Moparts

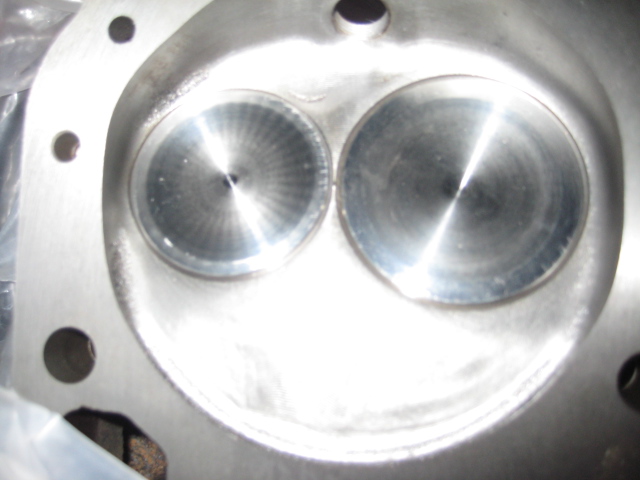

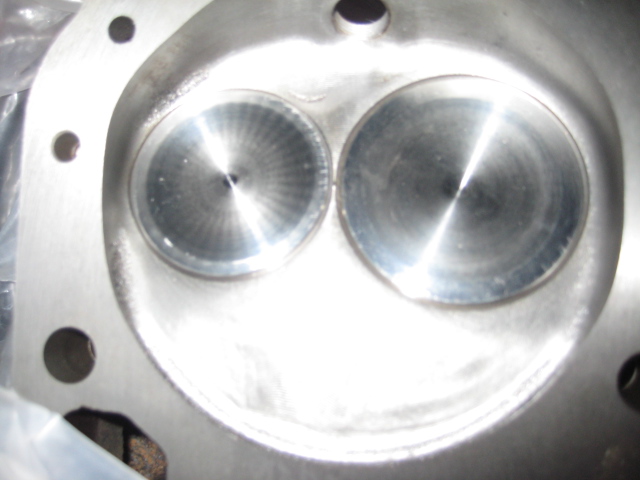

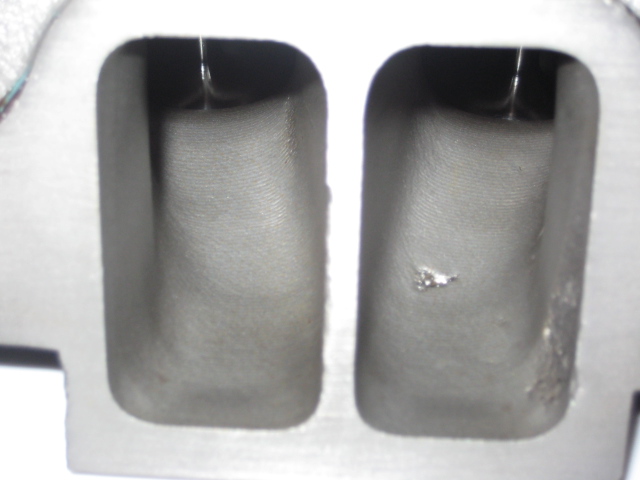

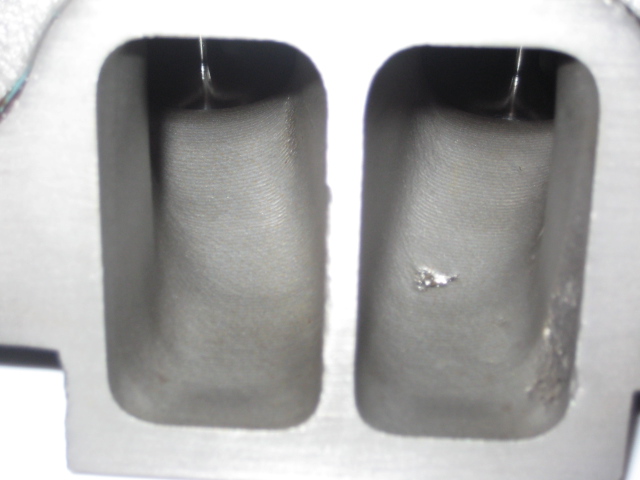

K&G Engines CNC Port 906 Heads

Posted By: parksr5

K&G Engines CNC Port 906 Heads - 10/13/17 01:45 AM

I just picked up my CNC'd 906 heads from K&G Engines last night. After speaking with the owner (Dave) over the years, I'd go home and searched Moparts to see if I could find info on the company and did not find much. More recently, I've seen some posts with praise for the company but, no pictures or anything. I've never heard anything but positive remarks in any conversations that I've had with people that have dealt with the company so; I pulled the trigger.

