Moparts

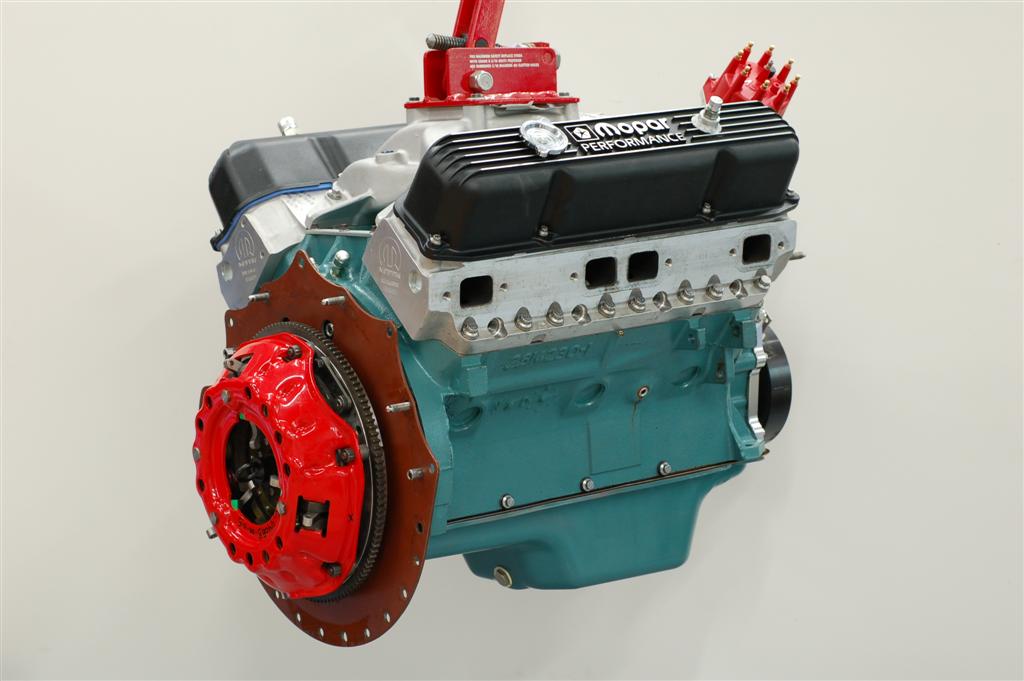

Strong B-block bottom end for max hp effort

Posted By: Lifsgrt

Strong B-block bottom end for max hp effort - 12/17/16 05:03 PM

Gents, I have a good block to start with. I would like your feedback on the best option for strengthening a stock block for 900+ hp. I know a race block built to the task would be better, but I'm building a stock blcok. I know there are quite a few mfgrs, I'm looking for products you have used and kept the bottom end together until something else gave way. Main caps obviously, steel or aluminum? Girdle worth it? Mfgrs for both? This is another of those issues where I don't want to save a penny and waste a dollar, but don't want to spend bigger $$ when less will do with a margin of safety. Thanks in advance, Merry Christmas.

Posted By: STEFF

Re: Strong B-block bottom end for max hp effort - 12/17/16 05:25 PM

You're not going to like the answers as stock block and 900hp dont work together. Anything you do is a band aid and will fail. Just a matter of when, not if.....If you want to spend wisely, spend on an aftermarket block.

Posted By: fbs63

Re: Strong B-block bottom end for max hp effort - 12/17/16 05:33 PM

By the time you pay for a good girdle (BCR) and have it installed plus good machine work on a stock block, you will be a $1000 short of a prepped good block. Plus 900 hp on motor is not easy in a flexing stock block. Save longer and buy a good block.

Posted By: WO23Coronet

Re: Strong B-block bottom end for max hp effort - 12/17/16 05:54 PM

His race class requires a stock block. You have a center weighted crank right. In another post another member recommended one and it seems you bought one?

Throw all the band aids you can at it, Girdle and a maybe hard block it

Posted By: sgcuda

Re: Strong B-block bottom end for max hp effort - 12/17/16 06:25 PM

Aluminum caps and longest, lightest, strongest rods available. Piston and pin weight at dead minimum. Maybe an SBC wrist pin?

Posted By: pittsburghracer

Re: Strong B-block bottom end for max hp effort - 12/17/16 06:42 PM

900 horsepower with a stock block is doable but its doable for a limited amount of runs. Besides doing all the band-aids I would recommend finding a good church and Praying as often as possible. Throw salt over your right shoulder, and attend more car shows than races. Good-luck. Oh and PLEASE stay away from detonation and 7500 plus RPM. An engine diaper is also good insurance too.

Posted By: EchoSixMike

Re: Strong B-block bottom end for max hp effort - 12/17/16 06:54 PM

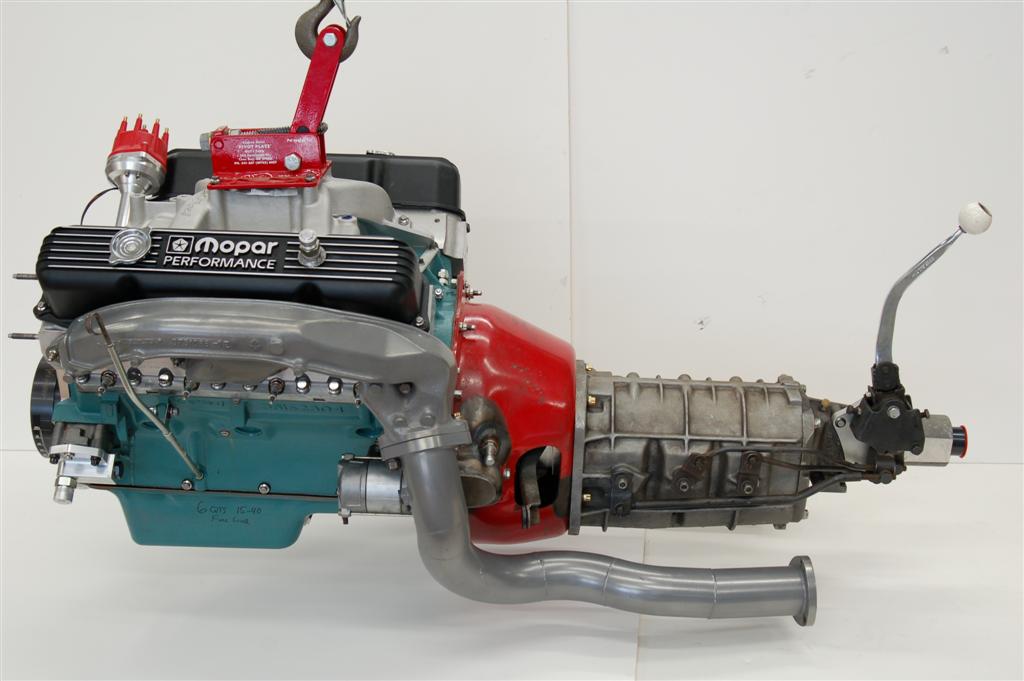

The BCR full kit girdle with aluminum maincaps seems to be best of current options. Maybe even consider magnesium alloy main caps for even greater vibration damping.

