Posted By: Bob_Coomer

Hemi problems again.. valve to valve clearance - 01/17/10 11:38 PM

Finally got everything mocked up, short block together etc. Despite some trouble with with the rotating assembly, (actually a rod bearing issue).

Well

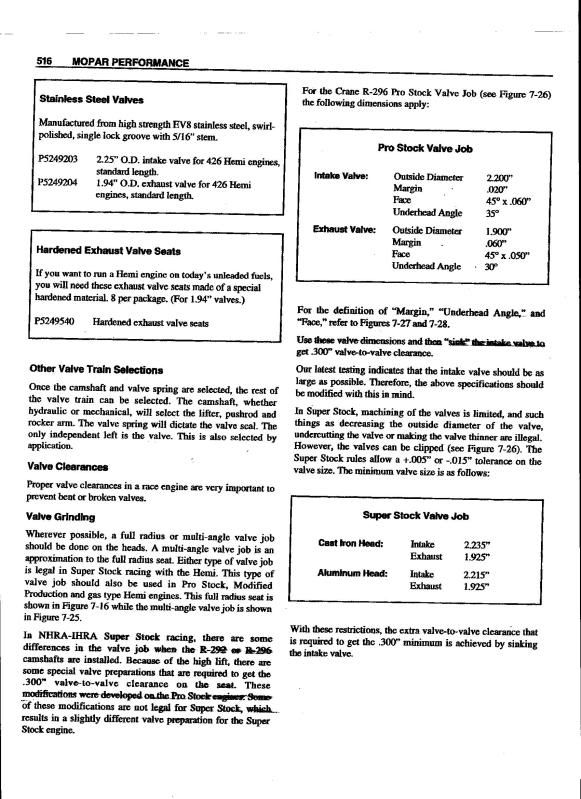

I talked with a few of some very helpful people on this board, so I decided to do some checking for possible valve to valve issue's. I measured the distance between the valves with the valves on the seat, and didnt like what i found.. Mopar calls for .280-.300 for cams above .700 lift. I had right at .255-.260 or so. So I knew this might be a problem..

Well this cam is has wide lobe centers of 112 LSA, I degree'd and checked the cam and installed it at a 109-110 ICL so its advanced a hair.

Well I was checking piston to valve clearance which is fine By the way...

Anyways

I was checking piston to valve clearance and noticed that the valves during overlap was very close, you can see the valve events pretty good looking through the intake port..How close..Well they didnt touch rotating the engine in the correct direction. But as I rotated the engine back words, I guess the slop in the timing chain etc retarded the cam, or changed the valve events enough that the valves clipped each other...They physically hit one another.. I had those light checker springs installed etc, so I didnt bend any valves etc. Luckily..

So now, I want to run this cam, so I must address the valves/heads to correct this issue. I know I can sink the valves, Should I sink just one valve like .050 or sink them both like .025? The valves are on diff angles so maybe I can gain more by sinking one valve compared to sinking the same amount off the other?

Can the valves them self's be back cut any to gain any radial clearance??

Even if I can take as little as .008-.010 off each valve diameter would help..

Thanks in advise

Bob Coomer

Posted By: Cab_Burge

Re: Hemi problems again.. valve to valve clearance - 01/18/10 12:22 AM

Clipping the valves is usally better than sinking the valve seats. Are these new valves? If so maybe grinding the valves a little first may solve the problem, if there real thick at the seat

Posted By: Rapid588

Re: Hemi problems again.. valve to valve clearance - 01/18/10 12:39 AM

Before getting too excited about them hitting i would set the valves up with the intended springs you are going to use, set with lash and then check again (going the correct direction). There will be a bit of deflection in the pushrods and the rest of valvetrain, big cams are a lot of times real close on valves missing each other, but if you do have to adjust i would cut the exhaust valve down slightly.

Posted By: B G Racing

Re: Hemi problems again.. valve to valve clearance - 01/18/10 01:00 AM

I would cut a little off each valve first,drop the seats a little second or a little of both.

Posted By: Moparteacher

Re: Hemi problems again.. valve to valve clearance - 01/18/10 02:32 AM

Yea..install the actual springs, set zero lash, pull your pistons and rods, leave the crank, assemble and install both heads on the block.

Now confirm actual v-v clearance with a feeler gauge up reaching through the bottom.

