Moparts

Big Ports, Big Flow #s, And Low Duration Camshafts

Posted By: Street Monkies

Big Ports, Big Flow #s, And Low Duration Camshafts - 01/12/15 06:15 PM

Like it says Is big flow #s and even bigger ports the way to go? Along with a low duration camshaft but the right lift for combo. For any small block racing engine.

Posted By: MR_P_BODY

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/12/15 06:20 PM

Quote:

Like it says Is big flow #s and even bigger ports the way to go. Along with a low duration but the right lift for combo.

Just as long as you have enough lift to fill the

cyls.. normally when you have big ports and big flow

it wants high rpm to be efficient.. duration also

tells you about the rpm.. so if your short on duration

those heads might never be efficient ..... JMO

Posted By: HotRodDave

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/12/15 07:03 PM

Look at the cams in the new hemis, high flow, bigish ports and very tiny duration cams give huge HP numbers. You get the best of everything low RPM power and high RPM power without the stupid long duration cams of the 70s. They do get some decent lift but not at the expense of added duration. An average performance cam duration numbers like a comp 280 magnum

230@.050 would be downright wicked in a 6.1 hydraulic roller.

Another thing to look at and glean information is the engine masters engines and cams, relatively short duration and very high lift with big flow numbers, that seems to be the biggest most consistant part of the recipe the winners use. The winning engines are making incredible TQ per cube and still making very nice HP up stairs.

Posted By: MR_P_BODY

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/12/15 07:07 PM

Quote:

Look at the cams in the new hemis, high flow, bigish ports and very tiny duration cams give huge HP numbers. You get the best of everything low RPM power and high RPM power without the stupid long duration cams of the 70s. They do get some decent lift but not at the expense of added duration. An average performance cam duration numbers like a comp 280 magnum [Email]230@.050[/Email] would be downright wicked in a 6.1 hydraulic roller.

Another thing to look at and glean information is the engine masters engines and cams, relatively short duration and very high lift with big flow numbers, that seems to be the biggest most consistant part of the recipe the winners use. The winning engines are making incredible TQ per cube and still making very nice HP up stairs.

Engine Masters are set up for torque.. thats where the

points for winning are... I also assumed he is playing

with old wedge stuff... try using modern rules on

that and see what you get

Posted By: Street Monkies

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/12/15 07:37 PM

Right Wedge it is. But I do look at a lot of the engine masters builds and I notice basically what we are all talking about. Low duration 230-250 @ .050 and 600-900 lift. Also they seem to run the biggest intake valve they can fit. In some of the heads the street class they must of moved guides to get a big valve like a 2.100" or bigger intake in RHS or Pro Comp smallblock heads. With the bore sizes they are running I'm sure they are exceeding the limit of the 52% bore to intake size. All and yes they do seem to get them spun up near 8,000 with a little duration cam. But like Mr P Body said they are looking to make torque and through a certain rpm range.

Posted By: MR_P_BODY

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/12/15 07:45 PM

Quote:

Right Wedge it is. But I do look at a lot of the engine masters builds and I notice basically what we are all talking about. Low duration 230-250 @ .050 and 600-900 lift. Also they seem to run the biggest intake valve they can fit. In some of the heads the street class they must of moved guides to get a big valve like a 2.100" or bigger intake in RHS or Pro Comp smallblock heads. With the bore sizes they are running I'm sure they are exceeding the limit of the 52% bore to intake size. All and yes they do seem to get them spun up near 8,000 with a little duration cam. But like Mr P Body said they are looking to make torque and through a certain rpm range.

Its been a while since I watched much of the engine

master stuff.. but if I recall they are playing in

a certain rpm range so what they are doing works

great for them to make a ton of torque in the low

rpm range... but most if not all of them would be

maxed out in rpm at some low point

Posted By: Hemi_Joel

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/12/15 08:24 PM

The valve trains in an Engimasters entry are like an Aztec maiden, sacrificed for the cause. .900+ lift, short duration, crazy valve spring pressure. They barely make it thru the contest.

Posted By: BradH

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/12/15 08:46 PM

Big Ports w/ Big Flow #s WITHOUT Big Velocity = Big Pig AND Big Disappointment.

If the head's velocity across the lift curve isn't sufficient, the flow #s don't mean anything and the large(r) runner volume just adds to the problem.

Posted By: Cogito

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/13/15 12:51 AM

Quote:

Big Ports w/ Big Flow #s WITHOUT Big Velocity = Big Pig AND Big Disappointment.

If the head's velocity across the lift curve isn't sufficient, the flow #s don't mean anything and the large(r) runner volume just adds to the problem.

What controls velocity?

Posted By: R5P7 Bantam

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/13/15 01:23 AM

What controls velocity?

Piston speed and port/runner shape. In essence, the geometric profile (tube) in which the air travels to the base of the valve head. This geometric shape starts at the top of the intake manifold (carb plate) and some may include the shape of the venturi's w/in the carb/throttle body.

Posted By: GTX MATT

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/13/15 01:37 AM

How about a stock cammed Hemi, partiularly the 66/67 grind?

Posted By: D-50

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/13/15 02:08 AM

My small block was in one of the engine master contest. It did not win but it made 662 hp @ 7300 rpm on pump gas at 394 ci.and has a 255/266 @ .050 roller cam. I do not consider that a whole lot of duration. Heads are Indy 360-2 and flow 337 @ .650 on intake.

Posted By: ahy

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/13/15 03:15 AM

Quote:

Look at the cams in the new hemis, high flow, bigish ports and very tiny duration cams give huge HP numbers. You get the best of everything low RPM power and high RPM power without the stupid long duration cams of the 70s. They do get some decent lift but not at the expense of added duration. An average performance cam duration numbers like a comp 280 magnum [Email]230@.050[/Email] would be downright wicked in a 6.1 hydraulic roller.

Another thing to look at and glean information is the engine masters engines and cams, relatively short duration and very high lift with big flow numbers, that seems to be the biggest most consistant part of the recipe the winners use. The winning engines are making incredible TQ per cube and still making very nice HP up stairs.