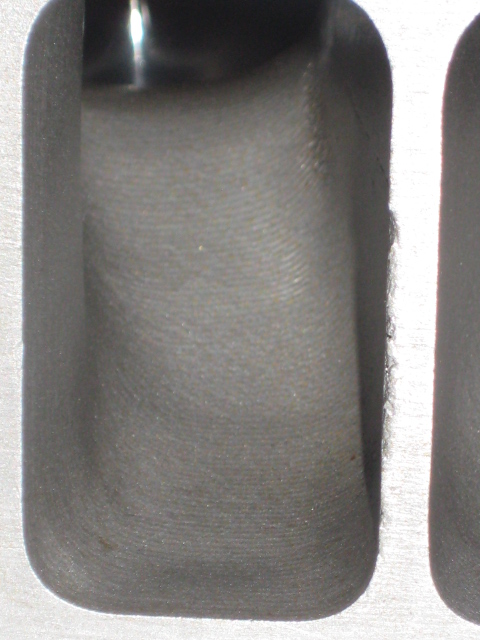

I figured I'd post some pics up.

Just a little back round on my plans so; we don't get the waste of money conversation rolling on using original casting heads. I plan on running my car in the FAST class at some point so; I will be required to run the 906's.

Dave was great to deal with; I have no complaints but, the SLA for completion did run over what I was originally told but, I understand as this is not a huge operation.

My camera is not the best so; these are about as good as it gets.

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/13/17 01:47 AM

.

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/13/17 01:48 AM

.

Posted By: sgcuda

Re: K&G Engines CNC Port 906 Heads - 10/13/17 02:24 AM

Is that a breakthrough that has to be epoxied? I had to do the same on my 915's.

Posted By: madscientist

Re: K&G Engines CNC Port 906 Heads - 10/13/17 02:33 AM

Heads look very nice.

I agree...your camera stinks.

Posted By: fast68plymouth

Re: K&G Engines CNC Port 906 Heads - 10/13/17 04:21 AM

Flow numbers?

I've heard "290-ish" thrown around from those heads.

Are the intake port openings pretty close in size to a valley pan gasket?

Posted By: A/MP

Re: K&G Engines CNC Port 906 Heads - 10/13/17 04:29 AM

Those pics are real proof of the CNC program for cast iron heads. I'd have to assume that the machining has to be done with some stealth because of the cast iron castings. Better to bring life to some old iron than to have it come back as some steel s!*t from china. If you don't mind,can you just let us know if the completed product was cheaper than buying new aluminum heads and having them ported in a similar manner?

Posted By: BradH

Re: K&G Engines CNC Port 906 Heads - 10/13/17 02:50 PM

Just a little back round on my plans so; we don't get the waste of money conversation rolling on using original casting heads...

Understood. My concern is cost of replacement if these 906s crack (not uncommon) and you have to start from scratch with another set.

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/13/17 03:03 PM

The spots that can be seen in the some of the pictures are simply imperfections in the casting; no break throughs or epoxy.

I’ve not placed the valley pan gasket up to the ports yet to see the difference between the two openings. For everyone’s information, this is his original program (although he has made tweaks to the program along the way). He has another program that he has written however; it is more aggressive and you must run a valley plate with that deal so; it would not be approved for FAST.

I do not have a flow sheet but, he claims 290-ish. His newer program I believe is claimed to be around 320-ish. I plan on driving this thing a lot too so; I did not want anything too aggressive and be overly concerned with cracks although, I know they can still happen.

I paid $1500 plus tax. That includes the CNC port job, new Ferrea 2.14 1.81 valves, new seats, guides, retainers, springs and ext. He has programs for other cast iron heads too; he had a 516 on the CNC machine when I was there. He had 10 sets of 516’s to do that customers sent in. My 906 heads were part of a batch of 20 that customers sent in (with numbers like these, I’m shocked that no-one has posted pictures).

I plan on working on the car this weekend- painting parts, disassembling things, cleaning, maybe re-assembling partially or all the way. I’d like to make it to the track this year but, I’m not going to push it.