Center weighted crank is a very good idea as well. S/F....Ken M

Posted By: WO23Coronet

Re: Strong B-block bottom end for max hp effort - 12/17/16 07:03 PM

I know it's probably been asked, but has anyone ever made a bedplate system for the mains (mains/girdle are all one piece)? Like they use on newer cars? I know it would be $$$, but it might be an option. Aluminum rods would help as well

Posted By: rowin4

Re: Strong B-block bottom end for max hp effort - 12/17/16 07:14 PM

As stated above get ready to spend some money. I started off with the original BCR girdle with the aluminum main caps, It looked so good I really had a hard time putting the oil pan on just covering up such a quality piece. This is NOT a bolt on system . As with any after market main cap install the block must be align bored. Then with the girdle, the bottom of the block [ pan rail ] and main caps must decked to make sure they are flat. The girdle is stud bolted to the pan rail and the girdle is stud bolted to the main caps tying it all together. Acid clean the block before any hard block is installed. This should be done and cured before any machining is done. I don't run anywhere near 900 Hp but it has held up for over 8 years for me

Posted By: mprhound

Re: Strong B-block bottom end for max hp effort - 12/17/16 07:45 PM

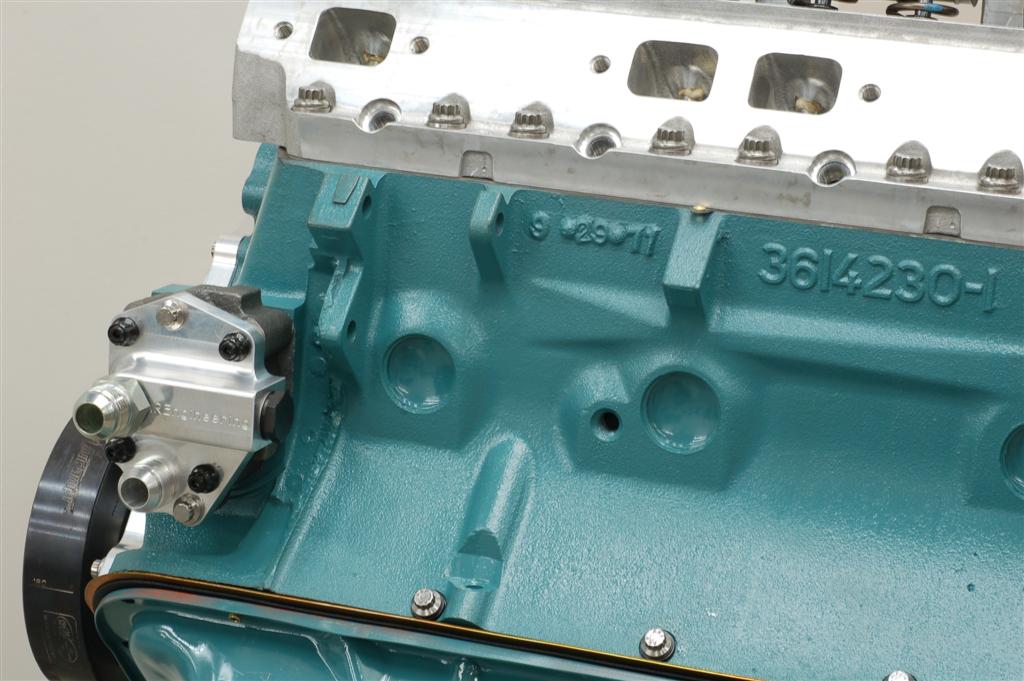

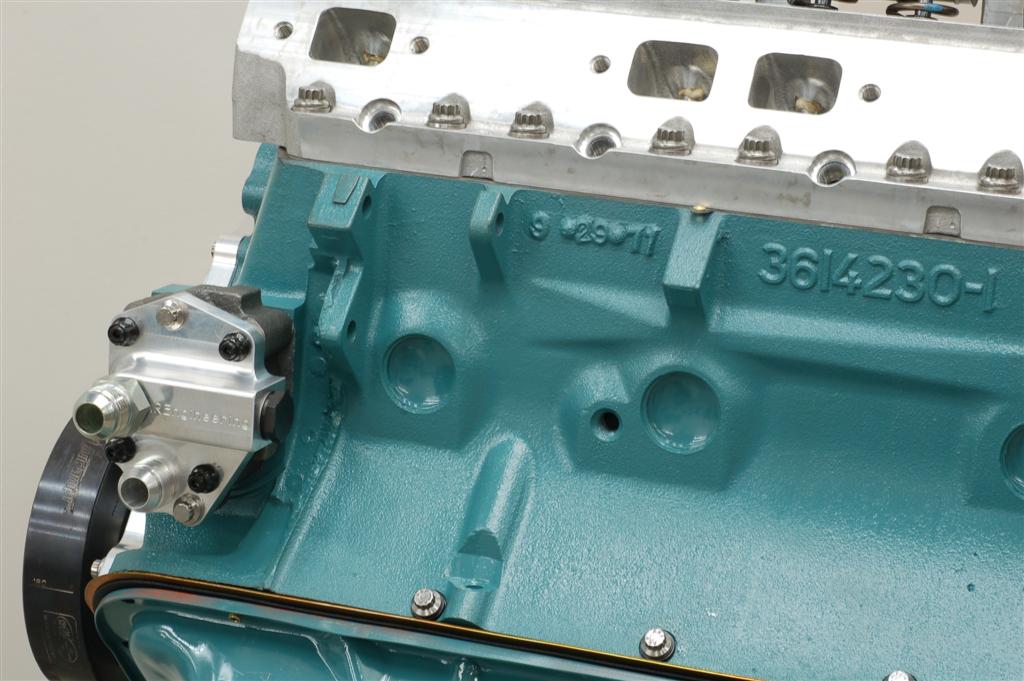

Are starting with the thick main web 230 block?