I love the new Hemi's... they have some tricks that make the setup work. Even the earliest versions benefited from 5 speed OD transmissions with deep first and some stall in the lock up converter. With EFI they would run smooth at cruising RPM... with gears and stall they would scoot. The newest have variable timing and intake length which makes it a much better engine... not as much stall and gear (shifting) needed to cover the weak low end + more on top.

We don't have that available on the wedges. That said, I don't think a "multipurpose" wedge needs more than 240 or 250 degrees duration even with big ports. Drag race, sure, go for duration and get plenty of stall on the converter... but not multi purpose.

Posted By: Cogito

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/13/15 06:31 AM

Quote:

What controls velocity?

Piston speed and port/runner shape. In essence, the geometric profile (tube) in which the air travels to the base of the valve head. This geometric shape starts at the top of the intake manifold (carb plate) and some may include the shape of the venturi's w/in the carb/throttle body.

This is the response I see most often on the internet.

How about valve events and ramp rates?

Posted By: Cogito

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/13/15 06:54 AM

I always enjoyed this Boss vs DZ 302 article...note compression and cam differences.

http://www.hotrod.com/how-to/engine/hrdp-1001-muscle-car-engine-shootout/

Posted By: HotRodDave

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/13/15 08:49 PM

Wonder why they left out the 340? It would be right there in the middle of the mix with some race headers and big carb, the factory 600 wouldn't hardly flow that and good headers are a proven 25+ hp. Even the 440 hp carb was a big step up in performance.

Posted By: Streetwize

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/13/15 10:06 PM

the thing about a good port is that even if the duration is relatively short, the torque (VE) beyond peak torque RPM does not drop off very rapidly, therefore the motor still makes good/great HP despite having what (on paper) looks like too small a cam. This holds true as long as the induction/compression and exhaust are also suitably matched. Fuel injection has a ton to do with that as well because you only need to move AIR through the manifold (fuel displaces about 7% or so of the available area of a wet port)

The modern Hemi or the Chevy LS2 are very good examples of what an efficient port can do.

I have an '06 trailblazer SS (I use to tow my Mopars) that at 364 cubes makes ~430 at the crank and pushes 4800 pounds to 13.6's at 102+ mph with really only a PCM tune and an electric fan conversion. The cam duration is something like 204/211 @.050

A good port and a small cam will still make great power and very broad torque. Cam timing is a big factor, but it isn't the only way to extend the RPM range.

Where you run into limitations is a proportionally huge port (like a Cleveland Boss 302) on a small displacement motor, it's hard to avoid a peaky (light switch) type torque and power curve with that type scenario. you effectively kill as much duration as you can to try to give it some "passable" bottom end....and (like ford) you gear the wee out of it (4.33 gears, etc).

Posted By: BradH

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/13/15 10:19 PM

Quote:

... Where you run into limitations is a proportionally huge port (like a Cleveland Boss 302) on a small displacement motor, it's hard to avoid a peaky (light switch) type torque and power curve with that type scenario. you effectively kill as much duration as you can to try to give it some "passable" bottom end....and (like ford) you gear the wee out of it (4.33 gears, etc).

That's along the lines of what I was going to add to my original post about how even a "good" head still needs to have enough cubes & compression under it to make the combination effective.

It's another example of a poor parts combination that looks cool on paper, but doesn't pan out in the real world.

Posted By: Cogito

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/13/15 11:34 PM

Quote:

Where you run into limitations is a proportionally huge port (like a Cleveland Boss 302) on a small displacement motor, it's hard to avoid a peaky (light switch) type torque and power curve with that type scenario. you effectively kill as much duration as you can to try to give it some "passable" bottom end....and (like ford) you gear the wee out of it (4.33 gears, etc).

In the hot rod article I posted, the Boss makes more torque sooner, as well as holds onto it longer, than the smaller port DZ. This seems contrary to what you're saying...?

I recently finished a set of LS3 heads going onto a 6.0 similar to yours (G8). They have virtually identical port dimensions as the Victor 440s I'll be using on my car (stock stroke 440). I haven't worked SBM stuff, but from what I've seen for BBMs, I have to think most use heads that are way too small.

Posted By: Oyvind Mopar

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 12:45 AM

I started building such a motor for street only 71 Charger; a 400 stroker (518) with 12,7 CR, St6 MaxWedge heads (slightly ported) and a mild 214/222 @ .050 roller cam at .540 lift with 1,7 rockers, and a Indy singleplane intake, 2" headers. Reason for doing this is our high price on gas, or E-85 (which it is planned for) along with a 5 speed overdrive and possible EFI, that small cam is to make it drivable with a good signal. Any comments on expected torque/ power?

Posted By: Street Monkies

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 01:46 AM

When you got cylinder that work efficiently you don't seem to need a high duration cam and all the extra air movement. But yet again you see guys with efficient heads and monster duration cams that turn rpm running real strong. Either set up has to be suited for the combo.

Posted By: WO23Coronet

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 01:50 AM

I'd think that combo would have ridiculous low end and as the guys on here have pointed out would hold onto the power pretty good, you might've even went to far?

Posted By: GTX MATT

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 02:00 AM

Head flow is king, period. If you've got a good set of heads you will make power.

Posted By: BradH

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 02:05 AM

Quote:

Head flow is king, period. If you've got a good set of heads you will make power.

It's not that simple...

Posted By: Street Monkies

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 02:07 AM

Correct. Big flow #s and even bigger ports sell heads. Doesn't mean it makes power for a given combination. There is a lot of other important details besides head flow like chamber design, velocity, swirl, port shape, and lot's more.

Posted By: WO23Coronet

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 02:16 AM

Oyvind's combo will make power for sure, just thinking he might've gone to small on the cam as 500+" will eat a lot of duration

Posted By: MR_P_BODY

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 02:23 AM

If I have a head that peaks flow at (we will say)

.700 lift.. I want a cam thats in the .800+ lift.. you

have a lot more time at the max(you would see the max

twice and all the time over it).. duration is rpm for

our wedge stuff... not really true with the new style

head that has a great velocity ... but I'm still

playing with old junk.. my last set was W-9

Posted By: goldmember

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 02:31 AM

Quote:

Quote:

... Where you run into limitations is a proportionally huge port (like a Cleveland Boss 302) on a small displacement motor, it's hard to avoid a peaky (light switch) type torque and power curve with that type scenario. you effectively kill as much duration as you can to try to give it some "passable" bottom end....and (like ford) you gear the wee out of it (4.33 gears, etc).

