Moparts

"Dynamic Comp Ratio" doesn't mean ZIP!!!

Posted By: BradH

"Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/29/18 11:47 PM

I've seen another round of posts here and elsewhere recently where the belief is that you can calculate a "Dynamic" CR based on the engine's static CR and IVC event to determine the octane requirement (tolerance?) of an engine.

It's bullsh!t.

Shoving a big-a$$ cam in a high CR engine in order to lower the cranking pressure is nothing but a Band-Aid to lower the operating compression ratio (the engine's Volumetric Efficiency % vs the calc'd "static" CR at at a given RPM) up to the RPM point where the engine is operating at 100%+ VE. At that point, the REAL "dynamic" cylinder pressure is going to be the calc'd "static" CR + the additional cylinder filling resulting from the VE efficiency exceeding 100%.

It's not me who is trying, or has tried, to get people to understand that DCR isn't telling you what you think it does.

==> Tim Wusz (formerly of Union 76 Racing Fuel and currently with Rockett Brand Racing Fuel) was quoted in Hot Rod at least 20 years ago that you can crutch the octane needed by bleeding off more pressure with extra duration, but that it only works up to a certain RPM point for a given engine, and you'll most likely need to run the ignition pulled back from optimum for an additional margin of safety. Beyond that point, you're at a very high risk of detonating.

==> Years ago on SpeedTalk, the late Harold Brookshire (the founder of UltraDyne Cams) and Mike Jones (of Jones Racing Cams) were involved in a lengthy thread where they both tried to get people to understand how the "Dynamic" CR calculation is anything BUT dynamic, and should not be used as a parameter for either building an engine or targeting a particular octane to use with that build.

And today I stumbled across a short article (since I'm not going to go digging thru the SpeedTalk archives to revive that old thread) where the author does a pretty decent job of explaining it, IMO:

http://www.matrixgarage.com/content/why-dynamic-compression-ratio-nearly-uselessDo I expect everyone is going to agree with this?

He11 no!

There are still some well-known engine builders who push the DCR approach in their pump-gas builds. If it works for them...

Agree or not, IMO you should at least read about it so that your understanding of this approach -- and why it's considered seriously flawed by some -- is clearer.

Carry on!

Posted By: Dragula

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 12:09 AM

I have never agreed with it. Read a bunch of the posts on here about it...compression is compression in my eye's. Show me the math I have always said...You can calc compression, and that I know is a fact.

I have learned what I can and cannot do on pump gas....because I just ain't going to pony up for race gas...

Posted By: Rob C

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 12:09 AM

Agreed! I keep telling people, but, you just can’t fix stupid when the cool aid ruined the grey matter further. Good luck! Keep preaching!

Posted By: lewtot184

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 12:31 AM

dynamic compression ratio stuff is "Oh-Hum" to me. never got lost in it. at best it's a moving target in my opinion.

Posted By: polyspheric

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 12:40 AM

I agree, well said, thanks.

Posted By: TRENDZ

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 12:55 AM

So what your saying is there is no validity in using lsa/ duration to widen the range that low octane fuel will operate in.

Wrong.

Posted By: Hemi_Joel

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 01:05 AM

My thinking was the same as BradH, so I asked someone who is pretty smart on this stuff. (A successful enginemasters contestant) If I remember right, he said that peak VE occurs at the same rpm as peak torque. Below that rpm, with a big womping cam, you are bleeding off enuff cylinder pressure to reduce the chance for detonation. And above peak torque, ve drops off naturally, also diminishing the chance for detonation.

Posted By: B3RE

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 02:23 AM

I've been trying to explain this to guys for years. The IVC alone doesn't acount for volumetric efficiency. The port CSA and approach angle, the intake ram tuning effect, rpm, and several other factors play a role. A 10:1 383 with stock 906s and a long runner dual plane will detonate before the same spec engine with -1s and a large single plane. Higher port velocity is more efficient at filling the cylinder at lower rpm where detonation occurs. That inertia is going to be different among different engine combinations, regardless whether the dynamic number remains the same.

Posted By: Rob C

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 06:24 AM

Oh oh Mike! Your talking science now, your going to confuse people!

LMAO!!!!

Nevermind that smarter people than us figured this out first years ago and told us in print several times as well as demonstrated it in there winning race engines.

Naaaaaaaaa, that would never work....

Posted By: 451Mopar

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 07:58 AM

As mentioned, the name is misleading. It is not dynamic at all, just a re-calculation of compression stroke length at the intake closing point and a rough estimate where that point is anyhow. I won't say it means zip, it does give a good indication of cranking compression pressure, and if the compression is way off for the cam size.

I don't recall where the DCR relationship to fuel octane came from?

It might have been an article comparing the DCR ratios of different "pump" gas engines? The calculation is being overstated and misused for estimating octane requirements.

Posted By: dizuster

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 03:47 PM

DCR is a nice easy way to show how the late intake valve closing point changes effective compression ratio. Sure with the right cylinder head the VE% still gets at or over 100% at some RPM. But with late IVC that RPM is always higher right? (big cams turn more RPM). The higher the RPM, the less prone the engine is to detonation.

Meaning without a doubt... late IVC (lower DCR) is better for detonation resistance.

This is a GREAT article about detonation if you have time to read it. That being said... some excerpts below about DCR DOES mean ZIP.

https://www.sciencedirect.com/science/article/pii/S0360128516300764From section 5.1

"Conventional knock is a race between the flame in the engine and the thermal auto-ignition of the unburned “end gas” [1]. The principle for avoiding engine knock is that the time of flame propagation to the end gas (τ1) is less than the time of the end-gas auto-ignition (τ2)."Obviously the faster the engine is turning, the shorter the combustion time, and the less time the end gas (part of the mixture away from the plug) has to auto-ignite. Since big cams have late IVC, they naturally want to turn more RPM. They also naturally bleed off pressure at lower RPM where detonation is most likely.

Again as stated in the paper above...

5.1.5.3. Lowering effective compression ratio [110,127,258,262,317–321]

Variable valve timing (VVT) is a practical way to change effective compression ratio at relatively low cost for the different engine operating regions. Late intake valve closure (LIVC) is commonly used at high load to achieve a lower effective compression ratio to avoid knock. Again... from another SAE paper...