Posted By: WO23Coronet

Re: Strong B-block bottom end for max hp effort - 12/17/16 08:40 PM

Answering for the OP here so forgive me if I get it wrong, but he's building a Daytona clone for salt flat racing, and the class requires a stock block from an engine that was available in that chassis. Daytona's only came with 440's and 426 Hemi's so it has to be a 440 block, he can't use a thick web 400 230 block unfortunately.

Posted By: mprhound

Re: Strong B-block bottom end for max hp effort - 12/17/16 09:08 PM

Here is what you need, a factory crossbolt wedge block ( I was told it is a nascar casting) this is nos

Posted By: TRENDZ

Re: Strong B-block bottom end for max hp effort - 12/17/16 10:00 PM

That is cool.

Posted By: Cab_Burge

Re: Strong B-block bottom end for max hp effort - 12/17/16 11:25 PM

Define good block please

I like and use Ductile Iron main caps with ARP main studs on all my builds that will exceed 600 HP on pump gas. I also choose to use and build 400 blocks for any wedge build, regardless of fuel type used, for motors built to make over 700 HP also

As already stated a good race block is the best choice to start with on any serious race build

PM on this for more information and help, if you want it

Posted By: Sport440

Re: Strong B-block bottom end for max hp effort - 12/18/16 12:40 AM

Answering for the OP here so forgive me if I get it wrong, but he's building a Daytona clone for salt flat racing, and the class requires a stock block from an engine that was available in that chassis. Daytona's only came with 440's and 426 Hemi's so it has to be a 440 block, he can't use a thick web 400 230 block unfortunately.

Will they be allowed to use power adders such as a turbo.

Posted By: Anonymous

Re: Strong B-block bottom end for max hp effort - 12/18/16 12:46 AM

900 wedge HP without power adders is almost impossible/ at least very hard without 4.5 inch bores

and it is silly to think that a stock block will hold 900 HP for long no matter what the heck you do to it ( unless perfectly tuned turbo or the like)

Please call Marsh Perf 336 283 0800 and get a new 440 block from him--he has two in stock ready to go --not cheap but hey he has the only two on the market I am guessing

DRY SUMP DRY SUMP

A Hemi is the right direction for that job but bet the bar is already set pretty darn high in that class

Just no good answer on making that goal with a $50 block and spending a grand+++ to slightly improve it is still a crapshoot

Wet sump in that application is rolling the dice

Posted By: cudaman1969

Re: Strong B-block bottom end for max hp effort - 12/18/16 07:28 AM

Real funny, been reading David Vizards book on porting. He shows on one page a 410 cu in small block Chevy single four making in excess of 1000 hp and we can't even get close. What a shame or are we talked out of it before we even try?

Posted By: DrCharles

Re: Strong B-block bottom end for max hp effort - 12/18/16 04:38 PM

How long did that SBC last, though

Posted By: MR_P_BODY

Re: Strong B-block bottom end for max hp effort - 12/18/16 05:15 PM

Real funny, been reading David Vizards book on porting. He shows on one page a 410 cu in small block Chevy single four making in excess of 1000 hp and we can't even get close. What a shame or are we talked out of it before we even try?

I assume this was a N/A engine... thats 2.44 HP

per ci.. thats a ton.. sounds like one of those

happy dynos

Posted By: slantzilla

Re: Strong B-block bottom end for max hp effort - 12/18/16 08:07 PM

Real funny, been reading David Vizards book on porting. He shows on one page a 410 cu in small block Chevy single four making in excess of 1000 hp and we can't even get close. What a shame or are we talked out of it before we even try?

I assume this was a N/A engine... thats 2.44 HP

per ci.. thats a ton.. sounds like one of those

happy dynos

When I read his carb book I really got that same feeling.

Posted By: pittsburghracer

Re: Strong B-block bottom end for max hp effort - 12/18/16 08:18 PM

High numbers sell ragazines. Rag a zines.

Posted By: MR_P_BODY

Re: Strong B-block bottom end for max hp effort - 12/18/16 08:29 PM

High numbers sell ragazines. Rag a zines.

Yeah I know.. everyone thinks that if I do that

I will end up with the same numbers.... NOT

Posted By: AndyF

Re: Strong B-block bottom end for max hp effort - 12/18/16 10:48 PM

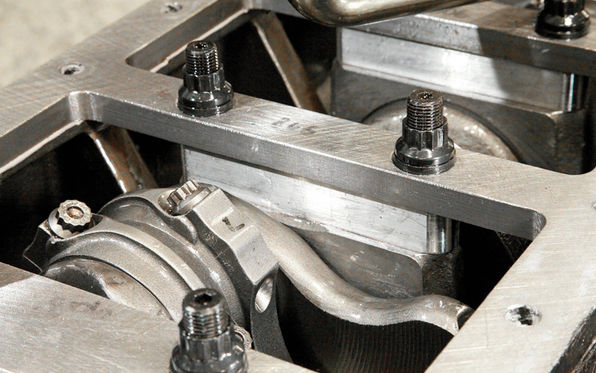

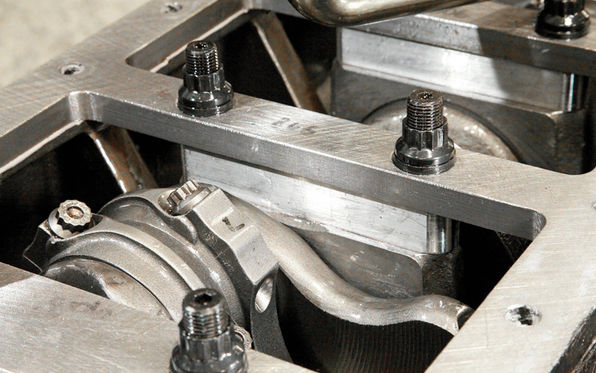

Well a super rigid billet dry sump pan might be an option. This one has 1/2 inch thick rails to help tie the bottom end together. I'd also probably use a cross bolt conversion if your block isn't cross bolted to start with.