That's along the lines of what I was going to add to my original post about how even a "good" head still needs to have enough cubes & compression under it to make the combination effective.

It's another example of a poor parts combination that looks cool on paper, but doesn't pan out in the real world.

Nothing worse than a great flowing head(300cfm?) that makes 425hp because it's got a tiny cam and other restrictions. My crude rule is if you don't make 2hp per CFM(in a street engine) something is off. Maybe I'm off but that's my street engine yardstick.

Posted By: R5P7 Bantam

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 02:34 AM

Quote:

Quote:

What controls velocity?

Piston speed and port/runner shape. In essence, the geometric profile (tube) in which the air travels to the base of the valve head. This geometric shape starts at the top of the intake manifold (carb plate) and some may include the shape of the venturi's w/in the carb/throttle body.

This is the response I see most often on the internet.

How about valve events and ramp rates?

Valve timing events are critical. We can get really in depth with this if you like......but for now we'll just keep it basic. As the piston lowers in the cylinder, it "pulls" on the intake port as the valve is opening (the scavenging effect). Just before the piston reaches BDC, the intake valve should close (tightly) thus getting the max cylinder volume of charge (air and fuel). It is very possible to actually achieve more than one atmosphere during this operation w/o forced induction. Then the piston goes up and down, and on the following up stroke it "pushes" the fired charge out the exhaust port.....But, this is where it gets good!!!! The velocity in which it travels out the exhaust while the intake begins to open (split overlap) can actually create a negative charge on the intake chamber thus pulling in the new fuel charge at a greater velocity that standard flow (ie, form of forced inducing). This fills the cylinder as the piston drops and......we're at the beginning. But, possibly more than one atmosphere of volume inn the cylinder = VE approaching and exceeding 100%.

Posted By: MR_P_BODY

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 02:45 AM

Valve timing events are critical. We can get really in depth with this if you like......but for now we'll just keep it basic. As the piston lowers in the cylinder, it "pulls" on the intake port as the valve is opening (the scavenging effect). Just before the piston reaches BDC, the intake valve should close (tightly) thus getting the max cylinder volume of charge (air and fuel). It is very possible to actually achieve more than one atmosphere during this operation w/o forced induction. Then the piston goes up and down, and on the following up stroke it "pushes" the fired charge out the exhaust port.....But, this is where it gets good!!!! The velocity in which it travels out the exhaust while the intake begins to open (split overlap) can actually create a negative charge on the intake chamber thus pulling in the new fuel charge at a greater velocity that standard flow (ie, form of forced inducing). This fills the cylinder as the piston drops and......we're at the beginning. But, possibly more than one atmosphere of volume inn the cylinder = VE approaching and exceeding 100%.

This is where a GOOD set of headers comes into play

with equal length primaries so it pulls on the

intake charge at the right time.. unlike the off the

shelf headers that fit in the car and thats about it

Posted By: Sport440

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 03:02 AM

Quote:

The velocity in which it travels out the exhaust while the intake begins to open (split overlap) can actually create a negative charge on the intake chamber thus pulling in the new fuel charge at a greater velocity that standard flow (ie, form of forced inducing). This fills the cylinder as the piston drops and......we're at the beginning. But, possibly more than one atmosphere of volume inn the cylinder = VE approaching and exceeding 100%.

Scavenging happens Here on overlap.

Posted By: GTX MATT

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 03:04 AM

Quote:

Quote:

Head flow is king, period. If you've got a good set of heads you will make power.

It's not that simple...

Sure its not, or else we wouldn't have aftermarket cams, intake, headers, carbs, etc. But its pretty easy to make power with the right set of heads. The power limit lies in the heads.

Posted By: Street Monkies

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 03:05 AM

Good info. Volumetric efficiency is very important to make power. Usually your street rod motors are only in the 80s and maybe 90s if they got it hyped up. A good all out race engine can start in the upper 90s and go in the 110-115 range. Usually takes a pretty big cam 260+ @ .050 a lot of cr 12:1+, good flowing heads 280+ ect to achieve anything over 100. Who also has good info on this is Rehere Morrison Championship Engine Assembly.

Posted By: BSB67

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 03:20 AM

Quote:

We can get really in depth with this if you like......but for now we'll just keep it basic.......

Just before the piston reaches BDC, the intake valve should close (tightly) thus getting the max cylinder volume of charge.....

Really?

Posted By: R5P7 Bantam

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 03:25 AM

Quote:

Good info. Volumetric efficiency is very important to make power. Usually your street rod motors are only in the 80s and maybe 90s if they got it hyped up. A good all out race engine can start in the upper 90s and go in the 110-115 range. Usually takes a pretty big cam 260+ @ .050 a lot of cr 12:1+, good flowing heads 280+ ect to achieve anything over 100. Who also has good info on this is Rehere Morrison Championship Engine Assembly.

Very true, but we're mixing the pews in the church.

High compression ratios's are not necessarily required for high VE. Also, large duration profiles are not the answer either.

Here's an example:

350 cu in engine Cam in the 260 - 270 deg @ 0.050"

Decent flowing head 10:1 static comp

VE at 6000 rpm < VE at 8000 rpm.

Why?

Posted By: Dunnuck Racing

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 03:49 AM

Don't believe everything you read here Brock. There is a LOT of completely wrong information on this post. That and some old school thinking that is irrelevant today.

Keith

Posted By: Street Monkies

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 05:27 AM

That's right Keith you know the game pretty good. For P7 Bantam the VE from what I understand is just how well the motor breathes. Back to the basics of the motor is just a air pump. Air needs brought in and back out and fuel needs brought in and burned. Yes even with a lower cr you can still have a some what high VE with a good camshaft that has good valve timing. Doesn't even have to be real high duration. Lot's of other factors that can pick up where other things lack. The valve timing is very important. I like to think of the valve timing as of how big the camshaft actually is or acts. When valve over lap comes into play it creates a whole new ball game. You can take a cam that's 276/284 @ .050 on a 108° lsa for an example that only has 64° of valve over lap. You can forget those big duration #s at .050 because the way it opens the valves. Now you have some what of a small cam that is set up for say a more efficient cylinder head and geared towards torque. For 6000-8000 rpm if a motor starts to breathe better as the rpm goes up then VE should go up or down depending on the combo. It's just like the curve of how the motor makes hp and tq. It starts off lower then climbs and for a while and maybe quit climbing then maybe it picks back up again. But either way it eventually quits climbing and starts to fall off.

