Posted By: gregsdart

Screen in lifter valley? - 04/19/16 11:15 AM

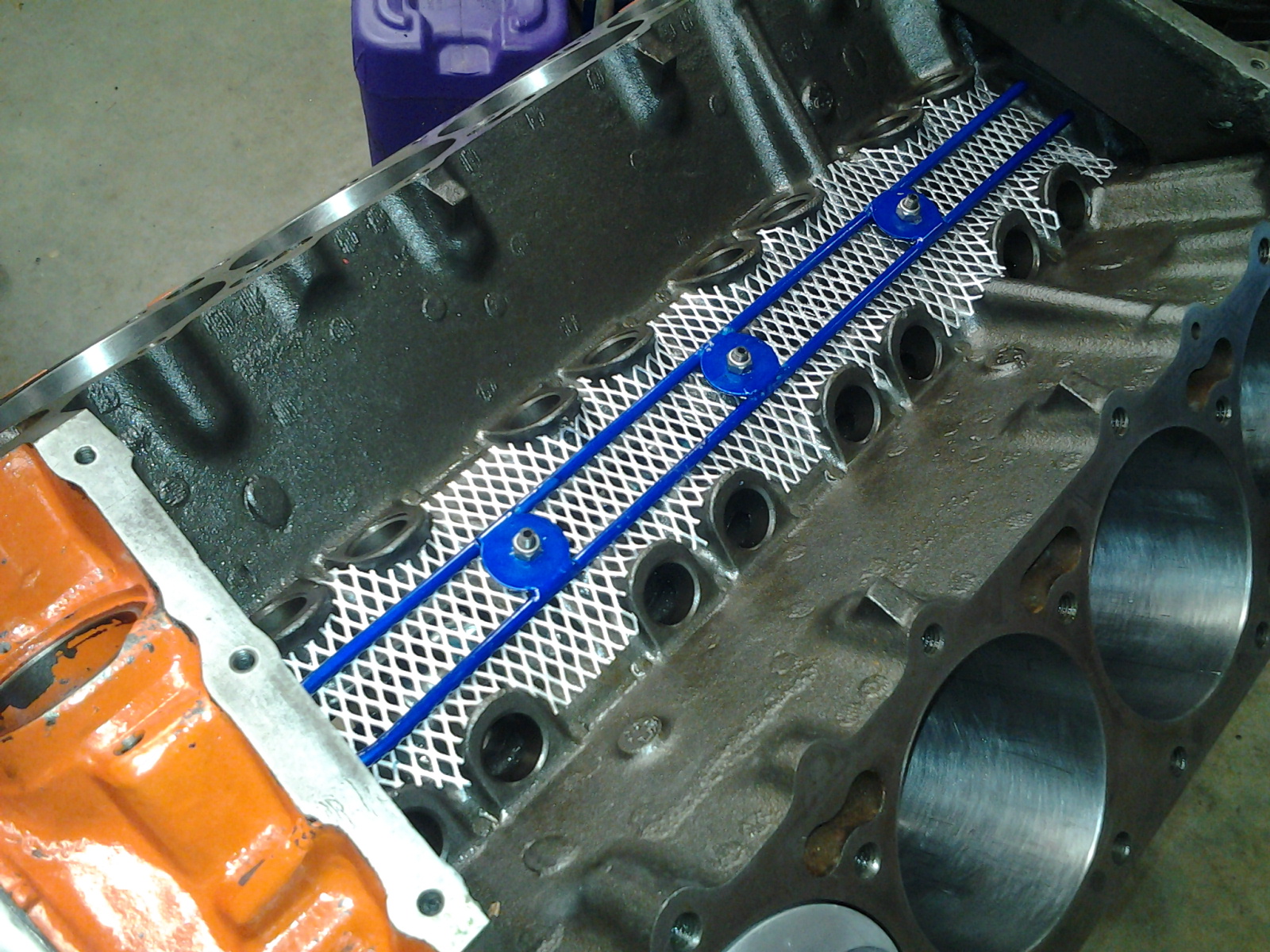

I want to put some form of screen into the lifter valley, but don't want a lot of oil piling up. Can anyone show me pictures, and what materials you used to do this to an iron block?

.jpg)