It might go back to the chassis dyno too.

Eventually, I’ll let everyone know the outcome.

Brad, if or when these crack; I'll throw a set of Stealth heads on it and be done. This car will not be cut up or caged and I want it to appear stock. As we all know, things can break and we can loose money; that's kind of par for the course.

Posted By: GY3

Re: K&G Engines CNC Port 906 Heads - 10/13/17 04:16 PM

What are the rest of the engine specs?

Posted By: an8sec70cuda

Re: K&G Engines CNC Port 906 Heads - 10/13/17 04:34 PM

Looks real nice and glad to see you're gonna put em to use. I like the idea of porting stock heads for some reason, even though we all know it isn't generally cost effective.

Looking forward to hearing how it runs!

Posted By: fast68plymouth

Re: K&G Engines CNC Port 906 Heads - 10/13/17 05:02 PM

I paid $1500 plus tax. That includes the CNC port job, new Ferrea 2.14 1.81 valves, new seats, guides, retainers, springs and ext.

Sounds like my days of porting 906's are over!!

That's super cheap.

I wonder how long it takes the cnc machine to port a 906 like that.

Posted By: JohnRR

Re: K&G Engines CNC Port 906 Heads - 10/13/17 05:06 PM

I paid $1500 plus tax. That includes the CNC port job, new Ferrea 2.14 1.81 valves, new seats, guides, retainers, springs and ext.

Sounds like my days of porting 906's are over!!

That's super cheap.

I wonder how long it takes the cnc machine to port a 906 like that.

I'd like to see a flow sheet on a bench I trust before going out on that limb ...

Have you had a set of these yet ? I wonder what a hand clean up after the fact would do to them ?

Posted By: fast68plymouth

Re: K&G Engines CNC Port 906 Heads - 10/13/17 05:36 PM

Even if they flowed 275-280...... That's still really cheap money.

Similarly equipped heads out of my shop....... new guides, ex seats, big valves, all new hardware, etc..... For $1500, you'd get a nice bowl blend, intake port gasket matched, some intake short turn work...... They'd flow around 260-ish.

As I mentioned in another thread......... It's pretty hard to compete "head to head" with a cnc machine when it comes to porting.

If someone has a program for the heads you want ported...... More than likely it will be less expensive to have them done that way.

As more and more shops buy cnc machines, it seems as though the prices for some of the more basic porting jobs have dropped a bit in price....... As the shops "compete" for the customer base.

Posted By: B3422W5

Re: K&G Engines CNC Port 906 Heads - 10/13/17 05:48 PM

I paid $1500 plus tax. That includes the CNC port job, new Ferrea 2.14 1.81 valves, new seats, guides, retainers, springs and ext.

Sounds like my days of porting 906's are over!!

That's super cheap.

I wonder how long it takes the cnc machine to port a 906 like that.

Thete will always be room for an old dinosaur like you Dwayne...... lol

Posted By: madscientist

Re: K&G Engines CNC Port 906 Heads - 10/13/17 05:49 PM

Even if they flowed 275-280...... That's still really cheap money.

Similarly equipped heads out of my shop....... new guides, ex seats, big valves, all new hardware, etc..... For $1500, you'd get a nice bowl blend, intake port gasket matched, some intake short turn work...... They'd flow around 260-ish.

As I mentioned in another thread......... It's pretty hard to compete "head to head" with a cnc machine when it comes to porting.

If someone has a program for the heads you want ported...... More than likely it will be less expensive to have them done that way.

As more and more shops buy cnc machines, it seems as though the prices for having some of the more basic porting jobs have dropped a bit in price....... As the shops "compete" for the customer base.

Yep. I have one more set of cast iron heads in me and they are my w2 heads. No more iron. I may call them and see if the have something for w2 heads. If not, maybe I can do a port and they can digitize it.

Posted By: fast68plymouth

Re: K&G Engines CNC Port 906 Heads - 10/13/17 06:06 PM

Another thing is, it sounds like they had some 30+ sets of bb Mopar iron heads to be done..... Which means they could buy all the valves, springs, retainers, etc. one time..... Which presents an opportunity to buy those parts at a better price..... Which helps with the bottom line.

As well as sort of an "assembly line" type of situation for doing the guide and seat work on multiple sets of heads with only one set up.

Obviously, if they have 30+ sets of BB Mopar iron heads there to be cnc'd, they've found a price point that's pretty attractive.

