Posted By: dvw

A look at the inside of a 727 that lives - 08/29/22 11:31 PM

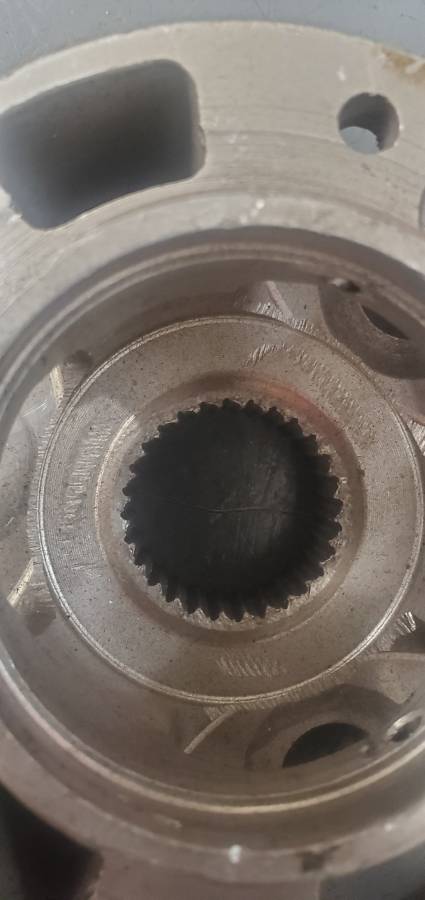

A lot of discussion about 727 strength. This trans has been in the car 10 years, over 850 passes. Car has been 1.27/8.98@149 3340lbs in poor air, 1.24/5,64@120.4 in decent air. It broke the converter this past weekend at NMCA at Norwalk. So the trans needed to be torn down to clean out the metal from the converter. All the metal found was steel. It appears to have ate the stator Torrington, maybe more? It ripped a mounting lug off the converter as well. In 2012 I traded a pair of 340 exhaust manifolds for the remnants of a blown up (low roller let go and took out the case) 65 push button stock eliminator trans. It had straight cut planets in stock carriers. Only 2 planet gears in the front planet carrier. The front and rear drums, and rear clutch retainer were aluminum. It had a straight cut sun shell, HD band strut and anchor. The rear was all Torrington. It also had a Turbo Action reverse manual valve body. The front drum had been machined for a 2 clutch capacity. Due to the snap ring location 5 clutches wont work. The steel falls into the snap ring groove. So a new A&A billet steel drum was used. I also removed the 2 straight cut planet gears from the front carrier(4 pin with 2 missing). A&A supplied a 3rd straight cut pinion which i loaded into a stock 3 pin carrier. A stock 65 core donor was used along with the usable parts. It ran this way for 2 years and then lost all forward gears. That fix will be in the next post.

Doug

Doug

![[Linked Image]](https://i.postimg.cc/hv4JN7V9/20220828-132421.jpg)

![[Linked Image]](https://i.postimg.cc/zGhftk4s/20220828-155657.jpg)

![[Linked Image]](https://i.postimg.cc/Wbg3SnBQ/20220828-155617.jpg)