Moparts

Chassis Guys, a little help please?

Posted By: Brad4406

Chassis Guys, a little help please? - 02/02/14 01:54 AM

I'm welding in the coil-over shock crossmember. Prior to this, the ladder bar suspension was triangulated, which came out perfect, and the lower shock brackets are welded onto the housing the same distance on each side from the axle flanges. I triangulated the ladder bar crossmember prior to welding, but didn't triangulate the shock crossmember as the directions did not call for it. My problem is the upper shock brackets on the newly welded in crossmember. All the instructions called for was making sure the shocks were perfectly straight up and down. I made sure the shocks were fully extended and used an angle gauge to make sure the shocks were perfectly straight up and down, but to make that happen, the drivers side shock upper brackets are 3/8" closer to the frame rail than the passenger side. Is this a big deal, or should I just get over it?

Posted By: dvw

Re: Chassis Guys, a little help please? - 02/02/14 03:23 AM

3/8" measured left to right or up and down?

If it's right to left and the lower brackets are the same distance from the axle flange, the housing isn't centered in the car.

Doug

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 02/02/14 03:52 AM

Doug,

It's left to right.

The housing has to be centered in the car. I dropped plum bobs from the outside of the frame rails, measured to the axle flanges and made sure the measurement was the same on both sides, measured front to rear from the trans crossmember frame rails to the rear axle, and then triangulated the measurements. I installed my diagonal link and checked triangulation one more time. I've checked the triangulation three times on the rear before I started the coil-over mock up. This is why I don't understand why it came out this way.

Brad

Posted By: CMcAllister

Re: Chassis Guys, a little help please? - 02/02/14 05:06 AM

Maybe a dumb question. Is the car level?

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 02/02/14 06:15 AM

It's not a dumb question, but yes, the car is level.

Posted By: dakotawilly

Re: Chassis Guys, a little help please? - 02/02/14 06:53 AM

Chinese tapemeasure? I would look for other places on the car to measure from and triangulate,factory frame rails?those tend to move around after years of abuse also.multiple measurements from different areas on the car should give you a better idea of whats not quite perfect.its there,you just need to be patient and keep looking,or use a laser off 4 sq points on the floor...............

Posted By: Quicktree

Re: Chassis Guys, a little help please? - 02/02/14 10:22 AM

a lot of builders tilt the top shock mount forward 10 degrees

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 02/02/14 03:14 PM

I will check centering of the rear axle again, but this time using the inside of the frame rails. Also, the shocks are used; so I guess it's possible one of the shafts might be bent so I'll check both of them today.

Posted By: PLUM BAD

Re: Chassis Guys, a little help please? - 02/02/14 05:39 PM

I made a set of shock simulators that are the length of my shocks eyelet to eyelet dimension at ride hight. A lot easier than using the actual shock.

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 02/02/14 05:51 PM

Quote:

I will check centering of the rear axle again, but this time using the inside of the frame rails. Also, the shocks are used; so I guess it's possible one of the shafts might be bent so I'll check both of them today.

If you start stacking up the tolerance in a production

car you can get about 1/2 off... the 3/8 isnt that much

Posted By: dakotawilly

Re: Chassis Guys, a little help please? - 02/02/14 06:59 PM

mr p is correct,back in the day I worked at the local dodge dealer as a mechanic,we used to see many strange things on the new models,bolts and parts missing,broken parts installed,one car came in with an odor nobody could find,and eventually,we found a baloney sandwich stuffed inside the door.nothing was ever perfect...............

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 02/02/14 07:20 PM

Quote:

mr p is correct,back in the day I worked at the local dodge dealer as a mechanic,we used to see many strange things on the new models,bolts and parts missing,broken parts installed,one car came in with an odor nobody could find,and eventually,we found a baloney sandwich stuffed inside the door.nothing was ever perfect...............

When I worked for GM we had a tinking noise in a

car.. I finally figured out it was in a rear quarter

panel behind the RR window... was a pint bottle and

still had a small bit of booze in it

Posted By: Thumperdart

Re: Chassis Guys, a little help please? - 02/02/14 09:33 PM

I still believe

makes workin on these cars sssoooo much easier so, why stop now...........

