Moparts

Drilling leaf springs

Posted By: mopar dave

Drilling leaf springs - 04/17/18 02:07 PM

Think there would be any issues with drilling my Cal vert monos? I need to slide the axle back to center the tire in the wheel well and i need the clearance for the bigger tire. Instead of buying another pair of front halfs, why couldn't i just drill another hole where it needs to be? Looks like the new hole would need to be drilled about 1/2" back from the other. I talked to cal vert about this a few years ago and they were totally against it, but i'm sure they don't want the liability. Thanks

Posted By: Clanton

Re: Drilling leaf springs - 04/17/18 02:50 PM

Use a 1/2" spacer in front of the spring eye mount,I did.

Posted By: mopar dave

Re: Drilling leaf springs - 04/17/18 02:58 PM

Thats a great idea, but mine are moved in and welded. Gonna have to replace or redrill front section.

Posted By: 6bblFLASH

Re: Drilling leaf springs - 04/17/18 03:04 PM

Is it solid front bushings/aluminum??

Could you have one machined offset?

Posted By: Clanton

Re: Drilling leaf springs - 04/17/18 03:05 PM

Do you use an aluminum sleeve in the front spring eye?Offset drill it.

Posted By: 6bblFLASH

Re: Drilling leaf springs - 04/17/18 03:14 PM

Do you use an aluminum sleeve in the front spring eye?Offset drill it.

N.E Ohio group logic!! LOL

Posted By: Clanton

Re: Drilling leaf springs - 04/17/18 03:29 PM

Do you use an aluminum sleeve in the front spring eye?Offset drill it.

N.E Ohio group logic!! LOL

Whew ok I thought it was just me.lol

Posted By: 67_Satellite

Re: Drilling leaf springs - 04/17/18 04:06 PM

I just moved the hole the locating pin sits in.

Posted By: Porter67

Re: Drilling leaf springs - 04/17/18 04:12 PM

My calvert springs had a second hole about a inch apart when I removed there two spring clamps to paint them which let me move the axle an inch and cheat on the wheelbase.

If they can sell them with a extra hole, why cant you drill one?

Posted By: GY3

Re: Drilling leaf springs - 04/17/18 04:13 PM

I just moved the hole the locating pin sits in.

Ditto.

Posted By: Bad340fish

Re: Drilling leaf springs - 04/17/18 04:31 PM

Yeah if you need to drill another hole in the perch, not the spring.

Posted By: mopar dave

Re: Drilling leaf springs - 04/17/18 04:55 PM

Yep, thats all i want to do without risk of the spring breaking. Yes, aluminum bushings. It would be easier to redrill the spring locating hole.

Posted By: mopar dave

Re: Drilling leaf springs - 04/17/18 04:58 PM

Didn't think about that. Guess i could drill the perch instead.

Posted By: mopar dave

Re: Drilling leaf springs - 04/17/18 05:00 PM

I don't think they want the holes too close together, but whats too close?

Posted By: johnnycuda

Re: Drilling leaf springs - 04/17/18 06:52 PM

If the car has CalTracs, you may run out of link bar adjustment, also the transmission yoke may not engage the trans enough if the rear is moved back.

Posted By: mopar dave

Re: Drilling leaf springs - 04/17/18 07:12 PM

I dont think the link bars will be an issue, but the yoke might as its already out further than recommend. Whats the recommended? 3/4"? I think mines currently 1". Will have to remeasure everything. Good call. Thanks

Posted By: Clanton

Re: Drilling leaf springs - 04/17/18 08:09 PM

I dont think the link bars will be an issue, but the yoke might as its already out further than recommend. Whats the recommended? 3/4"? I think mines currently 1". Will have to remeasure everything. Good call. Thanks

Good time to come out with the u-joint spacer 1/2" lol just kidding.The brake hose may be short,The axle twist may hit the shock,Drive shaft may be too short.Nothing simple.