Posted By: GTX MATT

Re: K&G Engines CNC Port 906 Heads - 10/13/17 06:10 PM

I paid $1500 plus tax. That includes the CNC port job, new Ferrea 2.14 1.81 valves, new seats, guides, retainers, springs and ext.

Sounds like my days of porting 906's are over!!

That's super cheap.

I wonder how long it takes the cnc machine to port a 906 like that.

Thete will always be room for an old dinosaur like you Dwayne...... lol

Someone needs to port the prototype, write the program, do the VJ... CNC porting is only as good as the program/port it produces

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/13/17 10:18 PM

Answers to some questions above

My car is a 69 Road Runner. The car scaled at 346X pounds without my 215lbs. It has a low deck 470. The rotating assembly is from 440 source. I’m currently running a Comp XE 274 cam which is .488/.491 lift and 230/236 duration at .50. Performer RPM intake, 850 Street HP, stock manifolds, 2.5” TTI exhaust, some pocket ported 213 heads with the same size valves as the new head (I bought the old ones from Hughes) and an 8 ¾ with a 3.73 gear. If the cc of the head chamber that is on the car right now is what I was told, (I take what I was told with a grain of salt) my current compression ratio is 9.65:1.

Before a few years ago, I had Hooker Comp long tubes with a compression bent 2.5” exhaust with Flowmasters. My best run with combo was 12.25 with Mickey Thompson Sportsman Pro Radials.

Last year, I went to the track once and got one clean pass and managed a 12.48 with the manifolds and new exhaust. I really think some 12.30’s would be easily obtainable; the track was just not there that day. The 12.48 run was the first pass of the day and I short shifted on the run (I was trying different things that day given the new exhaust set up).

Dwayne, Dave said one 516 takes 5 hours to cut on his CNC machine.

He also has CNC programs for aluminum heads; I just don’t know how many heads he has programs for.

Posted By: 68 HEMI GTS

Re: K&G Engines CNC Port 906 Heads - 10/13/17 11:55 PM

Cool thing about the CNC is you can be doing other things to make money while it's carving away on a head.

Posted By: DrCharles

Re: K&G Engines CNC Port 906 Heads - 10/14/17 12:32 AM

Posted By: fast68plymouth

Re: K&G Engines CNC Port 906 Heads - 10/14/17 01:14 AM

Cool thing about the CNC is you can be doing other things to make money while it's carving away on a head.

Exactly.

If there is 10hrs of CNC time on these heads, along with the other labor and all the parts........for $1500..... That's a tremendous bargain.

Posted By: fast68plymouth

Re: K&G Engines CNC Port 906 Heads - 10/14/17 01:17 AM

Last year, I went to the track once and got one clean pass and managed a 12.48 with the manifolds and new exhaust.

Was that with the OE type bias ply tires?

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/14/17 02:16 AM

Yes, that's them.

Dwayne, the 12.48 was with Mickey Thompson Sportsman Pro's; they were 28x10.50. They are a full treaded radial but, the side walls do wrinkle like a slick and the compound is pretty soft.

The tires were mounted on Weld Prostars however; I did put magnum's back on the car this year. The fronts are fully FAST legal (the wheels and the tires) but, the rears are 15X8's and I bought a set of American Racer tires to try; they're L60's which are 27.7x9.5 (a little smaller but, still not legal to run in FAST).

I've been switching things almost 1 at a time (with as much restraint as I can muster) as I'm interested to see the affects of the changes.

With the head swap, I will also be swapping intakes to a DP4B. Again, still not legal for FAST but, closer to a stock intake. As I know you are aware, the DP4B is only about 3/4's of an inch taller than the stock intake and looks very similar. Obviously the ports are considerably better and it's aluminum.

I took a stock intake to a local machine shop earlier this year and had them open up the upper plenum with a vertical mill but, that's as far as I've gotten with it. Most likely, you'll be getting a call within the next year or two to finish it up.

Posted By: A/MP

Re: K&G Engines CNC Port 906 Heads - 10/14/17 05:48 AM

I think we have all seen some pics of a CNC machine eating aluminum. With cast iron, that machine must be moving slowly to remove the chance of chatter or breakage. That's a real accomplishment to get that quality plus the R&D that goes into a successful program.

Posted By: RAMM

Re: K&G Engines CNC Port 906 Heads - 10/14/17 03:24 PM

I paid $1500 plus tax. That includes the CNC port job, new Ferrea 2.14 1.81 valves, new seats, guides, retainers, springs and ext.