Experimental investigation on early and late intake valve closures for knock mitigation... The application of Miller cycle through Late Intake Valve Closure (LIVC) or Early Intake Valve Closure (EIVC) for knock mitigation at high load on a turbocharged downsized spark ignition engine was experimentally investigated. By reducing the effective compression ratio due to a shorter compression stroke and hence achieving lower charge temperatures inside the cylinder, significant mitigation of knock tendency could be obtained. Don't get me wrong... being at the track and trying things is VERY valuable. People want to discredit science based findings because "they saw once" or "I heard once", or "I knew a guy who" type single events in an uncontrolled environment. We as racers have a lot of opinions on technical things based on VERY limited experience compared to the OEM's and universities. These guys are looking at knock at 240,000fps cameras, spending MILLIONS of dollars trying to prevent it to improve horsepower and efficiency.

If you look around for these types of published papers, you will see that it's basically common knowledge that a late IVC helps with detonation. Yet here we are still arguing about it...

Posted By: BradH

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 04:55 PM

Posted By: BradH

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 05:16 PM

Just to be clear, I did NOT say that a later IVC doesn't reduce cylinder pressure at lower RPM. What I said, and then referenced people waaaay smarter than I am in this arena, was that you can't calc a single DCR value and use it for an accurate build parameter and measure of octane requirement. And, that the late(r) IVC approach is basically a crutch with limitations on its effectiveness.

If I had VVT and a computer-controlled ignition that detects knock, etc. and could also adjust the timing as necessary, then that would be a highly sophisticated Band-Aid for the basic scenario of excessive cylinder pressure.

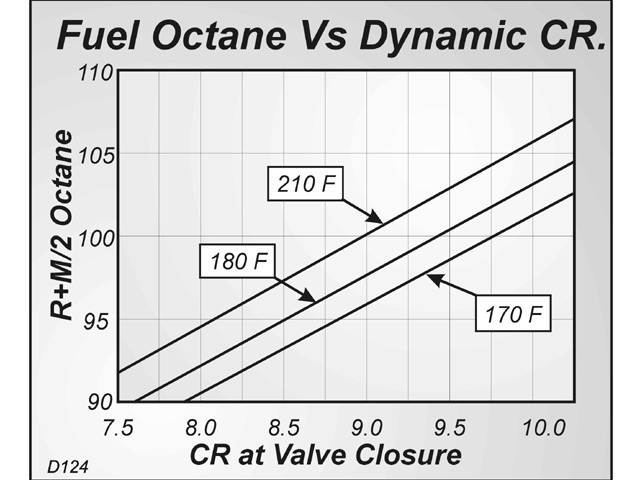

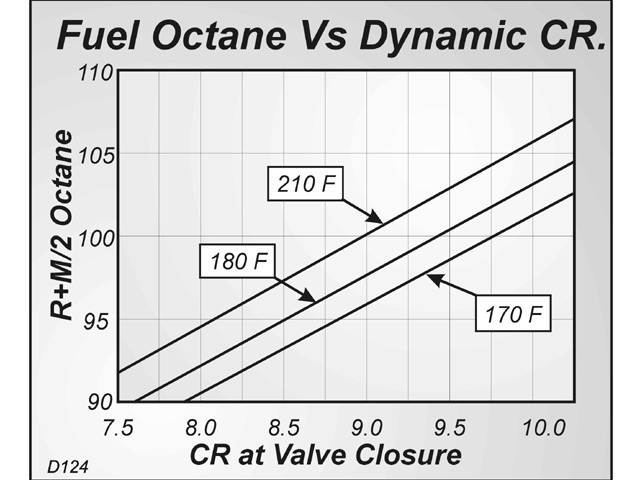

How many people on this board are using that sort of technology w/ their "traditional" SB / BB / Gen II Hemi builds?Someone asked where the correlation between DCR and octane was made: David Vizard, well-known engine tech writer, has a chart he's used in articles and his books that I posted below.

I own a LOT of DV books and have learned a bunch from him, but this stuff can't be interpreted as a One Size Fits All thing. You can't even get people to agree on what cam/lift point to use for setting the IVC event, so how can you derive anything about a value for which 5 different people might get an equal number of different answers?

Posted By: AndyF

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 05:44 PM

If you are building an engine then use the static compression ratio that works with the fuel you want to run. Pick a cam based on the power band that you want the engine to work in. The DCR is just something that is left over after you make those other decisions.

Posted By: 451Mopar

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 06:53 PM

Someone asked where the correlation between DCR and octane was made: David Vizard, well-known engine tech writer, has a chart he's used in articles and his books that I posted below.

I own a LOT of DV books and have learned a bunch from him, but this stuff can't be interpreted as a One Size Fits All thing. You can't even get people to agree on what cam/lift point to use for setting the IVC point, so how can you derive anything about a value for which 5 different people might get an equal number of different answers?

Thanks, I was the one wondering where that came from.

Your right on the IVC point also, some say to use 0.050 duration numbers, others advertised duration (0.006" hydraulic, and 0.020" solid?) At least the chart does show a difference for different temperatures, usually totally ignored in most discussions.

There is also the topic of "quench" distance, but usually no discussion of the "quench" area. There is a good difference between the "closed chamber" RPM / Stealth type heads with a "D" type chamber, and the Victor / Trick Flow heads with a heart shaped chamber. Not to mention the difference in spark plug locations and bore size.

For me, I use the advertised duration numbers to estimate IVC, and usually if the effective compression ratio is less than 8:1 I believe that I am giving up some low end torque and efficiency that could be improved with more static compression?

Posted By: B3RE

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 07:14 PM

The effective ratio is the same as static once the engine reaches 100% volumetric efficiency. If, for example, 8.5:1 dynamic was the cat's meow for pump gas, then why not build every engine for 8.5:1, and close the intake valve at BDC. I can hear the keyboards pounding already. But Mike, but Mike, you have to close it later so the flow inertia continues to fill the cylinder after BDC, and there is still adequate curtain area at BDC to flow air to fill the cylinder effectively.

Well, EXACTLY! Inertia comes into play as soon as the engine fires off, and there are too many factors involved to "shoot" for a given DCR. The VVT engines, as Brad stated, are computer controlled to run higher static numbers, make more power, and be more efficient.