Posted By: Cogito

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 07:21 AM

Quote:

Quote:

Good info. Volumetric efficiency is very important to make power. Usually your street rod motors are only in the 80s and maybe 90s if they got it hyped up. A good all out race engine can start in the upper 90s and go in the 110-115 range. Usually takes a pretty big cam 260+ @ .050 a lot of cr 12:1+, good flowing heads 280+ ect to achieve anything over 100. Who also has good info on this is Rehere Morrison Championship Engine Assembly.

Very true, but we're mixing the pews in the church.

High compression ratios's are not necessarily required for high VE. Also, large duration profiles are not the answer either.

Here's an example:

350 cu in engine Cam in the 260 - 270 deg @ 0.050"

Decent flowing head 10:1 static comp

VE at 6000 rpm < VE at 8000 rpm.

Why?

IVC happens ABDC.

Using the general rule of thumb that peak VE occurs at peak torque (again, in general), I'm curious to know how your example engine could be less VE @ 6k than 8k. Cylinder filling tapers off after peak torque...where max filling occurs...

Some have touched on what I've seen...big efficient ports, low overlap...the intake ports don't need the exhausts help. The advantage to this is greater driveability if a street/strip car...which is what I'm mostly familiar w/.

Don't expect to run an off the shelf cam on a head w/ what are thought of as 'big ports'. Conventional thinking...70s/80s ideas of what cam to use...will lead to the torqueless engines people are warning about.

Posted By: Oyvind Mopar

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 09:34 AM

Quote:

Oyvind's combo will make power for sure, just thinking he might've gone to small on the cam as 500+" will eat a lot of duration

Yes, I know. I do have some cams on the shelf, and this was the first try. Have not started the engine yet, but if too little cam I have another roller one symmetric at 242 degrees @050 with more lift. But as this is a street engine with manual and OD I would like to try the small first. In this combo I am not looking for high rpm horsepower, but driveability and spare power. I guess I will have a big detonation problem if running on gas. And with the small overlap I guess the headers do not help much either.....

Posted By: gregsdart

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 03:04 PM

"Very true, but we're mixing the pews in the church.

High compression ratios's are not necessarily required for high VE"

High CRs enhance cylinder fill because the overlap cylinder fill becomes more efficient. With less volume to pull on, the exhaust pulse vacuum can pull more fresh charge earlier increasing overall effectiveness. With the overlap period creating up to five times the draw of the piston at max velocity any change to the package is significant. Look at the latest Hemis, 10.4 or higher compression, big intake ports, very long tuned intake runners, short cam. It all has to be right, but then the power is amazing.

As to how much exhaust tuning helps, I think most know it is huge. Look what happens to hp when a motor is run with Zoomies. If there is no tuned length etc, power goes way down.

Posted By: BradH

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 05:19 PM

Quote:

Don't believe everything you read here Brock. There is a LOT of completely wrong information on this post.

Yup.

EDIT: And then it occured to me that he might have been referring to something I posted...

Posted By: TonyS451

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/14/15 07:07 PM

I am building a 10.5-1 520" with Indy EZ 295 Cnc's, Bullet hydraulic roller 252/258 .622 lift w/ 1.6's, 110lsa and Indy dual plane intake. Going in a heavy street car. Havnt dynoed it yet, but hopefully in the next month or two. This topic got me thinking that I might be a little undercammed/over headed...Any thoughts??

Posted By: 67mprfan

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 03:11 AM

Quote:

I am building a 10.5-1 520" with Indy EZ 295 Cnc's, Bullet hydraulic roller 252/258 .622 lift w/ 1.6's, 110lsa and Indy dual plane intake. Going in a heavy street car. Havnt dynoed it yet, but hopefully in the next month or two. This topic got me thinking that I might be a little undercammed/over headed...Any thoughts??

can you post your dyno results when you get them

Posted By: dmking

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 04:24 AM

i'm thinking it is also important to think about when the valve opens in relation to rod ratio.

a shorter rod does not have the piston up top very long as to a 6.7" or 7.1"

Posted By: TonyS451

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 05:35 PM

Quote:

Quote:

I am building a 10.5-1 520" with Indy EZ 295 Cnc's, Bullet hydraulic roller 252/258 .622 lift w/ 1.6's, 110lsa and Indy dual plane intake. Going in a heavy street car. Havnt dynoed it yet, but hopefully in the next month or two. This topic got me thinking that I might be a little undercammed/over headed...Any thoughts??

can you post your dyno results when you get them

Yes, I will post the results. Good or bad!

Posted By: Streetwize

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 05:59 PM

Tony,

I think you'll be fine.

Similar to my old 508 combo...Paul ( PHJ426 the guy who bought that motor from me) put a hydraulic flat tappet in place of the 252/258 HR and he's busting new ZL1 Camaros with it. in a 4200 pound 72 roadrunner....and that's with a lot less head than you have on yours.

Just be sure to do some radiusing of mainly the lower 1/2 plenum (Cyls 1-4-6 and 7) to runner transitions in the 440-2d manifold, there's a lot of cfm (and maybe 20hp potential flow) you leave on the table if you don't do it. not really needed with 906 size ports but definitely needed if you're feeding a max wedge.

So are they EZ 295's or the EZ-1's? I would definitely open them (both the heads and the manifold) up to MW if you haven't already, there's only upside to go max wedge at 520 cubes.

I run a 264/268@.050 Bullet HR on my 517 on 108 in at 102 with the Max Wedge Chapmans at 12:1.

Posted By: moparmanjames

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 06:46 PM

Quote:

Quote:

Head flow is king, period. If you've got a good set of heads you will make power.

It's not that simple...

