Posted By: Tig

Anyone tried this ?

Posted By: Stanton

Re: Anyone tried this ? - 12/21/23 03:58 PM

That would have taken some time to program !!!

Posted By: A727Tflite

Re: Anyone tried this ? - 12/21/23 04:30 PM

Saw this on some Glidden stuff way back. Piston domes too.

Posted By: gregsdart

Re: Anyone tried this ? - 12/21/23 04:40 PM

Simular to golfball airflow techknowlogy?

Posted By: Al_Alguire

Re: Anyone tried this ? - 12/21/23 04:46 PM

The term snake oil can be inserted here.....Its been around for a couple decades now

Posted By: B1MAXX

Re: Anyone tried this ? - 12/21/23 04:54 PM

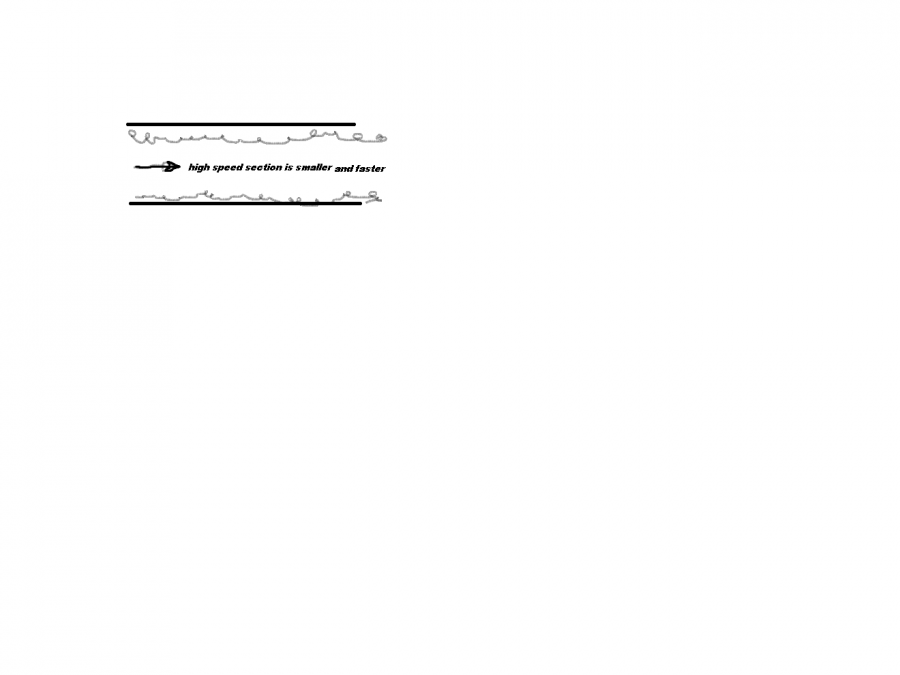

Builds up the boundary layer, makes the port "smaller" is my take.

Posted By: Tig

Re: Anyone tried this ? - 12/21/23 05:46 PM

Just wondering is all, there was quite a debate on faceache with both sides of the argument but no conclusive proof either way. Seems like the import guys are the majority of the "yays".

My take is if it did work, it would be available as an CNC option on every decent cylinder head available.

My take is if it did work, it would be available as an CNC option on every decent cylinder head available.

Posted By: 340Cuda

Re: Anyone tried this ? - 12/21/23 06:05 PM

The late Jim McFarland was a proponent of this. I respected Mr. McFarland a lot but there sure has not been wide spread adoption of the dimples.

Mythbusters did something like this on a whole car and I think in their opinion he made the car more aerodynamic.

Mythbusters did something like this on a whole car and I think in their opinion he made the car more aerodynamic.

Posted By: Brad_Haak

Re: Anyone tried this ? - 12/21/23 06:12 PM

Dimples, riblets ("shark skin"), burr finish... all forms of port surface finishing that some have claimed show improvements and others have doubted vociferously

Posted By: Mr PotatoHead

Re: Anyone tried this ? - 12/21/23 06:19 PM

You decide....