In short, the engine doesn't give a rat's patootie when the intake valve closes. It only knows how much of a charge is in the cylinder. Make peak torque at a higher rpm, have less chance of detonation. Even the exhaust system will have an effect on peak torque.

Posted By: BradH

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 08:28 PM

... you can't calc a single DCR value and use it for an accurate build parameter and measure of octane requirement...

You can't even get people to agree on what cam/lift point to use for setting the IVC event, so how can you derive anything about a value for which 5 different people might get an equal number of different answers?

More on the comments above, and then I'll let this run its course regardless of what direction is goes.

Let's take a real-world example from my latest build on the predictive power of a DCR value:

1. I've profiled my cam lobe curve and know that the SAE seat duration (measured at .004" lobe lift above lash) for my solid roller is 307* with .018" lash.

2. Using Wallace Racing's camshaft event calculator, I've determined that the SAE IVC is 77.5* ABDC

3. Using Wallace Racing's dynamic compression calculator, I've determined that with my static compression ratio of 11.47:1, the dynamic compression ratio is 8.06:1. It also "thinks" my dynamic cranking pressure is 161.44 PSI.

4. According to DV's DC/Octane chart, I can run 91 octane R+M/2 fuel at 170* F water temp (even though my car runs a 160* 'stat).

Observations:

A. My engine's cranking pressure is more like 190+

B. When we dyno'd the engine using 3500-72000 RPM pulls, there's no doubt in my mind it would have gone into "death rattle" at some point using 91 octane, regardless of .040" quench, aluminum heads & heart-shaped chambers

C. Anyone who wants to build an identical engine to prove me wrong is welcome to

So... let's "game" the calculator input and use the IVC @ .020" of 74* ABDC, despite that fact that we've now lost all the effect of lash on actual duration:

- "Your dynamic compression ratio is 8.37:1"

- "Your dynamic cranking pressure is 169.53 PSI"

According to DV's DC/Octane chart, I can run 92 or 93 octane R+M/2 fuel. And the 170 PSI calc'd cranking pressure is still waaaay below reality.

So... let's totally "crutch" the calculator input and use the IVC @ .050" of 57* ABDC, despite that fact that we've now lost all the effect of lash on actual duration AND have completely ignored the fact that the duration at .050" value can't be used accurately to extrapolate an IVC point due to the wide variety of cam profiles available with approx. the same .050" duration.

- "Your dynamic compression ratio is 9.60:1"

- "Your dynamic cranking pressure is 202.18 PSI"

According to DV's DC/Octane chart, I need to run 98 or 99 octane R+M/2 fuel.

Perhaps the last attempt is the most accurate at predicting cranking pressure and octane requirement... but it also required pulling 20* out of the MEASURED SAE IVC point, which is what the engine is actually going to "see" when running.

Familiar with the term GIGO? Garbage In, Garbage Out... If you have to f**k with the actual data that much to make your tool's results come out within reason, "something" is flawed.

Posted By: Pacnorthcuda

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/30/18 09:45 PM

IVC certainly affects VE

VE certainly affects Compression

Compression certainly affects an engine's propensity to detonate.

Posted By: dizuster

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 12:10 AM

You can't say that static compression ratio and IVC matter to detonation in one breath, and then say Dynamic Compression ratio doesn't mean ZIP in the next... since obviously the two biggest parameters to dynamic compression ratio ARE static compression ratio and IVC! You can try and spin what you said and what you meant anyway you want. In the end you can't un-tie SCR, DCR, and IVC from interacting.

No one said Dynamic Compression ratio was the ONLY build parameter that effects octane requirements either. But its a useful guideline just like everything else we use to try and build better motors.

One CSA of a head won't tell you peak RPM. One .050" duration number won't tell you peak RPM. One quench number won't guaranty detonation free operation. Yet we still use them as useful tools and guidance to build better motors.

At any rate... while dynamic compression ratio might not be the end all be all to tell you what octane you'd need... it's a HELL of a lot better then just saying you can only go to 10:1 and ignoring the cam.

Posted By: jwb123

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 12:28 AM

Their are a lot of vairables to cylinder pressure in a running engine. Dynamic compression ratio concept is that if the intake or exhaust valve is open its kind of hard to compress the air fuel mixture, so its calculated off of when intake valve closes. In a running engine the ramming effect of the air fuel charge affects cylinder pressure, because you can start to compress the air fuel charge against the in coming air fuel charge. I do not agree with the statement that dynamic compression does not mean ZIP. The comment was in referance to running high static compression pistons with a cam big enough to lower the cylinder pressure to run lower octane fuel. But lets look at the same issue from the other end. Put a big cam in a low compression engine and see what you get, a pig that sounds neat but won't get out of its on way. Before I understood better some of these factors as a youger man back in the 70's my freinds and I made this mistake several times. I am not an engineer and not very good at math, but I have used computer engine software to design my engine combinations for many years. Several years ago I built a couple pulling truck engines that were required by rules to run 91 octane fuel. Those engines had 13 to 1 static compression pistons, they one ran good enough to win the points championship that year, and get pulled for fuel inspection, etc. All legal and on the rules. The software I use calculates the dynamic compression and the cranking compression, idle vaccum, as well as the octane requirements of the engine. Knock on wood it has not let me down yet. Last engine I built for pump gas was a 500 cid wedge with 906 heads, for a roadrunner, it ran 10.90's with full interior and all steel body. It had 11 to 1 pistons, and a smaller cam because the owner wanted a decent idle, it had 16 inches of idle vacuum. One thing I will say all the variables to engine design have been pretty much thrashed out by the 1920's We keep revisiting those variables as technology, and materials improve, but the basic theroies all were worked out 100 years ago. Todays engines use viarable valve timing to run much higher static compression ratios and eliminate need for EGR and run super clean as far as emmissions go, so there is a big role for valve events to play in engine design.

Posted By: PorkyPig

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 12:35 AM

Posted By: Sport440

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 01:09 AM

You can't say that static compression ratio and IVC matter to detonation in one breath, and then say Dynamic Compression ratio doesn't mean ZIP in the next... since obviously the two biggest parameters to dynamic compression ratio ARE static compression ratio and IVC! You can try and spin what you said and what you meant anyway you want. In the end you can't un-tie SCR, DCR, and IVC from interacting.

