Moparts

Rocker Geometry Measurements

Posted By: B3RE

Rocker Geometry Measurements - 10/28/13 12:39 AM

Here are the measurement and spec instructions, required for calculating correct geometry, that so many of you have requested.

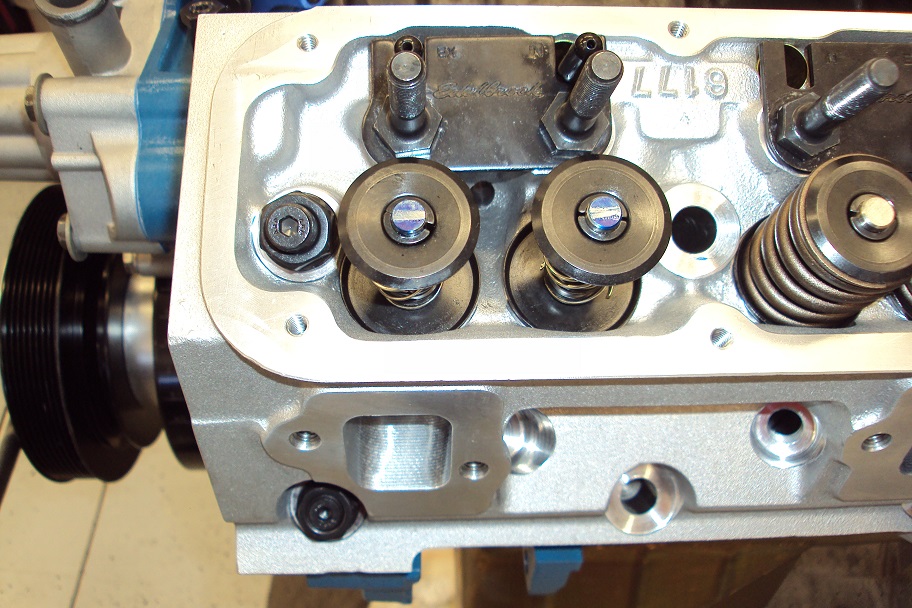

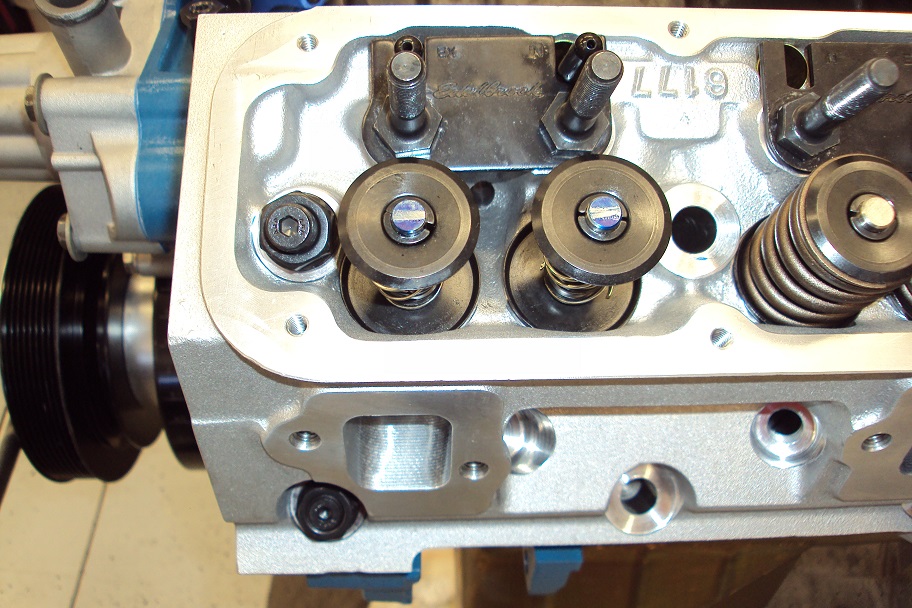

1. Distance between the top of the rocker shaft and the top of the valve stem. Measure the distance between the combination square and the tip of the valve stem using a caliper, feeler gages, or other accurate measuring device. Be sure the square is resting on top of the rocker shaft and the blade is on the same angle as the valve stem. (See Photo)

2. Diameter of the rocker shaft and the roller tip of the rocker arm.

3. Rocker ratio being used.

4. Valve lift from cam card w/ 1.5 ratio rocker, or just lobe lift.

With these measurements and specs, you can contact me and I can let you know if correction is necessary, and supply you with the appropriate kit to make it perfect, guaranteed.