.JPG)

Posted By: AndyF

Re: Strong B-block bottom end for max hp effort - 12/18/16 10:51 PM

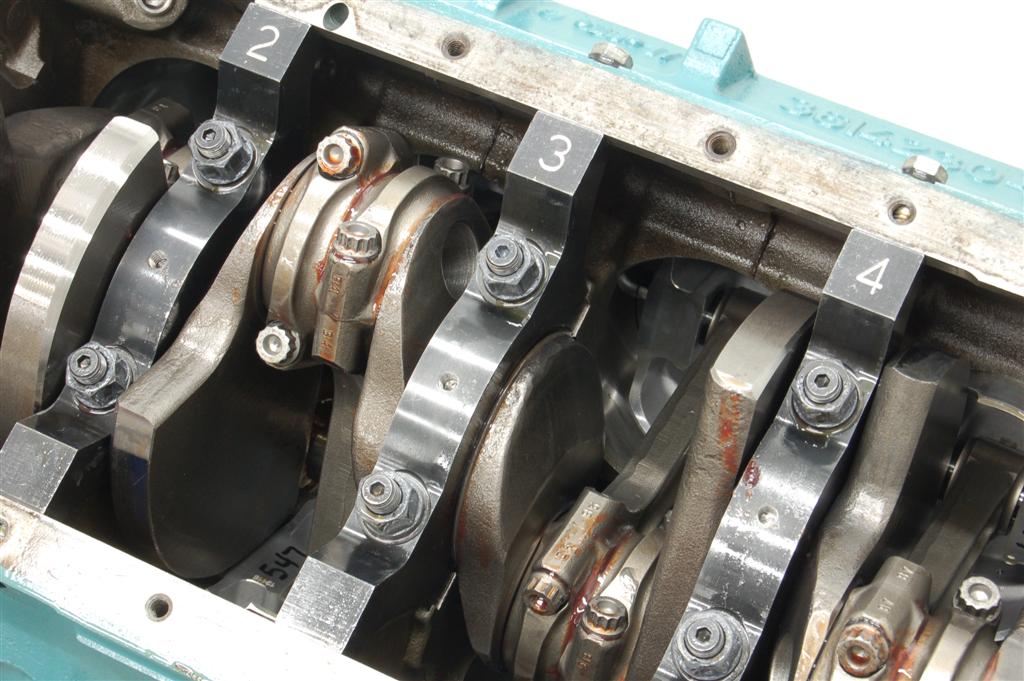

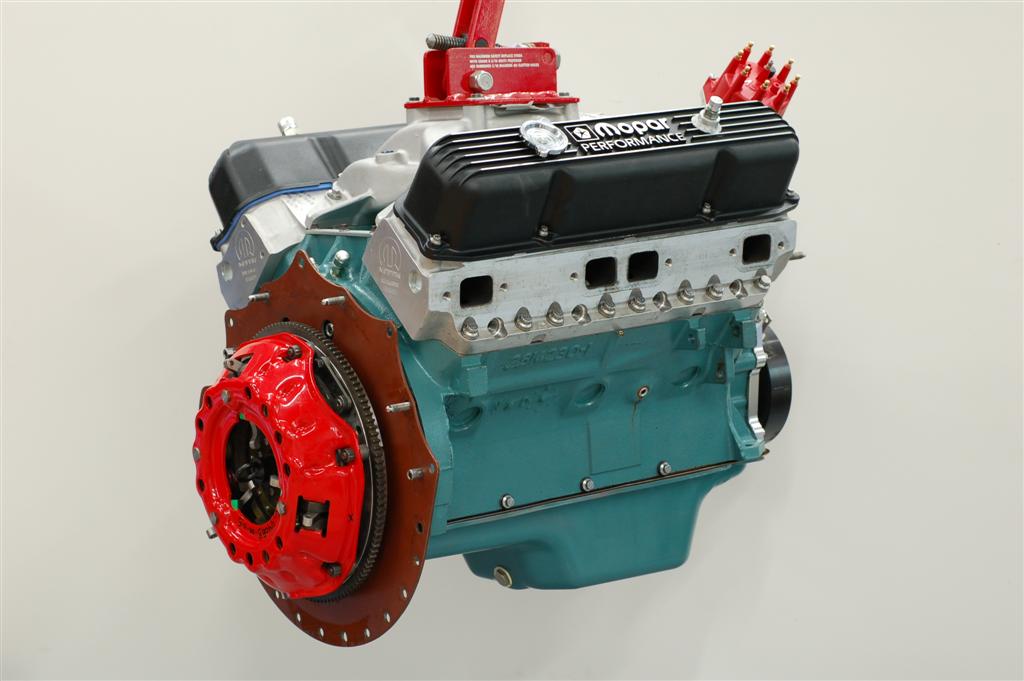

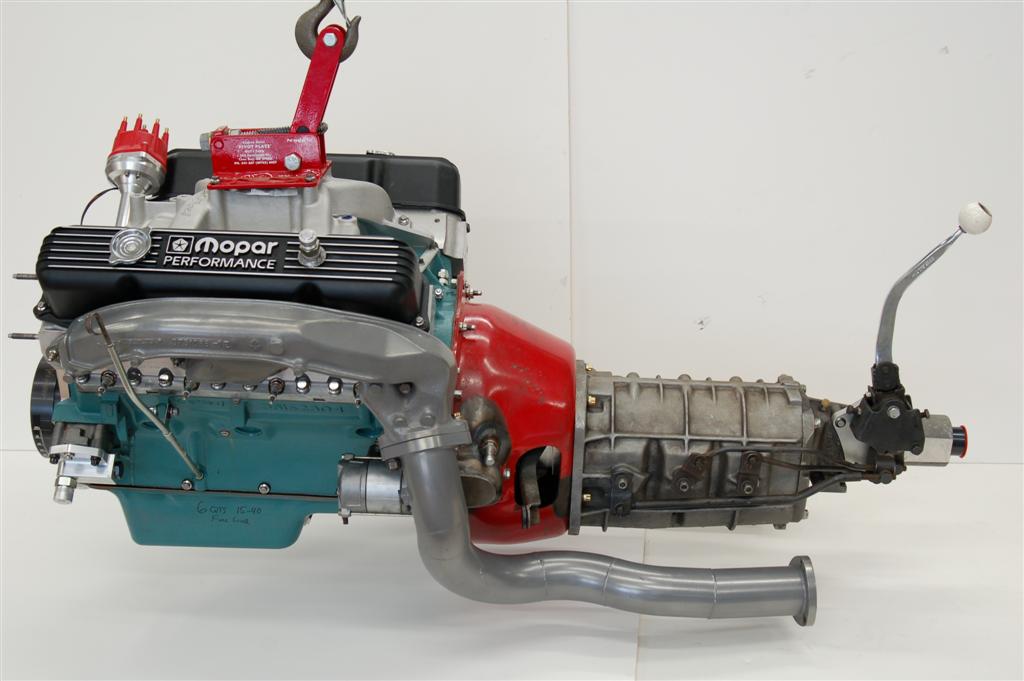

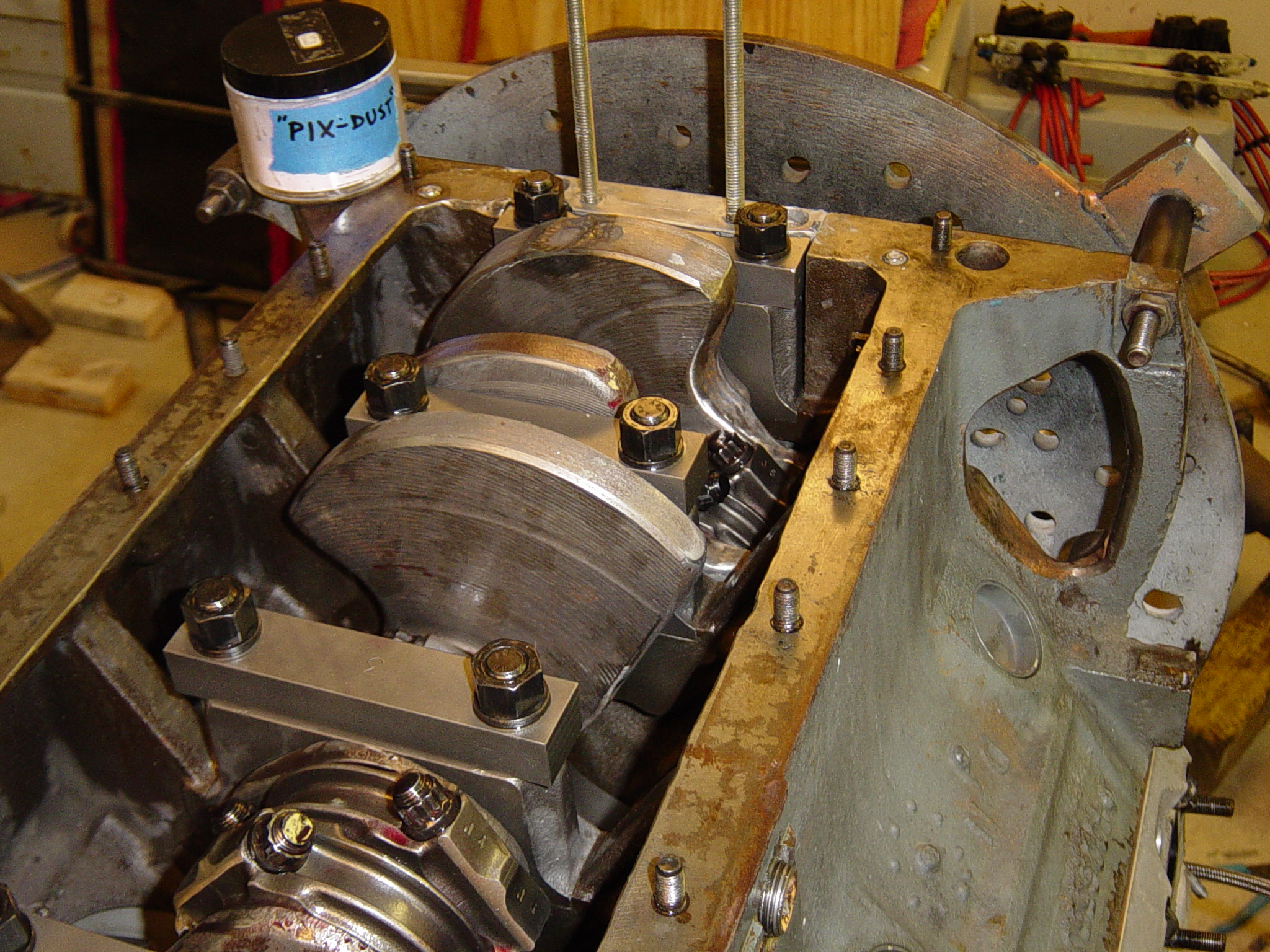

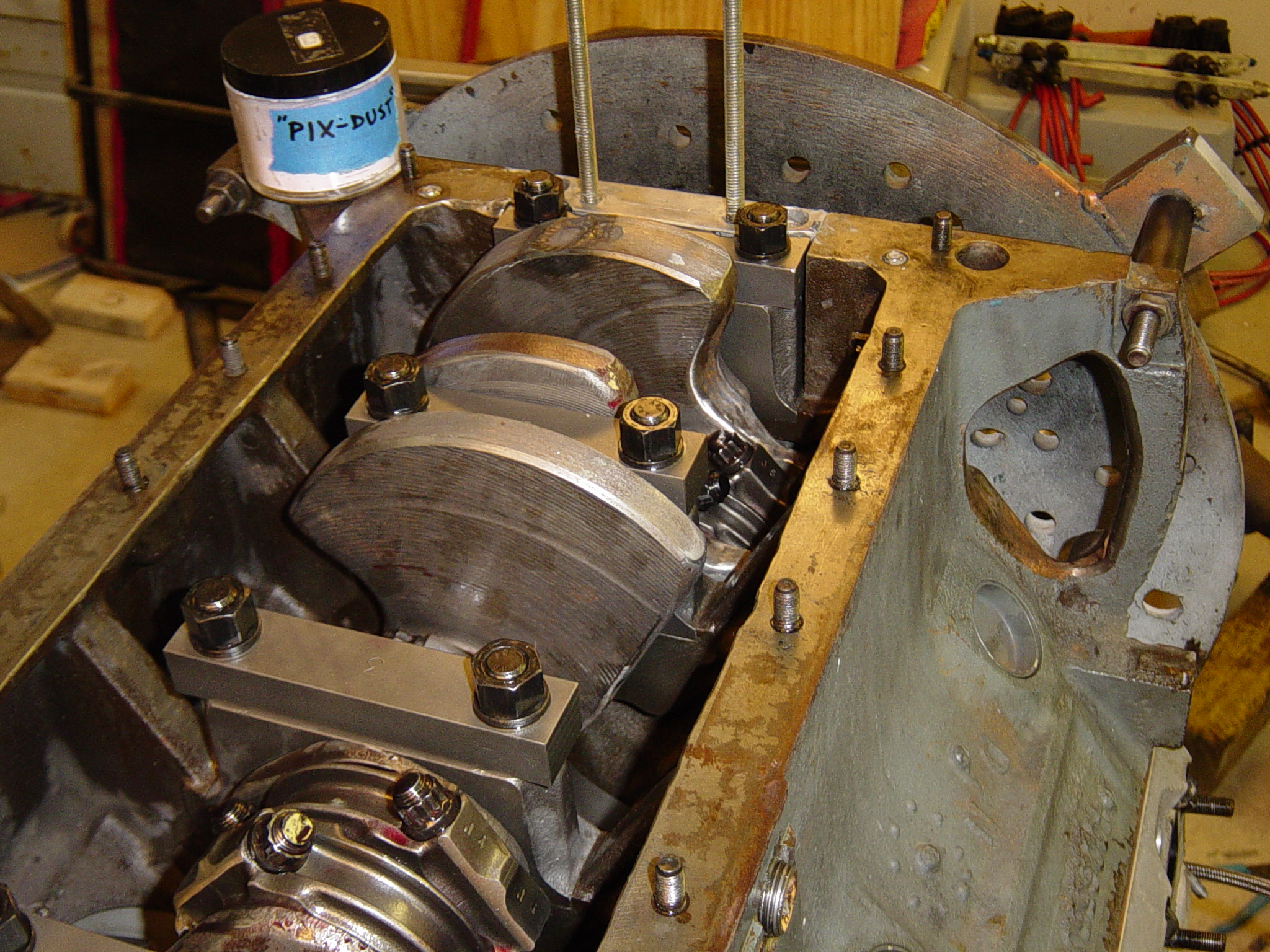

The low deck 512 that I have in my street car uses a 230 block that has been cross bolted. We also opened up the mains to the larger 440 bearing size. Here is a picture:

Posted By: racerx

Re: Strong B-block bottom end for max hp effort - 12/18/16 10:59 PM

Andy is that a stock block? This is the first I have ever seen this on a stock block.

how's it holding up for ya.?

Posted By: Monte_Smith

Re: Strong B-block bottom end for max hp effort - 12/18/16 11:28 PM

Those look like Pro-Gram caps. The install of those requires cutting on the already weak main web supports. That's why they are not hugely popular.

If I was doing the OPs build, it would consist of a half fill 440 block, alum caps, center weighted crank, as light a bobweight as I could get.............and prayer

Posted By: AndyF

Re: Strong B-block bottom end for max hp effort - 12/19/16 12:57 AM

Andy is that a stock block? This is the first I have ever seen this on a stock block.

how's it holding up for ya.?

Yep, it is a 230 cold weather block with all the mods. Even has roller cam bearings. Not sure what to say about it holding up. The engine was built about 10 years ago but it doesn't have much run time on it. It is in my '65 Coronet which mostly just sits in the shop so it doesn't have many miles on it.

Posted By: AndyF

Re: Strong B-block bottom end for max hp effort - 12/19/16 01:03 AM