Posted By: dakotawilly

Re: Chassis Guys, a little help please? - 02/02/14 09:38 PM

the worst problems I saw were during the big strike at chrysler in the early 80s,sabotage was abundant,seems 85% of the new cars has issues

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 02/02/14 09:56 PM

Quote:

the worst problems I saw were during the big strike at chrysler in the early 80s,sabotage was abundant,seems 85% of the new cars has issues

I dont know how that could happen... when we were on

strike we werent allowed onto the complex let along

on the line.. if they were up and running they had

so called scab workers... I never worked on the line

or even at a production plant... all my years were

at Engineering and I only went to plants on launch

or if they had issues in my line of work(fuel and

exhaust related issues)

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 02/02/14 10:56 PM

Quote:

I made a set of shock simulators that are the length of my shocks eyelet to eyelet dimension at ride hight. A lot easier than using the actual shock.

My best friend suggested that a couple days ago when I was having problems getting the springs off the shocks. I may go get some square stock tomorrow.

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 02/02/14 11:01 PM

Quote:

Quote:

I will check centering of the rear axle again, but this time using the inside of the frame rails. Also, the shocks are used; so I guess it's possible one of the shafts might be bent so I'll check both of them today.

If you start stacking up the tolerance in a production

car you can get about 1/2 off... the 3/8 isnt that much

Thanks, I feel better reading that.

I just checked from the inside frame rails; it appears that I was almost an 1/8" off to the driver's side. Now I'm questioning all of my measurements. I also just noticed that while placing the passenger side shock onto the crossmember that the shock collapses a small bit so I'll cut the crossmember out and mock it up again tomorrow. It was only tacked in anyway.

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 02/02/14 11:22 PM

Quote:

Quote:

Quote:

I will check centering of the rear axle again, but this time using the inside of the frame rails. Also, the shocks are used; so I guess it's possible one of the shafts might be bent so I'll check both of them today.

If you start stacking up the tolerance in a production

car you can get about 1/2 off... the 3/8 isnt that much

Thanks, I feel better reading that.

I just checked from the inside frame rails; it appears that I was almost an 1/8" off to the driver's side. Now I'm questioning all of my measurements. I also just noticed that while placing the passenger side shock onto the crossmember that the shock collapses a small bit so I'll cut the crossmember out and mock it up again tomorrow. It was only tacked in anyway.

I normally establish a centerline on the car and

work from that... and make sure its level... a little

here and a little there shows up on the build

Posted By: loaderpro

Re: Chassis Guys, a little help please? - 02/03/14 07:55 AM

You can find/build anything and everything off of a centerline string. Your garage or shop build should ALWAYS start with one. A bit of a pain to set up for the novice, but once you learn it, it is very easy, but very time consuming. I wear out tape measures when putting these things together! And Mike is right when he says 3/8 is close on a stock framed car...you have already found 1/8 of the 3/8, and I am betting if you did a centerline string you would find some more of it, or find where a small mistake was made. Generally we always strive to get it dead nuts, and sometimes you get it, but in reality a 1/8 plus/minus tolerance is the general rule.

Posted By: CMcAllister

Re: Chassis Guys, a little help please? - 02/03/14 09:21 PM

It's normal for an original body, especially one from that era, to be less than perfect. I will always try to get the suspension geometry dead nuts and do what you have to do to make it look right. Suspension and driveline geometry has to be correct. The rest is just along for the ride. Putting something together crooked to make it look right is a skill acquired when working with this old sheet metal.

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 02/04/14 09:22 PM

Obviously I should have done more research before attempting a ladder bar/coil-over suspension.

How do I determine centerline of the vehicle? Once it's determined, how do I find center on the rear axle and how do I ensure the axle is centered in the vehicle? I know I can't use the pinion as it is offset to the passenger side. That's why I thought if I just hung plum bobs off the rear frame rails and measured the distance to the axle flanges and made sure it was the same distance on each side that the rear would be centered. I already triangulated the ladder bar crossmember before welding, ensured the ladder bar brackets are evenly spaced on the ladder bar crossmember, and ensured both ladder bars are adjusted the same.

