Posted By: Hot 340

Made some stuff at work today - 11/26/11 12:12 AM

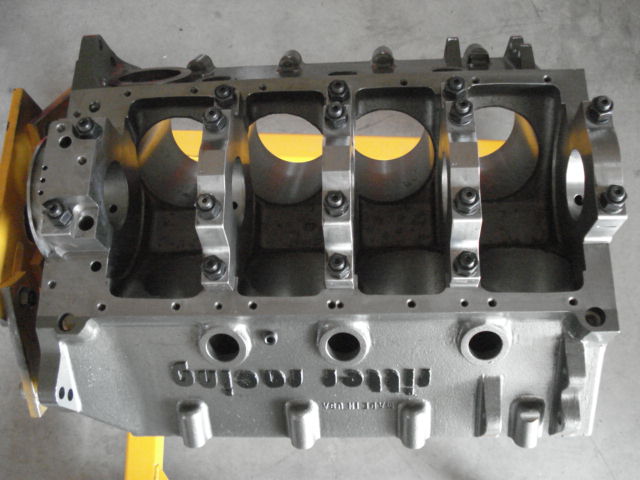

Had the day off but I went in and did some "government" work on my R3 build.

spacers to adapt a 420 to a tall deck

spacers to adapt a 420 to a tall deck

Quote:You suggested that to me in an older post, thats why it's there.

Looks good... I added the bolt by the dist on mine also

Quote:Quote:You suggested that to me in an older post, thats why it's there.

Looks good... I added the bolt by the dist on mine also

Hitman, I was on the fence about using phenolic, probably should have used it, but didnt. Not sure about nylon, I would make sure it could stand the temps. Worst part about phenolic is working with it, yuck.

Hitman, I was on the fence about using phenolic, probably should have used it, but didnt. Not sure about nylon, I would make sure it could stand the temps. Worst part about phenolic is working with it, yuck.

Quote:

Thanks for the compliments guys.. its always fun to make racecar parts.Hitman, I was on the fence about using phenolic, probably should have used it, but didnt. Not sure about nylon, I would make sure it could stand the temps. Worst part about phenolic is working with it, yuck.

Quote:

Beautiful work. I take it you have access to more than just a hacksaw, cutoff wheel and a die grinder.

Quote:

I saw the nylon used at the Engine Masters build off.I thought about it and it just made sense to me.It seals well,It stops the transfer of heat and is easy to work with.The guy who did it said if you do it in a mill sandwich it between plywood.Or better yet use a water-jet.Just something I want to try.As for the valley tray Im going to do another 3/8 MR-10 Lexon piece.That I have used before.It holds up and allows to to see whats going on in there.And can save you from pulling things down just to take a look.

Quote:

3

Quote:

Beautiful work. I take it you have access to more than just a hacksaw, cutoff wheel and a die grinder.

Quote:

3

Quote:Quote:

3

whats a 6M

Quote:Thanks.Quote:

Beautiful work. I take it you have access to more than just a hacksaw, cutoff wheel and a die grinder.

Really nice work...prettier and more useful than jewelry.

And GJ, We even have a hammer and chisel laying around somewhere.

And GJ, We even have a hammer and chisel laying around somewhere.

Quote:Its awesome stuff, hard as nails, probably the best temp insulator out there, but I have to jump in the shower the minute I get home from working with it. It makes you so itchy. Even if you use coolant, somehow it finds youQuote:

Thanks for the compliments guys.. its always fun to make racecar parts.Hitman, I was on the fence about using phenolic, probably should have used it, but didnt. Not sure about nylon, I would make sure it could stand the temps. Worst part about phenolic is working with it, yuck.

Yeah that phenolic makes some bad dust

.

.

nice work Terry. that sure would look nice in my car lol!

nice work Terry. that sure would look nice in my car lol!

Quote:

... In fact I am on another forum marketing a line of .125" plastic gaskets (the last pair of intake gaskets you'll ever need). J.Rob

Quote:Quote:Thanks.Quote:

Beautiful work. I take it you have access to more than just a hacksaw, cutoff wheel and a die grinder.

Really nice work...prettier and more useful than jewelry.

And GJ, We even have a hammer and chisel laying around somewhere.

Quote:Quote:

... In fact I am on another forum marketing a line of .125" plastic gaskets (the last pair of intake gaskets you'll ever need). J.Rob

A non-Mopar forum, I assume?