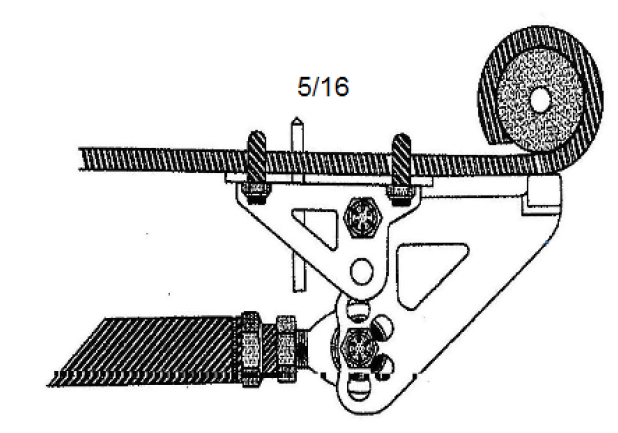

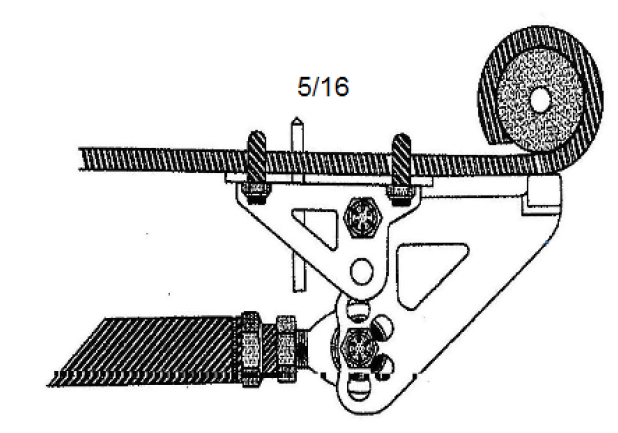

By the way, leveraging the question, I've received my brand new monoleafs from Calvert but currently I'm running with Assassin Traction Bars that require drill a 5/16 hole at leafspring to attach the front link of the bar.

Question: Some problem to drill this hole in the front segment of leaf spring?

Thanks

Posted By: mopar dave

Re: Drilling leaf springs - 04/17/18 08:15 PM

Looks like its a non issue if you have no hole in them. I think cal vert frowns on having 2 holes close together. What is too close i dont know, but sounds like 1" apart is fine.

Posted By: mopar dave

Re: Drilling leaf springs - 04/17/18 08:38 PM

I have another pair of front segments in the attic i could just drill another hole in as the hole in them is too far forward. The best option is just to drill the perches, way easier and less work.

Posted By: AndyF

Re: Drilling leaf springs - 04/17/18 08:40 PM

If you move the axle back an inch you'll have other problems such as shock mounts, clearance with fuel tank, driveshaft length and brake hose length. Double check all of those things before you get too far into the project.

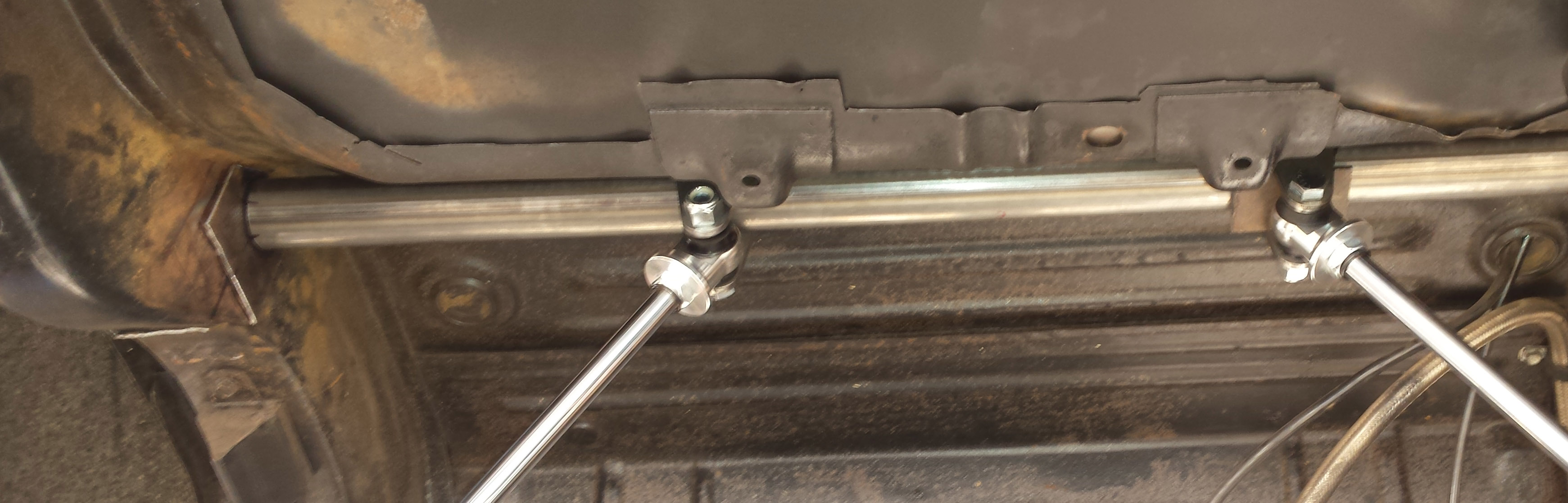

I made my own shock plates to work with CalTracs. It isn't easy to fabricate all of this stuff in a normal garage so be careful of how big the can of worms is that you are opening.