Posted By: moderncylinder

Re: Hemi problems again.. valve to valve clearance - 01/18/10 03:54 AM

hey bob i run .900 lift and .260 valve to valve,,,, ma mopar must have missed the boat on me.... the mopar jury must not apply to me..

do not go on assumption.... check your actual clearance with springs, lash up through the bottom of the cylinder,, if you have .025 run it

and pretty much noone runs .300 valve to valve anymore,, unless you are running a 426 with a cam from 1970

Posted By: LSP

Re: Hemi problems again.. valve to valve clearance - 01/18/10 12:47 PM

Check all the valve to valve measurements on the seat on each chamber. Note the chamber with the closest measurement, pull that piston/rod out and mock up the head/actual valvetrain on that cylinder. See that you have the minimum of .025" as Jeff said at valve overlap. I would leave the intakes alone, and sink/clip the exhausts to get your clearance.

Careful about following the mopar "bible" too much, that info is way outdated.

Posted By: B G Racing

Re: Hemi problems again.. valve to valve clearance - 01/18/10 01:08 PM

You can very easily check the clearence with a wire gage through the intake or exhaust port.Listen to whoever,I would look for a minimum of .035.

Posted By: sshemi

Re: Hemi problems again.. valve to valve clearance - 01/18/10 06:32 PM

Are you saying that the int and ex valves in the same cylinder are hitting each other when you turn the motor over only in one diretion?????

How the %#!" is that possible???

Is the cam twisting in one direction?

Posted By: MuscleMike

Re: Hemi problems again.. valve to valve clearance - 01/18/10 07:05 PM

FYI: odds are you will have intake pushrod clearance issues on #1 . The way they machined those old Mega blocks the intake pushrods hit the block.

Mike @MM

Posted By: B G Racing

Re: Hemi problems again.. valve to valve clearance - 01/18/10 07:43 PM

With close center long duration camshafts it is advisable to have a minimum of .280/.290 between the valves on the seat.Jeff may be getting away with .025 at the valve to valve intersecting point and only have .260 between the valves on the seat with the design of cam he is using.I would not and never recommend you use his numbers with that cam I gave you.The slightest deviation could spell disaster, a loose guide,slight varaying position of a guide center,or a side loading of the valve from unstabe or poor geometry.Even a pushrod bind can cause enough deflection in a long valve with a 5/16 stem to cause concern.I'am not doubting Jeff's claim,after all he is the head guru for race applications and especially SS/AH Hemis,and he would know better than any of us.If your that confident in his recommendation go for it,what do you have to loose?I stand buy what I said,I would rather be conservative and safe than be sorry later.Bob your not building a SS/AH granade and trimming or sinking those valve won't kill a 100hp for sure and you will sleep better.What ever you decide,good luck.

P.S.FYI, Jeff it is an early style cam.

Posted By: 52savoy

Re: Hemi problems again.. valve to valve clearance - 01/18/10 07:59 PM

Besides clipping the valves for clearance, no one mentioned(or I missed it) anywhere about cutting the exhaust valve to 1.900. I agree with BG..old school cams should be set up the old school way. I run a Crane R290 in my 477 and it's clipped with 1.900 exh valves. It wouldn't work(clear) any other way even with moving the cam timing around.

Posted By: Al_Alguire

Re: Hemi problems again.. valve to valve clearance - 01/18/10 08:16 PM

Good luck with it but if it were me I would mock it up as it is going to be run, lash, springs and all. Then see what you get. BTW the comment about the block and pushrod clearance is spot on, it is gonna need some grinding, even my World block needed a little with an appropriately sized pushrod.

Posted By: Cab_Burge

Re: Hemi problems again.. valve to valve clearance - 01/18/10 11:52 PM

I wouldn't even try that Crane with that LSA, it will make the EGT go sky high and loose a lot of the intake charge and compression out the exhausts

I did try a Crane R292-R296 (marine grind

)on 108 LSA in a 12.5 to 1 comp. ratio 426 cross ram motor with Bauman SS Carbs and that rascal wouldn't start to run until 4400+ RPM, not good for a bracket motor or a street motor

I tried to talk the customer out of using that cam but he had to have try it

Posted By: moderncylinder

Re: Hemi problems again.. valve to valve clearance - 01/19/10 02:32 AM

i know its an old cam bob,, something for a 426 sized motor,, with a 3.75 stroke,, i know its totally the wrong cam for bob but i think he got it for free or something like that..

you DO NOT need that much overlap with a sroker motor due to the less dwell at tdc respective to stroke travel, more overlap helps to scavange intake charge while the piston is moving about tdc, higher rod ratios need more overlap due to more dwell time for their respective stroke. i dont know what your cam is,, i forgot but i though it had like 72-74 degrees of overlap at .050,,, you would be better with 60 or so,,, maybe even 55 with a 572

"it worked back then so it will work today",,, sure the engine will start and run,, will it be the best cam, or close to it,, not even close,, you will "waste" alot of charge out the exhaust due to overscavaging cause,,,,,,,,, drumroll please.... what cab said.... it has too much overlap,, and if you had less overlap, youd have more valve to valve and youd be fine,, if you had the appropriate cam for your combo...

i understand getting things for free, and wanting to learn yourself that when you do what people tell you to it runs faster,,, im sure it wont be much of a headacche to just clip the margins,, i would not face them,, airflow would be better if you clipped them

Posted By: Anonymous

Re: Hemi problems again.. valve to valve clearance - 01/19/10 02:44 AM

bob, get rid of the cam and get the correct one, look at the big picture! its not really free when you have to go through all of this to get it to work, plus the cam isnt the right one for your application.

listen to jeff.

