Ok I think I finally got the rocker gear sorted out (I hope?).

I had the stands machined off and used the Billet Racing Parts.com Max Wedge Stands. I asked to have them set about 0.050" higher, but when I got the heads back the rocker stands were about 0.200" higher. With lash caps on the valve tips the sweep pattern looked OK, so I had to get longer pushrods.

I got the valve train back together and the engine running, but no oil to the front rocker arms.

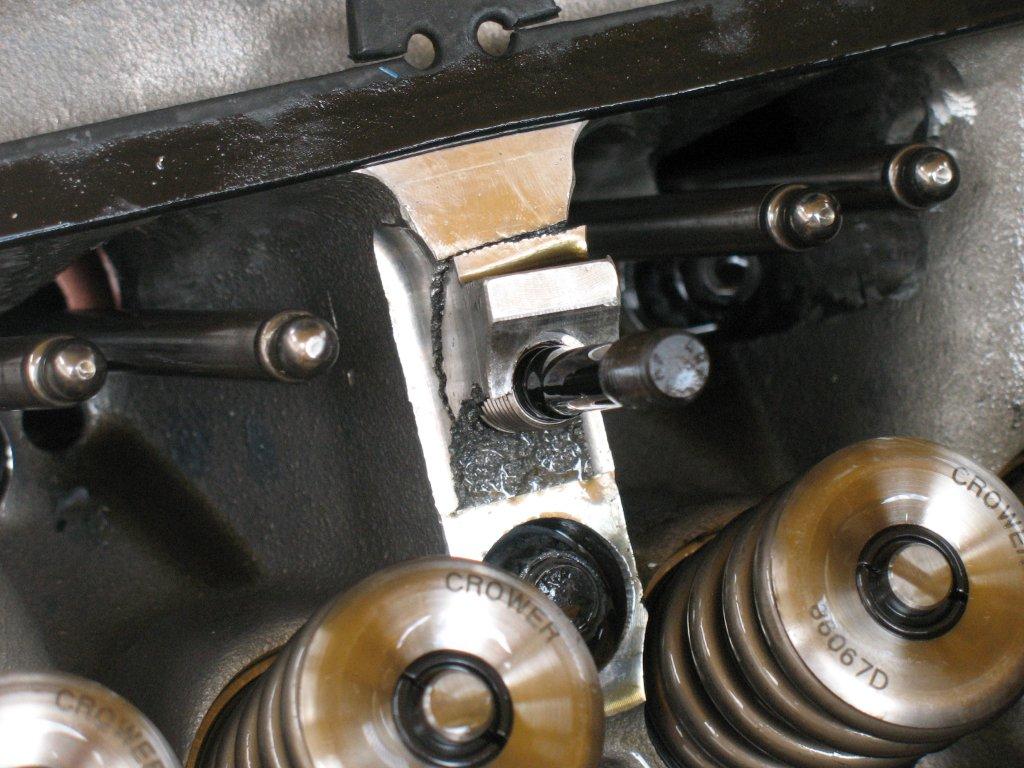

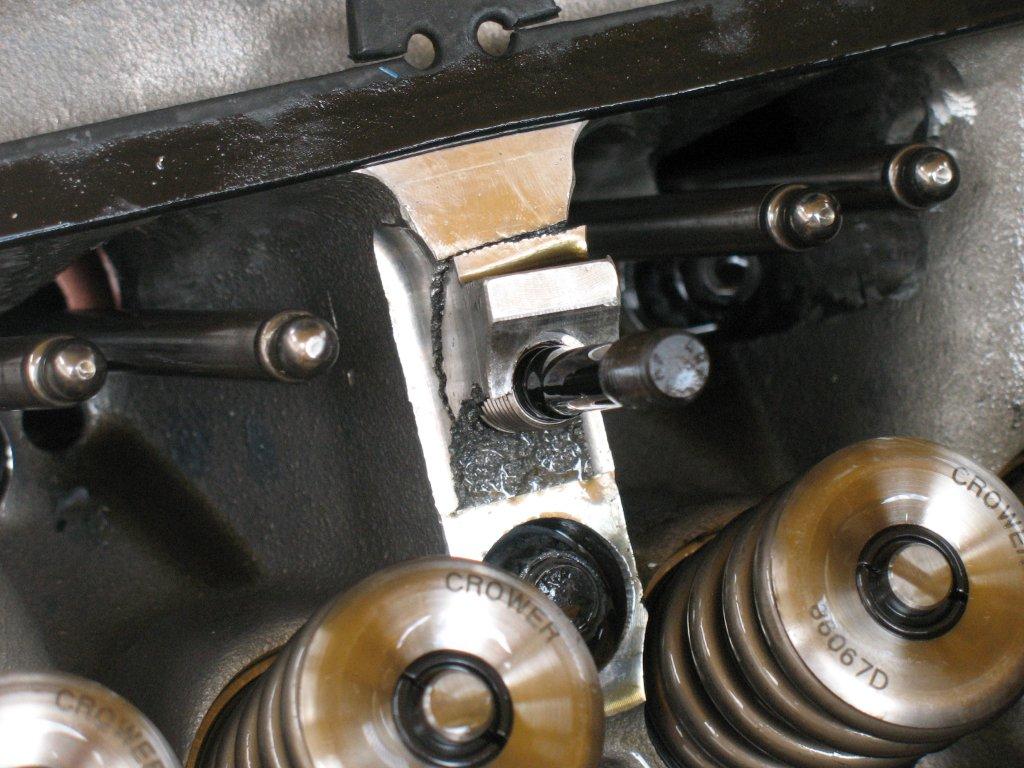

The machine shop used standard 3/8" Grade 8 bolts, but the T&D shafts are very thick walled (small oiling hole), so I had to grind down the bolt diameter a bit for oil flow through the rocker shafts. Engine was running OK, and allowed to warm up / run for about 20-minutes.

I then reved it up, and BANG! it started making bad noises again. Pulled the valve cover and found the pushrod for the center exhaust rocker out of place again (This is where I originally started..)

Removed the rocker shaft, and found the Heli-Coil halfway pulled out of the head (only a 1/2" long insert.) This is where the head originally broke, and the machine shop had this milled further down than the rest of the stands and used a spacer to make up the height difference, but did not make the bolt hole deeper and used the original length bolt, so the bolt only caught the first few threads of the heli-coil.

After some research, I decided to repair the bolt hole with a "Time-Sert":

http://www.timesert.com/index.htmlThis is like a threaded bushing and stronger than the heli-coil type insert. I also chose to use a stainless steel 3/4" long insert for the repair. I then used a longer bolt for plenty of thread engagement.

Fired the engine up again, and reved to 6,500+ RPM several times. So far the repair seems to be working good. Now if it just warms up so I can drive the car....

Anyone else use these "Time-Sert" repair kits?

They are pricy, but seem really nice of you need to fix a highly loaded bolt hole.

Now thats real nice.

Now thats real nice.  Are/were they new heads?

Are/were they new heads?  I'm guessing that it can be repaired, but I'd really want to know what caused it before I just fixed it and put it back together. Good luck.

I'm guessing that it can be repaired, but I'd really want to know what caused it before I just fixed it and put it back together. Good luck.

Worst thing they can say is no

Worst thing they can say is no