Moparts

flathead 6 removal

Posted By: zrxkawboy

flathead 6 removal - 06/16/15 05:29 AM

Getting ready to pull the 230 from my '57 Plymouth (for a rebuild). First time I've done any major work on one of these engines. Any tips or tricks specific to the flatheads? Thanks!

Posted By: poorboy

Re: flathead 6 removal - 06/17/15 03:39 AM

Only thing I can think of is to be prepared for the weight of those flathead 6s. they are much more heavy then one might expect, think Big block kind of weight!

These motors are pretty simple and very well engineered. I think, just because, I would be covering all the bolts and things you want to turn out with some penetrating oil. Gene

Posted By: Supercuda

Re: flathead 6 removal - 06/17/15 04:33 PM

One must for the old flathead, you must replace the water distribution tube in the block.

Posted By: RodStRace

Re: flathead 6 removal - 06/18/15 01:59 AM

I'd strongly suggest pulling the whole front clip (bumper first, then grille, radiator and bulkhead, fenders, etc. as one chunk). It's a lot easier than it looks, and darn near everything you touch (wiring, bolts, should be given a clean up and look anyway.

I've done this on a couple 40s cars and a mid fifties car.

You WILL need a friend to help get it off, but it sure makes stuff easier to pull.

For flatty info, the P15/D24 site is your best bet.

The Imperial club site may have some useful stuff too.

Posted By: ahy

Re: flathead 6 removal - 06/18/15 02:21 AM

When I pulled the flattie from a Power Wagon I pulled the whole clip like Rod suggested. Easy to do and made it much easier.

If you have a FSM it will probably have step by step... that is what I used plus an engine hoist and homemade lifting bar (4x4 with through bolt eyes basically).

Posted By: zrxkawboy

Re: flathead 6 removal - 06/18/15 05:46 AM

Thanks for the replies! I started on the little things tonight, and I have a dumb question. It looks like the bellhousing surrounds the flywheel (in front). Am I seeing this right? If so, how does this affect engine removal? Please excuse me: I've rebuilt engines before, but they've all been '60s and '70s...the oldest one was my '67 Plymouth.

Posted By: dogdays

Re: flathead 6 removal - 06/18/15 07:06 PM

My '64Dog Poly 318 has the bellhousing that wraps around the flywheel. I believe it's very much like yours, may even be the same. It weighs a ton, felt like 70lb to me. On my truck and I suspect on yours too, the transmission hangs out on the end of the bellhousing and doesn't have its own crossmember. I took the transmission off first and then pulled the engine complete with bellhousing. It's a bit tricky because you have to get the mounts up and over the engine mount insulator bolts, and there are two front, two back.

I instead unbolted the rear mounts from the frame.

Assembly: First I bolted on flywheel, then bellhousing. It's much more difficult to access the flywheel with the bellhousing in place. Then I mounted the transmission. That was a bad move. The transmission will not go over the rear huge crossmember, so I had to pull it all out and disconnect the transmission, which I put on the ground.

This time I got the stuff lined up and dropped the engine in, however I couldn't install the rear mounts because top of bellhousing hit the cab trans tunnel. So I picked the engine up a little and moved it forward, then installed the rear mounts onto the bellhousing. This time it went together well. I tightened all the bolts and then installed the transmission.

I am pretty sure that your bellhousing will bolt up to a 318. Everything should fit on a Poly motor, and on the LA motor there's one bolt hole that's in the wrong place at one of the lower corners. This is the bolt that holds the two together right next to a dowel. Many people just leave it out, but because where it was located I decided to have a bolt there. I marked where the matching hole was, drilled and tapped the bellhousing IIRC.

R.

Posted By: Supercuda

Re: flathead 6 removal - 06/19/15 02:27 AM

It has been so long since I removed a flathead 6 (38 Plymouth) that I forget. But I had the entire front end off that vehicle so room was plentiful.

Posted By: zrxkawboy

Re: flathead 6 removal - 06/19/15 02:28 AM

Thanks for the detailed reply, dogdays...it is very helpful!

Posted By: Supercuda

Re: flathead 6 removal - 06/19/15 02:42 AM

I can bet cash money that a flathead 6 bell will not fit any flavor of 318.

Poly to LA, yeah, flat 6 no.

Posted By: Mike P

Re: flathead 6 removal - 06/19/15 09:50 PM

Just my

pull the hood, bolt an engine leveler to the 6 and pull the engine and tranny as a unit, probably about 2 hours and you don't have a bunch of sheetmetal to worry about finding a place for (or scratch up depending on how good the paint is).