No one said Dynamic Compression ratio was the ONLY build parameter that effects octane requirements either. But its a useful guideline just like everything else we use to try and build better motors.

One CSA of a head won't tell you peak RPM. One .050" duration number won't tell you peak RPM. One quench number won't guaranty detonation free operation. Yet we still use them as useful tools and guidance to build better motors.

At any rate... while dynamic compression ratio might not be the end all be all to tell you what octane you'd need... it's a HELL of a lot better then just saying you can only go to 10:1 and ignoring the cam.

Well said, and I

Posted By: B3RE

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 02:42 AM

So, what is the magic number to run pump gas? Obviously, if so much credence is given to this one parameter, then someone has to have a number they are looking for. Otherwise, it is just a guessing game.

The fact is, there are engines that will rattle with less than 8:1, and others won't rattle at 10:1 DCR. How do you know what is correct? How can a tool be so valuable if the target is constantly moving, and the real world numbers don't correlate to the formula result? I'm not saying the DCR doesn't have some value if used properly, but when ALL parameters aren't considered, like is often the case, the DCR is almost meaningless.

I think Brad is showing his frustration that he built his engine to run on pump gas, using a DCR calculation, and it didn't work out that way. There are lots of guys out there blowing their stuff up from detonation, when they thought they were safe. And yet, guys are still recommending engines be built using the DCR. That being said, if that's what works for you, go for it.

Posted By: Neil

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 05:23 AM

The altitude your using the engine at would play a role in what you can get away with, correct? Boise is 2800 ft above sea level, and there are guys here with 10:1cr + engines running around on 91 octane (highest you can buy in this area) with no issues at all.

Several old school machine shops here that build every street engine at 9:1 cr and install a much larger than stock camshaft. The end result is something that often sounds nice, but is a pooch on the bottom end, and by the time the bigger cam comes on the heads (if they are stock) are signing off. This is how too many people end up with a rebuilt 440 with headers, etc. that runs 15 flat at 91 mph.

Posted By: BradH

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 06:52 AM

You can't say that static compression ratio and IVC matter to detonation in one breath, and then say Dynamic Compression ratio doesn't mean ZIP in the next... since obviously the two biggest parameters to dynamic compression ratio ARE static compression ratio and IVC! You can try and spin what you said and what you meant anyway you want. In the end you can't un-tie SCR, DCR, and IVC from interacting.

I don't have to "spin" anything and I never changed what I meant: DCR doesn't take into account how cylinder pressure changes across the RPM range due to VE and, therefore, is of limited or no value. It doesn't matter that DCR uses CR and IVC as inputs if the output calculated isn't of use.

Seeing that the DCRs of two different CR & cam combinations are the same still won't tell you the RPM at which the combination built with a higher CR and later IVC crosses over from less cylinder pressure to more cylinder pressure than the other combination.

If you want to know at what point in the RPM range an engine achieves peak VE and how well it carries the VE up to max RPM, you gotta put it on a dyno and collect the data.

Posted By: AndyF

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 07:01 AM

DCR only applies at very low engine speeds such as idle and perhaps cruise. Once some inertia ram effect takes place then DCR goes out the window. So if a person is concerned with how an engine will run at low speeds then DCR is something to pay attention to.

I would imagine DCR is a hot topic over in the Tug Boat and Tow Truck section of the board, not sure why it is a topic of discussion in the Race section though. Most race engine live in the RPM zone between peak torque and peak power and DCR is irrelevant at that RPM.

Posted By: BradH

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 07:01 AM

I think Brad is showing his frustration that he built his engine to run on pump gas, using a DCR calculation, and it didn't work out that way.

Naaaah. I knew when the CR ended up at 11.5 compared to the old build's 10.8, while the cam duration & LSA specs didn't really change, that the likelihood of still being able to run straight 93 was pretty slim. I brought race gas to blend with pump gas at the dyno just to play it safe.

Posted By: TRENDZ

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 02:16 PM

“DCR doesn't take into account how cylinder pressure changes across the RPM range due to VE and, therefore, is of limited or no value. It doesn't matter that DCR uses CR and IVC as inputs if the output calculated isn't of use.“

DCR= DYNAMIC compression ratio. The term dynamic TELLS you that it’s a changing value. If someone has chosen to use only one value of a constantly changing equation, the results will likely be less effective.

Throughout this thread, it appears that the mistake that people are making is they use “dynamic” as a fixed number/ point of reference.

So to me, It looks like (based on the first sentence in quotes) you assumed that dynamic is a fixed number.

Maybe that’s the whole basis of this thread???😳

Posted By: dvw

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 02:58 PM

How do we pick a combo? Voodoo? No, we use parameters. Cam, compression, head design, head material, operating altitude, engine temp,fuel type, and more. Miss any one of these factors and the desired goal may not be met. Static compression is just compiled number. Dynamic compression is also just a number. These are tools to point you towards the desired goal. Neither are set in stone. The more knowledge you have, the better chance of meeting the goal. Just like when you ask questions. Compile the answers, throw out what you don't believe in, and make your best stab at it.

Doug

Posted By: B3RE

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 03:05 PM

DCR only applies at very low engine speeds such as idle and perhaps cruise. Once some inertia ram effect takes place then DCR goes out the window. So if a person is concerned with how an engine will run at low speeds then DCR is something to pay attention to.

I would imagine DCR is a hot topic over in the Tug Boat and Tow Truck section of the board, not sure why it is a topic of discussion in the Race section though.

Well said, Andy! I was thinking the Irritation Pump section, but tow truck and tug boat works, too.

Posted By: B3RE

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 03:08 PM

I think Brad is showing his frustration that he built his engine to run on pump gas, using a DCR calculation, and it didn't work out that way.

Naaaah. I knew when the CR ended up at 11.5 compared to the old build's 10.8, while the cam duration & LSA specs didn't really change, that the likelihood of still being able to run straight 93 was pretty slim. I brought race gas to blend with pump gas at the dyno just to play it safe.

My mistake, Brad. I was thinking you built it for pump gas.

