Posted By: Uberpube

Ramcharger motor went to the dyno. - 03/01/24 05:33 AM

I've had this engine built for a while, but life, covid and work got in the way, finally found a couple days to get it ready and make the 5 hour round trip to the engine dyno.

-1978 440 block, bored .030 over, bushed lifter bores, line hone, decks cut square

-Milodon 8 qt truck pan, hv oil pump, windage tray, studded mains and heads.

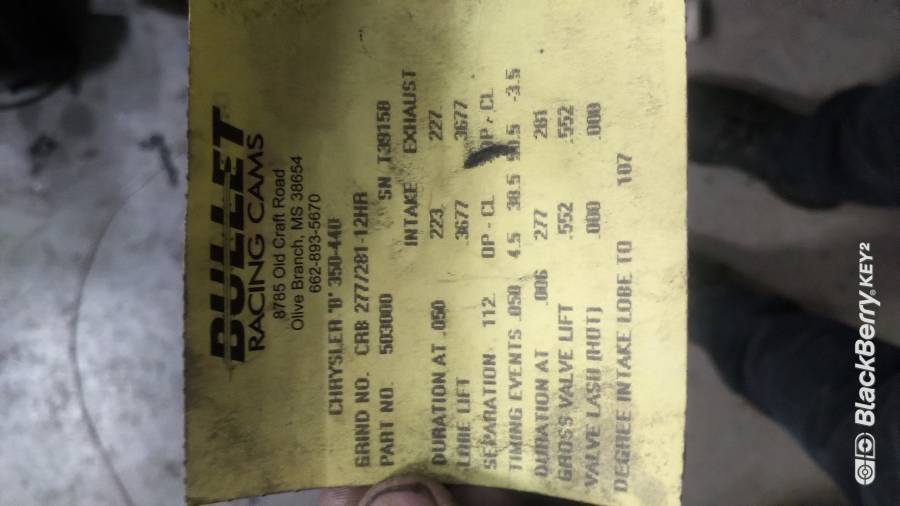

-Bullet racing cam, mild enough for the power brakes to work in truck application, hydraulic roller, .540 lift. morel lifters

-Trickflow 270 heads

-Indy dual plane match ported to heads.

-Comp cams promagnum rockers, 3/8 Smith Brothers pushrods, B3 racing shim kit.

-Eagle 4.250 crank and rods, Icon pistons 10-ish compression.

_Cometic Mls head gaskets .040, pistons were .009 to .011 below deck

-Proform distributor, QFT 950 vac secondaries with E/Choke.

2" mad dog fenderwell headers.