Sounds like my days of porting 906's are over!!

That's super cheap.

I wonder how long it takes the cnc machine to port a 906 like that.

Cheap? He's doing the porting for free! Unbelievable, literally.

I bet a cast iron head is 4-5 hours per head. J.Rob

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/17/17 02:24 AM

I worked on the car this weekend and ended up getting everything painted and got the passenger side head back on; that's about as far as I got.

I still need to remove the driver side head, clean the deck surface, place the new head on and button everything back up.

Dwayne, I took a pic; I'll have to add it later. The valley pan slightly hung over on one side of the center divider of the ports and the bottom of the pan hangs over into the ports slightly. I'm confident that there is enough wiggle room to center up the pan from side to side on the ports and I hope that when the intake is bolded down that the pan will pull down slightly and everything will be perfectly aligned.

I've had a bum shoulder for about a year; it made things real interesting trying to turn wrenches. Trying to place the head back on the car was really fun; it took me 4-5 tries to hit the dowels. I'd get it close to being into place and would mess around for 20 or so seconds but, would have to lift the head back up and out of the engine compartment and put it down; my shoulder just couldn't take it/wouldn't do what I wanted it to do.

Maybe you guys can help me out. My guess is I'm adding 40-50 cfm over what I have now. How many jet sizes do you think I should add as a baseline?

Posted By: CSK

Re: K&G Engines CNC Port 906 Heads - 10/17/17 02:42 AM

none to start with.

Posted By: pittsburghracer

Re: K&G Engines CNC Port 906 Heads - 10/17/17 03:12 AM

I worked on the car this weekend and ended up getting everything painted and got the passenger side head back on; that's about as far as I got.

I still need to remove the driver side head, clean the deck surface, place the new head on and button everything back up.

Dwayne, I took a pic; I'll have to add it later. The valley pan slightly hung over on one side of the center divider of the ports and the bottom of the pan hangs over into the ports slightly. I'm confident that there is enough wiggle room to center up the pan from side to side on the ports and I hope that when the intake is bolded down that the pan will pull down slightly and everything will be perfectly aligned.

I've had a bum shoulder for about a year; it made things real interesting trying to turn wrenches. Trying to place the head back on the car was really fun; it took me 4-5 tries to hit the dowels. I'd get it close to being into place and would mess around for 20 or so seconds but, would have to lift the head back up and out of the engine compartment and put it down; my shoulder just couldn't take it/wouldn't do what I wanted it to do.

Maybe you guys can help me out. My guess is I'm adding 40-50 cfm over what I have now. How many jet sizes do you think I should add as a baseline?

Sometimes less jet as it's more efficient

Posted By: AndyF

Re: K&G Engines CNC Port 906 Heads - 10/17/17 03:27 AM

Carbs self adjust. When more air flows thru carb the extra air pulls more fuel.

Posted By: bonefish

Re: K&G Engines CNC Port 906 Heads - 10/17/17 01:58 PM

next time you have to put the head on get a coupe 6 in or so lengths of all thread or a couple o studs,the dowels will line right up.

Posted By: 71yelladustr

Re: K&G Engines CNC Port 906 Heads - 10/18/17 02:20 PM

I have 2 sets from KG. A standard CNC port set, and a Max Wedge CNC 906 version w/ 2.25" intake valves. The Max wedge set uses a custom valley plate that he provides to make them work. They both are excellent quality for the money. Dave will set them up for you with the valve spring of your choice so they are ready to bolt on out of the box.

Posted By: shorthorse

Re: K&G Engines CNC Port 906 Heads - 10/20/17 06:47 AM

Dave just finished my old used Indy SR's. They had several issues. I wasn't even sure if they could be saved but Dave got everything corrected. They flow 343 now. Really good people; of course I would recommend KG Engines.

I have a good friend I race with and he was looking for someone to work on his heads. He said he eventually called Ray Barton and they suggested he call Dave at KG Engines.

Posted By: Scully

Re: K&G Engines CNC Port 906 Heads - 10/20/17 07:27 AM

I paid $1500 plus tax. That includes the CNC port job, new Ferrea 2.14 1.81 valves, new seats, guides, retainers, springs and ext.

Sounds like my days of porting 906's are over!!

That's super cheap.

I wonder how long it takes the cnc machine to port a 906 like that.