But hey what do I know.

Posted By: poorboy

Re: flathead 6 removal - 06/20/15 03:26 AM

Those inner fenders on that 57 make pulling the front sheet metal off a pita for sure. That and the bumper brackets go through the front sheet metal. Without the inner fenders and the front bumpers, its like 5 bolts and the clip lifts off, with the inner fenders and the bumper, its probably 30 bolts (1/2 of which are end wrench off & tend to break). Mopar was pretty serious about that front sheet metal not falling off.

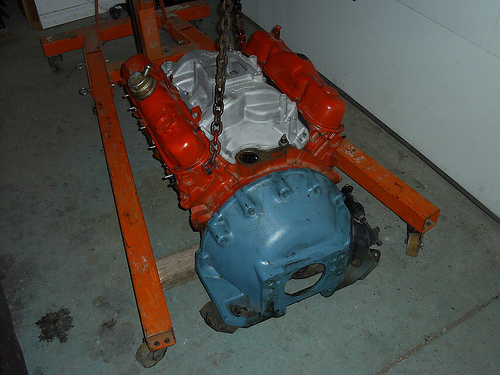

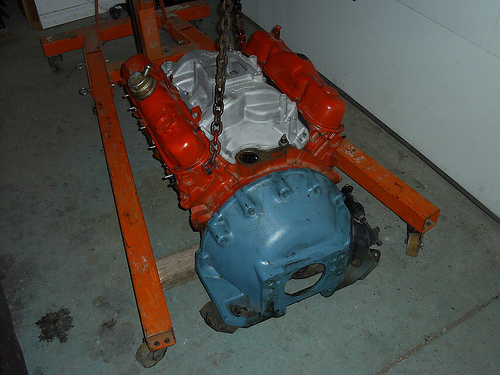

Pictures, notice how much stuff is removed from the sheet metal clip?

Gene

Posted By: Mike P

Re: flathead 6 removal - 06/20/15 04:53 AM

I should have mentioned it in my previous post, but better late than never. The best money you can spend at this point is to purchase a factory shop manual, which should answer most of your questions. There on E bag in both CD and paper form.

Dogdays did a nice writeup on his 64 truck but unfortunately his is a completely different setup than the Plymouth (which among other things does in fact have a transmission cross member). I could do a writeup on what needs to be done, but it would be from memory and rather lengthy and you will find all the info in the service manual.

Posted By: RodStRace

Re: flathead 6 removal - 06/20/15 05:33 AM

Well, Poorboy and Mike P have been there and done it, so I defer to their 1st hand experience.

The 54 (55?) I did wasn't as serious on the inner fenders!

Posted By: rowin4

Re: flathead 6 removal - 06/21/15 12:17 AM

Mark your wires as to where they connect, there's not that many but it always helps, take pictures if you can, bag the bolts/nuts and label , motor mounts, bell housing, manifold etc. It might seem a little much to do but if your not putting it back together tomorrow you'll appreciate the extra effort knowing where things went.

Posted By: zrxkawboy

Re: flathead 6 removal - 06/22/15 12:35 AM

Much thanks for all the input! BTW, I do have a FSM, but I don't see any instructions for engine removal. Maybe I need to dig deeper.

Posted By: poorboy

Re: flathead 6 removal - 06/22/15 06:53 PM

Most of the factory service manuals from the 40s & 50s make the assumption the mechanic is capable of pulling a motor out of the car without instructions. Times were much more simple then, and the process had not changed much. It is not like cars of today where specific processes need to be followed or you can't get it out.

Unfortunately, if you have only pulled motors out of new stuff, the way they did things back then are a bit strange.

My son's 57 Dodge wagon had a V8 with an auto. Because someone had already removed the front inner fenders before we got the car, we are not sure what was done, but we are in the process of re-installing those inner fenders, and there are a lot of bolts. The inner fenders are bolted to the fenders, to the radiator support, the firewall and have a coupler brackets attached to the frame!

We did remove the front bumper (Dodge is different then a Plymouth, at least, in appearance) and there were 8 bolts (on each side) attaching the bumper to the frame. At least 4 of those bolts (on each side) are only accessible with end wrenches and the proper combination of sockets & extensions. Fortunately, our car is a CA edition and the bolts actually un-wrenched. We have a MO parts car here, I suspect a guy would have to cut those bolts off, and that would not be fun (and this is at a welding shop). I can't imagine what a northern IL car would look like! Stuff would probably need to be cut to make clearance to cut the bolts. If you need to remove that front bumper, start loading the bolts with penetrating oil now. Once the bumper is removed, there are 2 bolts that hold the fender to the top of the firewall, two bolts at the bottom of the fenders to the cowl, and one large bolt in the center and the front sheet metal lifts off.

