Posted By: Chargerfan68

building back half car - 01/13/11 06:54 AM

A few more questions please...

When building a back half car with 4-link setup, in what order do the following steps/items happen in? What needs to be figured out first that would determine specific items ordered?

Certain things known:

1) Wheelbase established.

2) Tire size known (rim backspacing undetermined)

3) frame rail spacing established (26")

4) Tub size established (40")

I do not know the following yet (and need to determine the order which to figure them out)

1) ride height

2) Rear end housing width

3) backspacing of 15 X 15 rims

4) tub install height (based on ride height)

For mock up purposes for the build, do I just need the tire/rim to establish rear end width and tub location?

I know it is a lot of questions, but you guys have the knowledge.

Thanks,

Greg.

When building a back half car with 4-link setup, in what order do the following steps/items happen in? What needs to be figured out first that would determine specific items ordered?

Certain things known:

1) Wheelbase established.

2) Tire size known (rim backspacing undetermined)

3) frame rail spacing established (26")

4) Tub size established (40")

I do not know the following yet (and need to determine the order which to figure them out)

1) ride height

2) Rear end housing width

3) backspacing of 15 X 15 rims

4) tub install height (based on ride height)

For mock up purposes for the build, do I just need the tire/rim to establish rear end width and tub location?

I know it is a lot of questions, but you guys have the knowledge.

Thanks,

Greg.

What are you going to use for a car to attach everything to??

What are you going to use for a car to attach everything to??  Just kidding. I am not trying to offend you,,,I just think that I would be sort of 'intimidated' by the project every time I went into the garage. I have gotten into some big jobs like this in the past, but, don't think I will live long enough to do one like this now. Good luck and keep us posted with pics.

Just kidding. I am not trying to offend you,,,I just think that I would be sort of 'intimidated' by the project every time I went into the garage. I have gotten into some big jobs like this in the past, but, don't think I will live long enough to do one like this now. Good luck and keep us posted with pics.  and as for those pictures, My vision of a back half is completely different. Good luck with your project

and as for those pictures, My vision of a back half is completely different. Good luck with your project