Thete will always be room for an old dinosaur like you Dwayne...... lol

Someone needs to port the prototype, write the program, do the VJ... CNC porting is only as good as the program/port it produces

How does the program account for core shift which is in every one of these heads.

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/24/17 04:31 AM

I got it all back together and fired it up tonight. I had some things fight me so; it took a little longer than I would have liked. With the new intake, I had some clearance issues with a few things that I had to figure out tonight and then I dealt with human error for about an hour (I crossed the ground and hot wire on the alternator).

I got it up to temp and set the timing in the ball park; I need to back it off a degree or two. My helper wanted to go in and take a shower and go to bed; man, fiancé's.

It's obvious that I need to mess with the carb; I had a stumble that has not been there before. I have not put new plugs in it for a few years and a couple spark plug boots/connections seemed a little questionable so; I think I'm going to try and get some Firecore wires overnighted from Mancini tomorrow if possible. I'll do all of this before touching the carb.

I jacked it up and pulled the oil drain plug and called it a night. I'll finish the oil change tomorrow. So; hopefully I can get the required parts in time, set the idle screws, check the float levels and make any other adjustments to the carb before trying to make it to the track on Saturday.

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/24/17 04:33 AM

Oh, I checked for leaks too and everything was dry as a bone; one less thing to have to address or worry about.

Posted By: BSB67

Re: K&G Engines CNC Port 906 Heads - 10/25/17 01:10 AM

It's obvious that I need to mess with the carb; I had a stumble that has not been there before.

It it was a good carb before, consider looking for a vacuum leak.

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/25/17 02:51 AM

It's obvious that I need to mess with the carb; I had a stumble that has not been there before.

It it was a good carb before, consider looking for a vacuum leak.

Will do. I should have my new plug wires, plugs and coil tomorrow. I plan on switching all of that out first and then it's onto setting the idle adjustment screws with a vacuum gauge so; I should notice any oddities with the vacuum at that time.

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/27/17 05:28 PM

Some updates.

I got new Firecore 50 wires, new coil and new plugs installed.

I got a vacuum gauge on the car and set the idle mixture screws; I had the same vacuum reading as before; around 15hg. I did inspect all my vacuum lines and used a butane torch and moved it all around to check for leaks just to be safe; I found no issues. I also checked the float levels which were fine.

I took the car out for the first time a few nights ago and was not too impressed; it felt slightly faster but, I could tell it wanted more fuel especially at higher rpm. I had no detonation or temperature spikes but, the car just ran out of steam up top and just felt a little flat through the whole RPM range. I made two blasts and putted back home and pulled some plugs and confirmed that I’m way lean. Again, I have a bad off idle stumble too. I dealt with this issue when I first put the motor together; the thing likes a lot of pump shot which I gave it and it cleared the problem up (I think IAB’s and IFR’s need some tuning too but, I’m just trying to get this thing straightened out enough to make it to the track this weekend). Lastly, due to the shorter intake, I also noticed that my throttle pressure rod required adjustment.

I had 83/87 jetting to start; I went up to 86/91, added bigger pump nozzles and a 50cc accelerator pump to the rear bowl; the nozzle was too big for the 30cc pump to begin with but, I got rid of the bog without it in the past so; I never messed with it.

I took the car out again last night and the changes really woke it up. The bog is almost completely gone but, it still needs some more pump shot; I think I can get the bog out with some pump cam tuning now. I got the throttle pressure rod adjusted to my liking. The thing is still too lean and has too much timing based on where the line is on the ground strap of the plug.

So; before Sunday, I want to back the timing back 2 degrees to 36, check the idle mixture again and maybe up the jets a few sizes front and back and see how it runs and what the plugs look like. From there, if I still have the bog, I’ll add some more aggressive pump cams and jet it up more if it looks like I need it.

Hopefully Sunday night, I can post up some numbers from the track if everything goes good. They’re calling for some rain this weekend but, I think it’s supposed to quit early Saturday afternoon. I hope the track doesn’t decide to not open for some reason this weekend.

Posted By: fast68plymouth

Re: K&G Engines CNC Port 906 Heads - 10/27/17 05:55 PM

What are you hoping it runs this time out, and what is the goal for after it has the stock intake and bias ply tires on it?

Interesting about your carb needing so much jet.

Seems like a lot of these newer generation carbs need way bigger jets than they "should".