.JPG)

.JPG)

Posted By: mopar dave

Re: Drilling leaf springs - 04/17/18 08:45 PM

Absolutely, dont want to make this too difficult. I will check everything before i start, but 1/2" may be all i need and shouldnt cause any other issues.

Posted By: Porter67

Re: Drilling leaf springs - 04/17/18 09:13 PM

I dont know many who hasnt replaced the upper shock mount because the oem setup is weak and fails with time. A easy adjustment if needed.

The as delivered calvert shocks are big diameter truck shocks where ones like the QA1-a are easily 1/3 less in diameter. Not sure what Dave is using.

To me the only real question is the driveshaft engagement but the way most of us measure for a new shaft is regularly much longer then needed at least if going to the rear.

Yes check everything but overall your not building the next shuttle your just building your car. Daves a smart guy and what hes trying to do isnt rocket science.

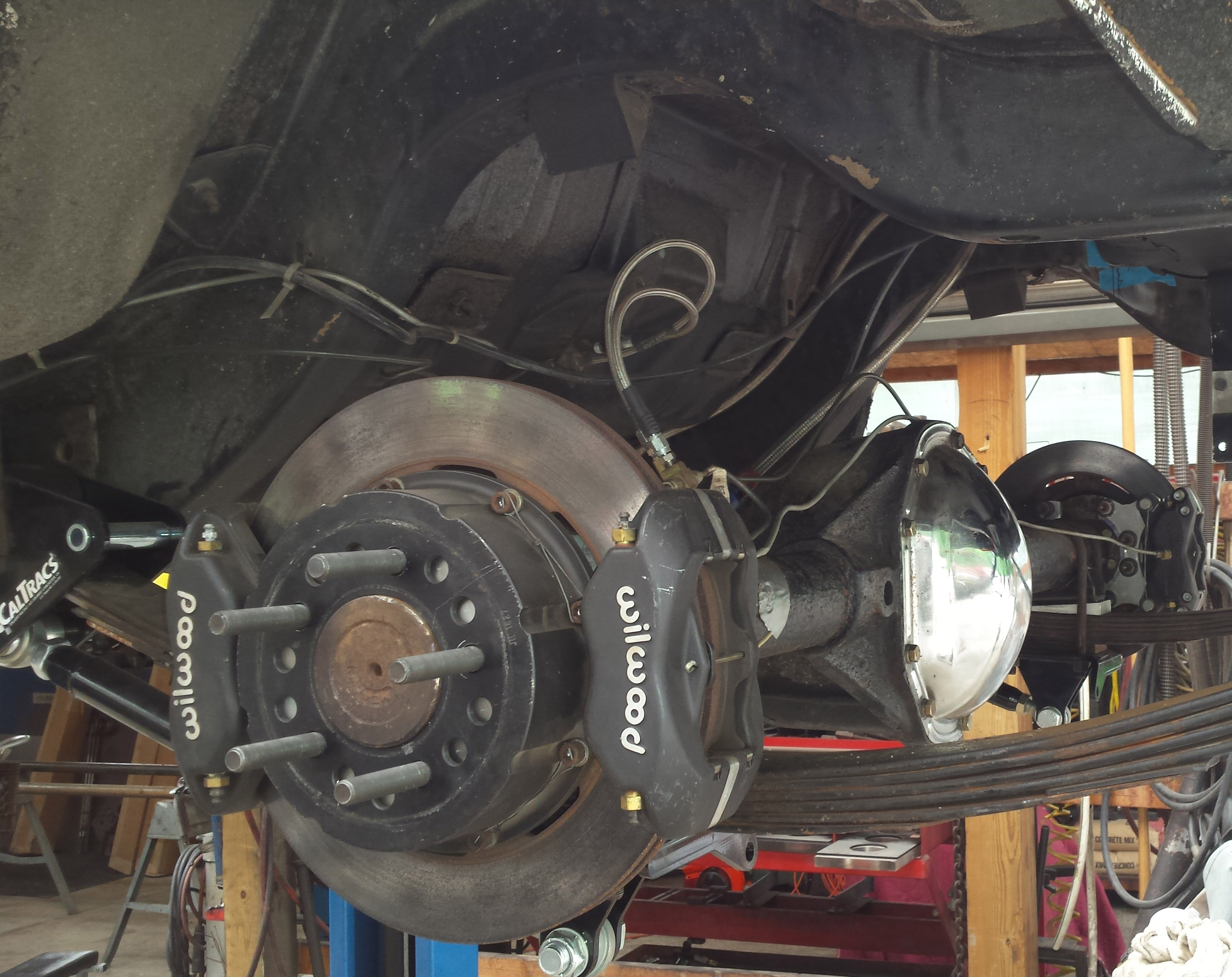

Andy, why did you have to make your own lower plates or did you make a copy of the whole calvert system? They are nice looking parts.

Posted By: cudaman1969

Re: Drilling leaf springs - 04/17/18 09:39 PM

I dont think the link bars will be an issue, but the yoke might as its already out further than recommend. Whats the recommended? 3/4"? I think mines currently 1". Will have to remeasure everything. Good call. Thanks

Good time to come out with the u-joint spacer 1/2" lol just kidding.The brake hose may be short,The axle twist may hit the shock,Drive shaft may be too short.Nothing simple.

Beat the heck out of the front wheel well for clearance, every Mopar stocker does that to get the 30" tire to fit.

Posted By: mopar dave

Re: Drilling leaf springs - 04/17/18 10:03 PM

Not the inner thats the problem. Its the outer wheel well lip. 3/4" of clearance and i'm getting 1" taller tires. I think tire would look better centered in the opening as well.

Posted By: Clanton

Re: Drilling leaf springs - 04/17/18 10:06 PM

You will be able to see if the axle hits the chock.I have QA-1 shocks now.

Posted By: Clanton

Re: Drilling leaf springs - 04/17/18 10:19 PM

Posted By: mopar dave

Re: Drilling leaf springs - 04/17/18 10:45 PM