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 02/04/14 10:01 PM

There is a couple of ways to find center line.. one

is to level the car and drop a plum bob from the front

K-member mounting holes(there are reference holes in

the frame rails also).. in the rear you might have

to use reference holes now since you most likely

dont have the front spring hangers anymore... once

you drop the points to the floor you can measure to

the center.. make sure you get a X measurement to see

if its not parallelogram'ed (one side forward of the other)...

once you see if its squared mark the frame/body for

a zero on both sides(those marks will be there for good)

and you can use them to align the diff

Posted By: BJS racing

Re: Chassis Guys, a little help please? - 02/04/14 10:11 PM

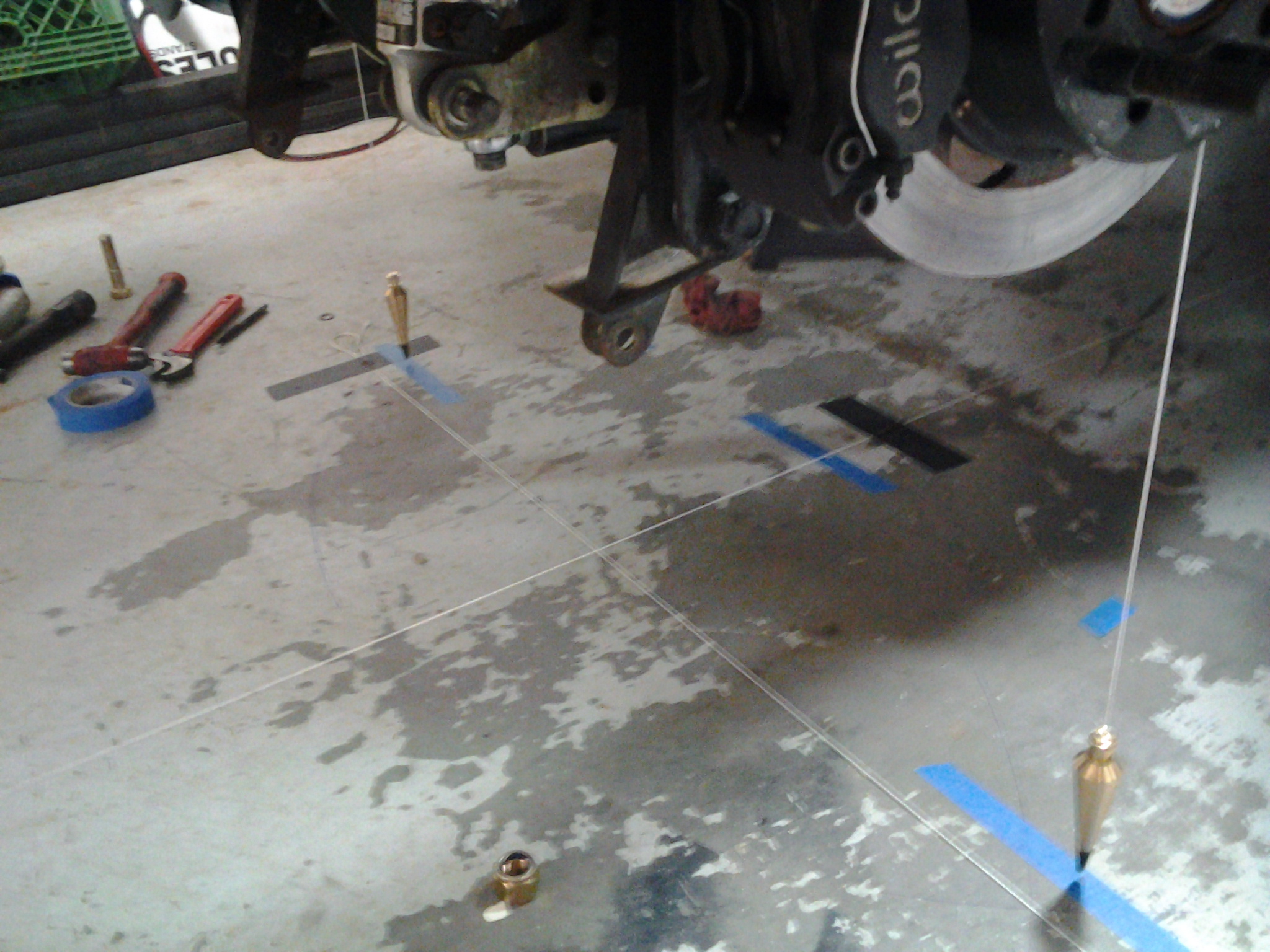

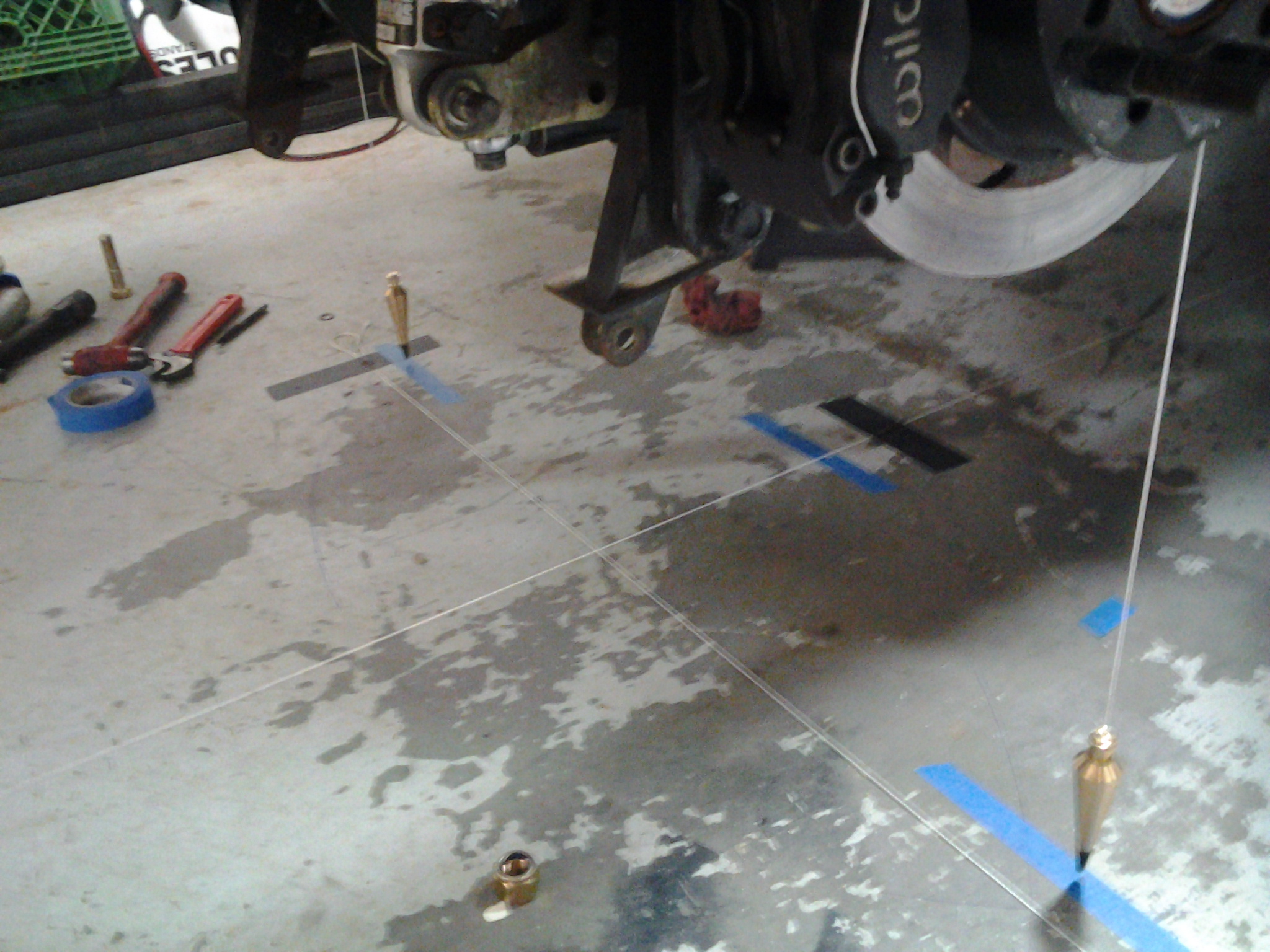

Something like this.

Posted By: BJS racing

Re: Chassis Guys, a little help please? - 02/04/14 10:13 PM

And at the front

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 02/04/14 10:22 PM

Quote:

Something like this.

If I'm working on a old body(other than my own... nevermind that)

I will get frame points and centerline points of each

wheel (spindle on the fronts and centerline of the axle

at the wheel mounting points) so I can see if the suspension

points are in the same relationship to the frame points

Posted By: BJS racing

Re: Chassis Guys, a little help please? - 02/04/14 10:25 PM

Quote:

Quote:

Something like this.