The FAST 511 I built was actually a tad rich with an ootb edelbrock 800AVS, took a little jet out...... Picked up a few hp.

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/27/17 07:07 PM

I really want that 11 second time slip this weekend but, given the time I have to work with, I understand that I may not get everything ironed out like I hope and that there will probably be a lot more tuning to do in the future. If I ran some 12 teens or lower, I'll be happy. Heck, I could be way off with how I think it's running too. I took it out the night before I took it to the track last year and it felt great but, ran over 2 tenths slower than the year before.

Funny you mention the jet and what I think is too much pump nozzle. I actually checked for vacuum leaks with the butane torch after the first few times I had the car out as I was surprised it needed as much fuel as I'm throwing at it. I thought that there may be another issue. Ultimately, I keep telling myself that if I add more fuel and it runs better, then, it needed more fuel and who cares what the actual jet sizes are.

My ultimate goal is to run some 11.50's to 11.80's on a stickier radial tire like I have on it (American Racer right now or the Mickey Thompson Sportsman Pros I had before) and whatever I run on the bias ply whenever I decide to go to that tire is what it runs.

Posted By: fast68plymouth

Re: K&G Engines CNC Port 906 Heads - 10/27/17 07:14 PM

That 511 ended up running 11.50's @118 in FAST trim in good air.

With some M&H 28x7 retro style slicks it went 11-teens.

The stock intake and ex manifolds really put the hurtin on the horsepower with that combo.

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/27/17 08:37 PM

That 511 ended up running 11.50's @118 in FAST trim in good air.

With some M&H 28x7 retro style slicks it went 11-teens.

The stock intake and ex manifolds really put the hurtin on the horsepower with that combo.

I spoke with Harry a few times at the FAST events at Trails. His Bee is as close to my car and what I want my car to be as any in the class which is why I approached him.

The exhaust manifolds hurt my car by a little over two tenths. I know the intake is a killer too.

Right now, the intake, carb, fuel line, electric fan and rear tires and wheels are all that is left that are not FAST approved.

In all honesty, it will probably be years before I run in the class but, you never know, I didn't plan on doing heads this year either and just got a wild hair.

Posted By: parksr5

Re: K&G Engines CNC Port 906 Heads - 10/28/17 03:12 AM

And the bad news came down about an hour ago; Trails cancelled their last event for the year so; it looks like I'll have to wait until next season.

I'm not happy but, it will give me some time to get this straightened out more. I have a wide band I bought a few months ago that I've not hooked up yet and I may go back to the chassis dyno too.

Posted By: markz528

Re: K&G Engines CNC Port 906 Heads - 10/28/17 03:38 AM

And the bad news came down about an hour ago; Trails cancelled their last event for the year so; it looks like I'll have to wait until next season.

I'm not happy but, it will give me some time to get this straightened out more. I have a wide band I bought a few months ago that I've not hooked up yet and I may go back to the chassis dyno too.

Still racing at Edgewater. Come on down!

Posted By: BSB67

Re: K&G Engines CNC Port 906 Heads - 10/28/17 05:17 AM

And the bad news came down about an hour ago; Trails cancelled their last event for the year so; it looks like I'll have to wait until next season.

I'm not happy but, it will give me some time to get this straightened out more. I have a wide band I bought a few months ago that I've not hooked up yet and I may go back to the chassis dyno too.

Still racing at Edgewater. Come on down!

Plus you’ll post better times and mph.

Posted By: Gtxxjon

Re: K&G Engines CNC Port 906 Heads - 10/17/21 02:51 PM

Hi Moparts,

Any 906 news, since the dreaded lockdown?

I'm building a 511ci motor with iron heads but not sure which ones to go for?

Got some very trick 906's by Rob Loring UK, some by Koffel and a set by Jeff Hauser Uk too.

But I also had a set of 452's by Koffel which I sold and now regretting!

They were very light as the machine work was awesome.

Milled a 100 thousanths and the quench area re-machined to approx 30 thousanths depth.

So as my ride is a 71 GTX for UK Superstock, I may go with some first gen 'flat-port' 902's...

Just because I have a spare set of them.

Lost most of the pics of the 'ICE heads' made by Rob Loring.

Raised port by approx 1/2'' and fitted a 5/8'' spacer onto each head.

Ports still 906 sized with air deflectors in the port floor, with Team 'G' domi intake

High compression 452ci motor in my Street Dart ran 10.44. (Dart in avatar)