Ill be sure to check that, but last time i was under there i didnt see any possible issues.

Posted By: ProSport

Re: Drilling leaf springs - 04/18/18 12:31 AM

Beat the heck out of the front wheel well for clearance, every Mopar stocker does that to get the 30" tire to fit.

Sir, please step away from the BFH

Posted By: mopar dave

Re: Drilling leaf springs - 04/18/18 12:57 AM

Should have some time to get under there this friday and get it part and maybe finished if i can drill the perches. Using the cal vert perch not sure what they look like on the bottom.

Posted By: cudaman1969

Re: Drilling leaf springs - 04/18/18 01:57 AM

Not the inner thats the problem. Its the outer wheel well lip. 3/4" of clearance and i'm getting 1" taller tires. I think tire would look better centered in the opening as well.

Didn't really mean the inner, just a phrase. The lip is what I meant, moved mine 1-1/2 " foward at the rocker, on a smooth arc from the top, cut it out, slice it down, weld back. I used the rear lip of an old set of front fenders.

Posted By: Clanton

Re: Drilling leaf springs - 04/18/18 06:29 PM

If you go ahead and drill the plate you may want to put a puck in the old hole to help keep the pin centered

Posted By: mopar dave

Re: Drilling leaf springs - 04/18/18 07:00 PM

Yeah. Been rethinking that. Think ill just drill new holes in the extra pair of front segments. Maybe i can sell the ones on the car now.

Posted By: mopar dave

Re: Drilling leaf springs - 04/21/18 02:54 PM

Measured everything up to get pinion angle. Looks like i have 1* pinion angle according to the spicer calculator.

http://spicerparts.com/calculators/driveline-operating-angle-calculator I only have a couple drill bits that will drill thru the springs. The larger bits will not. I'll have to take them to the machine shop to get them finished. The front segments on the car have a 1.5" arch and the ones replacing them have a 2" arch, so will the 2" arch spring set the ride height higher?

Posted By: Clanton

Re: Drilling leaf springs - 04/21/18 04:47 PM

I would think it would raise it some [1/4"] but the pinion may only gain 1 or 2* nose down.

Posted By: mopar dave

Re: Drilling leaf springs - 04/21/18 07:00 PM

I have a 6* shims going in. Looks like i have plenty of room.