The V8 car has some strange motor mounts. We ended up unbolting them from the motor and from the frame, as we lifted the motor, we took them out of the way.

There are several bolts (6 per side, I think) that hold the transmission crossmember onto the frame. and 3 (I believe) that attach the transmission mount to the crossmember.

There are 2 wires to the starter (remove the starter because it will be in the way to pull the motor/trans).

The throttle linkage is mechanical and you will want to pull the rod between the carb (or the manifold pivot bracket) & the pivot bracket on the firewall off.

The heater core (on the Dodge anyway) extends 6" or more out into the engine compartment above the back of the motor. It is attached with several screws (10 or 12) around the outside edge, plus the heater hoses, plus the blower vent tube. That heater core removal will free up a lot of space above the motor.

There is a ground wire attached to the back of the motor that attaches to the firewall and wires for the coil & generator that need to be removed. The oil pressure is mechanical and has a tube attaching it to the gauge, and the temp gauge is also mechanical and has a fitting that needs to be disconnected. Of course you will want to remove the rad & rad hoses. There is a heater hose from the back of the motor to a heat control valve on the firewall that will need to be disconnected. Disconnect the exhaust pipe at the manifold and if there is a bracket on the side near the trans, it will need to be disconnected too. Don't forget to remove the driveshaft, transmission linkage, e brake linkage, and speedometer connection. I've probably missed something.

Since the front sheet metal was pulled off our car, we only had to lift the motor a few inches, and we did not have to remove the trans crossmember.

You will need to remove the crossmember,(a floor jack will be helpful) and your motor & trans will be standing almost straight up and down as it comes up to come out. You will have to tilt the motor enough for the bottom belt pulley to clear the radiator support while the trans will still be in the trans tunnel, then pull the motor/trans forward and raise until the trans clears the tunnel. Then everything needs to move forward and be lifted up until the motor/trans clear the radiator support and clears the front end of the car. Slow movement, watchful eyes looking for things hanging up, and a pry bar are useful things to have then. Be careful not you use your hands to "protect" hard car parts, those parts are tougher then your hands, and easier to replace. Once clear, you may be able to turn the motor/trans sideways to clear the car in a little shorter distance. There is also the possibility, that instead of moving the motor & trans while its hanging on the engine hoist, the car may be carefully (and slowly) pulled rearward.

I am sure I missed something in the process, but this should be close. Personal safety needs to be a high priority. Even though I pulled hundreds of motors, impulse still wants me to put a personal body part between two metal objects to protect something. You need to keep yourself aware of where your putting your hands & arms, as well as where helpers may be putting their hands and arms. In my shop the rules are: If it starts to go bad, get out of the way and watch it crash! We can fix whatever metal stuff gets damaged.

Good luck,

Gene

Posted By: Mike P

Re: flathead 6 removal - 06/22/15 10:03 PM

I did a quick look at my manual and it doesn't give detailed instructions for engine removal and installation I stand corrected and Poorboy and zrxkawboy are right.

".....Most of the factory service manuals from the 40s & 50s make the assumption the mechanic is capable of pulling a motor out of the car without instructions....."

Another part of the explanation is that back when these cars were new when it came time to freshen the engine it was most often done with an "in car" overhaul. Basically the engine striped and the block and crankshaft were left in place. Valves were often just lapped and if they needed ground in the case of the flatheads, the valve grinder was a simple (and portable) hand grinder. There was even an "in car" crankshaft grinder if the crank needed redone.

The Plymouth bumper is not quite as complicated as the Dodge bumper (which for all intents and purposes are really 3 bumpers), but on the Plymouth there are brackets and bumper bolts on the very ends that are a real pain).

As far as the motor and transmission mounts the 6 cyl ones are a bit simpler than the V8 can mounts and can be left bolted to the engine and transmission respectively. The emergency brake cable and shift cable (if it's an automatic) will also need to be disconnected (that is covered in the shop manual). I would also recommend removing the engine fan for a couple more inches of clearance.

Personally I like the method of removing the engine that Gene describes which is as the engine is lifted moving the car back out under the engine rather than trying to move the cherry picker back (which usually sets the engine swinging). The engine leveler allows the steep angle needed to initially clear the radiator support and as the engine comes out it can be brought level again once the transmission clears the tunnel.