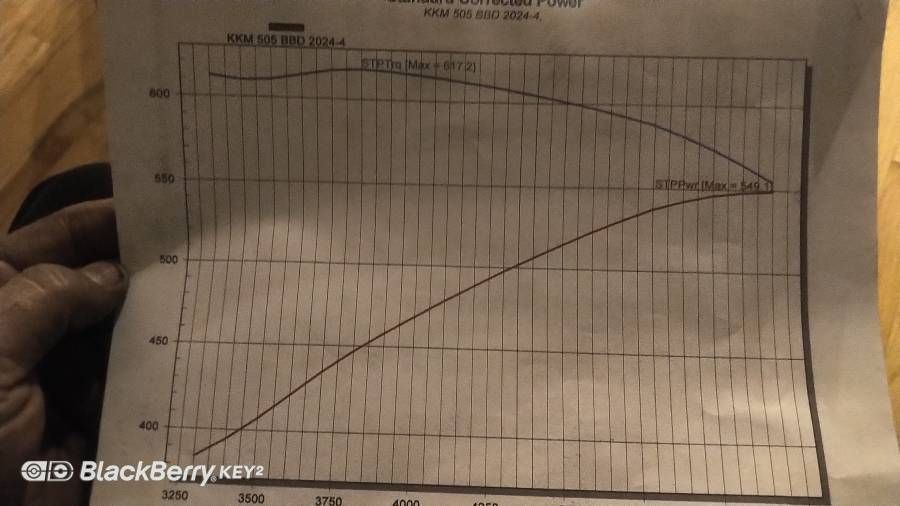

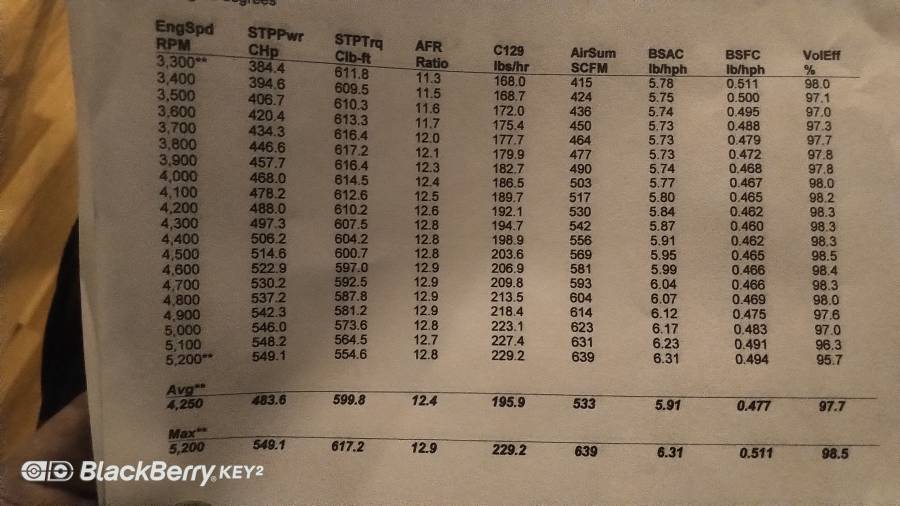

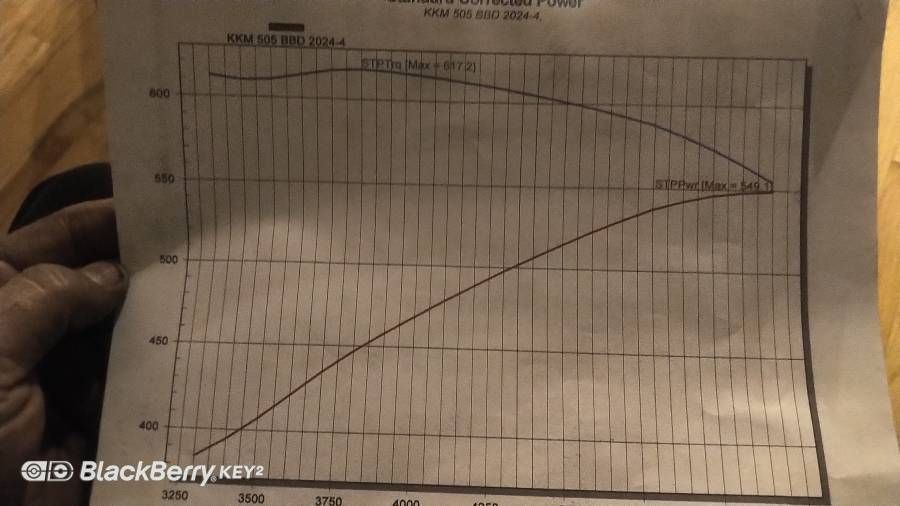

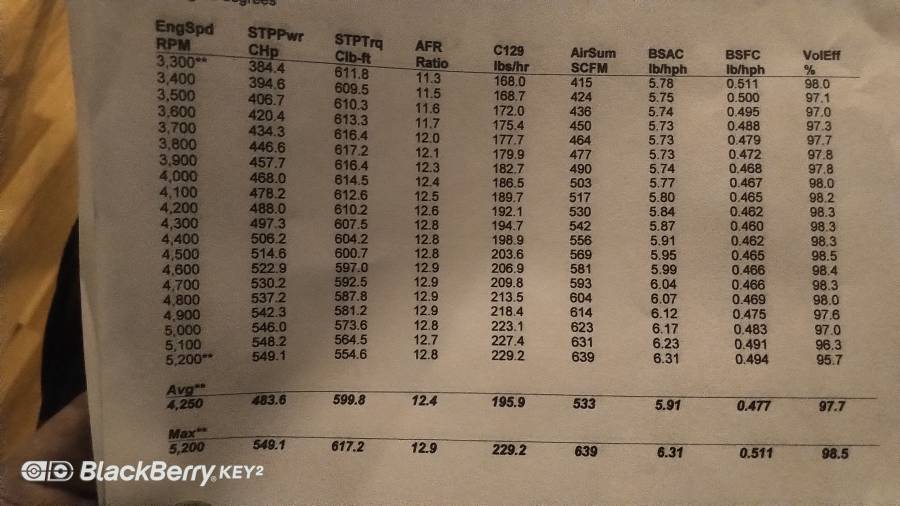

The torque is pretty good and should be fun in a truck with 37" tires and 5.13 gears. We capped it off at 5200, past there the valvetrain started to lose control and it would break up. If I ever go back into the heads I think I will revisit the springs.

It wasn't real picky, changing timing from 30-36 didn't really change much, neither did a jet change, it was kind of there right out of the box. We did gain a wee bit when we did a back to back spark plug change test.

I'm really glad it runs pretty well, no real leaks, the rear main stayed totally dry with a stock retainer and rubber seal with it installed clocked slightly. We cut the filter open, no metal, some rings particle on the mag plug. I can install the engine now and get the truck so it runs on its own power again, then send it back for paint.

-1978 440 block, bored .030 over, bushed lifter bores, line hone, decks cut square

-Milodon 8 qt truck pan, hv oil pump, windage tray, studded mains and heads.

-Bullet racing cam, mild enough for the power brakes to work in truck application, hydraulic roller, .540 lift. morel lifters

-Trickflow 270 heads

-Indy dual plane match ported to heads.

-Comp cams promagnum rockers, 3/8 Smith Brothers pushrods, B3 racing shim kit.

-Eagle 4.250 crank and rods, Icon pistons 10-ish compression.

_Cometic Mls head gaskets .040, pistons were .009 to .011 below deck

-Proform distributor, QFT 950 vac secondaries with E/Choke.

2" mad dog fenderwell headers.

The torque is pretty good and should be fun in a truck with 37" tires and 5.13 gears. We capped it off at 5200, past there the valvetrain started to lose control and it would break up. If I ever go back into the heads I think I will revisit the springs.

It wasn't real picky, changing timing from 30-36 didn't really change much, neither did a jet change, it was kind of there right out of the box. We did gain a wee bit when we did a back to back spark plug change test.

I'm really glad it runs pretty well, no real leaks, the rear main stayed totally dry with a stock retainer and rubber seal with it installed clocked slightly. We cut the filter open, no metal, some rings particle on the mag plug. I can install the engine now and get the truck so it runs on its own power again, then send it back for paint.