Not that simple but it's a damn good start. I'm just thankful that we have a few decent flowing big block wedge heads to choose from. Big block Hemi's are crazy expensive for the average mopar guy, I mean $2500 for a rocker arm setup? The new Hemi's are a blessing but I wish they would make a big block version.

Posted By: moparmanjames

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 07:01 PM

Quote:

Quote:

Quote:

What controls velocity?

Piston speed and port/runner shape. In essence, the geometric profile (tube) in which the air travels to the base of the valve head. This geometric shape starts at the top of the intake manifold (carb plate) and some may include the shape of the venturi's w/in the carb/throttle body.

This is the response I see most often on the internet.

How about valve events and ramp rates?

Valve timing events are critical. We can get really in depth with this if you like......but for now we'll just keep it basic. As the piston lowers in the cylinder, it "pulls" on the intake port as the valve is opening (the scavenging effect). Just before the piston reaches BDC, the intake valve should close (tightly) thus getting the max cylinder volume of charge (air and fuel). It is very possible to actually achieve more than one atmosphere during this operation w/o forced induction. Then the piston goes up and down, and on the following up stroke it "pushes" the fired charge out the exhaust port.....But, this is where it gets good!!!! The velocity in which it travels out the exhaust while the intake begins to open (split overlap) can actually create a negative charge on the intake chamber thus pulling in the new fuel charge at a greater velocity that standard flow (ie, form of forced inducing). This fills the cylinder as the piston drops and......we're at the beginning. But, possibly more than one atmosphere of volume inn the cylinder = VE approaching and exceeding 100%.

Pretty good info in general but more often than not with a performance cam, the cam will hold the intake valve open past bottom dead center to get maximum fill.

Edit: looks like Cogito covered this on the previous page, sorry for the rehash

Posted By: TonyS451

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 07:03 PM

Quote:

Tony,

I think you'll be fine.

Similar to my old 508 combo...Paul ( PHJ426 the guy who bought that motor from me) put a hydraulic flat tappet in place of the 252/258 HR and he's busting new ZL1 Camaros with it. in a 4200 pound 72 roadrunner....and that's with a lot less head than you have on yours.

Just be sure to do some radiusing of mainly the lower 1/2 plenum (Cyls 1-4-6 and 7) to runner transitions in the 440-2d manifold, there's a lot of cfm (and maybe 20hp potential flow) you leave on the table if you don't do it. not really needed with 906 size ports but definitely needed if you're feeding a max wedge.

So are they EZ 295's or the EZ-1's? I would definitely open them (both the heads and the manifold) up to MW if you haven't already, there's only upside to go max wedge at 520 cubes.

I run a 264/268@.050 Bullet HR on my 517 on 108 in at 102 with the Max Wedge Chapmans at 12:1.

Thank Bobby. My heads are the Max wedge CNC 295's from Indy and then given the once over, hand blend as needed and valve job by Dwayne Porter. The intake is the one AndyF used on his dyno mule and is also opened up to max wedge ports. I don't think any additional work was done to it other than port match. Btw, the cam I am running was actually a regrind of a comp cam I had. It was originally a 242/.555 110. Bullet agreed the Comp cam was a bit small, and said the regrind specs would be a better cam for my combination. However they did say I am still leaving a lot on the table...If I really wanted to make the most power possible, I would need a much rowdier solid roller, single plane, dominator, etc. Of course I already knew that.

Bobby, did you ever dyno your Chapman engine? Any chance you have pics of what you did to the intake?

Posted By: Streetwize

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 07:53 PM

Planning to chassis dyno the 517 in the spring and hopefully (if time allows) do some manifold/carb/ignition testing as well.

I was gonna say if you want to send me your manifold I could radius it for you, the turn from the vertical plenum wall to the runners in both the front and back is a bit too sharp, work the corners for a more gentle turn both down and then out towards the ports. you don't really need to enlarge the ports themselves beyond the plenum,

I wouldn't even try doing that because the roof of the lower is the floor of the upper and the casting is pretty thin between them. Plenty of meat where I'm referring to though.

Beyond that I also enlarged both plenum halves and took the divider down a bit more. I run a 1000CFM Pro-Systems carb on it, it's very responsive, but tough to get it to hook, even taking off in second and I shift it at 6800.

Posted By: BradH

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 09:15 PM

Quote:

Quote:

Quote:

Head flow is king, period. If you've got a good set of heads you will make power.

It's not that simple...

Not that simple but it's a damn good start.

Only if other key things are taken into account. Just because you've got a "good set of heads" that flow well doesn't mean they're the right set of heads for an application.

Put a set of 350cc ported Indy 440-1s on a stock-stroke 400 and you'll have a gutless pig below about 5500 and needs to rev to 8000 to even come close to making the heads "work". Not my idea of a good combination...

I'll take an "OK" set of heads for the right application over a "good set" of heads for the wrong one.

(And this is what results when some people make really generic - and flawed - statements that more detail-specific people take exception to.  )

)

Posted By: sixpackgut

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 09:41 PM

Quote:

Quote:

Quote:

Quote:

Head flow is king, period. If you've got a good set of heads you will make power.

It's not that simple...

Not that simple but it's a damn good start.

Only if other key things are taken into account. Just because you've got a "good set of heads" that flow well doesn't mean they're the right set of heads for an application.

Put a set of 350cc ported Indy 440-1s on a stock-stroke 400 and you'll have a gutless pig below about 5500 and needs to rev to 8000 to even come close to making the heads "work". Not my idea of a good combination...

I'll take an "OK" set of heads for the right application over a "good set" of heads for the wrong one.

(And this is what results when some people make really generic - and flawed - statements that more detail-specific people take exception to.  )

)

didn't the Brown Sugar car have small cubes with B1 heads and was extremely fast to the point that people thought he was spraying?? I think its more about the combo and and since I'm a street guy I prefer a smaller port but on a race car then I would say Big Heads

this just reminded me of, me and Quicktree went to the PRI show together. there was a set of BB edelbrocks RPM heads next to 360-1 Indy heads and Quick started laughing at the port size of the BB heads and how small the port was. I was at that point ashamed of my RPM heads and bought EZs

Posted By: MR_P_BODY

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 10:04 PM

Quote:

Quote:

Quote:

Quote:

Quote:

Head flow is king, period. If you've got a good set of heads you will make power.