As always, I am happy to answer questions. I like questions.

Posted By: Performance Only

Re: Rocker Geometry Measurements - 10/28/13 01:22 AM

In your picture, the bottom of the spring is not centered. doesn't that skew the math?

Posted By: Quicktree

Re: Rocker Geometry Measurements - 10/28/13 02:05 AM

BR can you tell us who you are and a little back ground? are you here to sell something? just curious

Posted By: onig

Re: Rocker Geometry Measurements - 10/28/13 02:18 AM

Thanks Mike.

Onig

Posted By: Mopar-Al

Re: Rocker Geometry Measurements - 10/28/13 02:26 AM

So the tee square doesnt have to be in the bubble, but rather line the edge on the springs? Does this work on all types of heads? Seems the tee square may not work on some? or use the opposit end. Also, cant you just explain the formula after the pic you just posted?

Posted By: B3RE

Re: Rocker Geometry Measurements - 10/28/13 02:37 AM

Quote:

In your picture, the bottom of the spring is not centered. doesn't that skew the math?

Seriously?????

From the original post: Quote:

Be sure the square is resting on top of the rocker shaft and the blade is on the same angle as the valve stem.

The picture is a reference to show how to position the square to take the measurement. The spring is an outer from a triple setup that gives a clear view of the square resting against the spring without interference from the retainer. Obviously that spring won't locate on the spring step in the head. Do you really find that troubling or do you just like trying to bust my chops? I'm trying to find ways to help Mopar guys, not tear down others.

Posted By: rowin4

Re: Rocker Geometry Measurements - 10/28/13 02:41 AM

I would think the bubble would have nothing to do with squaring things up as the head is on an angle on the engine, even on the bench. A better way to measure would be to have the spring off and square it up against the valve stem.

Posted By: Mopar-Al

Re: Rocker Geometry Measurements - 10/28/13 02:48 AM

Yeah, I pictured that in my head/what you said after I posted. If it wasn't so late, I'd go back in my shop and try this on my B1's, just to follow along.

Posted By: B3RE

Re: Rocker Geometry Measurements - 10/28/13 02:51 AM

Quote:

So the tee square doesnt have to be in the bubble, but rather line the edge on the springs? Does this work on all types of heads? Seems the tee square may not work on some? or use the opposit end. Also, cant you just explain the formula after the pic you just posted?

Using the bubble level doesn't mean anything. The idea is to find how high the rocker shaft sits in relation to the valve tip and on the same plane.

This will work on all shaft mount systems provided the measurements are correct.

I could explain the formulas, but I reserve that for business use.

Posted By: B3RE

Re: Rocker Geometry Measurements - 10/28/13 02:53 AM

Quote:

I would think the bubble would have nothing to do with squaring things up as the head is on an angle on the engine, even on the bench. A better way to measure would be to have the spring off and square it up against the valve stem.

I used to use a pic doing just that, but some guys couldn't figure out how to get the measurement with the spring on the head. Go figure.

Posted By: Mopar-Al

Re: Rocker Geometry Measurements - 10/28/13 03:01 AM

As always, I am happy to answer questions. I like questions.

Even if I don't like your answers. I didn't realize you were acting as a top secret rocket scientist. I may not be able to say what I see or think, but I can see what needs to be done and do it. It's just math.

Posted By: dvw

Re: Rocker Geometry Measurements - 10/28/13 03:17 AM

After reading a fair amount about rocker geometry. I settled on the theory that the center line of the rocker arm should be at a 90 degree angle to the valve stem at mid lift. What happens is when there is more valve lift the rocker pivot in relation to the valve tip needs to be moved down. It's simple math to figure it out.

Doug

Posted By: Crizila

Re: Rocker Geometry Measurements - 10/28/13 03:26 AM

Mike, How about us Magnum guys that are using rocker studs?

Posted By: B3RE

Re: Rocker Geometry Measurements - 10/28/13 03:32 AM

Quote:

As always, I am happy to answer questions. I like questions.