Even if I did drive it a ton I doubt I'd hurt the bottom end seeing how the engine has manifolds on it. Yep, cross bolted mains, roller cam bearings and manifolds - not exactly the best planned out combo........

Posted By: dartman366

Re: Strong B-block bottom end for max hp effort - 12/19/16 01:35 AM

Even if I did drive it a ton I doubt I'd hurt the bottom end seeing how the engine has manifolds on it. Yep, cross bolted mains, roller cam bearings and manifolds - not exactly the best planned out combo........

bet it's a hoot to drive tho.

Posted By: 72Swinger

Re: Strong B-block bottom end for max hp effort - 12/19/16 02:26 AM

HAHAHA Dayum Andy, mad scientist stuff you do kills me. Paranoia of failure can make one do some ridiculous stuff at times.

Posted By: dwayne welder

Re: Strong B-block bottom end for max hp effort - 12/19/16 05:58 PM

Andy what kind of adapter you have on the oil pump? And do you make that or who does. Thanks

Posted By: fast68plymouth

Re: Strong B-block bottom end for max hp effort - 12/19/16 06:11 PM

Says "AR Engineering" on it, so I'd say he made it.

Posted By: cudadon

Re: Strong B-block bottom end for max hp effort - 12/19/16 09:11 PM

Says "AR Engineering" on it, so I'd say he made it.

Pretty safe bet eh Dwayne!

How are you my friend?

Don

Posted By: AndyF

Re: Strong B-block bottom end for max hp effort - 12/19/16 11:45 PM

Andy what kind of adapter you have on the oil pump? And do you make that or who does. Thanks

That is a one of one custom part. It is basically an adapter for a remote filter and/or cooler but just without the internal 90 degree bends that all of the other adapters have.

