Moparts

andy's AR Engineering motor plate

Posted By: RustyM

andy's AR Engineering motor plate - 11/03/18 09:33 PM

Anyone know what length ARP studs to get for Andy's motor plate/ RB BLOCK / , 440 Source alum water pump housing?

Thanks

Posted By: ZIPPY

Re: andy's AR Engineering motor plate - 11/04/18 04:17 PM

No idea.

What I usually do is stack up the parts, take a caliper, open the jaws, put the pin in the hole, close the jaws to the desired stick-out and there is the length required. Probably need to round off to whatever's available. Need not be a lab quality caliper for that activity...el cheapo harbor freight or even a plastic one from the hardware store is fine.

Lacking a caliper and just wanting to measure, I'd stick a long screwdriver in the hole until it bottomed out... add however much stick-out you want, pull it out and measure with a tape, and there you go.

Posted By: rowin4

Re: andy's AR Engineering motor plate - 11/04/18 05:12 PM

No idea.

What I usually do is stack up the parts, take a caliper, open the jaws, put the pin in the hole, close the jaws to the desired stick-out and there is the length required. Probably need to round off to whatever's available. Need not be a lab quality caliper for that activity...el cheapo harbor freight or even a plastic one from the hardware store is fine.

Lacking a caliper and just wanting to measure, I'd stick a long screwdriver in the hole until it bottomed out... add however much stick-out you want, pull it out and measure with a tape, and there you go.

That's what I do.

Posted By: JAKE68

Re: andy's AR Engineering motor plate - 11/04/18 05:35 PM

so I don't have to buy one odd length stud I mill that position of pump to the same height as the others. since im not using power strg its ok.

Posted By: Twostick

Re: andy's AR Engineering motor plate - 11/04/18 06:24 PM

The plate is 3/8" thick plus gaskets nuts and washers so you need studs 7/8"-1" longer than the stock bolts depending on how thick the nuts are and how much thread you want showing when it's all torqued up.

Kevin

Posted By: RustyM

Re: andy's AR Engineering motor plate - 11/05/18 12:42 AM

Thanks guys.

No original bolts and yep, i can "all tread it" to measure up, no problem.

I just thought asking might be quicker/easier as someone might have the data or there might be a ARP bolt kit i wasn't aware of.

Thanks Guys, appreciate your time.

Posted By: OhioMopar

Re: andy's AR Engineering motor plate - 11/05/18 01:55 AM

Send Andy a PM?

Posted By: Cab_Burge

Re: andy's AR Engineering motor plate - 11/05/18 05:23 AM

I'm surprised he hasn't chime in with a AR Engr. part # yet

Posted By: cdwmotorsports

Re: andy's AR Engineering motor plate - 11/05/18 06:34 PM

All I used is all thread for my "studs"

Posted By: Sammy

Re: andy's AR Engineering motor plate - 11/06/18 12:07 AM

Anyone know what length ARP studs to get for Andy's motor plate/ RB BLOCK / , 440 Source alum water pump housing?

Thanks

Pretty sure they are 3.5" for the longest ones and 2.5 for the short ones. iirc

Posted By: dthemi

Re: andy's AR Engineering motor plate - 11/06/18 12:24 AM

Just a suggestion,

Don't use gaskets with a motor plate. Use silicone rtv, and tighten it as tight as you like. Using gaskets, you can only tighten the plate up so tight before the gaskets get pushed out. Chassis flex will get them one day too.

Posted By: gsmopar

Re: andy's AR Engineering motor plate - 11/06/18 03:44 AM

Just a suggestion,

Don't use gaskets with a motor plate. Use silicone rtv, and tighten it as tight as you like. Using gaskets, you can only tighten the plate up so tight before the gaskets get pushed out. Chassis flex will get them one day too.

I wish I read this a couple weeks ago! Thanks!

Posted By: markz528

Re: andy's AR Engineering motor plate - 11/07/18 12:05 AM

Just a suggestion,

Don't use gaskets with a motor plate. Use silicone rtv, and tighten it as tight as you like. Using gaskets, you can only tighten the plate up so tight before the gaskets get pushed out. Chassis flex will get them one day too.