Even if I don't like your answers. I didn't realize you were acting as a top secret rocket scientist. I may not be able to say what I see or think, but I can see what needs to be done and do it. It's just math.

No, I'm not a rocket scientist, but I do work very hard at what I do and I do it to help myself by helping others. You're right, it is just math, so if you can see what needs done, why did you ask for the formulas? And if you knew this was about the math, why didn't you step up and tell all those members, who still thought centering the roller on the valve was correct geometry, that they were wrong? And why didn't you explain it to them so they could clearly understand why it was wrong. Hmmmmmmmm?

Posted By: B3RE

Re: Rocker Geometry Measurements - 10/28/13 03:38 AM

Quote:

Mike, How about us Magnum guys that are using rocker studs?

The magnum guys have it easy, so to speak. You can correct geometry by altering the pushrod length, but drastic changes get dicey. You need to offset the rocker when large changes are made and that makes studs a real pain in the moon crease. (Or use rockers with a different fulcrum length)

Posted By: B3RE

Re: Rocker Geometry Measurements - 10/28/13 03:44 AM

Quote:

After reading a fair amount about rocker geometry. I settled on the theory that the center line of the rocker arm should be at a 90 degree angle to the valve stem at mid lift. What happens is when there is more valve lift the rocker pivot in relation to the valve tip needs to be moved up. It's simple math to figure it out.

Doug

There's a little more to it than that. The valve is not on the same angle as the stand so it must be offset as well. Now how do you accomplish moving the shaft up without major surgery?

Posted By: B3RE

Re: Rocker Geometry Measurements - 10/28/13 03:48 AM

Quote:

Thanks Mike.

Onig

You're welcome, sir.

Posted By: Mopar-Al

Re: Rocker Geometry Measurements - 10/28/13 04:45 AM

I guess you didnt read through my post all the way. So piss off. I dont play internet games. But I do help out the locals and friends with hands on. I thought maybe I could jot some things down that might help others. But I get this mental block when a jerk starts up with sarcasm. Just like this post won't be informative, it will be a kit forsale add.

Posted By: dvw

Re: Rocker Geometry Measurements - 10/28/13 11:32 AM

Quote:

Quote:

After reading a fair amount about rocker geometry. I settled on the theory that the center line of the rocker arm should be at a 90 degree angle to the valve stem at mid lift. What happens is when there is more valve lift the rocker pivot in relation to the valve tip needs to be moved up. It's simple math to figure it out.

Doug

There's a little more to it than that. The valve is not on the same angle as the stand so it must be offset as well. Now how do you accomplish moving the shaft up without major surgery?

That's a good question. You can shim the shaft. That will not address the shaft center line to valve stem dimension. In my case I have individual shaft T&D. I actually offset the rocker stand mounting holes in the head. The most common solution would be to mill the stands and replace them with blocks that have the rocker shaft hole in the right spot. Can you elaborate where your theory is on rocker to stem location?

Thanks Doug

Posted By: Performance Only

Re: Rocker Geometry Measurements - 10/28/13 12:02 PM

Quote:

Quote:

In your picture, the bottom of the spring is not centered. doesn't that skew the math?

Seriously?????

From the original post: Quote:

Be sure the square is resting on top of the rocker shaft and the blade is on the same angle as the valve stem.

The picture is a reference to show how to position the square to take the measurement. The spring is an outer from a triple setup that gives a clear view of the square resting against the spring without interference from the retainer. Obviously that spring won't locate on the spring step in the head. Do you really find that troubling or do you just like trying to bust my chops? I'm trying to find ways to help Mopar guys, not tear down others.

Yes, there's a couple of things I find troubling. when you said; Quote:

Be sure the square is resting on top of the rocker shaft and the blade is on the same angle as the valve stem. (See Photo)

Clearly the square is NOT on the same angle as the valve stem. If it was, the measurement would be different. If you're not careful enough to post a picture that shows things correctly, what other shortcuts will be next?

The other troubling thing is that your post is just a thinly veiled FOR SALE add to get people to call you and buy some kit. If you really wanted to help people you'd just post your formula so people can check to see if they have a problem. If they do, maybe they'll call you. Sorry, but your whole approach looks more like a snake oil salesman tactic as opposed to someone who's really trying to help.