Finally one thing you may or may not be aware of ……whether you have a stick or an automatic you will find that the flywheel/torque convertor is NOT held on with crankshaft bolts. They both use studs pressed into the flywheel/convertor that pass thru holes in the crankshaft flange and are retained with nuts on the engine side of the crank flange. In the case of the automatic this can be a real PIA to line up and get started when you leave the transmission in the car and are installing just the engine.

Posted By: moparx

Re: flathead 6 removal - 06/23/15 01:49 AM

and just for the record, those that haven't done several[or more] of these jobs WILL learn "NEW" words and phrases.

as stated above, be very careful to not hurt your self. years from now it might be a funny story to tell how your 2 fingers "disappeared", but it ain't gonna be so funny when it happens ![my one buddy knows from experience !]

Posted By: zrxkawboy

Re: flathead 6 removal - 06/23/15 05:36 AM

I appreciate all the helpful advice! I have one question: a guy on another forum (who also owns a 57 Plymouth) suggested unbolting the bellhousing from the trans, leaving the trans itself in place. I suppose this would require less "tilting" when pulling the engine. What do you guys think?

Posted By: Mike P

Re: flathead 6 removal - 06/23/15 02:07 PM

First, are we talking about a manual or automatic transmission?

Posted By: zrxkawboy

Re: flathead 6 removal - 06/23/15 02:31 PM

manual

Posted By: Supercuda

Re: flathead 6 removal - 06/23/15 04:08 PM

I've done it both ways, though not on a flat head, and have found that, at least in reassembly, it is much easier to treat the engine and trans as a complete unit. It is so much easier to mate the two outside the confines of the car than inside it's envelope.

Posted By: Mike P

Re: flathead 6 removal - 06/23/15 04:23 PM

While I would still pull engine and trans as a unit, the other alternative would be pull the drive shaft, undue the shift linkage and emergency brake, support the transmission and drop the rear cross member, undo the 4 bolts holding the transmission to the bellhousing and remove the transmission. The rear of the engine will also need to be supported as the transmission is pulled to prevent the engine tilting back and breaking the motor mounts.

As supercuda says, "... it is much easier to treat the engine and trans as a complete unit. It is so much easier to mate the two outside the confines of the car than inside it's envelope...."

Posted By: dogdays

Re: flathead 6 removal - 06/24/15 09:52 PM

This quote from qualityengineeredcomponents.com:

"Circa 1959, a bellhousing was used, mostly on the Dodge 230, that was the correct depth and had an useable mounting face for the NP230 and the A-833. The mounting depth is critical in the application due to the length of the input shafts. This bellhousing can be identified by the fact that it also has the v-8 block bolt pattern. Depending on the transmission selected there will very likely be a need to make modifications to the bearing retainer register interface as well as providing proper transmission mounting bolt hole locations.

It is also referenced on vintagepowerwagons.com.

R.

Posted By: poorboy

Re: flathead 6 removal - 06/25/15 04:41 AM

Dodge has made some strange specialty parts through the years. in the mid 60s, that made a slant 6 727 (and a matching manual trans bell) that also had a LA small block bolt pattern. Both were for heavy duty truck applications with the slant 6 and quite rare.

I suspect the mentioned bell for the flathead 6/ V8 is a pretty rare critter as well.

Rare in Mopar speak usually represents many $$$$$$$.

Gene

Posted By: dogdays

Re: flathead 6 removal - 06/25/15 08:08 PM

Well it isn't rare, they were on Dodge smallblock pickups through 1968. While looking this up I came across another bellhousing from a car, not the same casting as mine but you can see it here:

http://www.ebay.com/itm/57-DODGE-CORONET...38c&vxp=mtr Look at the lower attached picture for the flathead 6 mounting pattern. It shares the top bolt hole with the A/LA bellhousing.

Here is an excerpt from Sweptline.com:

"all truck small block bell housings are the

same castiron bell mounted to the crossmember

from at least 62 to 68 (used behind all truck

small blocks, slant six and the old flat head

six- across the line from the flat fender Powerwagons

D and W 100 200 pickups and Townwagons/panels). This truck bell was used in front

of all the manual truck transmissions offered

in those years (3speeds and 4 speeds

as well as some 5speeds).

I assume this bell is stock since it has a

np420 mounted to it (a 420 will not mount

to any car bells in those years). And from

what I can tell from my 66 parts book- and background- nothing

changes for the truck bell in those years."

The 340 pictured has the same bellhousing as was in my '64 and it has the wraparound BH which has the flathead 6 mounting holes in the front flange, ahead of the flywheel.