Posted By: polyspheric

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 03:08 PM

Gee, why didn't I think of this?

Oh, wait... I wrote about it, HERE, 10 years ago.

Posted By: B3RE

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 03:16 PM

How do we pick a combo? Voodoo? No, we use parameters. Cam, compression, head design, head material, operating altitude, engine temp,fuel type, and more. Miss any one of these factors and the desired goal may not be met. Static compression is just compiled number. Dynamic compression is also just a number. These are tools to point you towards the desired goal. Neither are set in stone. The more knowledge you have, the better chance of meeting the goal. Just like when you ask questions. Compile the answers, throw out what you don't believe in, and make your best stab at it.

Doug

This approach is understandable, since quantifiable data can be difficult to obtain for many of the parameters involved. That's where very expensive and time consuming research used by factory engineers, and high end race teams comes into play. The problem is the use of DCR as a singular factor in determining SCR and IVC. It just doesn't work by itself. Again, the engine doesn't care when the intake valve closes. It only sees volumetric efficiency. Get too much charge into the cylinder at too low an rpm, and it will rattle.

Posted By: B1MAXX

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 03:25 PM

If Dynamic comp. doesn't mean zip then put a 290 @ 50 cam in a 440 that had a static ratio of 8 to 1. and see what et you get. Then put a 250 @ 50 and see what et you get. If dynamic comp. does't mean anything why even close the valve?

In terms of detonation. Why does my 1988 dodge truck ping, but power tour mountain motors don't? Bet it has something to do with cam selection (along with other things). Detonation is easier to control at higher rpm. there is a point, probably you can stop detonation with rpm. So if we can help control lower rpm detonation with camshaft ivc and the upper rpm detonation with rpm. Sounds like a win win, if you know what your doing.

I had to put

into this pot

Posted By: hemi-itis

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 04:28 PM

I work with effective CR because it's adjustable from 11:1 pump gas and as high as 20:1 if you have steel ones

Posted By: rb446

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 05:31 PM

DELETED.

Posted By: LSP

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 07:31 PM

DCR only applies at very low engine speeds such as idle and perhaps cruise. Once some inertia ram effect takes place then DCR goes out the window. So if a person is concerned with how an engine will run at low speeds then DCR is something to pay attention to.

I would imagine DCR is a hot topic over in the Tug Boat and Tow Truck section of the board, not sure why it is a topic of discussion in the Race section though. Most race engine live in the RPM zone between peak torque and peak power and DCR is irrelevant at that RPM.

Bingo

Posted By: BradH

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 07:39 PM

DCR= DYNAMIC compression ratio. The term dynamic TELLS you that it’s a changing value. If someone has chosen to use only one value of a constantly changing equation, the results will likely be less effective.

Throughout this thread, it appears that the mistake that people are making is they use “dynamic” as a fixed number/ point of reference.

Show me a "DYNAMIC" CR calculator that accounts for the differences in VE that occur at 1000 RPM intervals from 1000 to 7000. If it's in an engine simulation program, then the program probably calculates BMEP, too, which IMO is a more useful data point.

What people typically use to calculate DCR isn't DYNAMIC at all because it's a single point-in-time calc that ignores VE completely. THAT'S really a STATIC CR calculator where the IVC event is changed from the default BDC to ### degrees ABDC; nothing DYNAMIC at all about it until it can factor in VE changes under different operating conditions.

I'm not the one who is getting confused between the meanings of DYNAMIC and STATIC, regardless of whether the subject calculation is named incorrectly.

/////////////////

This has been an enlightening discussion, if for no other reason than I am truly surprised by how difficult it seems for some people to grasp what I think is a pretty basic concept. However, it appears to be headed for a death spiral for that same reason.

I'm fine with agreeing to disagree, regardless.

Posted By: Skeptic

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 03/31/18 07:43 PM

DCR only applies at very low engine speeds such as idle and perhaps cruise. Once some inertia ram effect takes place then DCR goes out the window. So if a person is concerned with how an engine will run at low speeds then DCR is something to pay attention to.

I would imagine DCR is a hot topic over in the Tug Boat and Tow Truck section of the board, not sure why it is a topic of discussion in the Race section though. Most race engine live in the RPM zone between peak torque and peak power and DCR is irrelevant at that RPM.

If by "Race" you mean drag racing, sure. In the "Corners are Best" forum being able to drive and accelerate at part throttle and below peak torque is very relevant. Haven't found the "Tug Boat and Tow Truck" forum yet, is it a sub forum for the General board, where the penguins and hippos hang out?

Posted By: polyspheric

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/01/18 01:04 AM

Here's another I was just reading popcorn

you've probably read this one>>

I wrote it.

Observe the copyright notice: http://victorylibrary.com/mopar/cam-tech.htm

Posted By: dogdays

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/05/18 10:49 PM

I agree with BradH and AndyF (good company to keep) and have one thing to add: Most of the discussion of "will it knock" or "does it knock" are based on hearing the knocking.

At higher engine speeds at wide open throttle the engine is making so much noise that one cannot discern the knock. If we were to use knock sensors as the only method to tell whether or not the engine was knocking, people might have a completely different understanding of how and why and when knock occurs.

Over the years there have been several posts with pictures of destroyed parts with the evidence from bearing markings clearly pointing to detonation as the cause. Yet, the empirical data is reported as "the engine wasn't knocking". That's because with a big cam below the torque peak enough cylinder pressure bled off to avoid knock. After the torque peak when ram tuning starts to have an effect, knock occurs but isn't noticed.

R.

