Posted By: 65dragnet

rockers - 11/01/10 10:46 PM

Are stock max wedge rockers worth anything ? Do they make good race rockers ?

Quote:I've check a lot of ductile iron rockers and none of them where anywhere close to perfect

Thanks Crizila ! I normally run Crane ductile iron and the stock max wedge actually look stronger. I have a perfect set of them and I'm contemplating trying them on my 499 lowdeck.

The ratio where all over the plce, some sets varied .130 from the lowest lift to the highest lift when checking at the retainers

The ratio where all over the plce, some sets varied .130 from the lowest lift to the highest lift when checking at the retainers  I have sent several sets(Crane, Ersin, stock OEM BB and SB as well as 426 Hemi and Iskys to Rocker Arm Specilaties in Cottowood,CA PH #530-378-1075 to have the rockers bushed, blueprinted and have the ratio corrected

I have sent several sets(Crane, Ersin, stock OEM BB and SB as well as 426 Hemi and Iskys to Rocker Arm Specilaties in Cottowood,CA PH #530-378-1075 to have the rockers bushed, blueprinted and have the ratio corrected  Many other racers looking to make all of there parts perffect(as you can make them) for blueprinting use them also

Many other racers looking to make all of there parts perffect(as you can make them) for blueprinting use them also

The bushings alone will make them last forever and never gall again

The bushings alone will make them last forever and never gall again

Quote:I sure don't claim to be an expert when it comes to rocker are geometry. Fortunately, for me, I happen to know someone who is. It's a very complicated topic, with much more going on than just the ratio change due to the travel arc of the rocker arm. For instance," the effective rocker arm ratio is related to the travel of the contact point accross the tip of the valve stem. The large raduis of the tip of a pallet tip style rocker arm or the larger diameter of the roller on a roller tip rocker arm, the greater the travel of the contact point accross the tip of the valve stem - - - and therefore the greater the change in the effective rocker arm ratio as the valve goes through an opening and closing cycle. Since, in general, pallet tip style rocker arms have a larger tip radii than roller tip style rocker arms ( as reflected in the diameter of the roller on the tip of the roller rocker arm), pallet tip style rocker arms undergo a larger change in effective rocker arm ratio than roller tip rockers ( through a valve opening and closing cycle )." A typical 1.5 stock chevy pallet style rocker ( which seems to be the one abused most by those selling roller rockers ) can check ( if ploted )anywhere from 1.4 to 1.7 ratio through it's travel arc. Another area that can effect ratio is the rocker arm fulcrum point as it relates to valve stem height. Most advocate they should be the same height. Wrong! Due to the change in dynamics ( rpm and cyl pressure - which is usually never measured or taken in to consideration ), there is no perfect relationship between the rocker fulcrum and the valve stem height, but - one that is better than the accepted "same height "is to place the rocker arm fulcrum 1/3 of the maximum valve lift below the tip of the valve stem. I told you this crap was complicatedQuote:I've check a lot of ductile iron rockers and none of them where anywhere close to perfect

Thanks Crizila ! I normally run Crane ductile iron and the stock max wedge actually look stronger. I have a perfect set of them and I'm contemplating trying them on my 499 lowdeck.

The ratio where all over the plce, some sets varied .130 from the lowest lift to the ighest lift when checking at the retainers

I have sent several sets(Craen, ersoin, stock Mopars and Iskys to Rocker Arm Specilaties in Cottowood,CA PH #530-378-1075 to have the rockers bushed, blueprinted and have the ratio corrected

Many other racers looking to make all of there parts perffect(as you can make them) for blueprinting use them also

The bushings alone will make them last forever and never gall again

. I'm just touching on a few points here. I still use the 50/50 or half lift method ( per Lunati, Comp, and many others ) cause it's easier to do and seems to be good enough in most instances. Sorry for the rambling.

. I'm just touching on a few points here. I still use the 50/50 or half lift method ( per Lunati, Comp, and many others ) cause it's easier to do and seems to be good enough in most instances. Sorry for the rambling.

Quote:Mr. Pbody actually the cam is a 258/265 dur.@.050 with .587 lift @ 1.5

I would ask what lift cam... but for anything under

about .550 or so then yes use them

Quote:Yes, plunger depth can make a big difference in ratio - and for those that think the roller tip on a roller rocker actually rolls - well, at low rpm's they do. At high rpm's they "skid" cause they can't change direction fast enough.

There is also a lot variance once the rocker is bolted down. If it a perfect 1.5 rocker on a test shaft it may not be a 1.5 when installed. The push rod angle and the plunger depth in the lifter all add up to surprising variances in rocker ratios. we have shimmed the plunger to our installed depth and then take rockers and physically matched them to get a matched set of the max ratio. It took 3 sets of a name brand to do it and the rest went back as an unused return.

..i would be interested in them.

..i would be interested in them.

Quote:1. Magazine tech "experts" are - limited - and usually in bed with the equipment manufacturer - for obvious reasons. I can't remember the last time a mag did an article on a "something" where it turned out to be a total turd. Big mistake to believe everything you read in a magazine.

Here is an excerpt from an article in a Mopar mag.:

Quote:This from our own Dulcich (sp). Besides it was backing up a lot of what you were saying.Quote:1. Magazine tech "experts" are - limited - and usually in bed with the equipment manufacturer - for obvious reasons. I can't remember the last time a mag did an article on a "something" where it turned out to be a total turd. Big mistake to believe everything you read in a magazine.

Here is an excerpt from an article in a Mopar mag.:

Quote:Quote:1. Magazine tech "experts" are - limited - and usually in bed with the equipment manufacturer - for obvious reasons. I can't remember the last time a mag did an article on a "something" where it turned out to be a total turd. Big mistake to believe everything you read in a magazine.

