Posted By: StrokerPost

Help me get my mind around this...accurately. - 01/24/09 04:25 AM

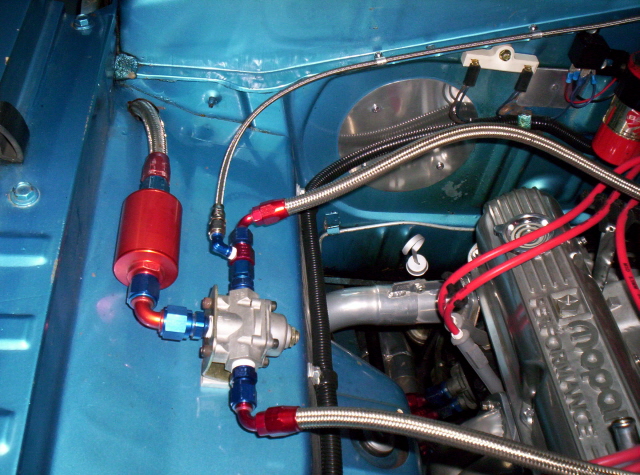

Ok, this is a fuel pressure question pertaining to WOT only. I'll use my car as the subject. I run a Mallory 140 pump fed by 10AN line from the cell to the pump, then 8AN all the way forward to the reg, then dual 6AN lines, one to each bowl and the press gage is reading press to the rear bowl, just off the reg. I set the press at 7.5 psi. At WOT, in high gear the cowl mounted gage will always be flicking between 6.5 & 7 psi, so obviously, its not maintaining press at WOT. My engine builder is always on me about correcting that to keep the press steady at whatever I have it set at, said I'm probably leaving something on the table ET wise. I've always maintained that that little bit of fluxuation isnt enough to be hurting anything, after all, the car is a deadly consistant, multi winning car (not to be read as bragging) so why waste $$$ to have a steady gage. This "fluxuation" has me puzzled now though, and I'm wondering, in a race environment, at WOT, how big a deal is it to rely on the low press area in the intake to PULL fuel through the jets vs adequate press PUSHING fuel to the jets? Obviously the car will run fine with fluxuating gage, but are you REALLY giving up any REAL performance by NOT having full press at WOT?  I've always kinda thought that the engine will pull what it needs so long as the bowls arent being sucked dry, and with only about 3/4 of a pound loss in press I dont see that happening, but, I'm willing to listen and explore that possibility. I'm not looking for ideas on a new pump or why the press is fluxuating, but is this an issue or not, with some explanation. Thanks for any and all input, I want to put this to rest in my head once and for all.

I've always kinda thought that the engine will pull what it needs so long as the bowls arent being sucked dry, and with only about 3/4 of a pound loss in press I dont see that happening, but, I'm willing to listen and explore that possibility. I'm not looking for ideas on a new pump or why the press is fluxuating, but is this an issue or not, with some explanation. Thanks for any and all input, I want to put this to rest in my head once and for all.

Ken.

I've always kinda thought that the engine will pull what it needs so long as the bowls arent being sucked dry, and with only about 3/4 of a pound loss in press I dont see that happening, but, I'm willing to listen and explore that possibility. I'm not looking for ideas on a new pump or why the press is fluxuating, but is this an issue or not, with some explanation. Thanks for any and all input, I want to put this to rest in my head once and for all.

I've always kinda thought that the engine will pull what it needs so long as the bowls arent being sucked dry, and with only about 3/4 of a pound loss in press I dont see that happening, but, I'm willing to listen and explore that possibility. I'm not looking for ideas on a new pump or why the press is fluxuating, but is this an issue or not, with some explanation. Thanks for any and all input, I want to put this to rest in my head once and for all.

Ken.

you are seeing the needle opening and closing. You will also never "push" fuel through the jets, thats not how a carburetor works. The bowls are not pressurized, they are filled to a level set by the float. If the needle was stuck open and the bowls were allowed to completely fill under pressure it would come out the vent, boosters, etc.

you are seeing the needle opening and closing. You will also never "push" fuel through the jets, thats not how a carburetor works. The bowls are not pressurized, they are filled to a level set by the float. If the needle was stuck open and the bowls were allowed to completely fill under pressure it would come out the vent, boosters, etc.

Well you and DT seem to be viewing it as I have been, not a big deal. Thanks for your thoughts guys. Any others care to weigh in? I am FAR from being an expert on this stuff and I know there are a bunch of savy guys here.

Well you and DT seem to be viewing it as I have been, not a big deal. Thanks for your thoughts guys. Any others care to weigh in? I am FAR from being an expert on this stuff and I know there are a bunch of savy guys here.

My message is if you can slow the car down in 1/4 MPH by fattening the mixture up enough until it slows down your fuel delivery system is probally okay, no matter what the fuel pressure gauges reads during the run, if you can't fatten it up enough to slow the cars MPH down you probally have a fuel delivery problem. I did not say fuel pressure problem

My message is if you can slow the car down in 1/4 MPH by fattening the mixture up enough until it slows down your fuel delivery system is probally okay, no matter what the fuel pressure gauges reads during the run, if you can't fatten it up enough to slow the cars MPH down you probally have a fuel delivery problem. I did not say fuel pressure problem