Posted By: mac56

? about 440 crank in low deck - 02/08/10 11:17 PM

Hello

Everything I read seems to recommend cutting the counter weights for better fitment. What is the difference between an RB compared to a B in respect to the crank? I understand it being easier to balance but most advertisements say it is for fit. Can someone explain this to me?

Thanks

Everything I read seems to recommend cutting the counter weights for better fitment. What is the difference between an RB compared to a B in respect to the crank? I understand it being easier to balance but most advertisements say it is for fit. Can someone explain this to me?

Thanks

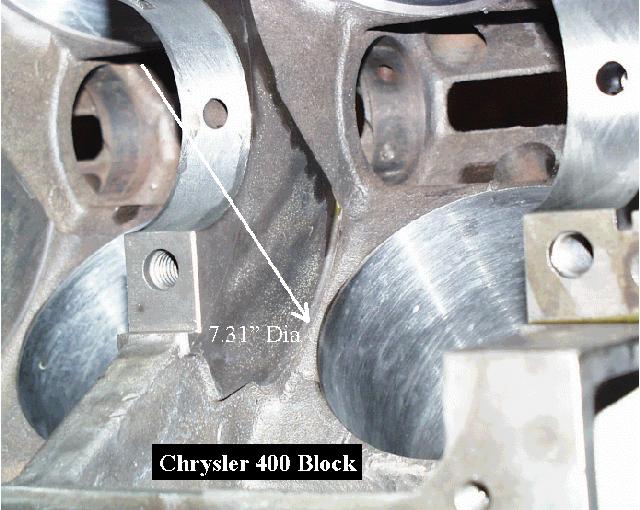

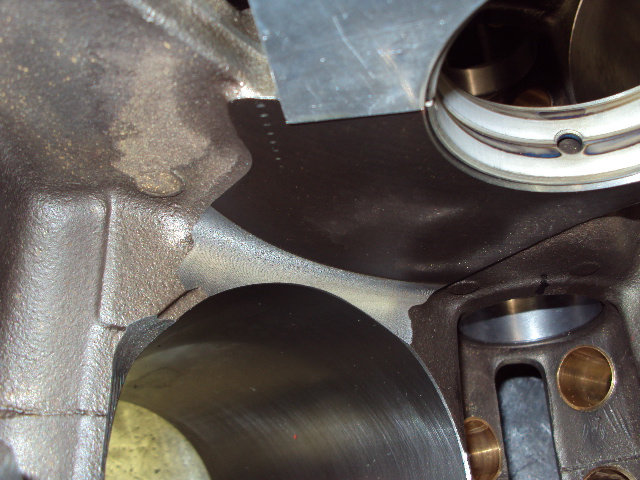

I've spent the time going from the lathe to mock up and still having fitment issues so I thought I'd eliminate the real problem. Now I don't have to put a half inch wide chamfer on a crank to keep it from hitting that spot nor do I have to whack the OD unless I want to do a "no holes" balance job. I've also turned the cranks down on some 4.375 combos and had to add a piece of heavy metal which I wouldn't have had to do if I had cut the block rather than the crank. Now If it's a combo that needs clearance at BDC, I only have to turn the crank(or cam cut the counterweight) enough to clear at BDC.

I've spent the time going from the lathe to mock up and still having fitment issues so I thought I'd eliminate the real problem. Now I don't have to put a half inch wide chamfer on a crank to keep it from hitting that spot nor do I have to whack the OD unless I want to do a "no holes" balance job. I've also turned the cranks down on some 4.375 combos and had to add a piece of heavy metal which I wouldn't have had to do if I had cut the block rather than the crank. Now If it's a combo that needs clearance at BDC, I only have to turn the crank(or cam cut the counterweight) enough to clear at BDC.