Posted By: TRENDZ

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/06/18 12:51 AM

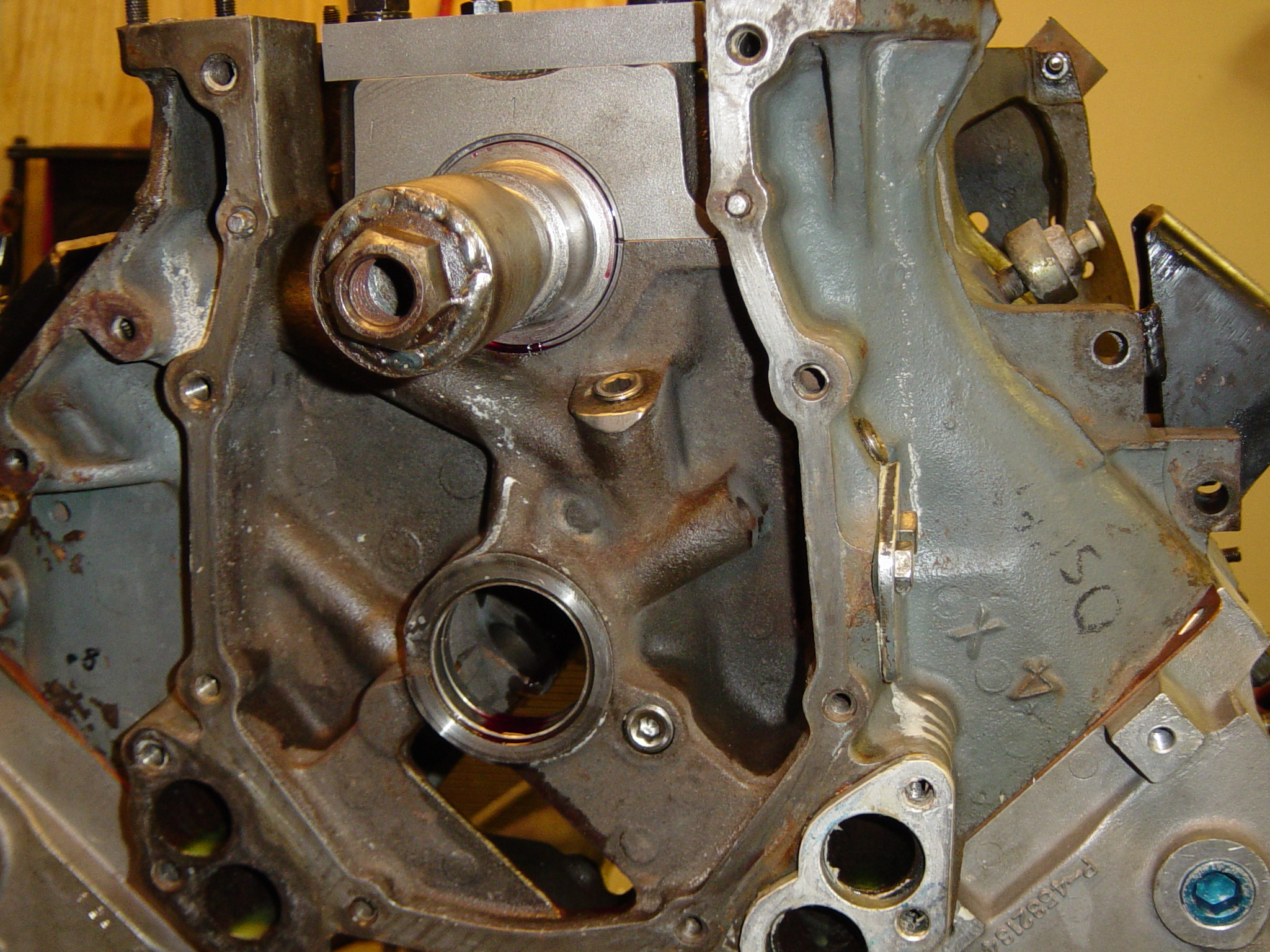

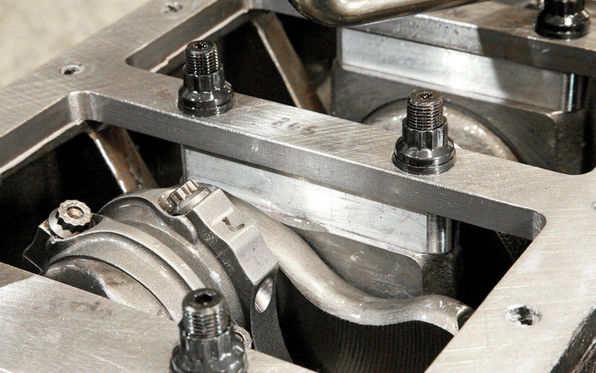

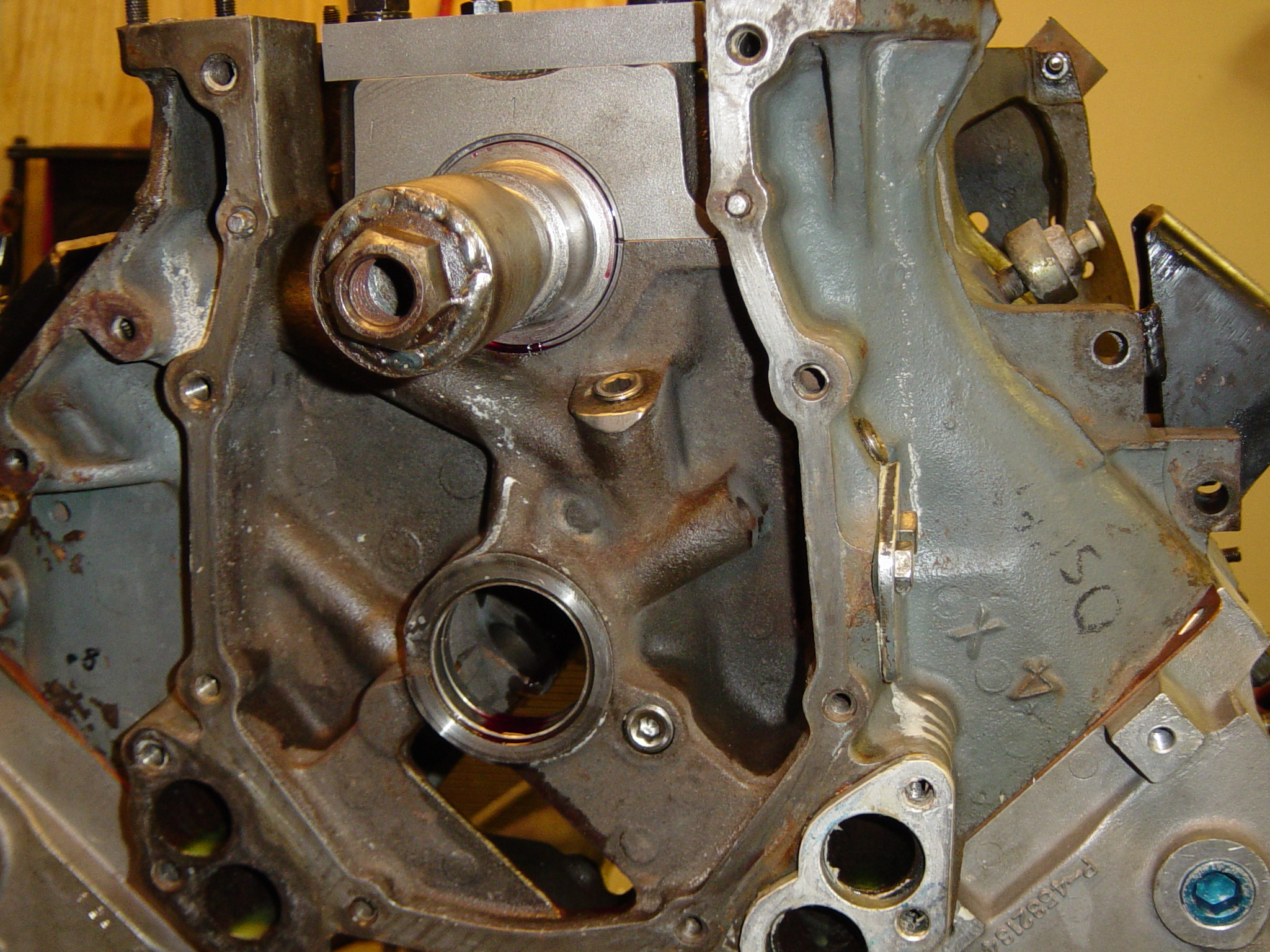

Lookie here at whats screwed into the side of the block behind the motor mount.

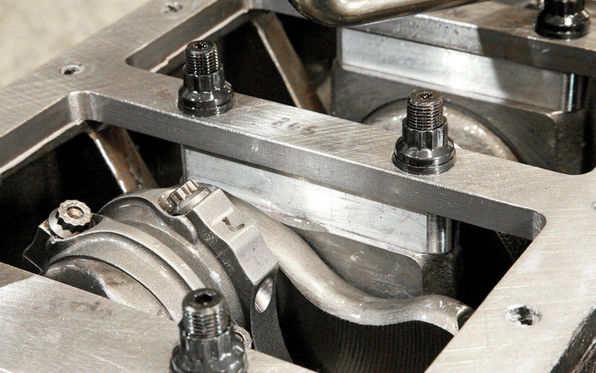

Look at the factory cap milled down with a strap across it. Notice the factory forged crank, and stock block.

How much power do you believe it could have made, for how many passes and heavy road use over years and years? Could this run on pump gas with the right cam? I wonder why most people on here can break a block at 600 hp when I reliably made over 1000?

Posted By: polyspheric

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/06/18 01:11 AM

Thanks, haven't seen that done in centuries.

Is the strap pre-loaded to anticipate ovalling under severe stress? I've seen references to .002" pre-load applied to the center span using shims, or a large fine thread jacking screw in the center of the strap. Fuel bikes used to hold the entire engine down by jacking against the frame above it.

The knock frequency (cycles per second) of actual combustion-related pressure spikes is definitely different from valve lash clatter, valve head ringing, chain roller, skirt slap, etc. and there are commercially available sensors in different frequencies to make sure retard is not triggered by something else. IDK how to determine the best for any specific engine, but probably many large V8s will be similar.

Posted By: TRENDZ

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/06/18 01:48 AM

No preload just flat. My intention was to keep the crank in the block if I had a cap failure. Never an issue with the caps. Bearings were inspected and replaced every 2 years.

The Ecu was electromotive. Now a very archaic system, they were ahead of their time when I was using it. ( not without problems)

I could get reliable knock signatures up to around 4500 rpm. Ecu could not log fast enough for any reliable data beyond that.

That engine had 5 different cams in it. Different combos of cams/ lash / pressure ratios, made huge differences with what I could get away with. This is with real data, from spending my own money on my own car. I always believed that it was mainly due to exhaust contamination... willing to reconsider that theory, but not abandon it completely.

