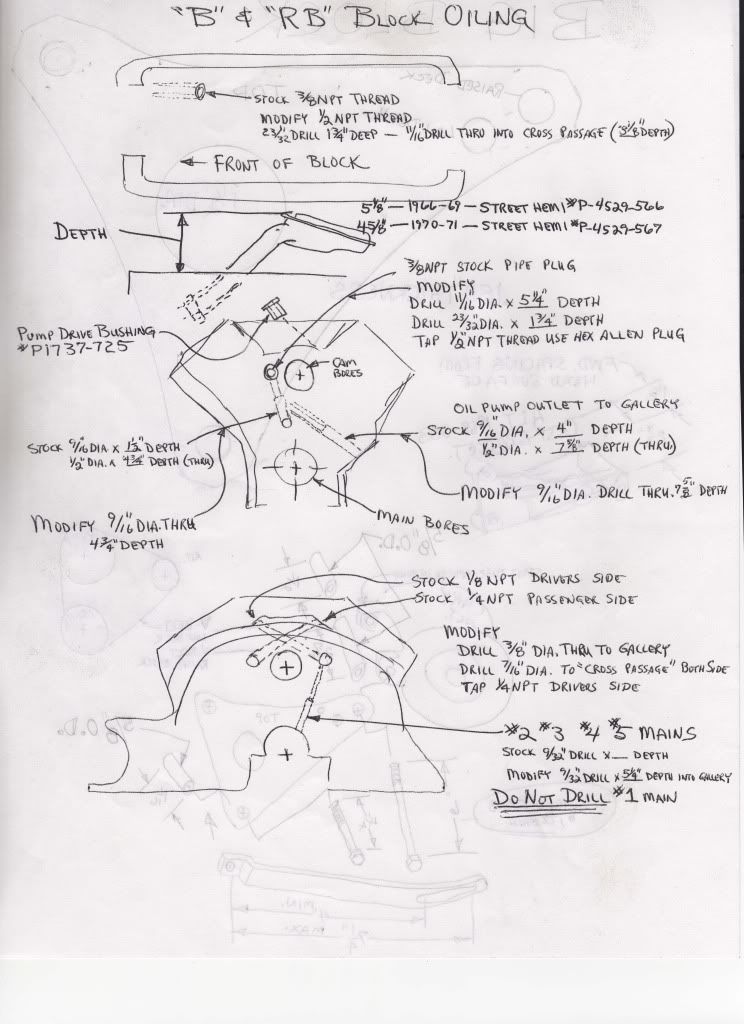

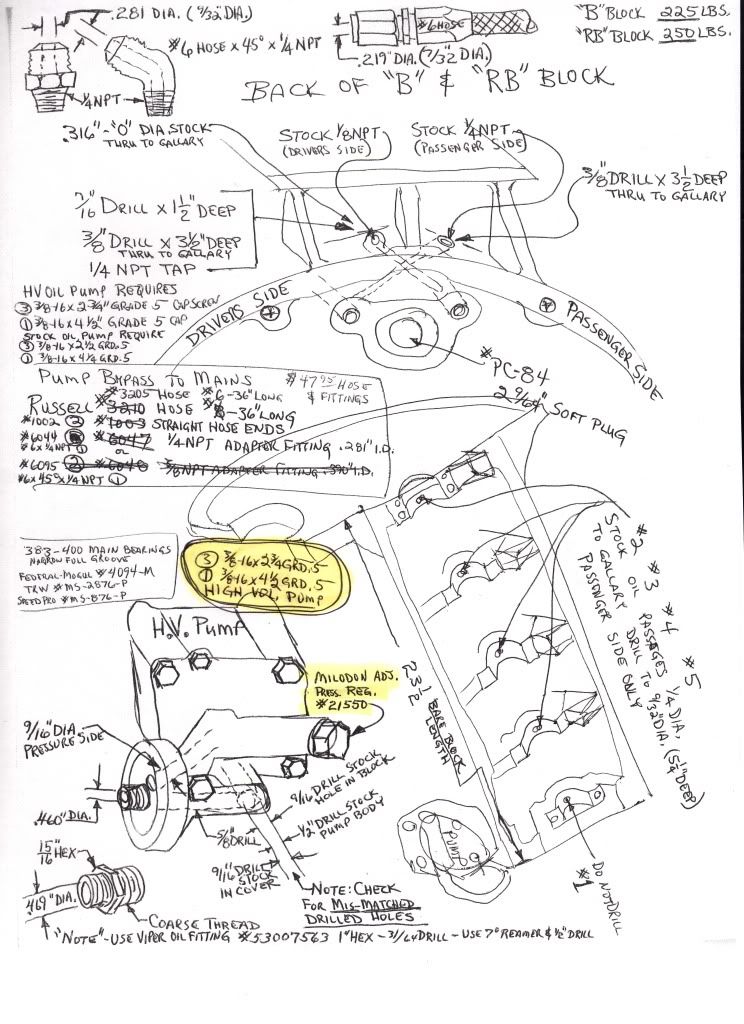

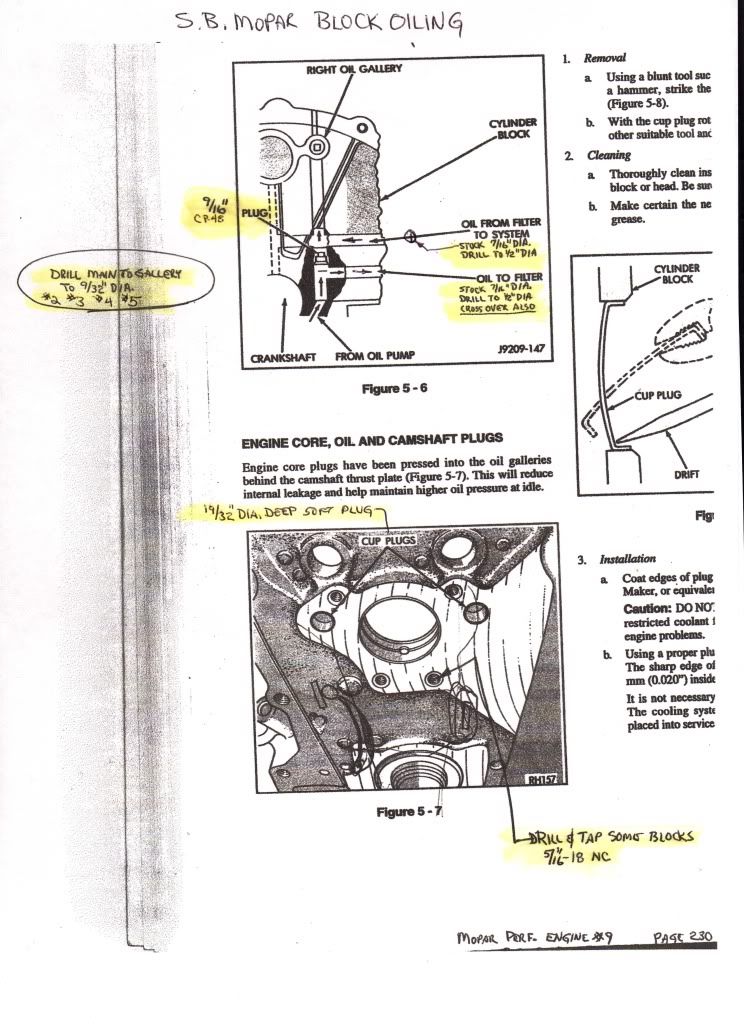

Had seen before somewhere pics of below half inch oil pickup mod from oil pan side and below oil pump mount enlarge and port pics when going to larger pick up on big blocks.Have original block and want to do it right,already have drilled and tapped block for pick up just could never get a good idea of where to modify from there.Would sure appreciate any help in this area and sure don`t want to mess up and wouldn`t mind any other good overall oiling tricks too for my library.  Thanks in advance....

Thanks in advance....

Thanks in advance....

Thanks in advance....

Keep em coming if you got em and edit this and put in tech archives then it doesn`t matter what the persons computer does.Thank you

Keep em coming if you got em and edit this and put in tech archives then it doesn`t matter what the persons computer does.Thank you

and never lost a bearing. ..until recently. But that was because of a mistake I made in bearing choices

and never lost a bearing. ..until recently. But that was because of a mistake I made in bearing choices  .

.