Posted By: Clanton

Re: Drilling leaf springs - 04/21/18 08:46 PM

You got it drilled and in?cool!

Posted By: mopar dave

Re: Drilling leaf springs - 04/21/18 10:55 PM

Those pics are before i started. I was only able to drill up to 1/4", after that drills would not cut. Gonna go look for some different drill bits tomorrow. I'm stopped for now. I pulled these springs out not paying attention to what spring came from what side. mixed up now. are they right and left side specific?

Posted By: mopar dave

Re: Drilling leaf springs - 04/21/18 11:11 PM

If i could have got the springs drilled, I would be done right now and moving on to the engine.

When I drilled mine, I used a center cutting end mill. That and a Bridgeport, but I would think a heavy drill press would do the same thing. I was surprised at how easy they were to drill. I always thought they were made of stronger stuff.

Posted By: mopar dave

Re: Drilling leaf springs - 04/22/18 01:25 AM

Yeah. My small drill bits went right thru, but when i got to the 1/4" going in small steps would not drill or cut any more.

The end mill did it in one step.

If you burned up a lot of bits, you may have hardened the metal right near the hole.

Posted By: moparx

Re: Drilling leaf springs - 04/22/18 03:38 PM

The end mill did it in one step.

If you burned up a lot of bits, you may have hardened the metal right near the hole.

if work hardened by using too fast of a speed drilling, a carbide endmill or drill is your only option now to finish the hole. most guys go way overboard on the rpm of the drill [especially with a hand drill], and tend to burn up the cutting edge, even with quality bits.

Posted By: mopar dave

Re: Drilling leaf springs - 04/22/18 04:12 PM

I was using a drill press. I may just run them down to the machine shop tomorrow.

Posted By: dodger mope

Re: Drilling leaf springs - 04/22/18 07:31 PM

a cheap glass carbide drill bit with a little luck could work,and slower speed

Posted By: mopar dave

Re: Drilling leaf springs - 04/23/18 01:52 AM

Bought a set of Milwaukee cobalt bits for hard metal. Wouldnt touch it. Looks like i will be dropping them off at the machine shop down the road. Thanks guys

Posted By: domingo

Re: Drilling leaf springs - 04/23/18 09:22 PM

drille a hole on the perch instead!

Posted By: mopar dave

Re: Drilling leaf springs - 04/23/18 11:02 PM

Probably should have, but dropped the springs off this morning. First shop turned me away.

Posted By: mopar dave

Re: Drilling leaf springs - 04/24/18 04:48 PM

I'm really second guessing this now. I dropped off the original front sections to the mono's which are 1/2" longer and 1.5" arch. The extra front sections i have are 2" arch and look to be heavier duty. Which front sections do you guys think would be best to use at getting this 511 hooked up at the track? I could just drill the spring perch and use the shorter heavier spring real easy. Thanks

Posted By: Clanton

Re: Drilling leaf springs - 04/24/18 05:05 PM

Sorry to see this is giving you such a problem

Posted By: geo.

Re: Drilling leaf springs - 04/24/18 05:40 PM

Do you have a spring shop in your area? many towns do.

They're used to doing HD truck stuff and may be able to advise you on this.

I hope it works out for you!

Posted By: mopar dave

Re: Drilling leaf springs - 04/24/18 05:41 PM

Its really not that big of a deal. Just curious if the heavier spring would be the one to use with my current combo. The original springs were installed when i had a small block

Posted By: mopar dave

Re: Drilling leaf springs - 04/28/18 03:32 AM

you were absolutely right. My drill speed on my drill press was too fast. Today i tried my fathers drill press which is set up with a slower speed and we drilled right thru without too much trouble. Springs are now installed and maybe tomorrow i can finish that up and get the car on the ground. Thanks

Speeds and feeds will get you every time. Glad to see you got it sorted out.

Posted By: mopar dave

Re: Drilling leaf springs - 04/28/18 03:18 PM

Thanks. I decided to use the shorter heavier front segment. Maybe this will help with getting it hooked up at the track.

