Posted By: Kam*Kuda

how do you check valve lash? potential issue - 09/14/17 04:10 AM

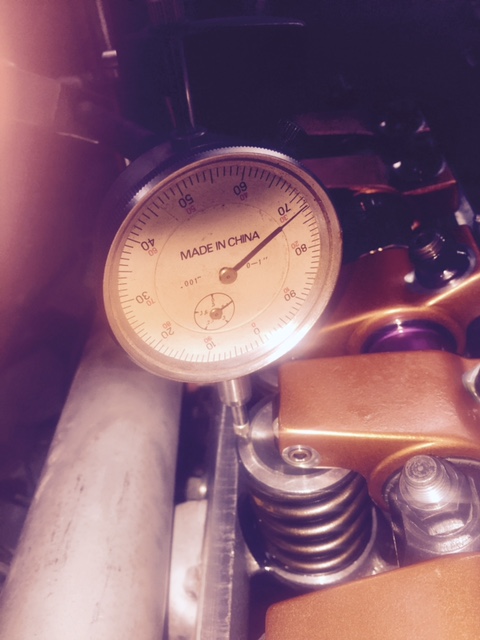

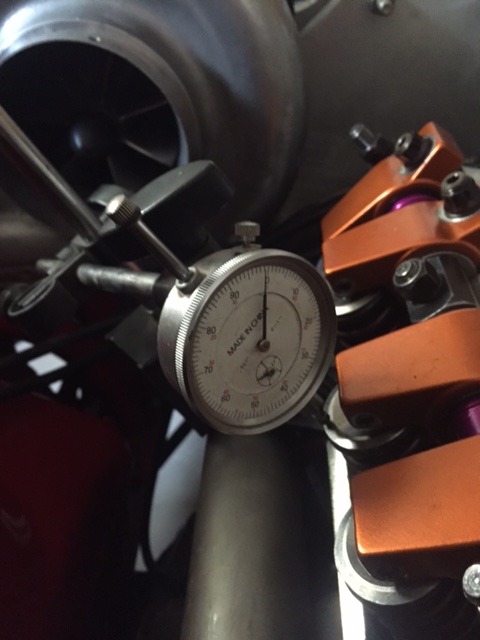

I recently checked the valve lash using the 180 degree method checking multiple rockers

the #1 exhaust valve needed a 2.5 turns to get the lash in spec!

All the others were close

It took me too long and the engine temperature dropped but I lashed them all at 020

I went out again after the engine was hot,

I rechecked using the intake opening exhaust closing method and it needed some changes back to 020

Specially the #1 exhaust went from 020 to 024

when it cooled it was at 17

Its a (Solid Roller cam)

I have relashed all the valve cold at 017

I plan to go out and drive it for a while and then let it cool and check the lash on all valve

Any thoughts or suggestions.

(i don't have a lot of experience)

the #1 exhaust valve needed a 2.5 turns to get the lash in spec!

All the others were close

It took me too long and the engine temperature dropped but I lashed them all at 020

I went out again after the engine was hot,

I rechecked using the intake opening exhaust closing method and it needed some changes back to 020

Specially the #1 exhaust went from 020 to 024

when it cooled it was at 17

Its a (Solid Roller cam)

I have relashed all the valve cold at 017

I plan to go out and drive it for a while and then let it cool and check the lash on all valve

Any thoughts or suggestions.

(i don't have a lot of experience)