If I'm working on a old body(other than my own... nevermind that)

I will get frame points and centerline points of each

wheel (spindle on the fronts and centerline of the axle

at the wheel mounting points) so I can see if the suspension

points are in the same relationship to the frame points

Probably should have used a different pic. that was when I was actually squaring up the rear housing off of center line and the perpindicular line. I think I have one from actually making the center line off of the 4 link bracket.

Posted By: loaderpro

Re: Chassis Guys, a little help please? - 02/05/14 06:22 AM

Quote:

Obviously I should have done more research before attempting a ladder bar/coil-over suspension.

How do I determine centerline of the vehicle? Once it's determined, how do I find center on the rear axle and how do I ensure the axle is centered in the vehicle? I know I can't use the pinion as it is offset to the passenger side. That's why I thought if I just hung plum bobs off the rear frame rails and measured the distance to the axle flanges and made sure it was the same distance on each side that the rear would be centered. I already triangulated the ladder bar crossmember before welding, ensured the ladder bar brackets are evenly spaced on the ladder bar crossmember, and ensured both ladder bars are adjusted the same.

Didn't mean to scare you...You can hang the rear in that way, then build the shocks and ladder bars around it. The string set up will help you find errors in any particular set up. It just takes time to set up. If you recheck all of your measurements and they are inside the 1/8 tolerance you are good to go. If not then I myself would lay it out on the floor and see whats amiss.

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 02/05/14 06:11 PM

Quote:

Quote:

Obviously I should have done more research before attempting a ladder bar/coil-over suspension.

How do I determine centerline of the vehicle? Once it's determined, how do I find center on the rear axle and how do I ensure the axle is centered in the vehicle? I know I can't use the pinion as it is offset to the passenger side. That's why I thought if I just hung plum bobs off the rear frame rails and measured the distance to the axle flanges and made sure it was the same distance on each side that the rear would be centered. I already triangulated the ladder bar crossmember before welding, ensured the ladder bar brackets are evenly spaced on the ladder bar crossmember, and ensured both ladder bars are adjusted the same.

Didn't mean to scare you...You can hang the rear in that way, then build the shocks and ladder bars around it. The string set up will help you find errors in any particular set up. It just takes time to set up. If you recheck all of your measurements and they are inside the 1/8 tolerance you are good to go. If not then I myself would lay it out on the floor and see whats amiss.

You didn't scare me, I was just thinking that maybe this was a little above my skill level. However, I changed my mind this morning.

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 02/05/14 06:12 PM

I had an epiphany this morning. For some reason, even though I used the tape marked garage floor for lining up all measurements previously, for some reason on the rear axle I was trying to use the vehicle rather than the floor. I don't know what I was thinking.

Thank you all for your inputs and guidance.

Posted By: sbsatellite

Re: Chassis Guys, a little help please? - 02/05/14 08:45 PM

So it is possible to level and find the center line and such with the rear axle and K member removed from the car? I was gonna try to tackle back halfing my car.

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 02/05/14 08:56 PM

Quote:

So it is possible to level and find the center line and such with the rear axle and K member removed from the car? I was gonna try to tackle back halfing my car.

Sure it is... you dont need all that extra junk in

the way... just do a GOOD job leveling the car first...

I spend hours just setting the car up level and finding

the center line... the better you get it right in

the beginning the better the job turns out

EDIT

I have a jig that I set the cars on... I level the

jig when I roll it into the shop then I level the car

on the jig... I clamp the car in location using the

sill plate flanges so it cant move once its in location

Posted By: cudaman1969

Re: Chassis Guys, a little help please? - 02/05/14 09:56 PM

its easy to set the axle center line square to the main center line by using the 4 6 10 formula. like a framing square on the floor, the main line 6 feet, axle line 4 feet, end of the 4 foot mark back to the 6 foot mark is 10 feet, a triangle, when the measurements are on there marks its square. wish i could show a drawing to make clear. its amazing how easy the build goes with those lines and plum bob.

total brain fade here, the # are 6-8-10 not 4-6, getting old is !!!!!

Posted By: sbsatellite

Re: Chassis Guys, a little help please? - 02/06/14 03:08 AM

Quote:

its easy to set the axle center line square to the main center line by using the 4 6 10 formula. like a framing square on the floor, the main line 6 feet, axle line 4 feet, end of the 4 foot mark back to the 6 foot mark is 10 feet, a triangle, when the measurements are on there marks its square. wish i could show a drawing to make clear. its amazing how easy the build goes with those lines and plum bob.