Posted By: moparx

Re: Drilling leaf springs - 04/28/18 03:56 PM

an interesting story regarding speeds and feeds. my brother installed a railing in a house he owned one time. just one of those cheapy, imported, lumber house specials. not thick steel by any standards, maybe .094-.100 at best. all the holes drilled ok until the last one. it was a real toughie ! my brother thought it was a combination of imported steel, who knows quality of the bit, and the fact there was many holes drilled with a used bit to start with. anyway, he just gives it all he got and finally, got it pushed through [hand drill of course]. the hole looked like he used a torch of some kind to blow it through, and the drill was "slightly" deformed on the tip. he had the drill wide open, and was pushing with all he had. one spin of the drill to cool it off some, and yep !

it was in REVERSE ! i still jack him about that from time to time !

Posted By: Clanton

Re: Drilling leaf springs - 04/28/18 04:23 PM

So the shorter spring allowed you room to drill the hole away from the factory hole?And still move the axle back as intended?

Posted By: mopar dave

Re: Drilling leaf springs - 04/28/18 04:29 PM

Yep. only had to move it 1/2". Dont see issues yet.

Posted By: Clanton

Re: Drilling leaf springs - 04/28/18 05:17 PM

Yep. only had to move it 1/2". Dont see issues yet.

You should be ok,The axle windup/shock controle is key.

Posted By: Sport440

Re: Drilling leaf springs - 04/28/18 06:17 PM

Did your driveshaft yoke clearance increase by 1/2"? You said you thought you may of already been sitting at 1" , but wasn't sure.

Posted By: mopar dave

Re: Drilling leaf springs - 04/28/18 07:18 PM

Not finished yet. With the pinion nose down t might be a wash.

Posted By: mopar dave

Re: Drilling leaf springs - 04/28/18 11:51 PM

Ran into a snag. Heavier springs set the rear of the car higher, about 1-1.5" higher. I don't like it. There coming back out tomorrow and i'll wait til the other front sections at the shop get done.

Posted By: mopar dave

Re: Drilling leaf springs - 05/04/18 12:57 AM

Picked up my original front sections from the shop. Got them installed. With a 6* shim i now have 4* pinion to shaft angle. Gained some tire clearance, but now may need a new drive shaft. The slip yoke is 1.75" from being all the way into the tail shaft. Didnt measure the yoke, but i would guess its 6 or 7" long where it goes into the tail shaft. That still gives me 4-5" of sline contact. Enough?

Posted By: madscientist

Re: Drilling leaf springs - 05/04/18 01:02 AM

Picked up my original front sections from the shop. Got them installed. With a 6* shim i now have 4* pinion to shaft angle. Gained some tire clearance, but now may need a new drive shaft. The slip yoke is 1.75" from being all the way into the tail shaft. Didnt measure the yoke, but i would guess its 6 or 7" long where it goes into the tail shaft. That still gives me 4-5" of sline contact. Enough?

That's borderline.

Posted By: Clanton

Re: Drilling leaf springs - 05/04/18 02:38 AM

I agree it is borderline but not that you could not drive with it.There will be a vibration if there is a real problem and could try it going slower.I think the runout was .060 on the slip yoke

Posted By: Sport440

Re: Drilling leaf springs - 05/04/18 03:37 AM

Picked up my original front sections from the shop. Got them installed. With a 6* shim i now have 4* pinion to shaft angle. Gained some tire clearance, but now may need a new drive shaft. The slip yoke is 1.75" from being all the way into the tail shaft. Didnt measure the yoke, but i would guess its 6 or 7" long where it goes into the tail shaft. That still gives me 4-5" of sline contact. Enough?

The splines don't start on the inside of the yoke until about a 1.25" or more in. So you have a lot less spline engagement then you think without truly measuring. Your borderline all right. You probably have less then 2",s of spline contact

Posted By: Clanton

Re: Drilling leaf springs - 05/04/18 03:52 AM

Picked up my original front sections from the shop. Got them installed. With a 6* shim i now have 4* pinion to shaft angle. Gained some tire clearance, but now may need a new drive shaft. The slip yoke is 1.75" from being all the way into the tail shaft. Didnt measure the yoke, but i would guess its 6 or 7" long where it goes into the tail shaft. That still gives me 4-5" of sline contact. Enough?

The splines don't start on the inside of the yoke until about a 1.25" or more in. So you have a lot less spline engagement then you think without truly measuring. Your borderline all right. You probably have less then 2",s of spline contact

I think my Dana yoke has splines to the opening,just saying

Posted By: Sport440

Re: Drilling leaf springs - 05/04/18 03:58 AM

That could be, thought ive seen a few myself like that. But remembered that a lot don't, checked two that I have and both are recessed by about a 1.25/1.5 or so. Figured he should check his to make sure.

