Posted By: MadMopars

Chemical Milling... - 01/27/14 07:21 PM

Before I begin, I just want to say this process can be dangerous if not done safely and responsibly. There's your warning.

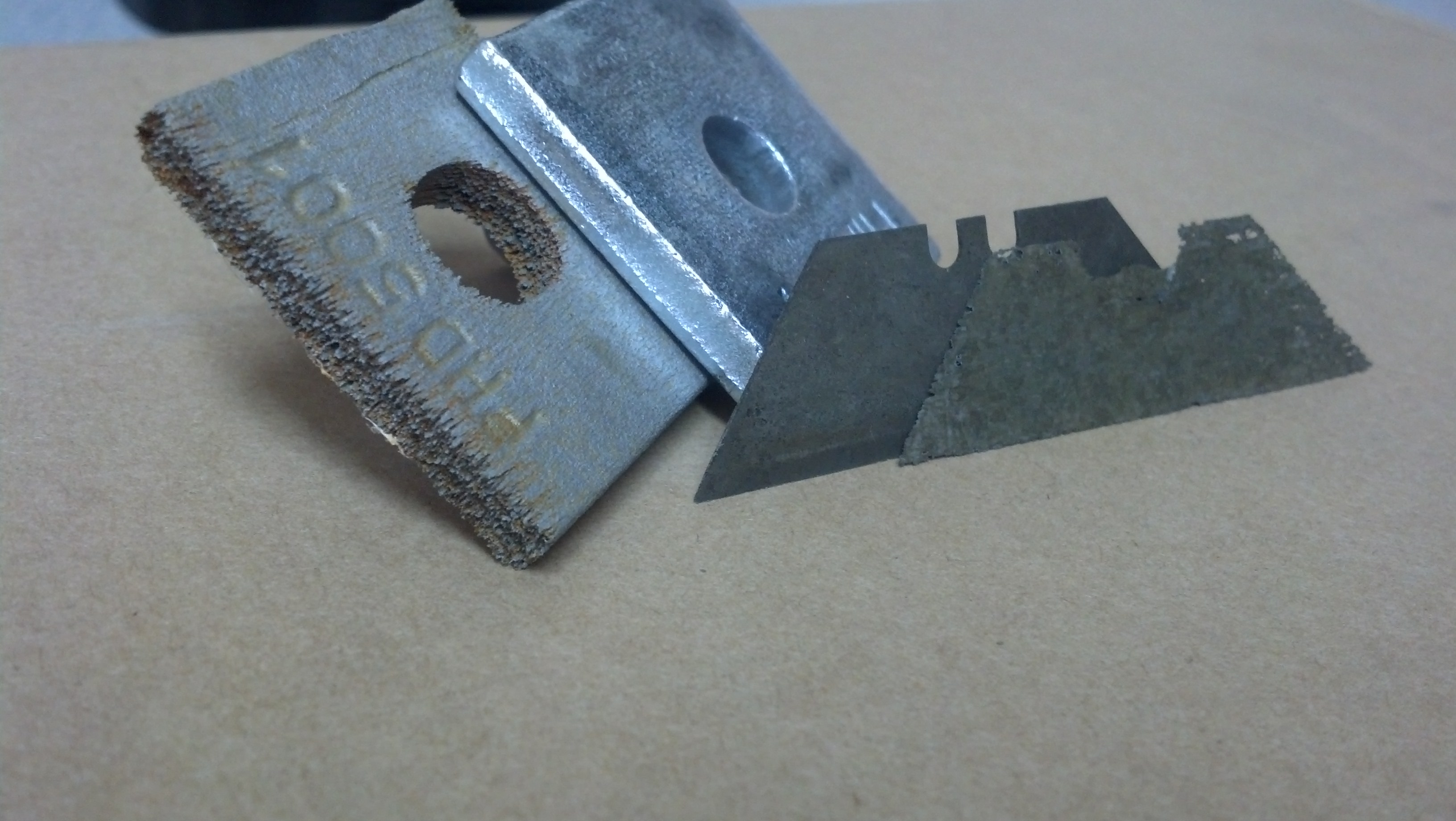

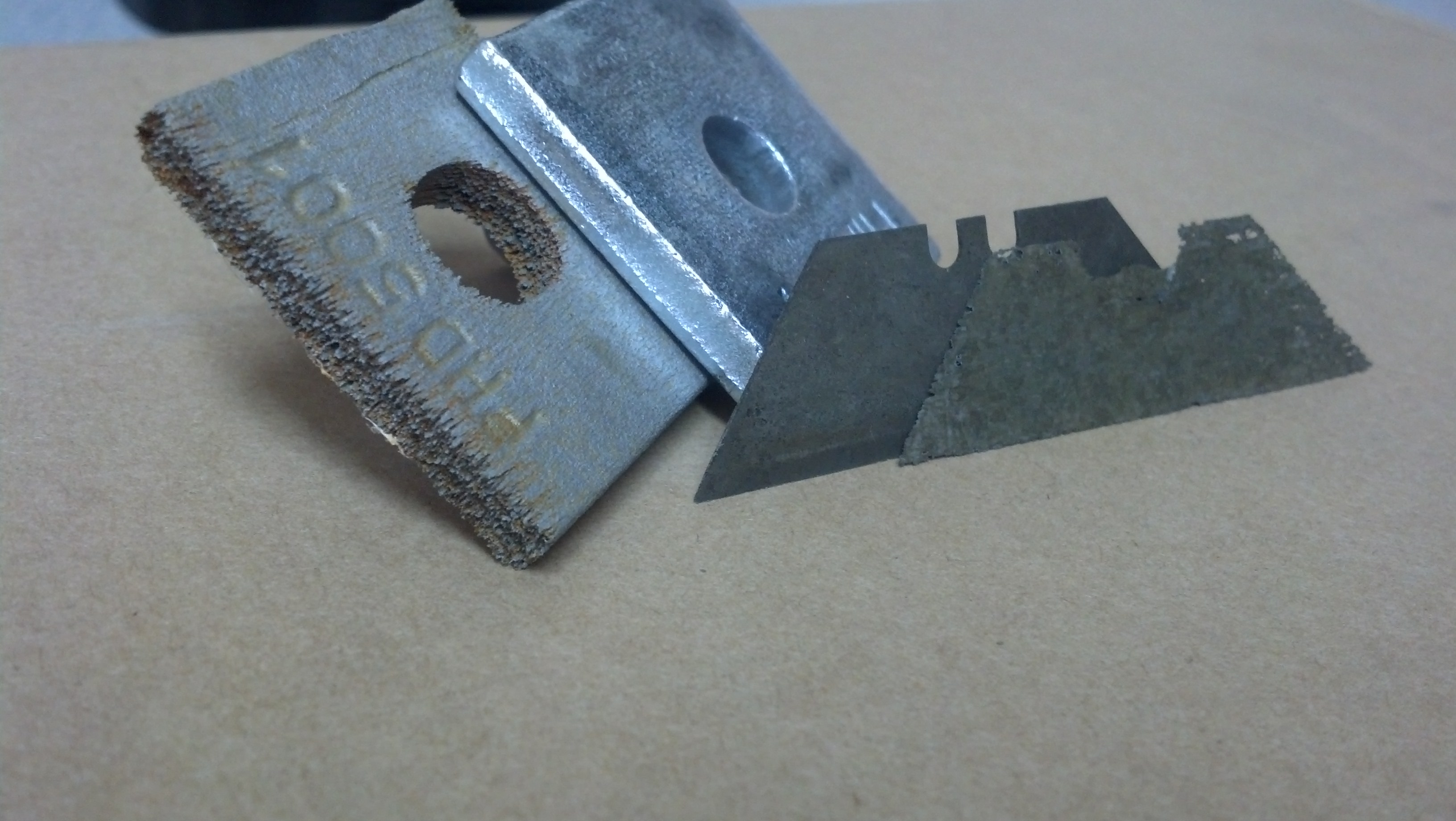

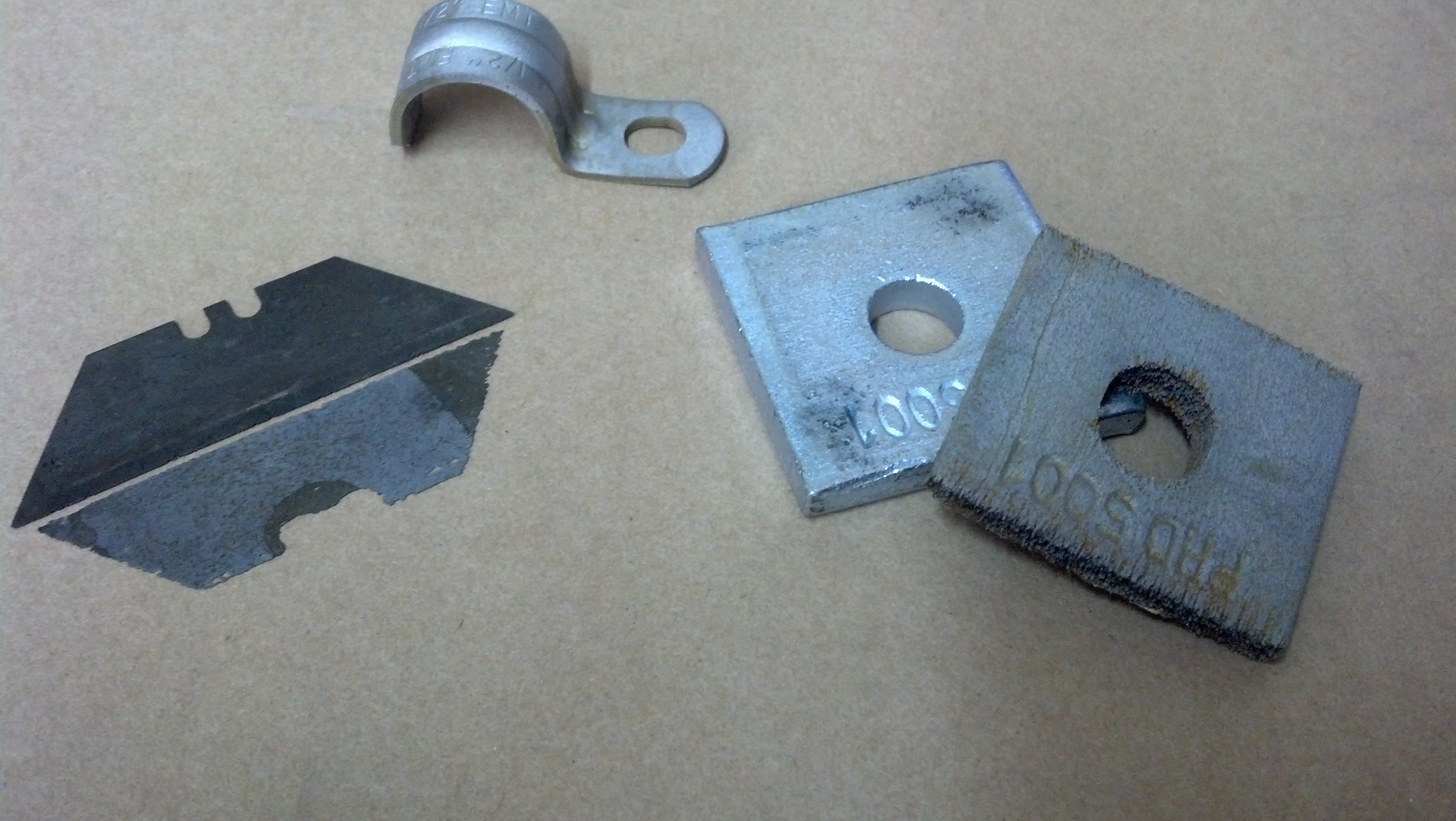

Just curious as to who else is familiar with the process of chemical milling and what the results were. I dipped 3 items in a 70/30 mix of Muriatic Acid and Water over the last several days. I used a surface rusted razor blade, a new square Uni-strut washer, and a new 1/2" conduit strap. The razor blade had a pretty even removal of material overall. At this point it is very flexible and does have some small pin holes in it. It's starting weight was approximately 4 KG but my scale will no longer see a reading from it. The Uni-strut washer starting weight was approximately 2.5oz. It's now at 1.7. The majority of the material came from the 2 ends which look to have been sheared and thus fatigued. Material also disappeared from the hole drilled in the center of it. The faces and other two ends have very little surface change to speak of. Lastly, the conduit strap did nothing. The zinc coating disappeared and that was it.

