Posted By: 70dusterjohn

sheet metal intakes.. - 09/15/09 06:00 PM

How thick of steel do they use for this.. Where can I get some flanges for a big block..

Quote:

yes most are aluminum but steel can be used. i've built one with 3/16 steel flanges and 18-20 gauge sheet to make the runners. yes its tedious but if your playing around there is nothing wrong with actually using steel. plus you can mig weld it, although tig works better and if really your in a bind i even saw one person braze it. he then had it powder coated and you couldn't even tell.

Quote:Jerry,I checked out your site,very impressive.With all that capability and access to the state of the art tooling,Cnc and etc. I can only question why you would even consider something as unconventional and outmolded as a steel manifold.We have built our own inhouse manifolds as well as supplied custom made ones from Tim Hogan for way far less than the dollars you have mentioned.The finish work to radius and blend a steel manifold would in it's self negate any cost savings.As advanced as your company is I would still question your logic and thought process for entertaining such a project"steel intake manifolds" weather it be one or 1000.To anyone that wants to try good luck.

for us that may build one or two manifolds in our lifetime to have something different and dont weld aluminum, its much cheaper to use steel, plus it lets me play at home with different ideas and fitments etc. sure if i was to go into manufacturing professional intake i would also make them aluminum, but they are not easier to make than an actual steel intake. lighter is also debatable because you have to use thicker aluminum. sure can they be lighter, of course, will they always be? no. again, can you make them out of steel yes. why would you? because you can and can't afford $4000 for a custom hogan or wilson intake.

Quote:

i agree that for an all out points car or someone that is racing every weekend i would pony up the cash for a hogan. but when your at that point you've exhausted all cast manifolds and need something different.

for a guy asking if he can use steel i would assume that its a garage build just because he can. i agree that professional shop should use aluminum, there are alot of advantages.

Jerry,I know John and just wanted to clarify for him that fabricated aluminum manifolds are commonally referred to as "sheet metal manifolds" and I don't think John had that consecpt in his mind so that he didn't get in over his head in a project with out all the information.

Jerry,I know John and just wanted to clarify for him that fabricated aluminum manifolds are commonally referred to as "sheet metal manifolds" and I don't think John had that consecpt in his mind so that he didn't get in over his head in a project with out all the information.

Quote:

Quote:

There are many different metals that can be made into sheet metal, such as aluminum, brass, copper, steel, tin, nickel and titanium. For decorative uses, important sheet metals include silver, gold, and platinum.

Your correct Fred,sheet metal is just a sheet of some sort of metal.John was applying the terminology to an intake manifold,thus we can all "assume" that he needed to be guided to correct material and application.What would a 4X8 sheet of platinum be worth?

Your correct Fred,sheet metal is just a sheet of some sort of metal.John was applying the terminology to an intake manifold,thus we can all "assume" that he needed to be guided to correct material and application.What would a 4X8 sheet of platinum be worth?

Quote:

Invisible Intake!!!!

And Aluminum can be mig welded....got a guy at work that can make Mig look like it was tigged.....didn't know alum could be migged with ordinary wire feed welder with just a couple simple accesories different rollers...straight argon...teflon liner.

Absolutely,at the construction company we mig weld all our aluminum structures,brackets and even truck bodys and accessories.For our race car shop we still like to tig weld.

Absolutely,at the construction company we mig weld all our aluminum structures,brackets and even truck bodys and accessories.For our race car shop we still like to tig weld.

Quote:you just gave me a reason. thanks.

Absolutely no good reason that I can think of to use steel.

Quote:

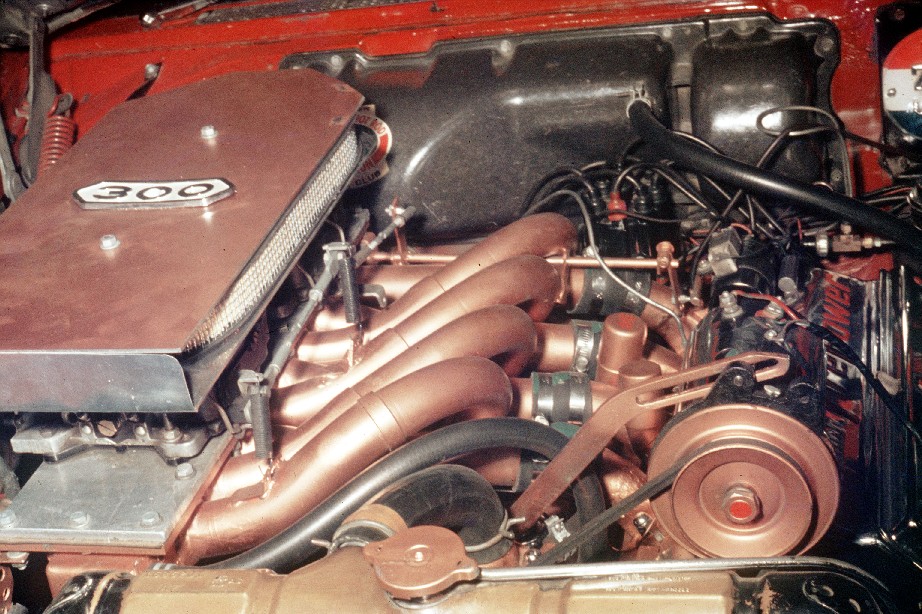

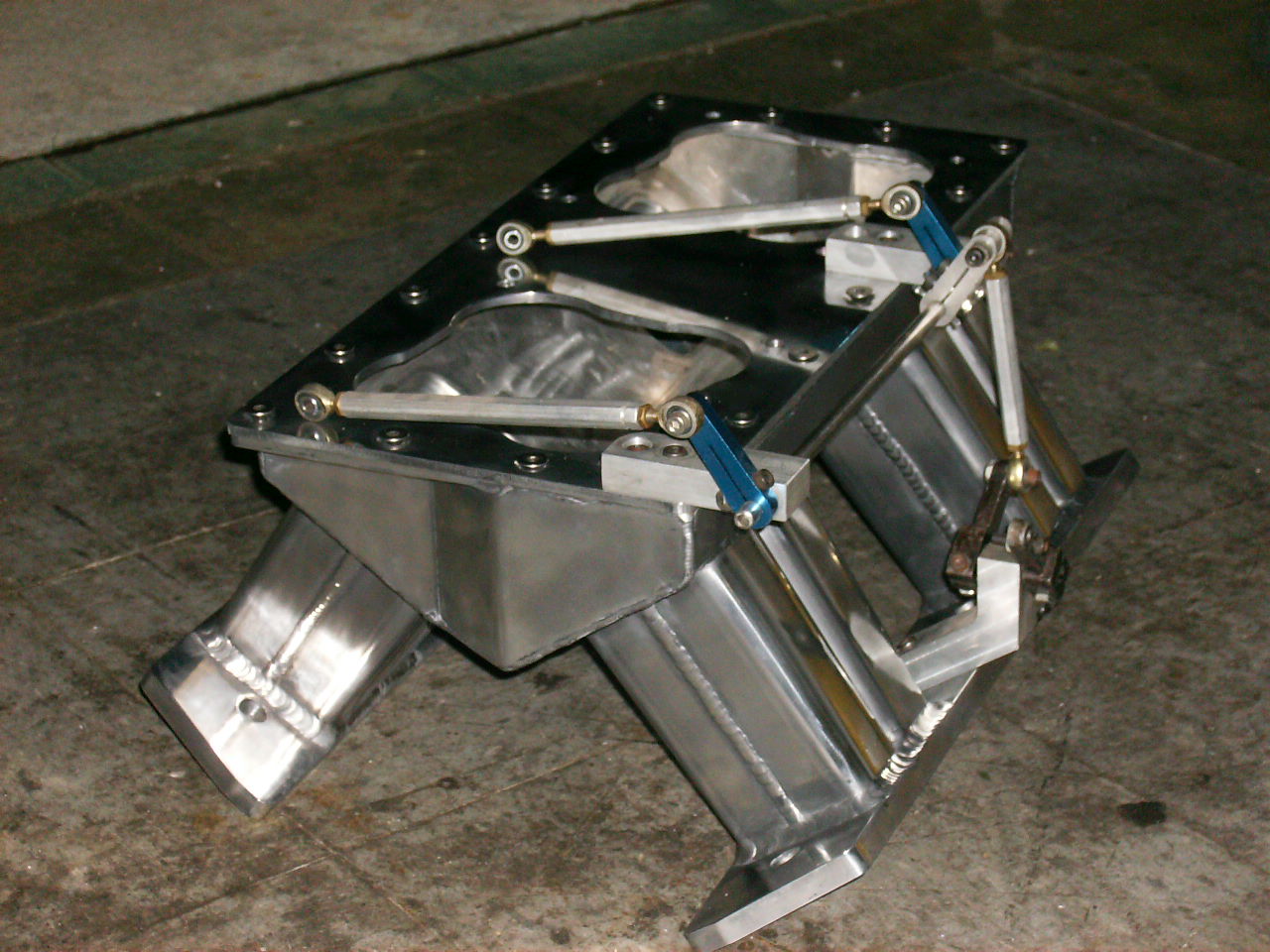

AMC intake prototype by herman lewis for his new heads..