Posted By: mopster

X-block sonic test results - 12/27/13 01:55 AM

Iīm starting a small block build, half race half street use, n/a E85, around 13:1 compression. Iīm using X-block and plan is to use 4.125" crank and 4.08" bore. I need the block to handle 700hp.

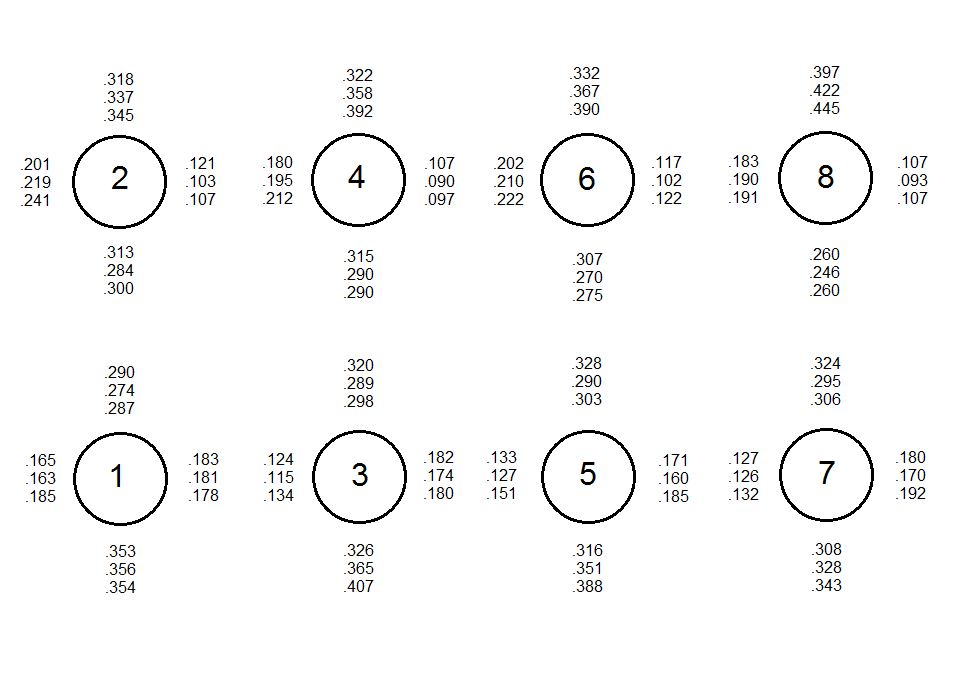

Now the sonic numbers are very nice from the thrust sides all around, but there are core shift in non-thrust direction. Worst spots are only .090" in cyl 4 and 8. I tested the block myself with Dakota Ultrasonics PR-82 tester which I calibrated before the test. I took a lot of readings and nothing was left unnoticed.

The block is now in 4.04" size, and I was thinking the bore centerlines could be moved about .020" in non-thrust direction when it gets bored .040" bigger. That way those thin walls wouldnīt get much more thinner really, but the guestion is, are they too thin already? If it was a production block then that would be the case, but this is more rigid raceblock with high nickel casting so Iīm not quite sure. I will consider sleeves if itīs too risky wihout them.

Now the sonic numbers are very nice from the thrust sides all around, but there are core shift in non-thrust direction. Worst spots are only .090" in cyl 4 and 8. I tested the block myself with Dakota Ultrasonics PR-82 tester which I calibrated before the test. I took a lot of readings and nothing was left unnoticed.

The block is now in 4.04" size, and I was thinking the bore centerlines could be moved about .020" in non-thrust direction when it gets bored .040" bigger. That way those thin walls wouldnīt get much more thinner really, but the guestion is, are they too thin already? If it was a production block then that would be the case, but this is more rigid raceblock with high nickel casting so Iīm not quite sure. I will consider sleeves if itīs too risky wihout them.

Not easy guesions but all input is appreciated.

Not easy guesions but all input is appreciated.