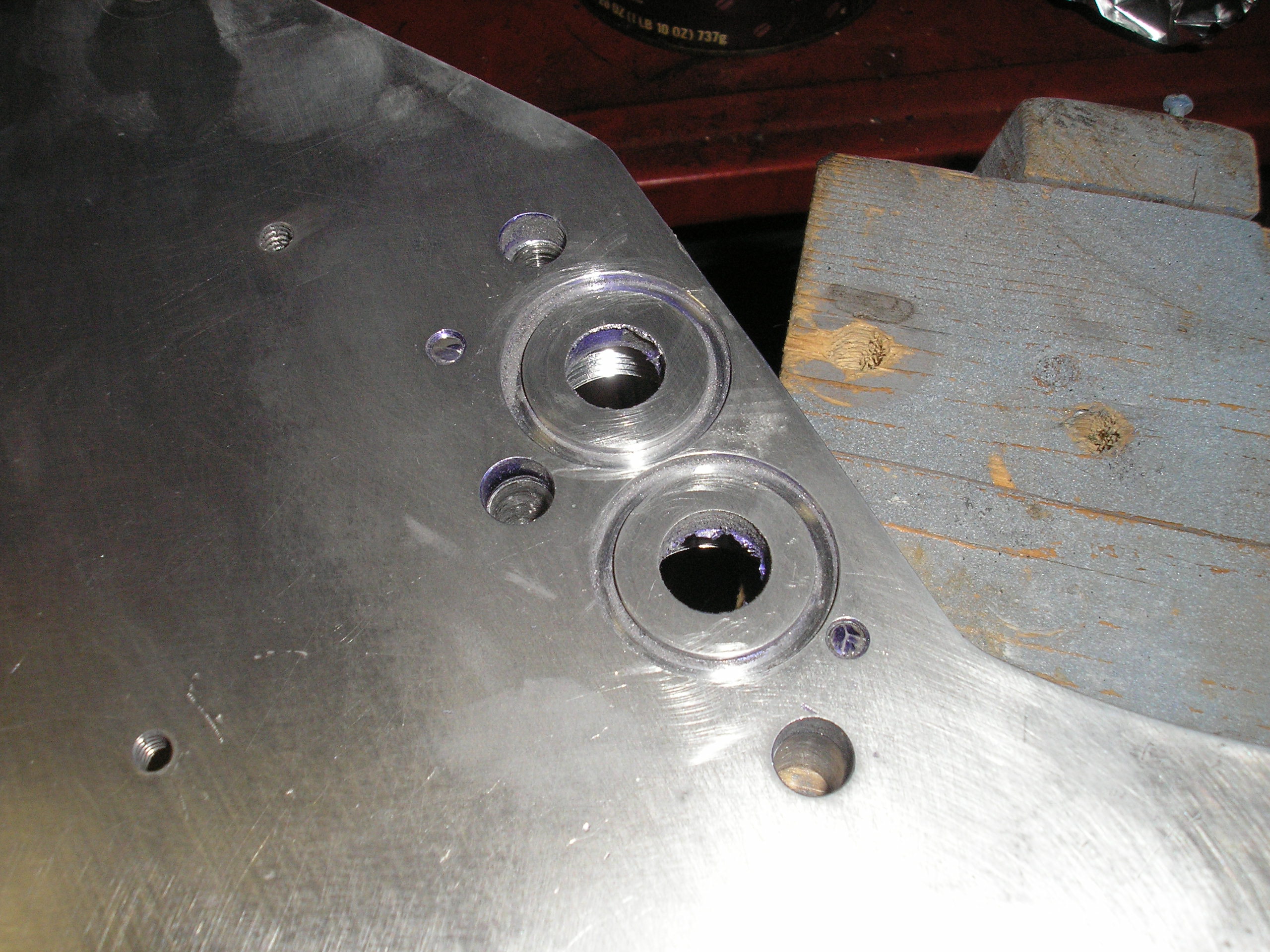

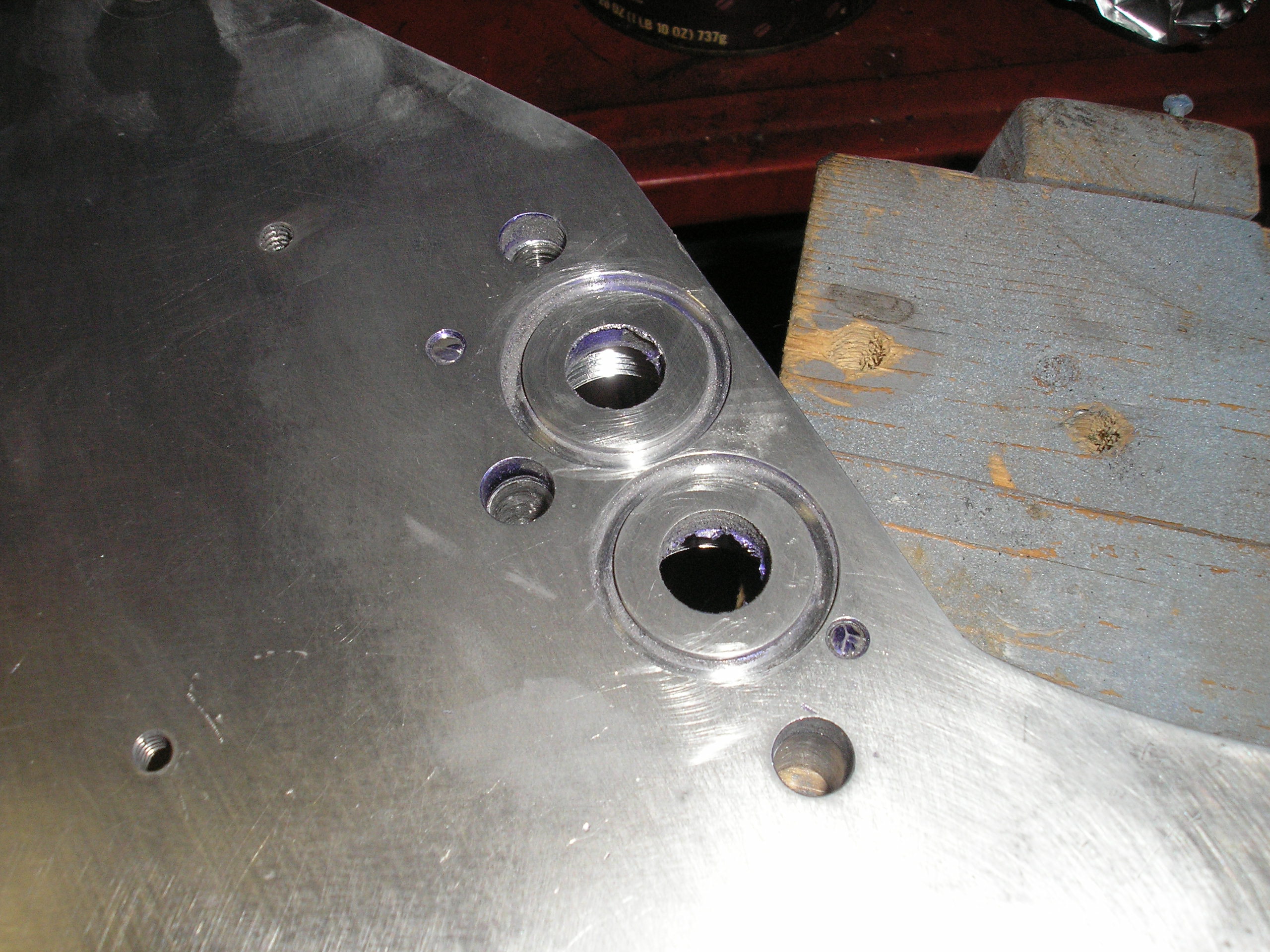

Actually I o-ring the plate to the block - solves all the problems.

Posted By: RustyM

Re: andy's AR Engineering motor plate - 11/07/18 12:32 AM

do you have the plate machined for an O ring?

Posted By: markz528

Re: andy's AR Engineering motor plate - 11/07/18 06:39 PM

Yes.

Posted By: RustyM

Re: andy's AR Engineering motor plate - 11/07/18 11:08 PM

sweet!

Posted By: ProSport

Re: andy's AR Engineering motor plate - 11/08/18 03:30 AM

MarkZ528, that is a great idea!!

I agree with dthemi, RTV, no gaskets. The one time I tried gaskets it bit me in the burnout box.

I use one all-thread stud on each side of the water pump to help hold and align everything on assembly. Then the rest I just measure for bolts.

I also used 'Rivnuts' to mount the motor plate brackets to the frame, worked great on my mid 10 sec Duster.