I was going to sell it as a product but decided it was too expensive to build in qty so I scrapped it. I use it all the time though, especially on the dyno.

Posted By: Skeptic

Re: Strong B-block bottom end for max hp effort - 12/30/16 10:38 PM

Well a super rigid billet dry sump pan might be an option. This one has 1/2 inch thick rails to help tie the bottom end together. I'd also probably use a cross bolt conversion if your block isn't cross bolted to start with.

Who Makes that piece Andy? It's a beauty, I didn't see it on your site.

Posted By: Monte_Smith

Re: Strong B-block bottom end for max hp effort - 12/30/16 10:54 PM

I am guessing that's made by Dailey Engineering, but could be wrong. That just looks life stuff he makes

Posted By: AndyF

Re: Strong B-block bottom end for max hp effort - 12/30/16 11:19 PM

I made the dry sump pan myself.

Posted By: polyspheric

Re: Strong B-block bottom end for max hp effort - 12/30/16 11:59 PM

If the purpose of the girdle is to prevent the pan rail and caps from moving, mild steel of the same thickness is far better than any aluminum.

Posted By: AndyF

Re: Strong B-block bottom end for max hp effort - 12/31/16 01:48 AM

True, but I don't think I'd be able to pick up the pan if it was made from steel. It is already super heavy in aluminum.

Posted By: gregsdart

Re: Strong B-block bottom end for max hp effort - 12/31/16 05:48 AM

I would start with a good center weighted, lightened to the max crank. I would stay with the small BB main bearing, and consider a small rod bearing like a 2.100. You can then get a fairly light custom rod to fit your combo. The center weight crank loads the main saddles more evenly, and I saw it eliminate cap walk on my cross bolted Megablock when I switched to one.