It's not that simple...

Not that simple but it's a damn good start.

Only if other key things are taken into account. Just because you've got a "good set of heads" that flow well doesn't mean they're the right set of heads for an application.

Put a set of 350cc ported Indy 440-1s on a stock-stroke 400 and you'll have a gutless pig below about 5500 and needs to rev to 8000 to even come close to making the heads "work". Not my idea of a good combination...

I'll take an "OK" set of heads for the right application over a "good set" of heads for the wrong one.

(And this is what results when some people make really generic - and flawed - statements that more detail-specific people take exception to.  )

)

didn't the Brown Sugar car have small cubes with B1 heads and was extremely fast to the point that people thought he was spraying?? I think its more about the combo and and since I'm a street guy I prefer a smaller port but on a race car then I would say Big Heads

this just reminded me of, me and Quicktree went to the PRI show together. there was a set of BB edelbrocks RPM heads next to 360-1 Indy heads and Quick started laughing at the port size of the BB heads and how small the port was. I was at that point ashamed of my RPM heads and bought EZs

It is all about the combo and where the engine spends

MOST of its time... with a small cube engine and a

large set of heads(port flow and cross section) the

engine will have to turn up the revs to make the head

efficient.. BUT if the WHOLE combo is set up for the

revs and you plan on spending the time up in the revs

then it becomes efficient.... JMO so I dont offend

anyone

Posted By: HotRodDave

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 10:25 PM

"Just because you say no offense does not mean you can say anything you want"

Posted By: Clanton

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 10:25 PM

Is there any info on paper[port speed,cubic inch,stroke big/small]to back up what this subject is about?Perhaps the port air speed FPS for a cubic inch Min/Max.

Posted By: Streetwize

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 10:25 PM

It's probably also worth noting that it's realtively easier to achieve high VE and also hang on close to peak VE longer in a relatively low(er) rpm engine, really regardless of displacement.

The reason is that with a 4 cycle engine the frictional losses(rings/bearings/valvetrain spring pressures and lobe friction) and the drag from the rotational masses all increase at the square of the RPM....so it's like applying an increasingly linear load to the crank as RPM goes up. Kind of like a tractor pull sled, the further up you go, the more drag is applied that the heads and charge have to overcome. The higher you want to rev it, the stiffer springs and stronger/larger (generally) components you need to get there. The only way F1 motors rev as high as they do (in excess of 22,000rpm) is because they don't have conventional valvesprings for the crank to have to overcome. Imagine how much power you would have at the wheels if you camshaft and valvetrain were driven by an electric servomotor instead of a crank and chain driven camshaft. That's the way things have been moving and it's remarkably simple to do today.

And also....generally, after peak VE RPM occurs (for a given motor) the RATE of crank acceleration begins to slow in terms of RPM (or probably more accurate to say Revs/Second per second. That's why hanging on to (as close to) peak VE allows the power curve to continue to rise. And with a flat torque curve the rate of rise is essentially linear (rises proportional to RPM increase )

The optimum port size/shape and valve timing is all relative to the size of the engine AND (more importantly) the range of RPM you want to apply load to that engine. Obviously compression and induction/exhaust optimization all come into play as well.

Posted By: BradH

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/15/15 11:30 PM

Quote:

The optimum port size/shape and valve timing is all relative to the size of the engine AND (more importantly) the range of RPM you want to apply load to that engine. Obviously compression and induction/exhaust optimization all come into play as well.

Yep.

Posted By: deaks

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 02:51 AM

Quote:

Quote:

Quote:

Quote:

Head flow is king, period. If you've got a good set of heads you will make power.

It's not that simple...

Not that simple but it's a damn good start.

Only if other key things are taken into account. Just because you've got a "good set of heads" that flow well doesn't mean they're the right set of heads for an application.

Put a set of 350cc ported Indy 440-1s on a stock-stroke 400 and you'll have a gutless pig below about 5500 and needs to rev to 8000 to even come close to making the heads "work". Not my idea of a good combination...

I'll take an "OK" set of heads for the right application over a "good set" of heads for the wrong one.

(And this is what results when some people make really generic - and flawed - statements that more detail-specific people take exception to.  )

)

Hutch on here runs a stock stroke 383 with 440-1 heads, i believe he shifts about 8200 and runs about 9.8 if i remember correctly.

Mick

Posted By: LaRoy Engines

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 03:23 AM

It's not a small block. Does have what I think are bigger than average heads and a smaller cam. We were doing some factory iron head tests and had the Indy EZ heads in the shelf.

440 .030 over, old TRW 6-pack pistons w/ stock rods, 10.5:1 compression, EZ Max Wedge heads flowing 360 cfm @ .700", Edelbrock Victor intake, 850 Mighty Demon carburetor, XE285HL camshaft 241/247 @ .050, .545/.545, 1.6 rockers.

Start dyno pull at 3,500rpm. 500 lb-ft from 3,500-6,000 rpm. Peak torque 543 @ 5,200 rpm and peak HP of 595 @ 6,400 rpm. Don't know if that's good or bad, just is what it is. Never pulled it lower in the rpm range with this combination so can't speak on that.

Posted By: Cogito

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 04:42 AM

Quote:

The only way F1 motors rev as high as they do (in excess of 22,000rpm) is because they don't have conventional valvesprings for the crank to have to overcome. Imagine how much power you would have at the wheels if you camshaft and valvetrain were driven by an electric servomotor instead of a crank and chain driven camshaft. That's the way things have been moving and it's remarkably simple to do nowadays.

Here's that detail oriented stickler BradH spoke about coming out in me.

It takes energy to compress a valvespring, yes, but as the valve closes and the spring lengthens, the stored potential energy is then returned to the system...net delta E = 0.

The 'forces' required to move the valves up and down at ultra high rpm are unchanging regardless of what type of valve spring is used. Formula 1 engines don't use mechanical springs because they are unable to handle the frequencies incurred, not because of forces the crank must overcome. The pneumatic springs they use don't have the mechanical limitations of metal, as well as reduce weight in the system.