Posted By: fourgearsavoy

Re: andy's AR Engineering motor plate - 11/09/18 03:48 AM

I have had Superformance gaskets on mine with no sealer at all and it's completely dry. I think the problem is some guys use sealer with gaskets and that is just not right. Two clean machined surfaces and the correct gasket is all you need

Gus

Posted By: Cab_Burge

Re: andy's AR Engineering motor plate - 11/09/18 05:00 AM

I've used the Fel Pro Teflon coated water pump gaskets on a lot of the race motors I've used with both motor plates and elephant ears with no leaks

My next race car will have O rings milled into the motor plate so no need for water pump gaskets

Posted By: rowin4

Re: andy's AR Engineering motor plate - 11/09/18 06:15 AM

As for O-ring plates, Andy , maybe you could offer it as a option? On the gaskets, Years ago with elephant ears the gaskets would start leaking after a short time due to the engine torquing the plates back and forth.. I have never had a gasket leak on Andy's motor plates on either car. I use stock FelPro water pump gaskets.

Posted By: rowin4

Re: andy's AR Engineering motor plate - 11/09/18 06:17 AM

Just a suggestion,

Don't use gaskets with a motor plate. Use silicone rtv, and tighten it as tight as you like. Using gaskets, you can only tighten the plate up so tight before the gaskets get pushed out. Chassis flex will get them one day too.

Actually I o-ring the plate to the block - solves all the problems.

Looking at the picture , the o-ring depth looks pretty deep.

Posted By: racerx

Re: andy's AR Engineering motor plate - 11/09/18 01:09 PM

Is the o-ring really needed

?It does look to be groove deep.

Posted By: madscientist

Re: andy's AR Engineering motor plate - 11/09/18 03:44 PM

Just a suggestion,

Don't use gaskets with a motor plate. Use silicone rtv, and tighten it as tight as you like. Using gaskets, you can only tighten the plate up so tight before the gaskets get pushed out. Chassis flex will get them one day too.

Actually I o-ring the plate to the block - solves all the problems.

Looking at the picture , the o-ring depth looks pretty deep.

The depth of the groove is based on the section of the o-ring.

I'd suspect that they are using a pretty thick section on the o-ring to keep the thing strong enough to not get torn while stuff is moving around.

Posted By: AndyF

Re: andy's AR Engineering motor plate - 11/09/18 06:30 PM

I o-ringed the AR376 SB plate. If you look close you can see that I o-ringed the timing cover also. It is an expensive process for billet parts. I'm not sure how the OEM's make the o-ring parts in production. They must have some special tooling to keep the cost down.

.JPG)

Posted By: dthemi

Re: andy's AR Engineering motor plate - 11/10/18 03:19 AM

O rings are for sure nice, and no clean up swapping stuff around. I'm always in too big of a hurry to go to the track lol.

I've seen more than I can remember, days ended early from gaskets, and motor plates, on all makes. Just seems like an unnecessary risk to me.

Posted By: sgcuda

Re: andy's AR Engineering motor plate - 11/10/18 04:34 PM

Like mentioned, big blocks probably have the worst issues because the only mounting points are the 3 bolts on each side of the block outlets. Just add a tension rod from the lower left corner of the block or timing cover, and come up at about a 45 degree angle to the front plate. That will greatly decrease shearing motion at the mounting flanges for the coolant passages.

Posted By: markz528

Re: andy's AR Engineering motor plate - 11/10/18 05:19 PM

Just a suggestion,

Don't use gaskets with a motor plate. Use silicone rtv, and tighten it as tight as you like. Using gaskets, you can only tighten the plate up so tight before the gaskets get pushed out. Chassis flex will get them one day too.

Actually I o-ring the plate to the block - solves all the problems.

Looking at the picture , the o-ring depth looks pretty deep.

I'm an o-ring junkie. I o-ring anything that I can because its just so clean and does a great job of sealing. No mess to clean up when taking apart! I have yet to have anything leak that I have o-ringed as long as the o-rings are fresh (replaced the o-rings on the valve covers after about 12 years - they were due).

There are several configurations of o-ring grooves. The one I use is quite simple but has served me well. The groove dimension is straight out of the Parker o-ring manual. The one negative on this type of groove is the o-ring is loose and you have to use a dab of grease to keep from falling out during installation.

With my new cnc I am tempted to experiment with different types of grooves. Might on future projects.