I have a friend with a dyno set up for aircraft engines. Can’t get into what he does, but he has in-cylinder high speed transducers for setting timing curves at “lean of peak” on lyco engs. Very neat to be able to visualize knock coming in. These are very expensive spark plugs!

The sensors are some of the fastest reacting, yet still are only accurate at lowere engine speeds(fine for prop aircraft engines)

Posted By: GTX MATT

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/06/18 02:58 PM

Trendz where did you drill/tap for the knock sensor?

Posted By: BradH

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/06/18 07:57 PM

I agree with BradH... (good company to keep)...

Depending upon who you ask, that opinion might get you on somebody's hate list.

Posted By: TRENDZ

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/06/18 09:28 PM

Trendz where did you drill/tap for the knock sensor?

Just used the water drain hole. The theaded portion of the sensor is only a mount, there is no pass through. As long as the sensor is touching the material you are trying to listen to, it will work. Sort of like putting your ear to a screwdiver that is in contact with something noisy.

Brad, if you are referring to me, I assure you you are not on my hate list! Much respect for anyones opinion here. Nobody is ever 100% right or wrong.

Posted By: Twostick

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/06/18 10:10 PM

Lookie here at whats screwed into the side of the block behind the motor mount.

Look at the factory cap milled down with a strap across it. Notice the factory forged crank, and stock block.

How much power do you believe it could have made, for how many passes and heavy road use over years and years? Could this run on pump gas with the right cam? I wonder why most people on here can break a block at 600 hp when I reliably made over 1000?

Timing is everything...

Kevin

Posted By: ccdave

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/06/18 11:57 PM

Lookie here at whats screwed into the side of the block behind the motor mount.

Look at the factory cap milled down with a strap across it. Notice the factory forged crank, and stock block.

How much power do you believe it could have made, for how many passes and heavy road use over years and years? Could this run on pump gas with the right cam? I wonder why most people on here can break a block at 600 hp when I reliably made over 1000?

