Posted By: B5496RR

727 Turbo Action T/C contacts flexplate to crankshaft bolts - 10/31/16 04:41 AM

I recently installed a new Turbo Action 10" T/C, 3800 stall. Soon after I noticed a leak from the bell housing. The front pump bushing, seal, o-ring, gasket and pump bolt washers were all replaced at this time.

I found the following upon removal of the torque converter for inspection of the leak.

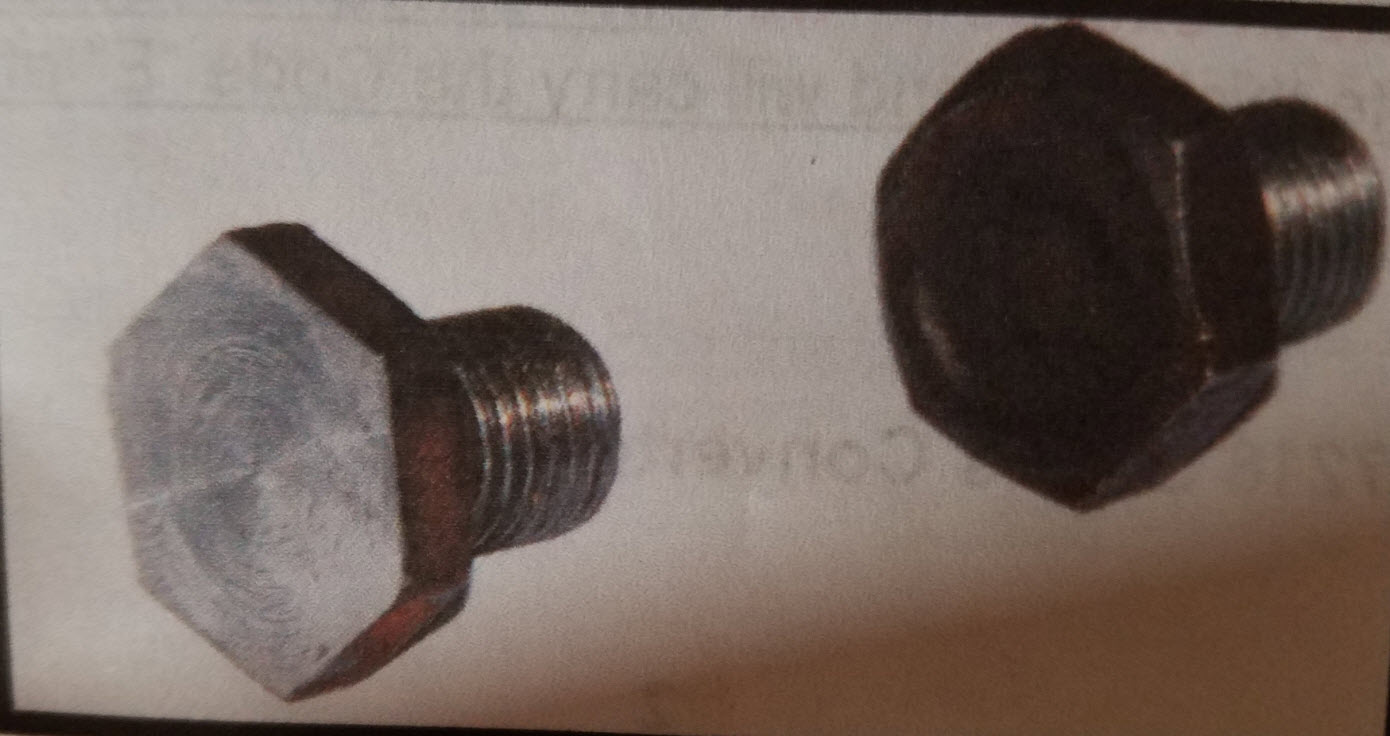

The Turbo Action T/C is contacting the flexplate to crankshaft mounting bolts on a BB Chrysler. The Dynamic converter it replaced does NOT have any witness marks were it contacted the bolts and it also did not leak transmission fluid from the bellhousing.