Posted By: Sport440

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 04:44 AM

Quote:

Quote:

We can get really in depth with this if you like......but for now we'll just keep it basic.......

Just before the piston reaches BDC, the intake valve should close (tightly) thus getting the max cylinder volume of charge.....

Really?

Yep, totally wrong. Not even close.

Posted By: Pacnorthcuda

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 04:59 AM

Quote:

Quote:

Quote:

We can get really in depth with this if you like......but for now we'll just keep it basic.......

Just before the piston reaches BDC, the intake valve should close (tightly) thus getting the max cylinder volume of charge.....

Really?

Yep, totally wrong. Not even close.

Maybe in a Briggs & Stratton...... Maybe...nah, not even then.

Posted By: GTX MATT

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 06:43 AM

Quote:

Quote:

Quote:

Quote:

Head flow is king, period. If you've got a good set of heads you will make power.

It's not that simple...

Not that simple but it's a damn good start.

Only if other key things are taken into account. Just because you've got a "good set of heads" that flow well doesn't mean they're the right set of heads for an application.

Put a set of 350cc ported Indy 440-1s on a stock-stroke 400 and you'll have a gutless pig below about 5500 and needs to rev to 8000 to even come close to making the heads "work". Not my idea of a good combination...

I'll take an "OK" set of heads for the right application over a "good set" of heads for the wrong one.

(And this is what results when some people make really generic - and flawed - statements that more detail-specific people take exception to.  )

)

It's generic on purpose. If you have a good set of heads you will make power. "Good" would mean they're matched to your application. I didn't say good flowing, I just said "good" for a reason.

I know what you're saying.

Posted By: moparmanjames

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 07:14 AM

Quote:

Quote:

Quote:

Quote:

Head flow is king, period. If you've got a good set of heads you will make power.

It's not that simple...

Not that simple but it's a damn good start.

Only if other key things are taken into account. Just because you've got a "good set of heads" that flow well doesn't mean they're the right set of heads for an application.

Put a set of 350cc ported Indy 440-1s on a stock-stroke 400 and you'll have a gutless pig below about 5500 and needs to rev to 8000 to even come close to making the heads "work". Not my idea of a good combination...

I'll take an "OK" set of heads for the right application over a "good set" of heads for the wrong one.

(And this is what results when some people make really generic - and flawed - statements that more detail-specific people take exception to.  )

)

You make a valid point but really, it's kind of an excessive example.

A better comparison that got me thinking a few years back was when I think it was Car Craft or whatever magazine built a small block chevy 400 and a big block chevy 400 both with decent heads and a hydraulic cam and ran them in a 70 something Chevelle.

Even though the Big Block weighed over 200lbs more it beat the small block every time by like 3 tenths, they both ran in the 12's.

Now this isn't the end all be all of the argument but it did show that at least for that combination the bigger port head in a heavy car with small cubes won the battle.

Posted By: goldmember

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 07:33 AM

Quote:

It's not a small block. Does have what I think are bigger than average heads and a smaller cam. We were doing some factory iron head tests and had the Indy EZ heads in the shelf.

440 .030 over, old TRW 6-pack pistons w/ stock rods, 10.5:1 compression, EZ Max Wedge heads flowing 360 cfm @ .700", Edelbrock Victor intake, 850 Mighty Demon carburetor, XE285HL camshaft 241/247 @ .050, .545/.545, 1.6 rockers.

Start dyno pull at 3,500rpm. 500 lb-ft from 3,500-6,000 rpm. Peak torque 543 @ 5,200 rpm and peak HP of 595 @ 6,400 rpm. Don't know if that's good or bad, just is what it is. Never pulled it lower in the rpm range with this combination so can't speak on that.

So your posted combo uses approx 262 cfm from those heads? That's the kind of combo that would be a bummer to me. Heads that are capable of real output on a street hp build. We have a NSS car 3730lbs 452 cid that makes 650hp with much weaker heads,pump gas,small roller cam,crappy intake,etc and I am pissed that it's such a turd. Match the parts and good things happen. I'm not knocking you as I'm sure you see limiting parts to that build.

Posted By: BradH

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 07:47 AM

Quote:

We have a NSS car 3730lbs 452 cid that makes 650hp with much weaker heads,pump gas,small roller cam,crappy intake,etc and I am pissed that it's such a turd.

So, what does the turd run?

Posted By: goldmember

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 07:54 AM

It runs 130-132mph. 65 B body with a roll bar and 240lb driver.

Posted By: Cogito

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 08:49 AM

Quote:

Quote:

It's not a small block. Does have what I think are bigger than average heads and a smaller cam. We were doing some factory iron head tests and had the Indy EZ heads in the shelf.

440 .030 over, old TRW 6-pack pistons w/ stock rods, 10.5:1 compression, EZ Max Wedge heads flowing 360 cfm @ .700", Edelbrock Victor intake, 850 Mighty Demon carburetor, XE285HL camshaft 241/247 @ .050, .545/.545, 1.6 rockers.

Start dyno pull at 3,500rpm. 500 lb-ft from 3,500-6,000 rpm. Peak torque 543 @ 5,200 rpm and peak HP of 595 @ 6,400 rpm. Don't know if that's good or bad, just is what it is. Never pulled it lower in the rpm range with this combination so can't speak on that.

So your posted combo uses approx 262 cfm from those heads? That's the kind of combo that would be a bummer to me. Heads that are capable of real output on a street hp build. We have a NSS car 3730lbs 452 cid that makes 650hp with much weaker heads,pump gas,small roller cam,crappy intake,etc and I am pissed that it's such a turd. Match the parts and good things happen. I'm not knocking you as I'm sure you see limiting parts to that build.

Can you provide specifics of the engine? Too vague to use as a datapoint...

Posted By: goldmember

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 09:19 AM

Quote:

Quote:

Quote:

It's not a small block. Does have what I think are bigger than average heads and a smaller cam. We were doing some factory iron head tests and had the Indy EZ heads in the shelf.

440 .030 over, old TRW 6-pack pistons w/ stock rods, 10.5:1 compression, EZ Max Wedge heads flowing 360 cfm @ .700", Edelbrock Victor intake, 850 Mighty Demon carburetor, XE285HL camshaft 241/247 @ .050, .545/.545, 1.6 rockers.