Posted By: mopar dave

Re: Drilling leaf springs - 05/04/18 04:15 AM

I'll have to check that, but i don't think so. I had to get the splines lined up before the yoke would even start to go on the trans shaft.

Posted By: mopar dave

Re: Drilling leaf springs - 05/04/18 04:24 AM

I figured i can street drive it as long as it doesn't vibrate and i don't think it will. It fits very snug. Whats the worst thing that could happen at the track?

Posted By: madscientist

Re: Drilling leaf springs - 05/04/18 04:35 AM

I figured i can street drive it as long as it doesn't vibrate and i don't think it will. It fits very snug. Whats the worst thing that could happen at the track?

It's far enough out of the shaft to wobble and then BOOM out goes the drive line.

Posted By: Clanton

Re: Drilling leaf springs - 05/04/18 03:16 PM

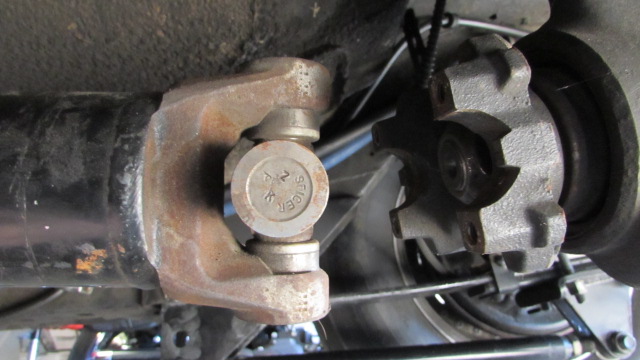

Posted By: mopar dave

Re: Drilling leaf springs - 05/04/18 03:37 PM

Thanks for the pic. Looks like only 5.5" long. Mine is a spicer as well. Looks like the one in the pic has way less spline contact than mine.

Posted By: Clanton

Re: Drilling leaf springs - 05/04/18 07:15 PM

Less contact how?The output goes 1" past the seal/shine on the yoke.If yours is longer it may be splined to the tip like mine.I don't know.

Posted By: mopar dave

Re: Drilling leaf springs - 05/04/18 08:30 PM

I only have about an inch of rust showing on mine.

Posted By: Clanton

Re: Drilling leaf springs - 05/04/18 08:42 PM

I checked mine and I only have 2 1/2" of spline contact with the output shaft That is half of the total spline in the yoke.I twisted the spline and just replaced the yoke and now think I mistook a longer drive shaft when the splines were just stopping the yoke from going on more.

Posted By: Clanton

Re: Drilling leaf springs - 05/04/18 08:46 PM

I only have about an inch of rust showing on mine.

Yep mine is worse than yours.

ps:I will make the drive shaft longer instead of taking out the 1" shim that moved the springs back.

Posted By: mopar dave

Re: Drilling leaf springs - 05/05/18 05:00 AM

I have a rubber dust boot on the end of my tail shaft and the main shaft protrudes about a 1/4" past that rubber boot as well.

Posted By: Sport440

Re: Drilling leaf springs - 05/05/18 05:48 AM

I have a rubber dust boot on the end of my tail shaft and the main shaft protrudes about a 1/4" past that rubber boot as well.

I know of two sizes of dust boots, theres a shorty 1" boot or so and a longer 2.5" boot or so. I'm sure they are mated with the correct yoke. Not sure about the specifics about the differences. But originally these were and are street production cars.

I myself used the shorty boot to help achieve about 3/4 to 1/2" clearance from bottoming out the yoke. Ive been there with the wider clearances of the driveshaft wobble and actually loosing one. Was fortunate that I didn't catapult when I lost the loose clearance one.

Posted By: Clanton

Re: Drilling leaf springs - 05/05/18 02:45 PM

To make full use of my yoke I could make my driveshaft 2" longer and still have room to back it out of the axle with 3/4" to clear the cap that is 1/2" deep on the pinion.Do you know what you have yet?

Posted By: mopar dave

Re: Drilling leaf springs - 05/05/18 03:01 PM

no. been busy. If i have time today i will pull the shaft out and measure the slip yoke. Looks like my drive shaft is 1" too short at the moment. Gonna call strange if i need a new shaft.

Posted By: Clanton

Re: Drilling leaf springs - 05/05/18 03:11 PM

I am lucky there is a place near me Custom clutch and u joint in Cleveland I just drive to in 30 minutes.Keep us posted.