As far as the rest of the shortblock, definitely use a partial fill, and a girdle with steel main caps would be on my list. I would also sneak up on the tuneup, starting conservatively, and never look for that last hp.

Posted By: RAMM

Re: Strong B-block bottom end for max hp effort - 12/31/16 05:25 PM

If the purpose of the girdle is to prevent the pan rail and caps from moving, mild steel of the same thickness is far better than any aluminum.

^^^^^^^^^^^^^^^^This is the way I see it as well. I had a slightly different take on it though and tried to incorporate the best of both aluminum (shock absorbing) and steel for(strength). As many have mentioned a light bob weight and a center counter weighted Bryant or Winberg crank will go a long way. Hardblock it halfway but start with a block that sonics well. I have found that the cylinder strength is a problem and have split cylinders at around the 800 hp range if you get into detonation.

Not sure what cylinder head you are using but valve position sucks so bad in most of the inline valve OEM config'd offerings it wont be all that easy to make 900hp. If you could share the rules it would make helping easier. J.Rob

Posted By: TRENDZ

Re: Strong B-block bottom end for max hp effort - 12/31/16 06:12 PM

I like that set up. What did you do at the rear?

My mods didn't involve a girdle, but used tool steel straps across all 5 main caps. I had seen caps crack apart, and figured the straps would hold it together if they failed. I had to make a reverse lip oil pan at the rear because of the studs/bolts. Held 1100hp (turbo).

I agree with you on cylinder walls. Although mine never cracked, they were a bit barrel shaped(no block filler).

Posted By: Skeptic

Re: Strong B-block bottom end for max hp effort - 12/31/16 07:17 PM

I made the dry sump pan myself.

Any chance for a production run of those?

Posted By: dart games

Re: Strong B-block bottom end for max hp effort - 12/31/16 08:58 PM

think ramm and trendz are on to something here,trendz,whats that hole in the rear of block,is that for convertor bolts or cooling

Posted By: Monte_Smith

Re: Strong B-block bottom end for max hp effort - 12/31/16 09:04 PM

The hole is likely just weight, as it surely sacrifices nothing in that area for strength. My "race" blocks, I used to do the same thing as well as grinding off motor mount ears and anything else I could. Can save quite a few pounds but it's a lot of work. I have even seen blocks with that total corner cut off. How many bellhousing bolts do you really need? Where is the trans going? And how many guys have those holes stripped in their trans anyway? They don't do anything. Cut em off

Posted By: TRENDZ

Re: Strong B-block bottom end for max hp effort - 12/31/16 09:27 PM

The hole was for converter bolts, weight was just a side benefit. Because the pan was made with a reverse lip, and was a rear sump, and was very wide, I had no room to get at the converter bolts in the normal sense. Very much an after thought on my part. I didn't realize the issue until it was in the car. Had I realized the issue, I would have built the pan different. Live and learn

Posted By: Cab_Burge

Re: Strong B-block bottom end for max hp effort - 12/31/16 09:48 PM

My thinking on any main support girdle for BB Mopars or other blocks like ours(FE Ford) that doesn't have a press on interference fit girdle onto all of the fasteners, shouldered main studs and shouldered oil pan studs, isn't holding the main caps in place other than front to rear movement. They're not adding strength up in the main webbing where it is needed on the stock RB blocks

They may look good and make some users fell happy but are they really helping the bottoms of the blocks to become stronger and reduce or stop main webbing cracking and cap walk

I do buy and use stronger after market main caps(usually Ductile iron, not steel

) and main studs to help prevent main cap breakage for any motor I build that will exceed 600 HP now

I really wish there was a real fix for the main webbing in the stock blocks, all years of the RB as well as the non cold weather 400 blocks

Posted By: fast68plymouth

Re: Strong B-block bottom end for max hp effort - 12/31/16 10:35 PM

Admittedly, I have no experience building a motor for a land speed application, but using really light weight internals isn't how I think I'd go about it.

The parts need to be durable enough for an extended period of time under heavy load.

IMO, this is more similar to a marine application than a drag motor.

The acceleration rate is very low, so heavier parts should have almost zero affect on the speed of the vehicle.

I understand the concerns about the mains, but if a rod or wrist pin fails because they arent HD enough, it's all over.

There is going to need to be a balance found between the strength needed for the application vs how light the parts can be.

Posted By: HOTMOPR

Re: Strong B-block bottom end for max hp effort - 01/01/17 02:31 AM

Ive been well over a 1000 for a couple years now. Its a 230 block partial fill. steel caps. 3/8" thick girdle, Studs everywhere the girdle. I have also had good results using 3m weatherstrip adhesive on the girdle to block rail. I apply it liberally install the girdle and then bolt it down for a few days to dry before installing the pan. I get zero leaks and no shifting from the girdle. Only sucks at refresh time.. My motor is also boosted so I only spin it to 6800.

Posted By: TRENDZ

Re: Strong B-block bottom end for max hp effort - 01/01/17 05:42 AM

That was always my question on the functionality of girdles. How solid can they be when sandwiched in between gaskets? I always felt that a girdle should be "glued" to the rail, but fastened directly with flush mount tapered locating bolts in an alternate pattern of the pan gasket, so that the girdle isn't dependent on being held in place by a compressible gasket/ hardware.

Posted By: rebel

Re: Strong B-block bottom end for max hp effort - 01/01/17 05:49 AM

my girdle is glued to the rail on one side & only has a gasket on the pan side. the cap studs are doing all the work holding it together, the pan bolts do nothing but hold the pan on

Posted By: gregsdart

Re: Strong B-block bottom end for max hp effort - 01/01/17 06:25 AM

Look at a KB double bolted block for an idea of what I think would help a stock block live. The double bolt , both top and side, main caps would have to be very large, because the only way to build it would be to build it all below the pan rail. that would create quite a massive add on structure, but if money is not an issue, well, thats' what racers do to win.

The idea is to make the whole deal, main caps and what they are bolted to, so massive that any load put on a single bearing is also transferred to the adjacent two and beyond. That would greatly reduce the stress on the main web area of the cap at the center of the load.

Posted By: dvw

Re: Strong B-block bottom end for max hp effort - 01/01/17 05:55 PM

If I used a girdle it would be sealed with anaerobic sealer. For those who don't know its designed the seal two machined halfs. Looks and smells like Locktite. Comes loose very easy when the parts are tapped loose in side shear. Very thin and drys hard between the parts. Drys as soon as there is no air.