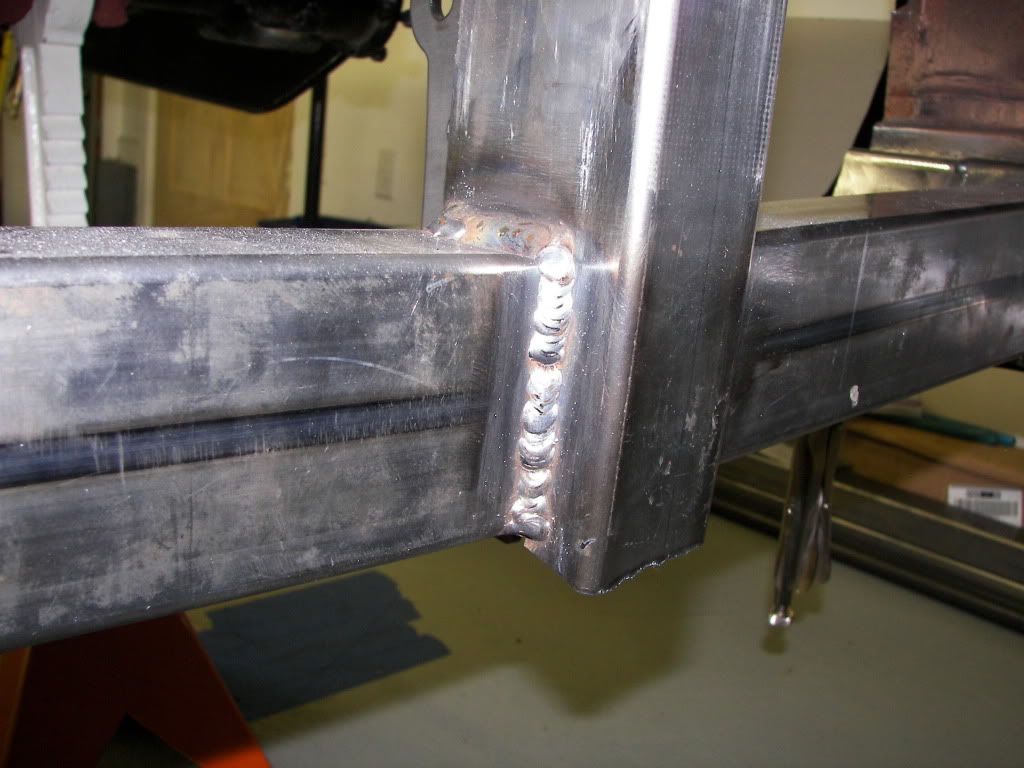

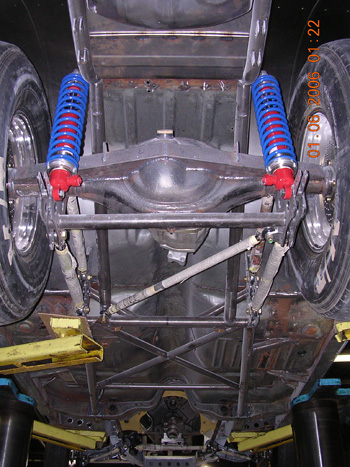

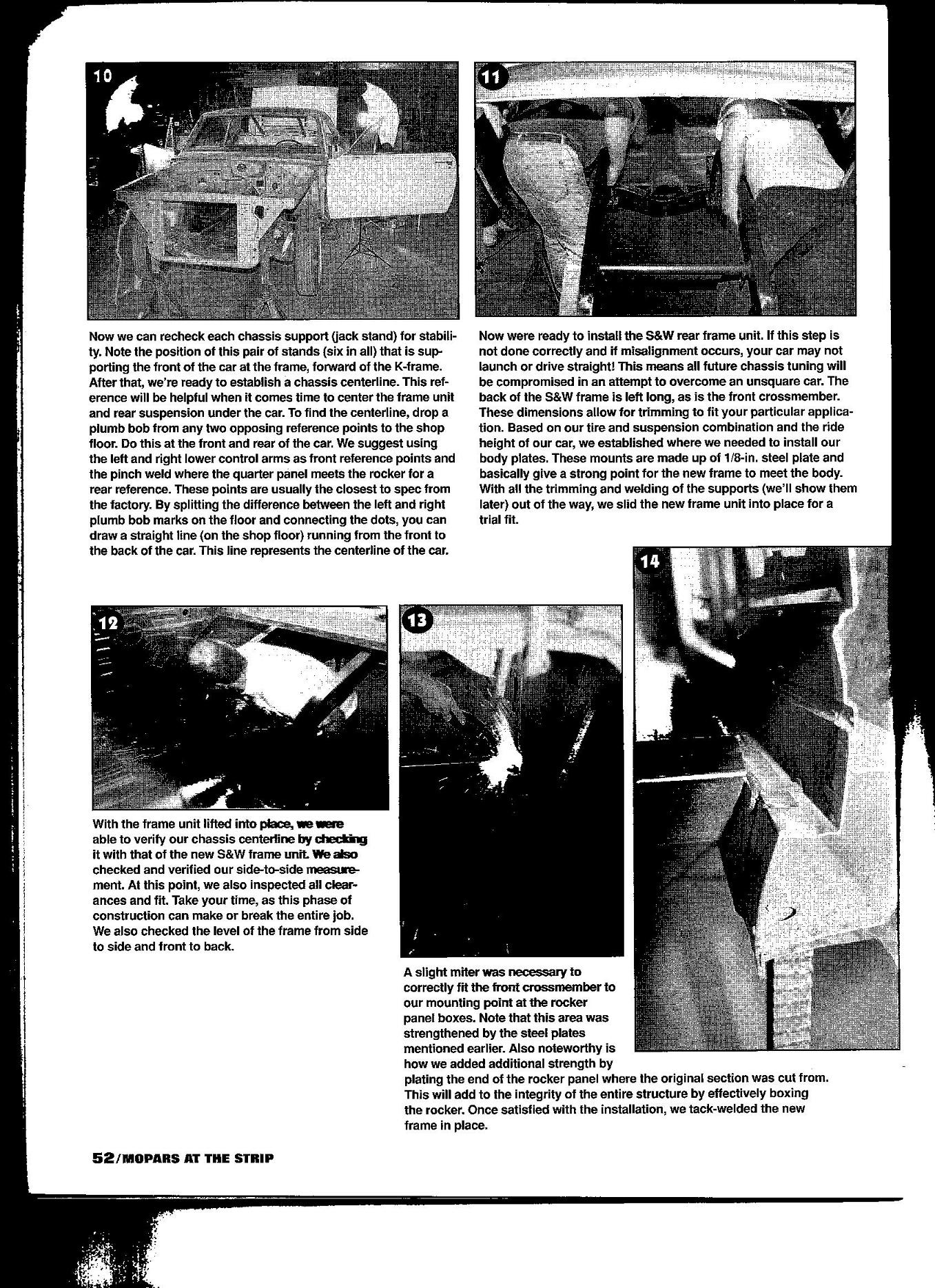

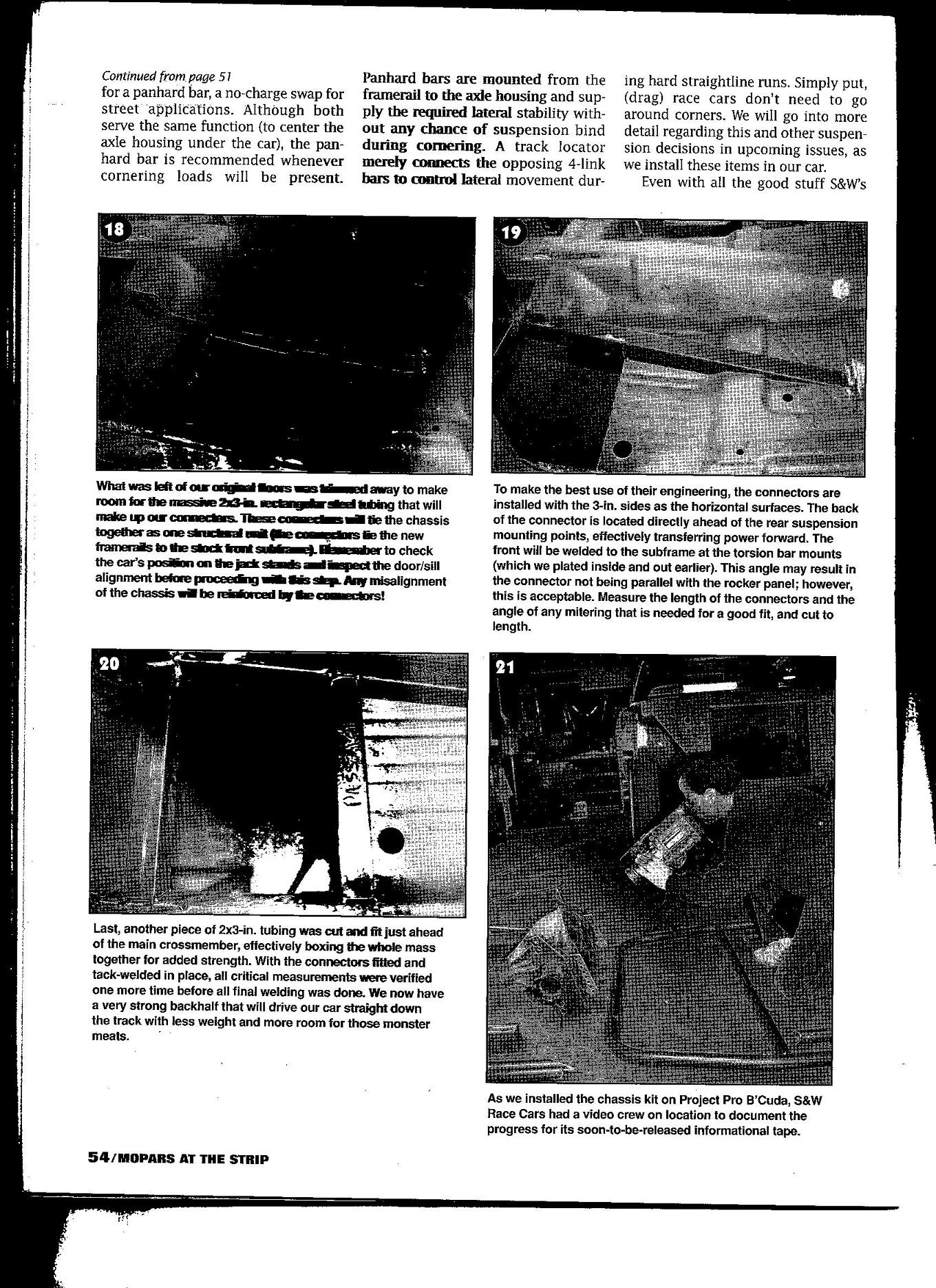

When I back halfed mine, I welded short 2x3 tubing to the remaining spring frame location and inside rocker area , then welded the rear frame rails to that. My frame connectors are welded into my original frame ,a short piece , which remained, my ladder bar crossmember is welded to my frame connectors which comes straight back from the front frame.

When I back halfed mine, I welded short 2x3 tubing to the remaining spring frame location and inside rocker area , then welded the rear frame rails to that. My frame connectors are welded into my original frame ,a short piece , which remained, my ladder bar crossmember is welded to my frame connectors which comes straight back from the front frame.

Are you c/m cage?

Are you c/m cage?