Posted By: Diplomat360

Re: Anyone tried this ? - 12/21/23 08:55 PM

Interesting...the prior reading I've done on this topic was focused on preventing the fuel, once it began falling out from the air stream from actually settling down on the port walls. Idea here being that those vortices would 'shake' the droplets back up into the airstream before they ever got a chance to come in contact with the port wall.

Ultimately the goal there was to keep the fuel in suspension and therefore make more of it available for efficient burn in the chamber, thus producing more power.

Ultimately the goal there was to keep the fuel in suspension and therefore make more of it available for efficient burn in the chamber, thus producing more power.

Posted By: Tig

Re: Anyone tried this ? - 12/21/23 09:21 PM

Originally Posted by Diplomat360

Interesting...the prior reading I've done on this topic was focused on preventing the fuel, once it began falling out from the air stream from actually settling down on the port walls. Idea here being that those vortices would 'shake' the droplets back up into the airstream before they ever got a chance to come in contact with the port wall.

Ultimately the goal there was to keep the fuel in suspension and therefore make more of it available for efficient burn in the chamber, thus producing more power.

Ultimately the goal there was to keep the fuel in suspension and therefore make more of it available for efficient burn in the chamber, thus producing more power.

Good point, flow numbers may not tell the whole story. I'm guessing no-one has any non-dimpled v's dimpled dyno numbers or track results ?

Posted By: 360view

Re: Anyone tried this ? - 12/21/23 09:42 PM

I am not sure if Larry Widmer’s forum posts are still on the web, but he did a much better job of describing how a small number of exactly spaced dimples can improve airflow.

Larry Widmer’s dad was an aerodynamic engineer justly famous for his contributions to the F-16 design.

This article describes how a dimple just past mid chord on the upper side of a wing improves flow.

http://www.journals.theired.org/assets/pdf/20151019_064614.pdf

Why do golf balls benefit from all around dimples?

A round ball is a terrible, terrible, terrible shape for an airplane wing.

Dimples all around make the golf ball a slightly less terrible wing shape - but only if the spin of the golf ball is correct to create up lift.

If the spin is wrong the dimples actually make the golf ball go right, left, or “down lift” into the grass faster.

Bumps most times work better than dimples.

Bird wings have bumps and notches rather than dimples.

Larry Widmer’s dad was an aerodynamic engineer justly famous for his contributions to the F-16 design.

This article describes how a dimple just past mid chord on the upper side of a wing improves flow.

http:/

Why do golf balls benefit from all around dimples?

A round ball is a terrible, terrible, terrible shape for an airplane wing.

Dimples all around make the golf ball a slightly less terrible wing shape - but only if the spin of the golf ball is correct to create up lift.

If the spin is wrong the dimples actually make the golf ball go right, left, or “down lift” into the grass faster.

Bumps most times work better than dimples.

Bird wings have bumps and notches rather than dimples.

Posted By: B1MAXX

Re: Anyone tried this ? - 12/21/23 10:12 PM

A moving ball is different than the stationary walls of a port. Increasing the boundary layer speeds up the velocity keeping the fuel suspended. Fuel drops out at a slowdown point. At least by my thinking.

Posted By: Al_Alguire

Re: Anyone tried this ? - 12/21/23 11:22 PM

Let me try again SNAKE OIL.....

Posted By: Brad_Haak

Re: Anyone tried this ? - 12/22/23 02:04 AM

Originally Posted by Al_Alguire

Let me try again SNAKE OIL.....

which is why I find it interesting that BES offers (offered?) the dimpling as an add-on upgrade for certain CNC programs

Posted By: bobby66

Re: Anyone tried this ? - 12/22/23 04:55 AM

Originally Posted by gregsdart

Simular to golfball airflow techknowlogy?

Yep.....