I wish you could show a picture too...

Posted By: dvw

Re: Chassis Guys, a little help please? - 02/06/14 04:20 AM

One thing I haven't seen discused. Assuming the rear axle is 90* to the vehicle centerline. The axle not being centered in the car shouldn't bother anything. I know my 1/4 panels are slightly different side to side. I adjusted my track bar so that the fender gap is the same on both sides as the tire sidewall clearance is very tight. The axle is now closer to the left frame rail than the right by about 1/4". The car tracks straight, leaves straight, drives straight at the top end.

Doug

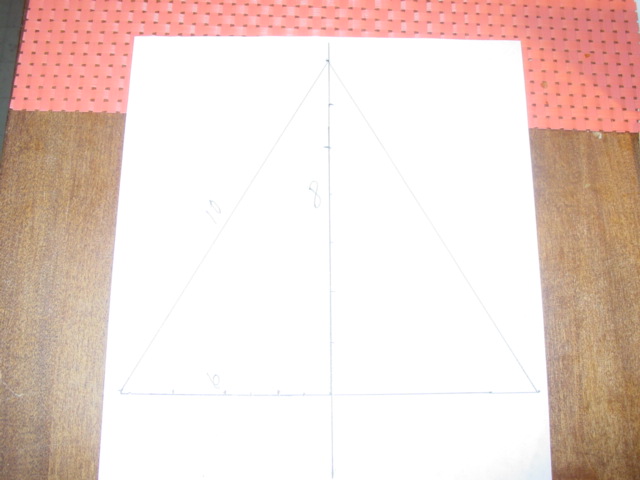

Posted By: cudaman1969

Re: Chassis Guys, a little help please? - 02/06/14 05:43 AM

Quote:

Quote:

its easy to set the axle center line square to the main center line by using the 4 6 10 formula. like a framing square on the floor, the main line 6 feet, axle line 4 feet, end of the 4 foot mark back to the 6 foot mark is 10 feet, a triangle, when the measurements are on there marks its square. wish i could show a drawing to make clear. its amazing how easy the build goes with those lines and plum bob.

I wish you could show a picture too...

The numbers are 6-8-10 not thinking right, diagram i made

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 02/09/14 05:01 PM

Well, after I replum bobbed, remarked the floor, and used the floor markings for all measurements this time, it turned out perfect; both sides are equal distance from the frame rails and both shocks are straight up and down. Everything is tacked and ready for final welds, which I'm about to do now.

Once again, thank you all for your help, guidance, and words of encouragement so I could get this done. I'll try to snap some pictures later today and post them.