Posted By: AndyF

Re: andy's AR Engineering motor plate - 11/10/18 05:41 PM

Harvey Tool makes dovetail o-ring cutters that capture the o-ring. Just drop it in, run the circle one way and then run it back the other way.

http://www.harveytool.com/prod/Dovetail-...lowance_81.aspx

Posted By: TRENDZ

Re: andy's AR Engineering motor plate - 11/10/18 07:41 PM

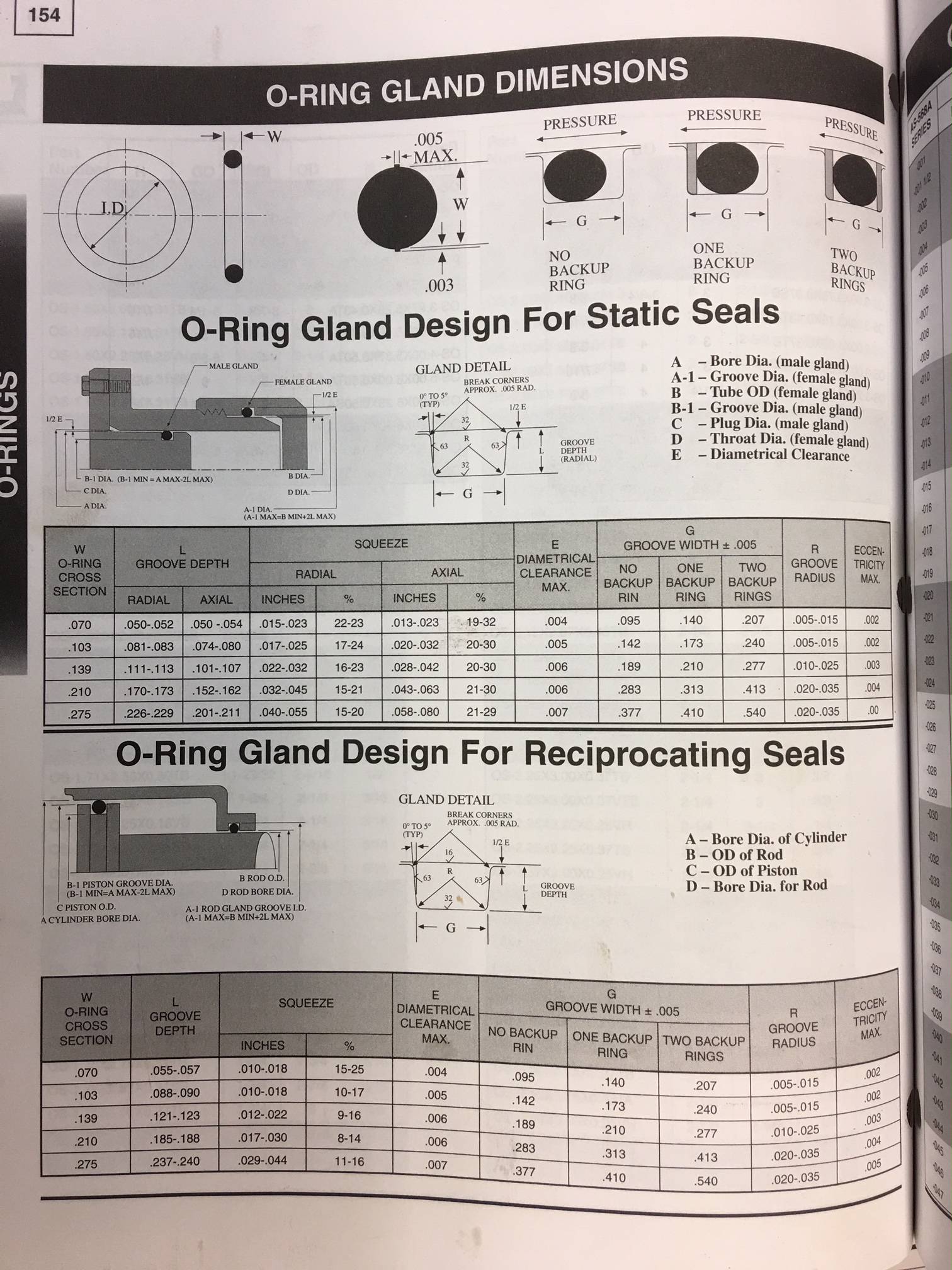

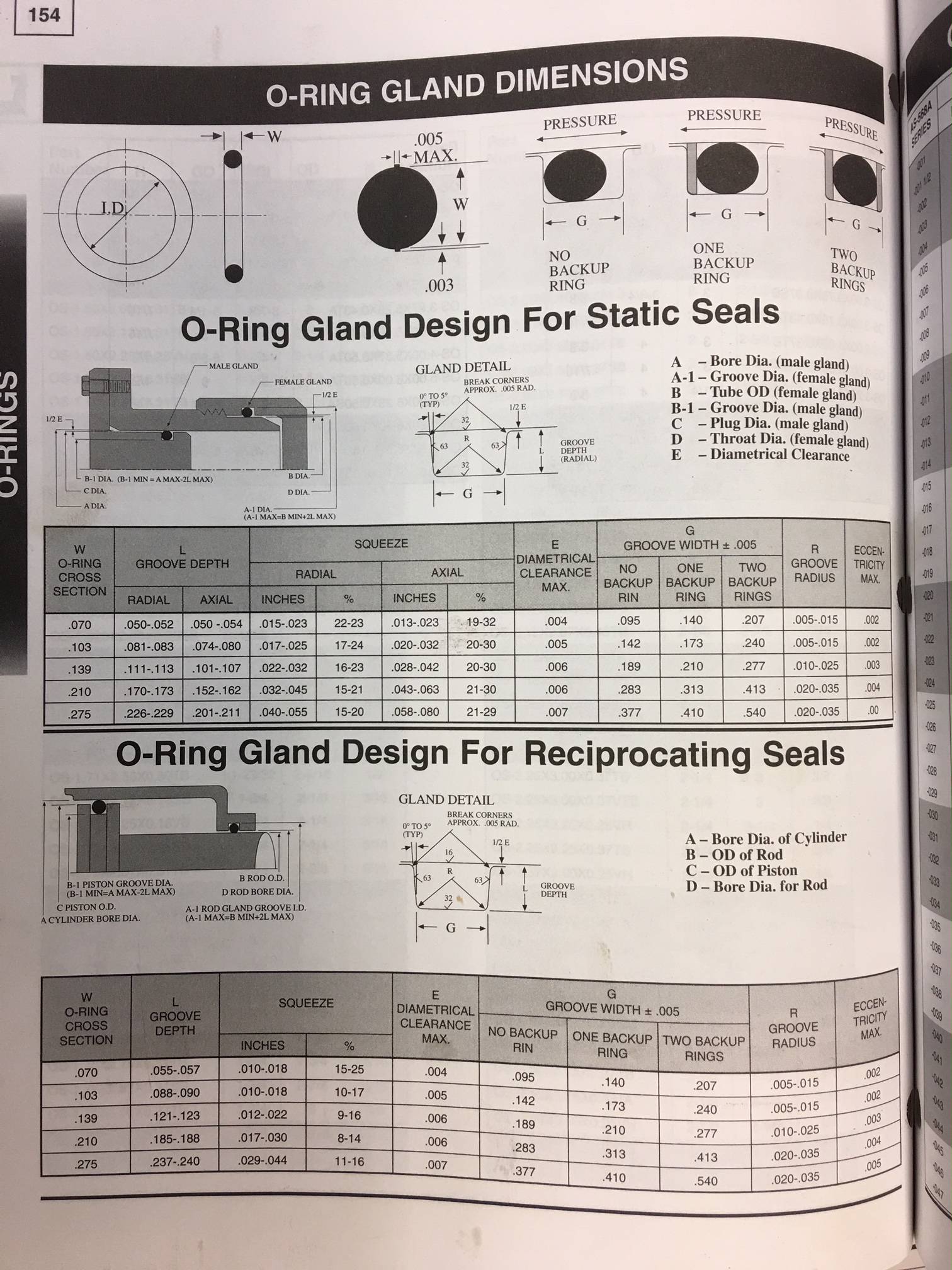

I keep this in my phone, as I too, am an o ring junkie...

Posted By: dthemi

Re: andy's AR Engineering motor plate - 11/10/18 07:56 PM

Quad orings are great for sketchy surfaces too. I use them on hemi spark plug tubes. Kinda like having 2 orings in the same space as one.

Posted By: TRENDZ

Re: andy's AR Engineering motor plate - 11/10/18 09:02 PM

The charts shown are correct for o rings and quad rings. O ring “dash” numbers are equivalent between the two. Back up rings also follow this numbering system. The dash number indicates size. The prefix to the dash number determines material and form.

A great resource for o rings is McMaster Carr. You can find size, material, form on thier site, and the price for a typical bag of 50 rings is usually in the $7.00 range.

Sorry if this derails the topic, but I thought it could be of use.

Posted By: rowin4

Re: andy's AR Engineering motor plate - 11/11/18 03:32 AM

After the machining process o-rings are a lot cheeper than gaskets .

Posted By: markz528

Re: andy's AR Engineering motor plate - 11/12/18 11:48 PM

Andy - thank you very much! I had not seen that solution before and its looks great! I plan on getting one to try.