Posted By: Diplomat360

W2 stroker build - cam gear interference? - 05/23/21 12:49 AM

Hmm...weird one I have here.

So having finished driving the oil pump shaft bushing into the block I figured I might as well get the cam in and make sure there is nothing weird about this setup, you know, gears mesh nicely, etc.

The cam is a custom ground Comp Cams hydraulic roller with a regular compatible gear drive, meaning (per the tech's email):

...and I am using the MP hardened shaft that I used with the last flat tappet cam I had. Great shape actually. OK, so far so good.

So I stuck the cam in, got the front retaining plate bolted on, slowly went ahead to turn the cam (while checking that drive teeth were meshing nicely with the oil pump drive), all was good until I hit a certain spot...then literally STOP!!! The cam was stuck...so I wiggle the darn thing around, back and fort, back and forth, toss some extra oil at it and repeated, only to find the same "interference point".

Hmm, weird I thought. I removed the cam and re-installed one of my old hydraulic flat tappet ones...spun it...super easy, no stuck spots. So at least the bushing install appears to be fine (I actually used the proper tool for it).

I tossed the roller back in there, sure enough, got to a hard spot again. But I did notice that the more turns I got on it, the easier it got. So I literally employed my daughter for the next phase, she came out to provide the honorary oil squirter duty while I hooked up my dril and started to turn the assembly on slow speed. After about 10 secs. of this I stopped, checked things out, everything seemed fine, but I could still feel a stuck spot in there. So while it got a lot smoother it was nowhere near like all the other cams I have ever installed.

