[quote=polyspheric]Not my strong subject (is there one?) but it seems to me that to relieve its load the pinion gear tries to move backward (toward the D/shaft).[quote]

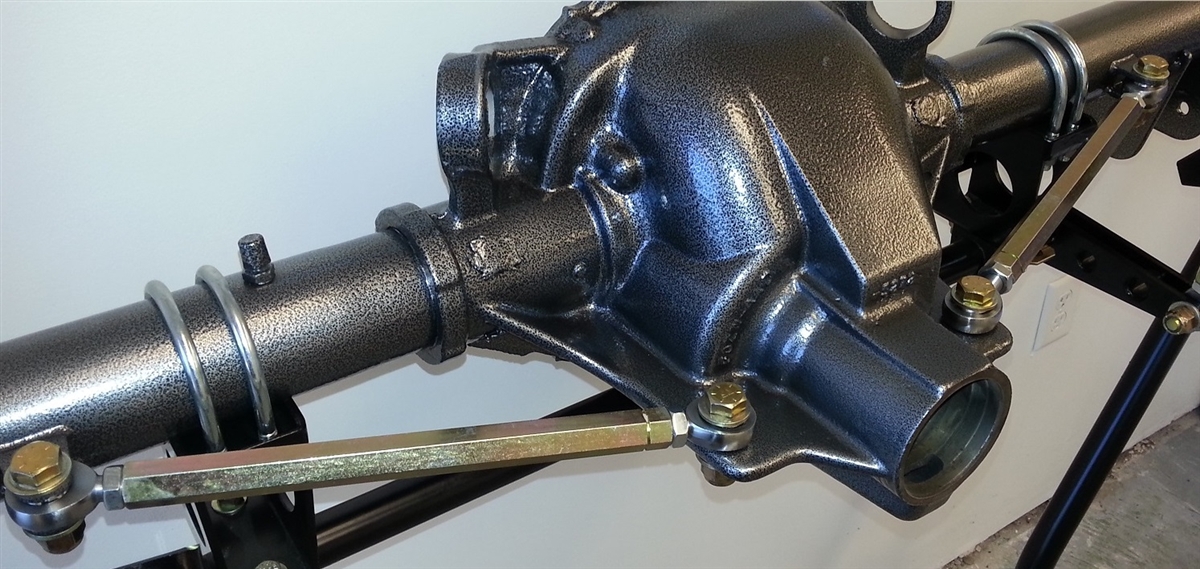

But its reactionary force is against the Ring, so the ds sees nothing of this force battle. The ring is forced to the drivers side, and towards the rear, as the hypoid gears push away from each other, or try to. This rearward force of the ring from an overhead view is counterclockwise in direction, which is why the Drivers side cap is loaded in tension, and I believe always the first to fail. The pass side cap mainly is just for positioning and stabilization.

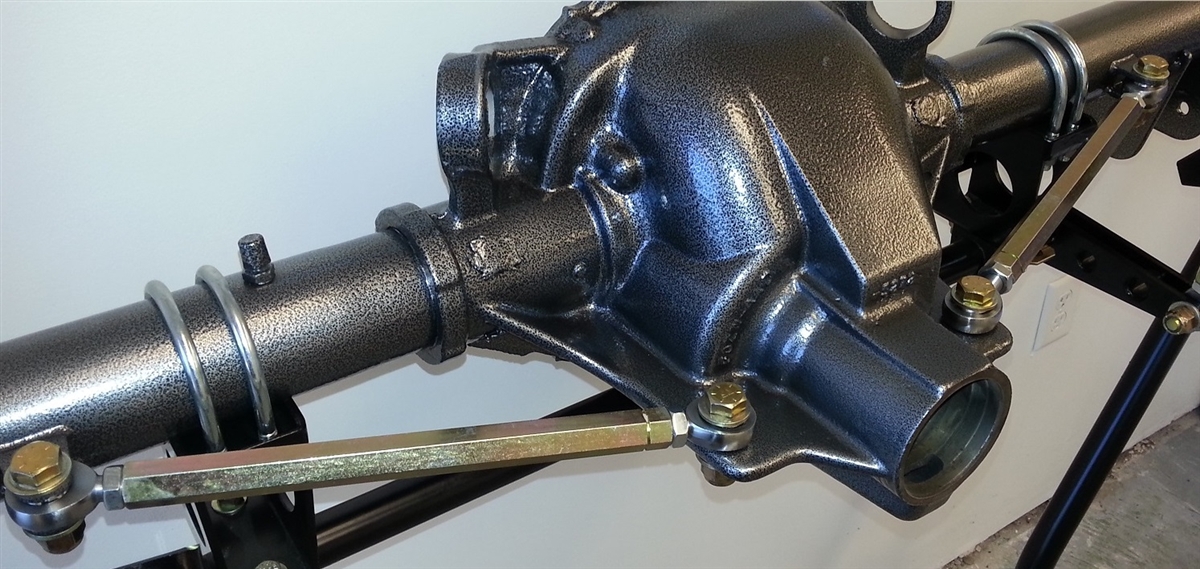

As it has been mentioned, the greater the spring/control rod inset on the housing, the more leverage there is from a dead weight, and any acceleration forces to act on the housing from the bearing ends towards the center section by increased leverage. The back brace helps slightly with the dead weight angle, and will be much more helpful with the acceleration bending forces. However I think those forces might be over rated, when at the power levels for an 8.75.

I also doubt a spline fit 20"+ axle can add that much load to a bearing cap from housing flex. So how much is this housing really flexing? It would also be odd that this housing flex transmitted thru the spline axle normally only breaks the Driver side center section cap. Now that could be because its a combination of the way the cap is loaded with the housing flex, but.....

None of my reasoning here applies to tire shake conditions when the forces are chaotic and off the chart.

Now with the rotational twisting of the housing under acceleration, two things stand out to me, a back brace is a rather poor choice to resist torsional twist of the housing, but it does improve matters, and in the situation where the springs are relocated, and moved in towards the center, the housing by design is now much stiffer, in a rotational standpoint, as the dimensions are all shortened on the center section side, and not sure any twisting is taking place outside of the springs, in the first place.