Although I was pleased to see results over the duration of several days, I did determine that control of where material is removed from is probably my main concern with the process. I believe tempering and fatigue are questionable areas that need to be considered prior to dipping.

Cost and time considered, I was real impressed with the rate of deterioration for lack of a better word. I'm just not sure that continuation of attempting to lighten parts wouldn't come without a few hard lessons.

That being said, has anyone else attempted this or familiar with the process? Any words of wisdom to offer?

Just curious as to who else is familiar with the process of chemical milling and what the results were. I dipped 3 items in a 70/30 mix of Muriatic Acid and Water over the last several days. I used a surface rusted razor blade, a new square Uni-strut washer, and a new 1/2" conduit strap. The razor blade had a pretty even removal of material overall. At this point it is very flexible and does have some small pin holes in it. It's starting weight was approximately 4 KG but my scale will no longer see a reading from it. The Uni-strut washer starting weight was approximately 2.5oz. It's now at 1.7. The majority of the material came from the 2 ends which look to have been sheared and thus fatigued. Material also disappeared from the hole drilled in the center of it. The faces and other two ends have very little surface change to speak of. Lastly, the conduit strap did nothing. The zinc coating disappeared and that was it.

Although I was pleased to see results over the duration of several days, I did determine that control of where material is removed from is probably my main concern with the process. I believe tempering and fatigue are questionable areas that need to be considered prior to dipping.

Cost and time considered, I was real impressed with the rate of deterioration for lack of a better word. I'm just not sure that continuation of attempting to lighten parts wouldn't come without a few hard lessons.

That being said, has anyone else attempted this or familiar with the process? Any words of wisdom to offer?

.

.

They bought a plant up (in El Mirage) in the high desert later, if you knew someone that worked thier you could get them to still do it back in the late 1980 and early 1990s

They bought a plant up (in El Mirage) in the high desert later, if you knew someone that worked thier you could get them to still do it back in the late 1980 and early 1990s