I assume the back portion of the converters are different but if that's so I assume others with Turbo Action converters have the same problem.

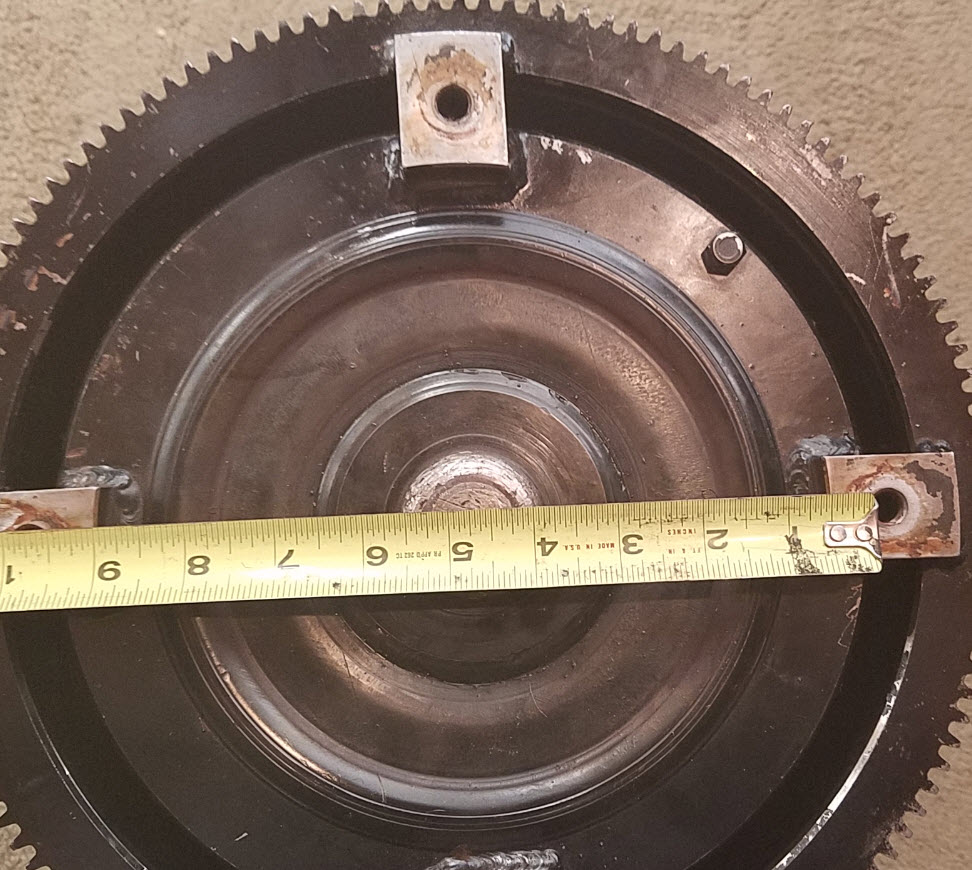

Using a B&M 17203 Flex plate

Any idea why this occurred with the Turbo Action converter?

How does one correct this issue?

Anyone else run into this same issue?

Also in one of the pics I circled a wear area in red. It can NOT be felt with a finger nail. Is this from the front pump gear and is it normal?

I found the following upon removal of the torque converter for inspection of the leak.

The Turbo Action T/C is contacting the flexplate to crankshaft mounting bolts on a BB Chrysler. The Dynamic converter it replaced does NOT have any witness marks were it contacted the bolts and it also did not leak transmission fluid from the bellhousing.

I assume the back portion of the converters are different but if that's so I assume others with Turbo Action converters have the same problem.

Using a B&M 17203 Flex plate

Any idea why this occurred with the Turbo Action converter?

How does one correct this issue?

Anyone else run into this same issue?

Also in one of the pics I circled a wear area in red. It can NOT be felt with a finger nail. Is this from the front pump gear and is it normal?