YOU MILLED DOWN THE FACTORY CAP AND PUT A METAL STRAP ACROSS IT

Shame on you for thinking out of the box and posting that modification on Moparts

Nice mods

It’s refreshing to see different modifications other than what’s typically seen here

Posted By: maximum entropy

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/07/18 12:17 AM

dynamic cr will make, or break a combo. it's true. [/i]calculating[/i] it accurately is just about impossible, and i suspect, therein lies the crux of your grievance. 10 engine builders will give you 10 different sets of parameters for accurately measuring it. sorry, but it's actually super important.

Posted By: Wedgeman

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/07/18 01:34 AM

You can't say that static compression ratio and IVC matter to detonation in one breath, and then say Dynamic Compression ratio doesn't mean ZIP in the next... since obviously the two biggest parameters to dynamic compression ratio ARE static compression ratio and IVC! You can try and spin what you said and what you meant anyway you want. In the end you can't un-tie SCR, DCR, and IVC from interacting.

No one said Dynamic Compression ratio was the ONLY build parameter that effects octane requirements either. But its a useful guideline just like everything else we use to try and build better motors.

One CSA of a head won't tell you peak RPM. One .050" duration number won't tell you peak RPM. One quench number won't guaranty detonation free operation. Yet we still use them as useful tools and guidance to build better motors.

At any rate... while dynamic compression ratio might not be the end all be all to tell you what octane you'd need... it's a HELL of a lot better then just saying you can only go to 10:1 and ignoring the cam.

Well said, and I

Totally agree !! These are the first steps I take to figure out hhow the engine will react..a hell of a good picture at least !

Posted By: Porter67

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/07/18 03:53 AM

Alot of good info posted but also as posted I think its just another factor in a whole mixed bag of factors in the total build.

Ive always tried to pick the minds of the racers who are currently/actively racing and winning at it. B cause they be doing somting right.

We started doing that in the early 80-s with our SS pulling tractor 466/6 blocks they have the bottom end design just like a BB mopar.

We machined all flush with a hint off the pan rail and ran an 1 inch thick al plate with long long bolts to absorb some of the shock.

Lookie here at whats screwed into the side of the block behind the motor mount.

Look at the factory cap milled down with a strap across it. Notice the factory forged crank, and stock block.

How much power do you believe it could have made, for how many passes and heavy road use over years and years? Could this run on pump gas with the right cam? I wonder why most people on here can break a block at 600 hp when I reliably made over 1000?

YOU MILLED DOWN THE FACTORY CAP AND PUT A METAL STRAP ACROSS IT

Shame on you for thinking out of the box and posting that modification on Moparts

Nice mods

It’s refreshing to see different modifications other than what’s typically seen here

Posted By: Blusmbl

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/07/18 02:52 PM

I have a friend with a dyno set up for aircraft engines. Can’t get into what he does, but he has in-cylinder high speed transducers for setting timing curves at “lean of peak” on lyco engs. Very neat to be able to visualize knock coming in. These are very expensive spark plugs!

The sensors are some of the fastest reacting, yet still are only accurate at lower engine speeds(fine for prop aircraft engines)

The spark plug transducers definitely have accuracy issues at higher engine speeds. There are also transducers available that are designed to be installed in specially machined cylinder heads, those are accurate at higher rpm than the spark plug versions. It's really awesome technology, but it's usually into the hundreds of thousands of dollars range to get an engine set up with it.

https://www.kistler.com/en/applications/...essure-testing/https://www.avl.com/-/all-in-one-indicating-systems

Posted By: RAMM

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/07/18 03:15 PM

Lookie here at whats screwed into the side of the block behind the motor mount.

Look at the factory cap milled down with a strap across it. Notice the factory forged crank, and stock block.

How much power do you believe it could have made, for how many passes and heavy road use over years and years? Could this run on pump gas with the right cam? I wonder why most people on here can break a block at 600 hp when I reliably made over 1000?

YOU MILLED DOWN THE FACTORY CAP AND PUT A METAL STRAP ACROSS IT

Shame on you for thinking out of the box and posting that modification on Moparts

Nice mods

It’s refreshing to see different modifications other than what’s typically seen here

The aluminum straps were left .002" proud for some squish. J.Rob

Posted By: ccdave

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/07/18 05:44 PM

Very nice JRob but I wouldn’t use those springs with that rocker

Posted By: ric3xrt

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/07/18 07:03 PM

I have a friend with a dyno set up for aircraft engines. Can’t get into what he does, but he has in-cylinder high speed transducers for setting timing curves at “lean of peak” on lyco engs. Very neat to be able to visualize knock coming in. These are very expensive spark plugs!

The sensors are some of the fastest reacting, yet still are only accurate at lower engine speeds(fine for prop aircraft engines)

The spark plug transducers definitely have accuracy issues at higher engine speeds. There are also transducers available that are designed to be installed in specially machined cylinder heads, those are accurate at higher rpm than the spark plug versions. It's really awesome technology, but it's usually into the hundreds of thousands of dollars range to get an engine set up with it.

https://www.kistler.com/en/applications/...essure-testing/https://www.avl.com/-/all-in-one-indicating-systems We use AVL's systems when we do long tern duration and endurance engine testing. for both aerospace and auto manufactures.

Amazing tech,

Posted By: lewtot184

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/07/18 07:35 PM

anybody recall seeing the pictures of flat head fords with the straps across the main caps?

Posted By: LA360

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/08/18 08:25 AM

I don't buy in to it, if you asked a Nascar or Pro Stock engine builder if they looked in to it, the answer would be no.

There was a discussion regarding it on one of the Racing Engine discussion groups on Facebook about the very subject recently, it was an interesting read.

Posted By: dthemi

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/08/18 01:56 PM

Something interesting to me is static compression ratio and efficiency.

Prostock engines aren't much more than 14:1 static, since they fill the cylinder so well. VS normal stuff that will make more power at 16.5 static because they can't get enough in the chamber.

Posted By: PorkyPig

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!! - 04/09/18 06:55 PM

Here's another company that sells cylinder pressure testing equipment that is used with race engines.

http://www.tfxengine.com/index.htmlClick on the graph of the pressure chart to see more details of what is measured.