Posted By: mickm

cam bearings too tight - 09/28/11 12:50 AM

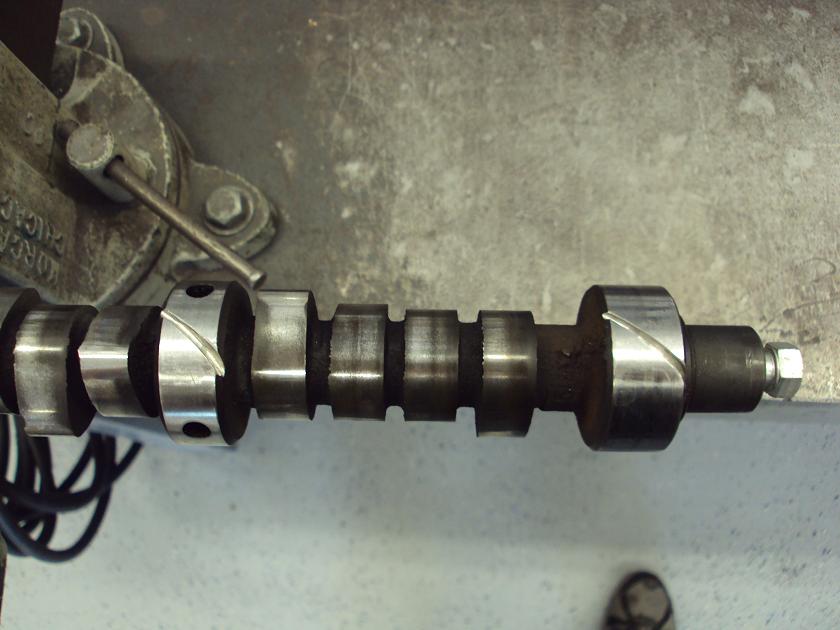

got the block back from the machine shop, and the cam wouldn't go in. took it back, and we started playing with it. out of the block, bearings fit nicely on the cam. in the block, 3 out of the 5 were too tight. we did a lot of playing around, but finally i had to leave.

this is a mopar hemi (not world) mega block.

in the end, he found that all the holes were .0005 to .001 too small, and so were crushing the bearings when they were inserted in the block.

i brought him an old cam, and he grooved the journals on the lathe, and then inserted the cam and made 1 turn and removed it. buffed the bearings with scotchbrite, and now the cam fits like a dream!

how common is this on these blocks? i've heard of issues with these before, but all of the holes to be too small?

also the hole to the driver side head from the #4 bearing did not match perfectly, so i had him enlarge the hole in the bearing so it is completely open.

anything else i should be aware of here??

this is a mopar hemi (not world) mega block.

in the end, he found that all the holes were .0005 to .001 too small, and so were crushing the bearings when they were inserted in the block.

i brought him an old cam, and he grooved the journals on the lathe, and then inserted the cam and made 1 turn and removed it. buffed the bearings with scotchbrite, and now the cam fits like a dream!

how common is this on these blocks? i've heard of issues with these before, but all of the holes to be too small?

also the hole to the driver side head from the #4 bearing did not match perfectly, so i had him enlarge the hole in the bearing so it is completely open.

anything else i should be aware of here??