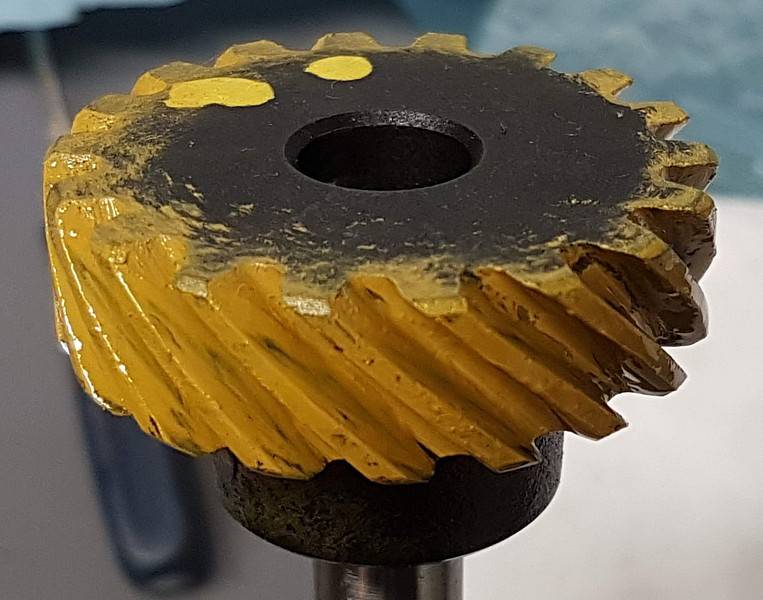

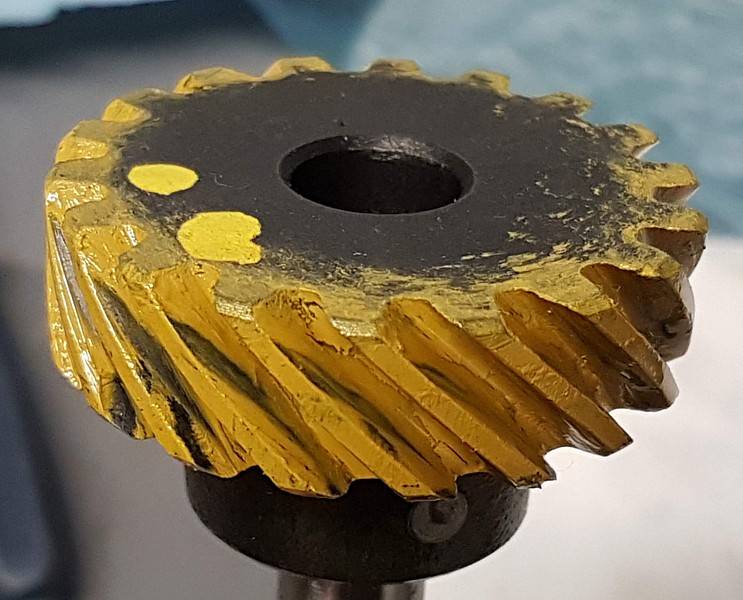

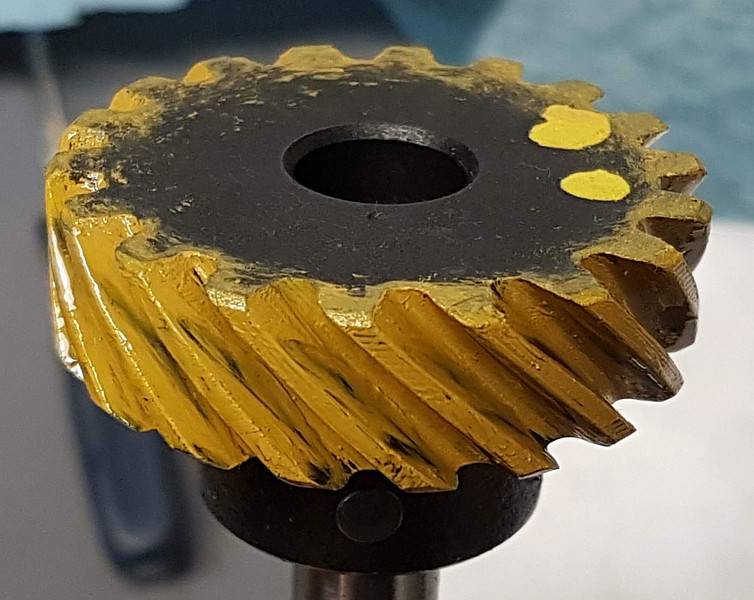

So I pulled everything apart and took a few photos of the gear mesh pattern. You can see how the tight spot has let these spotty mesh markings, while the smooth part has a nearly continuous mark left.

I've never messed with anything other than hydraulic flat tappet cams, so maybe this extra tightness/interference is a normal thing for this kind of a retro-fit setup.

I'm curious, does anything here jump out at you guys? Is this a tell-tale sign of something else being wrong with the cam? Could it be bent? I don't think so because the tight spot is only across about three teeth...but who knows?

So having finished driving the oil pump shaft bushing into the block I figured I might as well get the cam in and make sure there is nothing weird about this setup, you know, gears mesh nicely, etc.

The cam is a custom ground Comp Cams hydraulic roller with a regular compatible gear drive, meaning (per the tech's email):

Quote

...The cam you have is what is called Austempered Ductile Iron, which is basically the same material a flat tappet cam would be made of, but it is heat treated instead of parkerized like flat tappet cam would be so that the roller profile can be ground onto it and so that the hardened roller wheels can ride on the lobes without damaging the cam...

...and I am using the MP hardened shaft that I used with the last flat tappet cam I had. Great shape actually. OK, so far so good.

So I stuck the cam in, got the front retaining plate bolted on, slowly went ahead to turn the cam (while checking that drive teeth were meshing nicely with the oil pump drive), all was good until I hit a certain spot...then literally STOP!!! The cam was stuck...so I wiggle the darn thing around, back and fort, back and forth, toss some extra oil at it and repeated, only to find the same "interference point".

Hmm, weird I thought. I removed the cam and re-installed one of my old hydraulic flat tappet ones...spun it...super easy, no stuck spots. So at least the bushing install appears to be fine (I actually used the proper tool for it).

I tossed the roller back in there, sure enough, got to a hard spot again. But I did notice that the more turns I got on it, the easier it got. So I literally employed my daughter for the next phase, she came out to provide the honorary oil squirter duty while I hooked up my dril and started to turn the assembly on slow speed. After about 10 secs. of this I stopped, checked things out, everything seemed fine, but I could still feel a stuck spot in there. So while it got a lot smoother it was nowhere near like all the other cams I have ever installed.

So I pulled everything apart and took a few photos of the gear mesh pattern. You can see how the tight spot has let these spotty mesh markings, while the smooth part has a nearly continuous mark left.

I've never messed with anything other than hydraulic flat tappet cams, so maybe this extra tightness/interference is a normal thing for this kind of a retro-fit setup.

I'm curious, does anything here jump out at you guys? Is this a tell-tale sign of something else being wrong with the cam? Could it be bent? I don't think so because the tight spot is only across about three teeth...but who knows?