Posted By: mopar dave

Re: Drilling leaf springs - 05/05/18 03:47 PM

Ok, i have some pics. now, from the base of that slip shaft to the edge of the boot measures 2", but the main shaft is out past the boot 1/4".

Posted By: mopar dave

Re: Drilling leaf springs - 05/05/18 03:50 PM

couple more. The yoke is splined to the bottom and measures 5.5" deep.

Posted By: mopar dave

Re: Drilling leaf springs - 05/05/18 03:53 PM

couple more. The u joint measures 3" from the pinion saddle.

Posted By: mopar dave

Re: Drilling leaf springs - 05/05/18 03:53 PM

what length of drive shaft should i order?

Posted By: Clanton

Re: Drilling leaf springs - 05/06/18 02:42 AM

I think if you put a jack under the pinion the length will be a little shorter but maybe only 1/4".No takers on the length?

Posted By: Clanton

Re: Drilling leaf springs - 05/06/18 02:45 AM

couple more. The u joint measures 3" from the pinion saddle.

So that 3" is with the yoke all the way in the trans?

Posted By: OhioMopar

Re: Drilling leaf springs - 05/06/18 03:02 AM

what length of drive shaft should i order?

If you order from Dr. Diff, he asks for two measurements, and some other questions, of course. But Idk if you have to call to have something other than a 1350 joint shaft made.

Posted By: mopar dave

Re: Drilling leaf springs - 05/06/18 03:27 AM

yes, with it all the way into the trans. I calculate 2 3/4 of spline engagement statically. Probably 3" under load. Enough or do i need a new drive shaft?

Posted By: Clanton

Re: Drilling leaf springs - 05/06/18 03:39 AM

I would go with a 46" ds but I fear the rubber boot is still holding the yoke out.

Posted By: mopar dave

Re: Drilling leaf springs - 05/06/18 03:42 AM

The boot flattens out when i slide the yoke all the way in.

Posted By: Clanton

Re: Drilling leaf springs - 05/06/18 03:43 AM

The cove on the yoke should go to the trans housing not the boot so you need to add the boot length.

Posted By: Clanton

Re: Drilling leaf springs - 05/07/18 06:00 PM

I would think if you took your measurement with the yoke cove just back from the boot 1/4" to 1/2" the length would be good to pull the u joint from the pinion and have room.I think this will give you the 1" you want to be able to move it.

Posted By: mopar dave

Re: Drilling leaf springs - 05/07/18 07:10 PM

Yep, yur right. Just spoke with Dynotech drive shafts and they suggest 1" from pinion yoke. Shaft should be 45.5" to be correct. 2 3/4" Spline contact is enough for strength. The problem is with the front u joint to far away from the tail shaft bushing support.

Posted By: Clanton

Re: Drilling leaf springs - 05/07/18 07:58 PM

Thank you for your information you got!How much do you think a new shaft with ends and joints will cost?250$Wait I bet with new ends,ballance will be more like 350$

Posted By: Clanton

Re: Drilling leaf springs - 05/07/18 08:12 PM

My guy said 335+tax 3.5" mild steel new ends,joints weld balance 2 days tops.

For anyone in the area 216-431-1630 3417 St Clair Ave Cleveland Custom clutch n joint

Posted By: mopar dave

Re: Drilling leaf springs - 05/07/18 10:17 PM

No problem. My current drive shaft is from Dynotech. They quoted me $415 without slip yoke. Gonna call Strange yet. Thanks

Posted By: huimerind

Re: Drilling leaf springs - 05/07/18 10:40 PM

Sorry, if off topic, but how thick is the caltrac mono leaf front segment?

Posted By: mopar dave

Re: Drilling leaf springs - 05/07/18 11:01 PM

I will have to guess about 1/4". Im at work right now.

Posted By: mopar dave

Re: Drilling leaf springs - 05/08/18 12:08 AM

Strange suggests 3.5" chromemoly tube with 1350' and no yoke$435. Wow. Way more than i was looking to spend.

Posted By: Clanton

Re: Drilling leaf springs - 05/08/18 01:01 AM

Strange suggests 3.5" chromemoly tube with 1350' and no yoke$435. Wow. Way more than i was looking to spend.

LOL ask if they price match.This is tough I know to invest

Posted By: mopar dave

Re: Drilling leaf springs - 05/08/18 01:37 AM

Will make some more calls tomorrow.