Posted By: gregsdart

Update; low oil pressure problems. - 09/14/18 01:50 PM

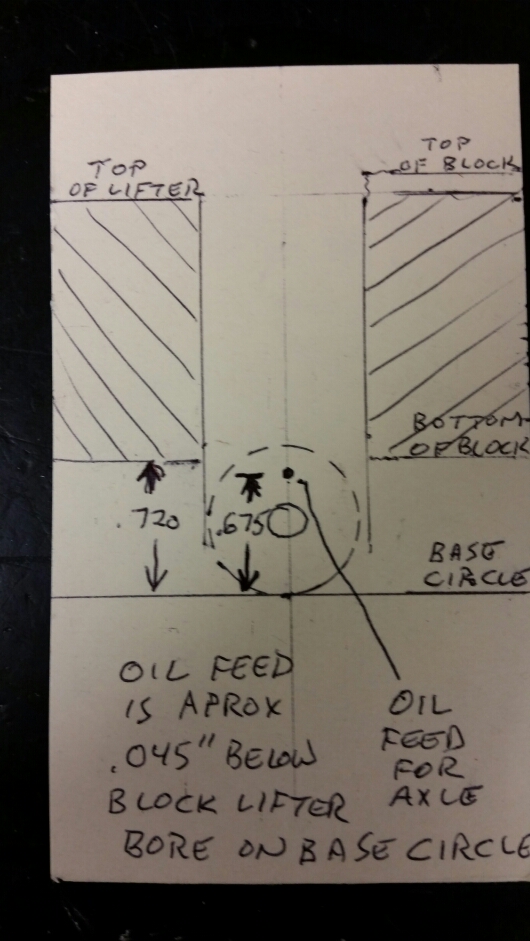

My 528 Megablock motor lost a lot of oil pressure after installing a new rollercam , oil through the pushrod Isky EZ roll lifters and pushrods with very large holes( .050+). Pressure was 40 psi on the gauge in the traps with 10 inch of vacuum, so actual was about 45 psi. I sent the pushrods back and had them restricted to .040. That didn't show a lot of improvement at all. So my guess is the Isky lifters are partly to blame, having a reputation of being a bit undersized from what i hear. I installed a Milodon pump with the five lobe configuration and that brought it up to 50 psi on the gauge, or about 55 to sixty in the traps. The bypass was shimmed till it shows 80 psi cold at startup. The block is bronze bushed, with .062 hole for oil to the lifters. I run Vr1 20w50 oil. Single line pickup system. Still not wildly happy with this deal. Any thoughts?