Here is an excerpt from an article in a Mopar mag.:

Quote:Sorry, I was just looking at the ratio issue.Quote:Quote:1. Magazine tech "experts" are - limited - and usually in bed with the equipment manufacturer - for obvious reasons. I can't remember the last time a mag did an article on a "something" where it turned out to be a total turd. Big mistake to believe everything you read in a magazine.

Here is an excerpt from an article in a Mopar mag.:

Crizila - You should read that article again - it actually supports what you were saying

- that after a certain lift height the factory paddle style has a limitation - but before that works very well.

Quote:Looks like a good tool but will it make compensation for push rod angle? It is a lot of work but we do it right on the engine with a lifter shimmed solid at the preload we are using. Very time consuming but about as accurate as you can get per application.

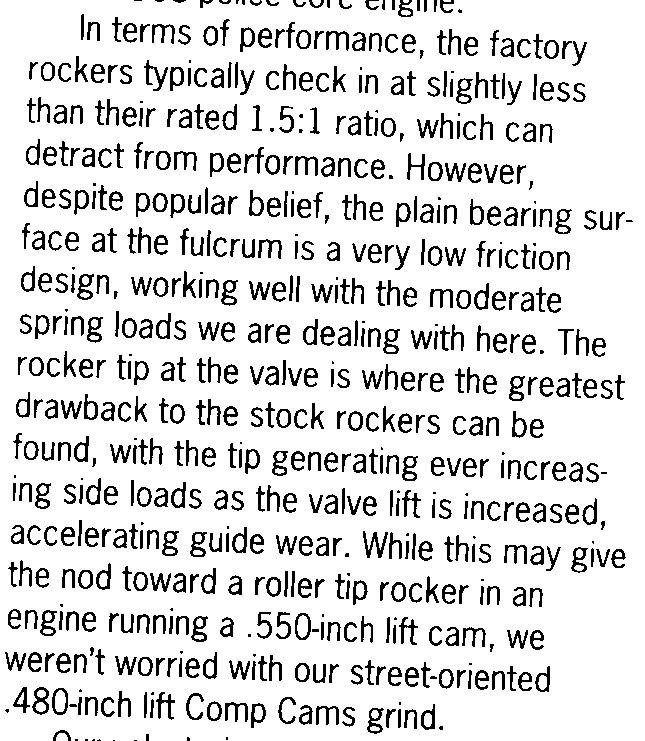

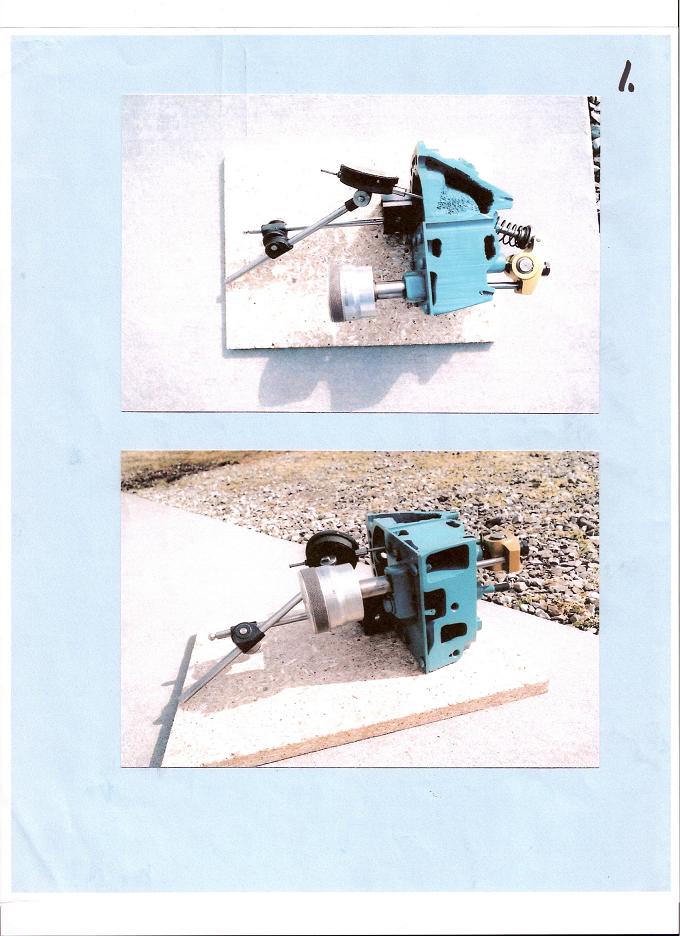

rocker ratio testing tool.

Quote:No, it's just for testing / comparing / plotting rocker ratios. Your way is the best if you want to include any "outside influences".Quote:Looks like a good tool but will it make compensation for push rod angle? It is a lot of work but we do it right on the engine with a lifter shimmed solid at the preload we are using. Very time consuming but about as accurate as you can get per application.

rocker ratio testing tool.

Quote:That tool would be handy to insure a full set of rockers with the same values. It may take several sets to make up one well matched one. (Been there - Done that)Quote:No, it's just for testing / comparing / plotting rocker ratios. Your way is the best if you want to include any "outside influences".Quote:Looks like a good tool but will it make compensation for push rod angle? It is a lot of work but we do it right on the engine with a lifter shimmed solid at the preload we are using. Very time consuming but about as accurate as you can get per application.

rocker ratio testing tool.

Quote:

Are stock max wedge rockers worth anything ? Do they make good race rockers ?