I'll see if I can clarify.

You are throwing a lot of data out without the analytics.

The other way. That's the analytics with an example that was handy for me to upload. LOL.

Your also saying the distributor never moves and you set initial by welding inside.

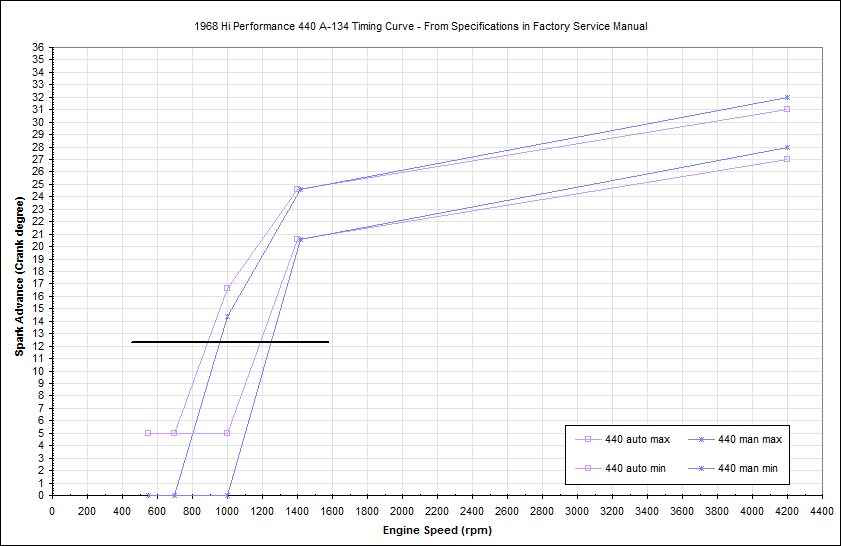

Seriously. For the purpose of

showing the effect on the timing, yes that is what this first graph with the black line shows.

![[Linked Image]](https://board.moparts.org/ubbthreads/ubbthreads.php/ubb/download/Number/393106/filename/1968-440-A134-Timing-shortslots.png)

We could just look at it as advance. That's often harder for people to picture how that effects the timing curve.

This example is about changing the advance so more initial timing can be used without changing the middle and top end timing.