Plan to do anything along those lines for BB Mopars?

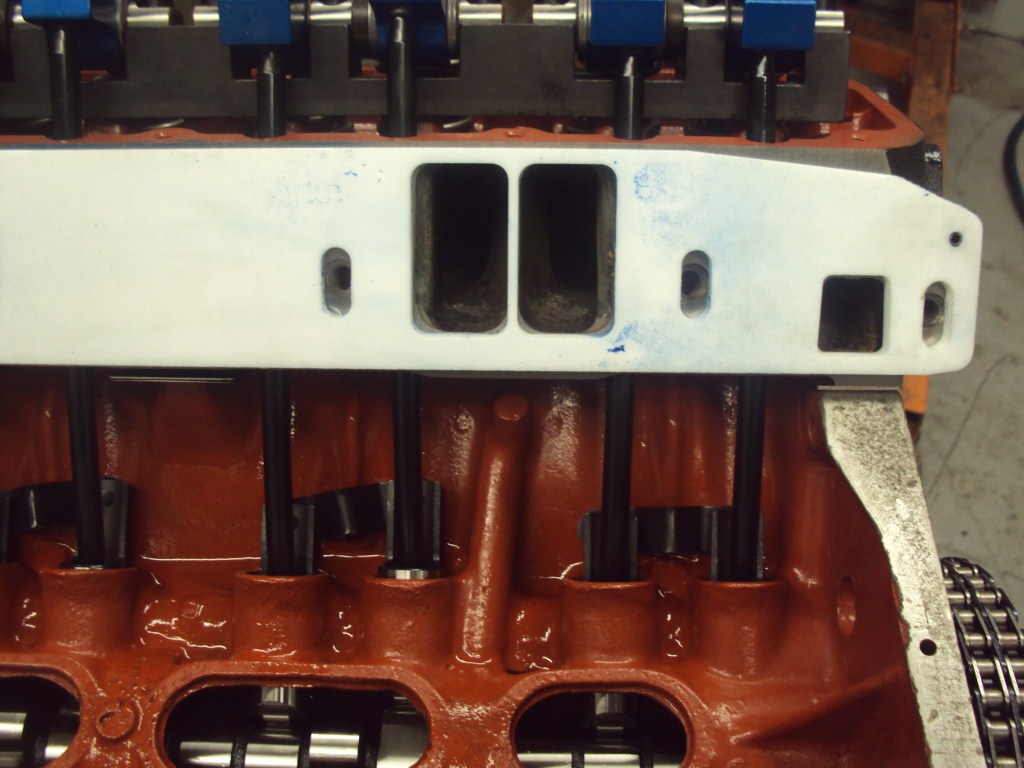

Quote:regular 1/2" 6061. Hit it with some alcohol and scotch-brite.

How did you get that finish on the valley plate? Did the stock come like that or did you hit it with some sort of abrasive roll/belt sander? If it came like that, what kind of aluminum stock is that?

Quote:Quote:

3

Beautiful work. When I worked in the toolroom at a diecasting plant several years ago, that's what we called it too! Government jobs, usually on a night shift. J.Rob

Quote:Quote:regular 1/2" 6061. Hit it with some alcohol and scotch-brite.

How did you get that finish on the valley plate? Did the stock come like that or did you hit it with some sort of abrasive roll/belt sander? If it came like that, what kind of aluminum stock is that?

Quote:Didnt consider making it a two piece or anything. Im lazy.Quote:Quote:regular 1/2" 6061. Hit it with some alcohol and scotch-brite.

How did you get that finish on the valley plate? Did the stock come like that or did you hit it with some sort of abrasive roll/belt sander? If it came like that, what kind of aluminum stock is that?

Nice work, but did you consider making it a 2 piece? Or make it with a removable panel to be able to work in the lifter valley without pulling a head.

Quote:

Nice work, but did you consider making it a 2 piece? Or make it with a removable panel to be able to work in the lifter valley without pulling a head.

Quote:Yep, it slides out with the heads on it. I think it will clear the front of the car..Quote:

Nice work, but did you consider making it a 2 piece? Or make it with a removable panel to be able to work in the lifter valley without pulling a head.

If you cut it right. You pull the bolts slide if forward and it will come right up. This is only on tall decks. On short decks the plate sits over the heads.

Leon