Posted By: dave571

piston skirt to crank clearance, help engine guru's - 06/15/09 04:36 AM

OK

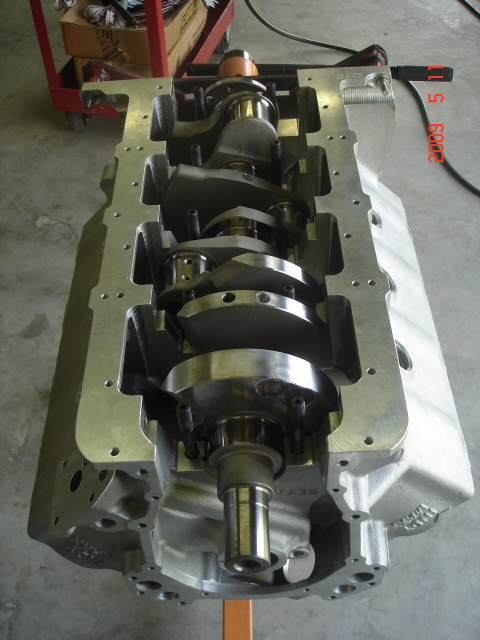

My buddy is putting his 451 together.

When we roll it over, the comp height is good, etc, PROBLEM is that the piston skirt just touches the crank counter weghts almost dead on at BDC.

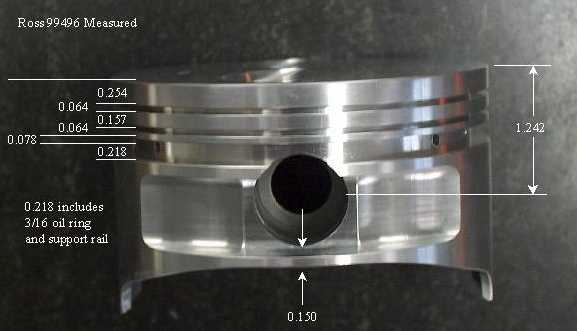

It seems to be about .004" interferance. The skirt is quite thin there, so we were going to have a little machined off.

How much clearance should there be there?

.020? ,030?

Thanks!

My buddy is putting his 451 together.

When we roll it over, the comp height is good, etc, PROBLEM is that the piston skirt just touches the crank counter weghts almost dead on at BDC.

It seems to be about .004" interferance. The skirt is quite thin there, so we were going to have a little machined off.

How much clearance should there be there?

.020? ,030?

Thanks!