Brad

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 02/09/14 05:14 PM

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 02/15/14 03:45 AM

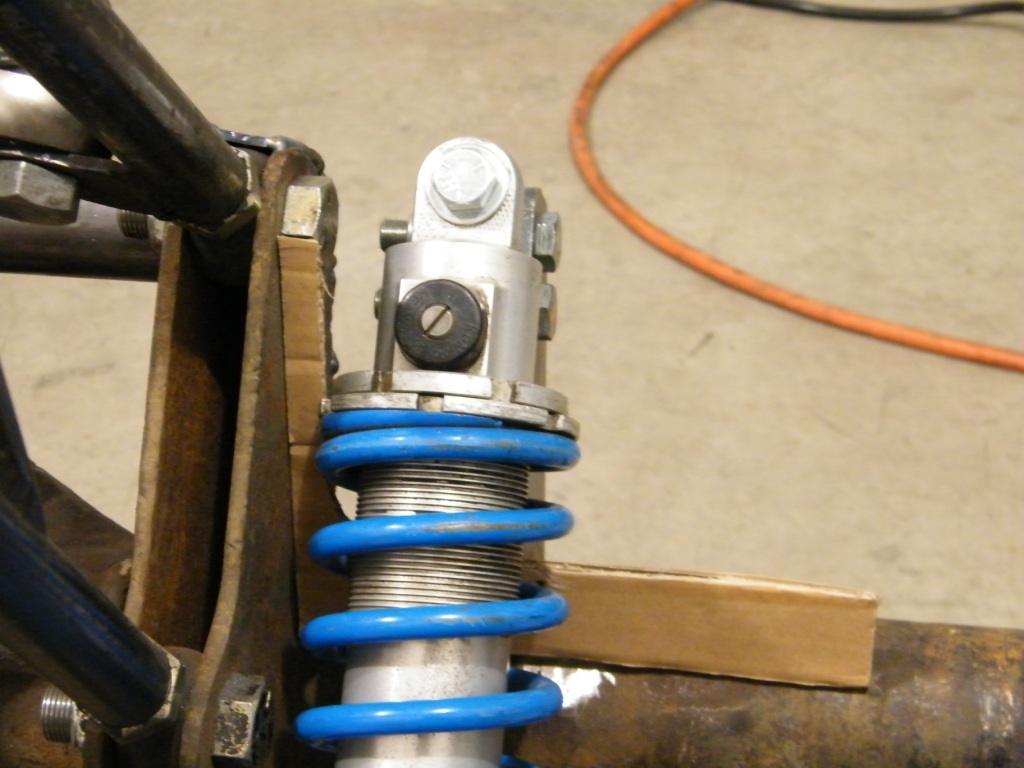

Well, I finally got some pics today. I think it turned out great!

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 02/15/14 03:47 AM

Check out Mr. Unbreakable. He's like, what's taking so long? Bring it!

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 02/15/14 03:51 AM

Quote:

Check out Mr. Unbreakable. He's like, what's taking so long? Bring it!

It helps to box in the back also(when you get to it)

looks good... sets nice

EDIT

I dont know if you will street drive it BUT a gusset

down on the right rear ladder bar mount will help

it a TON... it takes out the side ways flex the

diagonal link applies

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 02/15/14 04:43 AM

What do you mean by, "box in the back"? I'm not familiar with that. Do you have an example of what you mean?

I do plan to drive it on the street. I'm not familiar with a gusset, but I'm assuming it means to take a piece of metal that will fit between the back of the ladder bar brackets and weld it in between them so that it will close that area and also prevent it from flexing as you mentioned. Is that right? I've seen people weld a thin plate on the bottom of their lower control arms that I'm assuming serves the same purpose. Would there be any benefit to gusseting both sides while I'm at it?

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 02/15/14 05:15 AM

You can see the gusset on the left of the shock(sorry

its all painted black) but its a wedge welded to the tube

down to just above the lower bar mount to kill the

side flex.... the lower hole where the lateral link

mount is sorta out in space and this stiffens it up..

boxing the rear of the bar mounts helps stiffen them

up... I dont have a pic of that completed.. but a

3/4" wide plate welded to the back of the ladder bar

mounts

EDIT

In this pic the back of the brackets wasnt boxed in

yet... I forgot till later

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 03/02/14 03:12 AM

Here are a few pics of the template for the gusset I intend to create for the ladder bar bracket. Please let me know if you think it will be strong enough. It will be 1/4" plate that will be 1/2" wide against the ladder bar bracket and 1-1/2" wide against the axle housing. I will also be anchoring it to the shock bracket as I notched it for attachment of the soon to be created bracket. These first two pics are of the gusset template without the shock installed.

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 03/02/14 03:13 AM

Second pic without the shock.