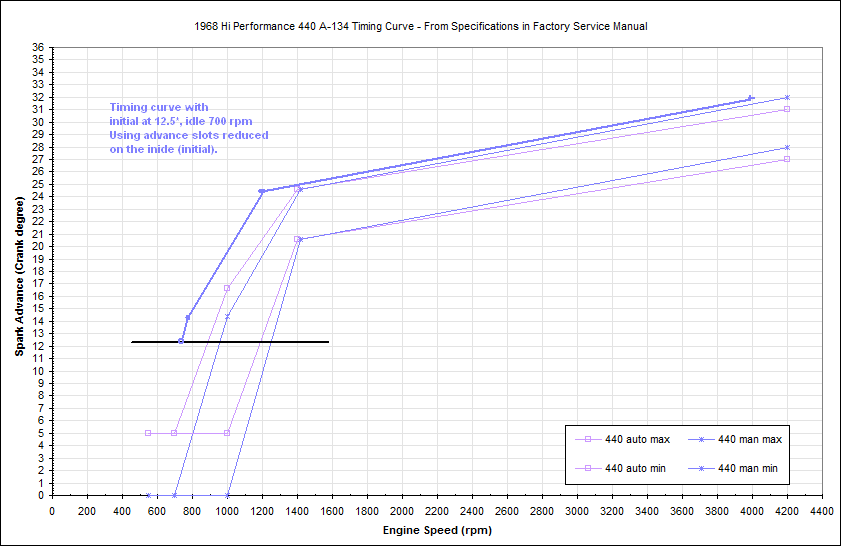

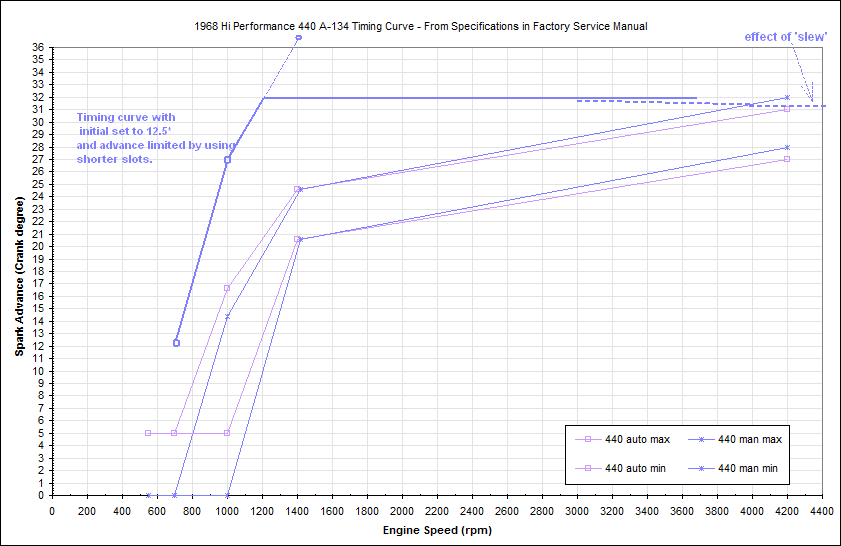

The next graphs were illustrating how the curve would shift if the initial timing desired (12*) was set at 700rpm.

![[Linked Image]](https://board.moparts.org/ubbthreads/ubbthreads.php/ubb/download/Number/393113/filename/1968-440-A134-Timing-shortslots2.png)

Was this just a linear computer equation you used, or a generated graph from actual experimentation?

There is no equations here at all. Those are the timing and advance specifications from the 1968 Plymouth Service Manual. Anything within those lines would have been acceptable. I'm assuming the top or maximum timing for the examples where I sketch in the result of a change. Its not the real curve. Its just four points connected so its easier to see.

I just measured several Prestolite dual point cams. Everything from the Hemi Cap 15deg distributor adv (0 initial), to a tach drive race cam, and several intermediate ones. The inside of the slot is at the exact same point at about 7/16" from collar. The difference is the length moving outward. I do not have as many Chrysler cams loose, but did check two 8s versus a 11 and again the inside distance from collar was the same. In this case 3/8".

That's interesting. I thought I'd seen some variation in distance from collar with the Chrysler cams, but not much. I don't have any points cams to check. Am verious as to the pre-68 non-CAP vs the later ones for the same engines.

One thing certainly seen is angling of the slots in some of the longer advances.

As said in beginning you can do this either way, but that does not mean your tuned right. Weld up to limit mech adv. Set initial by housing rotation, set advance curve by spring choice and tension (adjustable).

Yes.I agree. If you have a selection of springs, or can wind your own, then it doesn't matter. But the heavy long looped spring, which can be really important, is really difficult to find if you don't have a collection already. So that's why for most folks, the inside is easier approach.

Sure, the weights cut a curve, but the rotation is small compared to 360 degree circle. So it can be treated as linear. Well within a tolerance of the mechanical play, bearing clearance, spring rate etc.....

Now you lost me here. LOL. If you're describing the arc of the weights, and the changing angle of the spring, the design is pretty good because it helps to compensate for the centripital force. Some of the aftermarket designs really fail to do that.

![[Linked Image]](https://board.moparts.org/ubbthreads/ubbthreads.php/ubb/download/Number/393106/filename/1968-440-A134-Timing-shortslots.png)

![[Linked Image]](https://board.moparts.org/ubbthreads/ubbthreads.php/ubb/download/Number/393113/filename/1968-440-A134-Timing-shortslots2.png)

![[Linked Image]](https://board.moparts.org/ubbthreads/ubbthreads.php/ubb/download/Number/393114/filename/1968-440-A134-Timing-short-wrong-slew.png)