Doug

Posted By: dartman366

Re: Strong B-block bottom end for max hp effort - 01/01/17 11:32 PM

That was always my question on the functionality of girdles. How solid can they be when sandwiched in between gaskets? I always felt that a girdle should be "glued" to the rail, but fastened directly with flush mount tapered locating bolts in an alternate pattern of the pan gasket, so that the girdle isn't dependent on being held in place by a compressible gasket/ hardware.

there is no gasket between the girdle and the block on my BCR kit, I used a very light coat of grey silicon between the girdle and pan rail, all the perimeter bolts are studs and the nut's are counter sunk into the girdle, then there is the pan gasket and pan over top of those nut's and that is held in place by another set of nut's on the exsisting pan rail stud's, you can drop the pan and never disturb the girdle, nice well thought out system in my opinion.

Posted By: WedgeFED

Re: Strong B-block bottom end for max hp effort - 01/01/17 11:47 PM

Posted By: TRENDZ

Re: Strong B-block bottom end for max hp effort - 01/02/17 01:17 AM

That was always my question on the functionality of girdles. How solid can they be when sandwiched in between gaskets? I always felt that a girdle should be "glued" to the rail, but fastened directly with flush mount tapered locating bolts in an alternate pattern of the pan gasket, so that the girdle isn't dependent on being held in place by a compressible gasket/ hardware.

there is no gasket between the girdle and the block on my BCR kit, I used a very light coat of grey silicon between the girdle and pan rail, all the perimeter bolts are studs and the nut's are counter sunk into the girdle, then there is the pan gasket and pan over top of those nut's and that is held in place by another set of nut's on the exsisting pan rail stud's, you can drop the pan and never disturb the girdle, nice well thought out system in my opinion.

Ok. Pretty much what I was thinking on how it should be. Never used one myself.

As for dad's setup there, Pretty dang nice. SKILZ!

Posted By: dartman366

Re: Strong B-block bottom end for max hp effort - 01/02/17 01:41 AM

That was always my question on the functionality of girdles. How solid can they be when sandwiched in between gaskets? I always felt that a girdle should be "glued" to the rail, but fastened directly with flush mount tapered locating bolts in an alternate pattern of the pan gasket, so that the girdle isn't dependent on being held in place by a compressible gasket/ hardware.

there is no gasket between the girdle and the block on my BCR kit, I used a very light coat of grey silicon between the girdle and pan rail, all the perimeter bolts are studs and the nut's are counter sunk into the girdle, then there is the pan gasket and pan over top of those nut's and that is held in place by another set of nut's on the exsisting pan rail stud's, you can drop the pan and never disturb the girdle, nice well thought out system in my opinion.

Ok. Pretty much what I was thinking on how it should be. Never used one myself.

As for dad's setup there, Pretty dang nice. SKILZ!

he must be a machinist by trade?? look's pretty nice, kind of like the way the small blocks are, cap's are tied together but not to the block/panrail, I used a Hughes on my 408 and they just tie the caps together like that.

Posted By: WO23Coronet

Re: Strong B-block bottom end for max hp effort - 01/02/17 05:00 AM

Since this is a land speed deal and weights probably not a huge issue (maybe a benefit) I'd make a one piece girdle (or bedplate) with the mains intergrated right into them that bolts to the pan rail. Make it maybe 2" above and beyoned the pan rail (probably approximately 4" above the mains)? Cost effective for a normal application? Absolutely not. For a class that requires a stock block but 900+hp to win and you want it to stay together, absolutely. It would also act as a shield as well and keeps parts contained should something fly apart.

Making it from one piece would be best (but $$$), but I guess you could also weld some steel main caps (440source has them) to a thick plate of steel as well and do it that way.

Posted By: Saskabusa

Re: Strong B-block bottom end for max hp effort - 01/03/17 05:45 AM

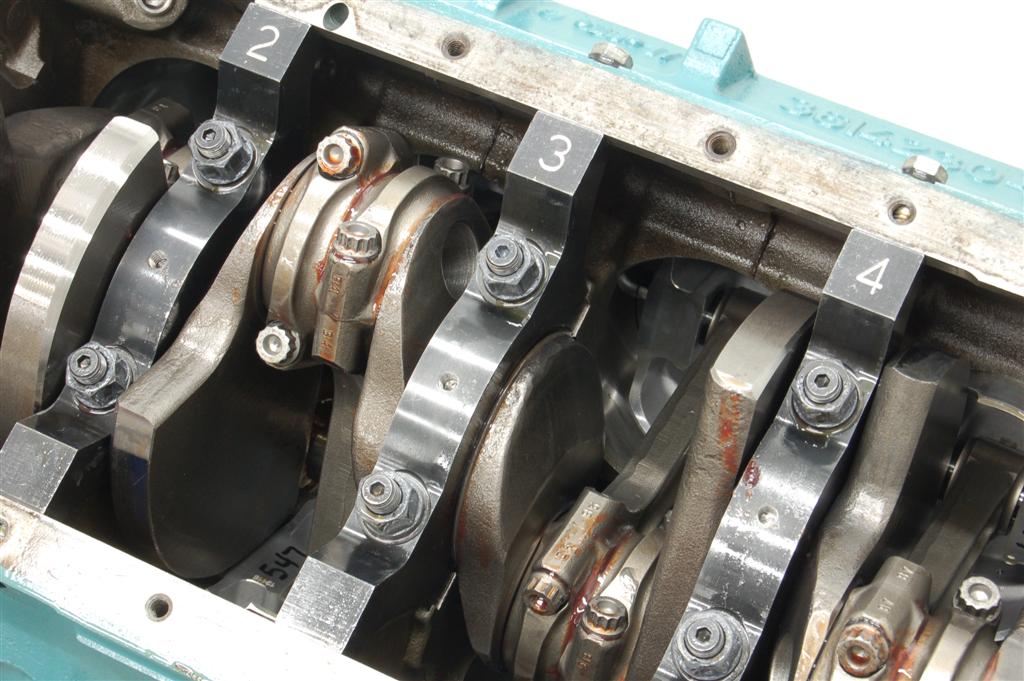

Something my Dad created.

That look interesting. Was this ever run?

Posted By: WedgeFED

Re: Strong B-block bottom end for max hp effort - 01/05/17 10:37 PM

He is a machinist and it is tied to pan rails. He has done a couple of them. This one has not run yet as for he bought a KB block for the Mercedes this go around. He does not like the girdles that tie in with the oil pan bolts so this was his creation. He did not want to cut into the webbing in the block for program caps either.