Posted By: mr_340

Re: Hemi problems again.. valve to valve clearance - 01/19/10 02:53 AM

Jeff, what sort of LSAs are they running now in SS/AH? I've heard something around 112, but that was a few years back.

Posted By: Jimi_Vignogna

Re: Hemi problems again.. valve to valve clearance - 01/19/10 03:07 AM

bob it has always been that you need .250 between the valves so they dont hit each other.

Posted By: ro23car

Re: Hemi problems again.. valve to valve clearance - 01/19/10 09:12 PM

id buy a bigger rubber band

Posted By: Bob_Coomer

Re: Hemi problems again.. valve to valve clearance - 01/20/10 12:23 AM

I just dont think the cam is way off in left field for the engine..I wished it was about 5 deg smaller on both the intake and exh side as for as duration goes...I like the 112 LSA etc.

The cam is 290°@.050 on the intake and 300°@.050 on the exh looks like overlap is about 71 deg or so. I degree'd the cam in at 109.5-110 LSA which worked out to be exactly what the cams valve events written on the cam card. I liked the fact that the lift at the valve retainer was .775 for the intake and .755 for the exh.

I would love to know how much they can move this cam on a regrind. They probably couldnt tell me unless it was sent in and they knew things like hardness depth etc. Id say .010-.015 would be max they could move whats there including the base circle. Anyone know for sure or have any cam experience?

Looking at Comps Master Cam lobe library..I still would be looking at numbers in the mid 280's on the intake and low to mid 290's on the exh, with about the same LSA give or take a degree or so.

probably a DR or XR intake Lobe and a XCX or JX exh lobe.

Yep

Its a money thing now, buying parts twice is what has hurt me...Changing directions during the build, and not doing my home work has cost me time and money.

Things like Cam, lifters, valve springs,retainers, spring cups, cams, intakes, and even valve covers. But one way or another, the engine will be finished and running well. Even if things are optimal for my combo..They can be changed, I never cared to work on my stuff. I have even been known to take apart good engines for no apparent reason..just too have a look. So labor around here doesnt cost about $0.25 per/hour.

Posted By: Frito

Re: Hemi problems again.. valve to valve clearance - 01/20/10 05:41 PM

Bob, I know you like to go fast, BUT remember, this is a bracket motor not SS/AH. Approach the build as such. I need to get over and look at this baby soon.

Posted By: 52savoy

Re: Hemi problems again.. valve to valve clearance - 01/20/10 07:37 PM

Bob, hopefully this post has lost steam

I talked to Jack Moore(Moore&Moore) over the weekend at the Columbus swap met. He said, he actually ran as good if not better with an old profile cam(R296) in his 572incher.

ain't say'n no'mo

Fred

Posted By: Anonymous

Post deleted by Defbob - 01/21/10 03:24 AM

Posted By: Anonymous

Post deleted by Defbob - 01/21/10 04:26 PM

Posted By: ZIPPY

Re: Hemi problems again.. valve to valve clearance - 04/06/19 09:30 PM

This was a helpful thread to me many years later, I have .040" measured from the bottom and it seemed

Fine, but I was questioning it.

Thanks for the knowledge shared here.

Zombie thread alert.

it says the purple cam is the most powerful cam for a 440

it says the purple cam is the most powerful cam for a 440

not unusual with bigger cams on the 426 hemi motors, be very careful when setting the cam up and make sure to check them like what has already been said to do

not unusual with bigger cams on the 426 hemi motors, be very careful when setting the cam up and make sure to check them like what has already been said to do

)on 108 LSA in a 12.5 to 1 comp. ratio 426 cross ram motor with Bauman SS Carbs and that rascal wouldn't start to run until 4400+ RPM, not good for a bracket motor or a street motor

)on 108 LSA in a 12.5 to 1 comp. ratio 426 cross ram motor with Bauman SS Carbs and that rascal wouldn't start to run until 4400+ RPM, not good for a bracket motor or a street motor  I tried to talk the customer out of using that cam but he had to have try it

I tried to talk the customer out of using that cam but he had to have try it

Bob,

Bob,  (thats what my wage works out to be)

(thats what my wage works out to be)