Posted By: Al_Alguire

Re: Anyone tried this ? - 12/22/23 04:28 PM

Originally Posted by Brad_Haak

Originally Posted by Al_Alguire

Let me try again SNAKE OIL.....

which is why I find it interesting that BES offers (offered?) the dimpling as an add-on upgrade for certain CNC programs

I can guarantee you if there was something there EVERY Comp car and PS team out there would be doing it. We work with one of the most prominent head porters in the country on our stuff and he does a LOT of comp stuff. He said they tried it years ago and it was worth nothing. I tend to believe him more than the internets. Having spent alot of time around top comp teams and very good friends with a person who has built some of the fastest comp stuff out there I can tell you without a doubt its not used by the top teams.

I would not be surprised that BES offers it. Possibly to appease those who insist. We race with alot of folks who run BES stuff and none of them use it

Posted By: Brad_Haak

Re: Anyone tried this ? - 12/22/23 04:41 PM

Originally Posted by Al_Alguire

Originally Posted by Brad_Haak

Originally Posted by Al_Alguire

Let me try again SNAKE OIL.....

which is why I find it interesting that BES offers (offered?) the dimpling as an add-on upgrade for certain CNC programs

I can guarantee you if there was something there EVERY Comp car and PS team out there would be doing it. We work with one of the most prominent head porters in the country on our stuff and he does a LOT of comp stuff. He said they tried it years ago and it was worth nothing. I tend to believe him more than the internets. Having spent alot of time around top comp teams and very good friends with a person who has built some of the fastest comp stuff out there I can tell you without a doubt its not used by the top teams.

I would not be surprised that BES offers it. Possibly to appease those who insist. We race with alot of folks who run BES stuff and none of them use it

Not surprised... at all

Even Chad Speier as a big proponent of the burr finish technique has stated it's not always appropriate for the application; I think that applies pretty much to all of this stuff

Posted By: Stanton

Re: Anyone tried this ? - 12/23/23 05:44 PM

"Builds up the boundary layer, makes the port "smaller" is my take."

No. The principle is the same as "vortex generators", the point being to keep airflow against the surfaces - ideally making use of the full port volume, not decreasing it.

No. The principle is the same as "vortex generators", the point being to keep airflow against the surfaces - ideally making use of the full port volume, not decreasing it.

Posted By: Jamie McGrath

Re: Anyone tried this ? - 12/23/23 08:16 PM

I’ve seen some very tight golf balling of front straps of 1911’s by a well known gun smith, but I have always wondered it one were too golf ball nearly all the pendulum of a Tunnel Ram/Rat Roaster/STR up too about 1/4in where the port entry is, if that wouldn’t aid port velocity and enhance the fuels atomization and distribution?

Posted By: B1MAXX

Re: Anyone tried this ? - 12/24/23 08:31 PM

Originally Posted by Stanton

"Builds up the boundary layer, makes the port "smaller" is my take."

No. The principle is the same as "vortex generators", the point being to keep airflow against the surfaces - ideally making use of the full port volume, not decreasing it.

No. The principle is the same as "vortex generators", the point being to keep airflow against the surfaces - ideally making use of the full port volume, not decreasing it.

The way I see it....

I can see it helping to grab and turn it though over the short side but that theory didn't work for me when I tried it once.

Posted By: 340Cuda

Re: Anyone tried this ? - 01/02/24 09:59 PM

This may not be related at all but I thought of this thread when a saw a rule change today for NHRA Pro Stock engines:

"Surface of plenum area must remain smooth"

https://www.nhraracer.com/content/general.asp?articleid=72922&zoneid=132

"Surface of plenum area must remain smooth"

https:/

Posted By: John Brown

Re: Anyone tried this ? - 01/02/24 11:39 PM

Originally Posted by 340Cuda

This may not be related at all but I thought of this thread when a saw a rule change today for NHRA Pro Stock engines:

"Surface of plenum area must remain smooth"

https://www.nhraracer.com/content/general.asp?articleid=72922&zoneid=132

"Surface of plenum area must remain smooth"

https:/

NHRA always a party pooper. Making rules where no rules were needed. Make a basic framework of rules, and then let then inovate.

![[Linked Image]](http://i.imgur.com/HlOAUnc.jpg)