Posted By: Brad4406

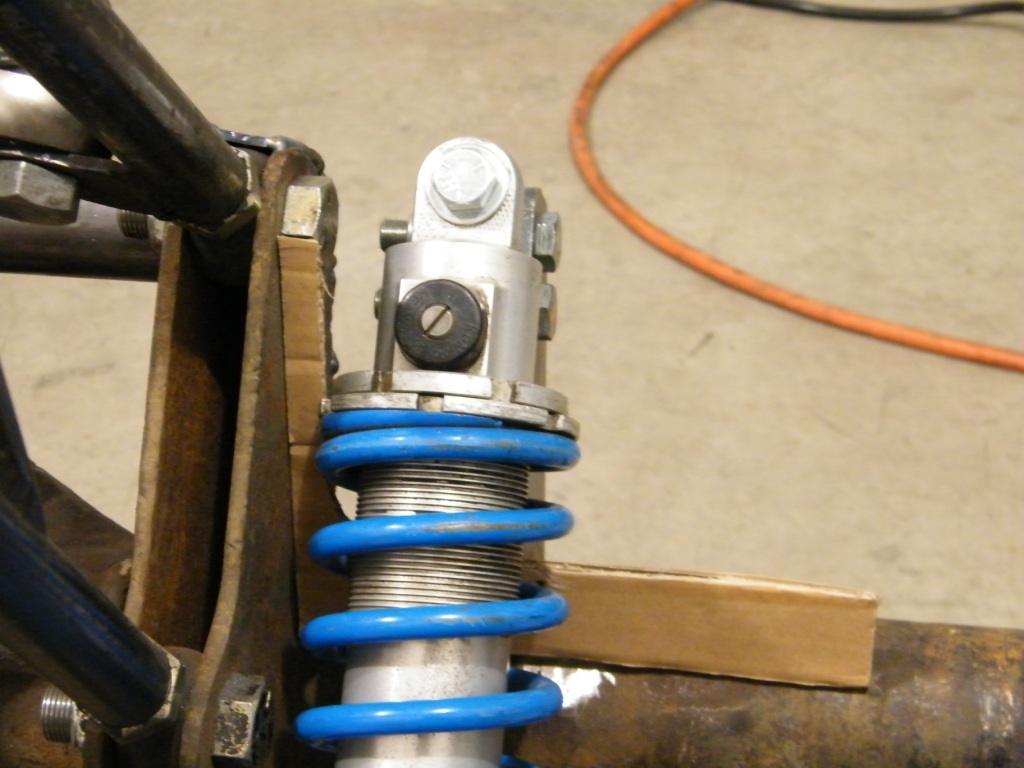

Re: Chassis Guys, a little help please? - 03/02/14 03:14 AM

First pic with shock installed.

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 03/02/14 03:16 AM

Second pic with shock installed.

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 03/02/14 03:51 AM

Quote:

First pic with shock installed.

I would try to get it in on the inside of the brackets..

that is too close to the spring and it does move a

little... but you got the idea.. make the radius larger

and give it more material if you can fit it in on the

inside

EDIT

Looking at it a bit closer you can put a brace/gusset

over to your shock mount then run the gusset to the

shock mount... your trying to stop any side flexing

caused during cornering from the diagonal link

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 03/02/14 04:01 AM

Do you think I should weld to the carrier part of the axle housing? The reason why I ask is because there is only 1-1/8" of axle housing between the ladder bar bracket and the carrier part of the housing.

I also have another option of making a square bracket with an oval cut in it for the shock to go inside of.

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 03/02/14 04:05 AM

Also when we mount the shocks we dont normally have

them 90* to the rotation... basically turn that 90*

and bolt it in from the side ... I normally use these

brackets for the lower shock mount

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 03/02/14 04:08 AM

I edited my other post.. take a look back

Posted By: MR_P_BODY

Re: Chassis Guys, a little help please? - 03/02/14 04:17 AM

Also if you want to weld to the cast housing thats

fine but you have to use nickle rod for the cast side..

which ever way works easiest for you(most likely the

housing side)

Posted By: Brad4406

Re: Chassis Guys, a little help please? - 03/02/14 04:22 AM

Thank you for the ideas. I think I'll try to design a bracket that ties to the shock bracket and then gusset the shock bracket.

makes workin on these cars sssoooo much easier so, why stop now...........

makes workin on these cars sssoooo much easier so, why stop now...........

You can find/build anything and everything off of a centerline string. Your garage or shop build should ALWAYS start with one. A bit of a pain to set up for the novice, but once you learn it, it is very easy, but very time consuming. I wear out tape measures when putting these things together! And Mike is right when he says 3/8 is close on a stock framed car...you have already found 1/8 of the 3/8, and I am betting if you did a centerline string you would find some more of it, or find where a small mistake was made. Generally we always strive to get it dead nuts, and sometimes you get it, but in reality a 1/8 plus/minus tolerance is the general rule.

You can find/build anything and everything off of a centerline string. Your garage or shop build should ALWAYS start with one. A bit of a pain to set up for the novice, but once you learn it, it is very easy, but very time consuming. I wear out tape measures when putting these things together! And Mike is right when he says 3/8 is close on a stock framed car...you have already found 1/8 of the 3/8, and I am betting if you did a centerline string you would find some more of it, or find where a small mistake was made. Generally we always strive to get it dead nuts, and sometimes you get it, but in reality a 1/8 plus/minus tolerance is the general rule.