Start dyno pull at 3,500rpm. 500 lb-ft from 3,500-6,000 rpm. Peak torque 543 @ 5,200 rpm and peak HP of 595 @ 6,400 rpm. Don't know if that's good or bad, just is what it is. Never pulled it lower in the rpm range with this combination so can't speak on that.

So your posted combo uses approx 262 cfm from those heads? That's the kind of combo that would be a bummer to me. Heads that are capable of real output on a street hp build. We have a NSS car 3730lbs 452 cid that makes 650hp with much weaker heads,pump gas,small roller cam,crappy intake,etc and I am pissed that it's such a turd. Match the parts and good things happen. I'm not knocking you as I'm sure you see limiting parts to that build.

Can you provide specifics of the engine? Too vague to use as a datapoint...

452" Victor heads, bowl blend,VJ and guides corrected,10.8to1 comp, mid 250's/.640gross 108lsa 105 ICL,Indy modman intake(yuck), 2 edelbrock 600 carbs(MORE YUCK),2" hooker headers. It's getting more comp and cam as we type. The other restrictions will stay as they are not for me to change.

Posted By: BradH

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 01:26 PM

Quote:

It runs 130-132mph. 65 B body with a roll bar and 240lb driver.

3730#s w/ the 240# driver, or plus the 240# driver?

Is the 650 HP reference from engine dyno data, or estimated from on-track performance?

Posted By: LaRoy Engines

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 04:17 PM

Quote:

Quote:

It's not a small block. Does have what I think are bigger than average heads and a smaller cam. We were doing some factory iron head tests and had the Indy EZ heads in the shelf.

440 .030 over, old TRW 6-pack pistons w/ stock rods, 10.5:1 compression, EZ Max Wedge heads flowing 360 cfm @ .700", Edelbrock Victor intake, 850 Mighty Demon carburetor, XE285HL camshaft 241/247 @ .050, .545/.545, 1.6 rockers.

Start dyno pull at 3,500rpm. 500 lb-ft from 3,500-6,000 rpm. Peak torque 543 @ 5,200 rpm and peak HP of 595 @ 6,400 rpm. Don't know if that's good or bad, just is what it is. Never pulled it lower in the rpm range with this combination so can't speak on that.

So your posted combo uses approx 262 cfm from those heads? That's the kind of combo that would be a bummer to me. Heads that are capable of real output on a street hp build. We have a NSS car 3730lbs 452 cid that makes 650hp with much weaker heads,pump gas,small roller cam,crappy intake,etc and I am pissed that it's such a turd. Match the parts and good things happen. I'm not knocking you as I'm sure you see limiting parts to that build.

Sure, I see. Was just attempting to show from my experience a big head/small cam build. The 451 build with the Edelbrock RPM heads pulled the same 500 lb-ft @ 3500 rpm but was still carrying 565 lb-ft @ 7200 rpm. Like you say, just a better match to the parts.

Posted By: Clanton

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/16/15 05:33 PM

I am just trying to help by posting these links to info.I myself need #'s to look at I cant just think of it.

https://www.google.com/url?sa=t&rct=...qSIItz7YVWTkADwhttps://www.google.com/url?sa=t&rct=...YxoyLhKn-4ETy2g I hope this helps in some way.

Posted By: sublimehemi

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/20/15 08:25 AM

just wanted to post my recent build...

528 hemi all alum

out of box regular non victor edelbrock/mopar hemi heads

out of box mopar/barton 4150 single plane

right around 10.1 compression

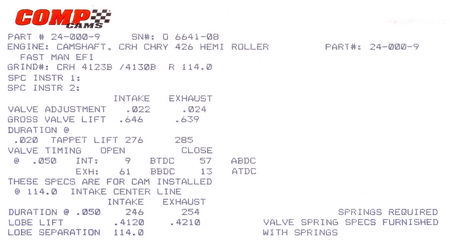

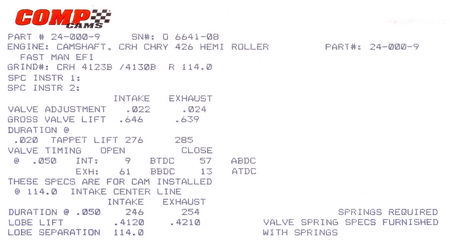

super tiny duration efi rich nebel book hemi camshaft advanced 4 degrees

comp elite super lightweigt mechanical roller lifters

barton roller rockers with pushrod oiling

made 670 hp at 6200 and 660 tq at 4200 not a happy dyno either very hard to make hp on this dyno

we all were very impressed....my engine builder mike and dale chenoweth said good luck on even getting 600 hp...he and his dad built many hemis...one thing for sure is it did not like anything past 30 deg total and hp drop is very quick after 6200...but all in all i am so happy cause i have a motor that idles like a baby and pulls excellent vacuum 13-14...operates well with little 3200-3400 tight stall and baby 3.54 gears...

Posted By: sublimehemi

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/20/15 08:26 AM

pic of hemi....i actually dropped a .05 degree of duration off cam so it was ordered as 241 249...but the size of the elite lifter wheel diameter probably increased it by .03? anyways i could of put a set victor jr hemi heads and 270 280 duration and had 110 or 108 lsa but bigger stall and bigger gears and would have been needed and low end tq would of suffered but it probably would have done 750 hp at 6700 6800?but then idle would be rough and no vacuum...be careful on your camshaft selection!!

.jpg)

Posted By: Clanton

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/20/15 03:53 PM

What do the heads flow?I think your cubic inch really helps.Do you have cranking psi #'s?

Posted By: sublimehemi

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/20/15 09:05 PM

i think 330-340 and victor jr are 380...no psi data... im happy i went with this combo.....my duration is so puny and my lsa at 114.. so for cam that in it...makes for a great street engine with usable rpm range..

Posted By: Clanton

Re: Big Ports, Big Flow #s, And Low Duration Camshafts - 01/20/15 10:02 PM

Thanks for the reply!I figured you may have 400cfm+ being lead by your engine size.

)

)

.jpg)