Posted By: mac56

Re: Rocker Geometry Measurements - 10/28/13 01:19 PM

Quote:

I guess you didnt read through my post all the way. So piss off. I dont play internet games. But I do help out the locals and friends with hands on. I thought maybe I could jot some things down that might help others. But I get this mental block when a jerk starts up with sarcasm. Just like this post won't be informative, it will be a kit forsale add.

Why all the negativity and name calling. If you disagree with the information just say why and I will figure out the world isn't flat.

Posted By: justinp61

Re: Rocker Geometry Measurements - 10/28/13 01:49 PM

Quote:

Why all the negativity and name calling. If you disagree with the information just say why and I will figure out the world isn't flat.

It's the attitude B3RE has taken in his answers. He may well have a good product and it may take care of some valve train issues. I'd try a different approach though  .

.

Posted By: 72Swinger

Re: Rocker Geometry Measurements - 10/28/13 03:17 PM

Man why do some people always have to question free advice? The guy says "do this" and maybe I can help. And people act like they're making a deal with the devil. How about use a digital level on the valve tip, then use same reading on your square, then measure. Don't be a square about the square doods......

Posted By: Performance Only

Re: Rocker Geometry Measurements - 10/28/13 04:27 PM

Quote:

Man why do some people always have to question free advice? The guy says "do this" and maybe I can help. And people act like they're making a deal with the devil. How about use a digital level on the valve tip, then use same reading on your square, then measure. Don't be a square about the square doods......

The basis for the advice is fine by me. I believe wholeheartedly that people should check and correct their rocker arm geometry if needed. The problem I have is when someone claims to help, but only if you call him so he can sell you something. In this case rocker shaft spacers, offset or otherwise. No problem, just place an add instead of misleading people.

Basically just post the formula so people can check their stuff. If there's a problem they can decide how to deal with it.

Posted By: Quicktree

Re: Rocker Geometry Measurements - 10/28/13 04:31 PM

Quote:

Man why do some people always have to question free advice? The guy says "do this" and maybe I can help. And people act like they're making a deal with the devil. How about use a digital level on the valve tip, then use same reading on your square, then measure. Don't be a square about the square doods......

I would at least like to know who he is and what his back ground is

Posted By: Mopar-Al

Re: Rocker Geometry Measurements - 10/28/13 04:35 PM

Quote:

Quote:

Why all the negativity and name calling. If you disagree with the information just say why and I will figure out the world isn't flat.

It's the attitude B3RE has taken in his answers. He may well have a good product and it may take care of some valve train issues. I'd try a different approach though  .

.

My post would have been a lot different if the op would of not put me on front street like a bad kid in a class room to be made example of. My eyes and ears are open, but as I said. I have a hard time trying to get any words out that I see in my mind and hands on. Alos, I don't let people back me in a corner. Never have. When I have info to share.... I share it. Without trying to belittle whom I am talking to. So it is what it is. This isnt a classroom, it's the race section on a very large site. We share information, give tips, fellowship, and just participate in the upcoming events. Other vendors or sales people usually get moved to a different forum.

Posted By: 72Swinger

Re: Rocker Geometry Measurements - 10/28/13 04:50 PM

Quote:

Quote:

Man why do some people always have to question free advice? The guy says "do this" and maybe I can help. And people act like they're making a deal with the devil. How about use a digital level on the valve tip, then use same reading on your square, then measure. Don't be a square about the square doods......

The basis for the advice is fine by me. I believe wholeheartedly that people should check and correct their rocker arm geometry if needed. The problem I have is when someone claims to help, but only if you call him so he can sell you something. In this case rocker shaft spacers, offset or otherwise. No problem, just place an add instead of misleading people.

Basically just post the formula so people can check their stuff. If there's a problem they can decide how to deal with it.

I think the formula is his and he wants to keep it that way. Who can blame him? Sounds like he wants your measurements when and if you call him so he can use his formula to either have a solution or tell you your junk isnt to far off to worry about. I understand where everyone is coming from but I also dont like to see a guy who may possibly know his s$%t get thrown under the bus over a picture of a measurement. Education isnt free here in America last I checked. I for one an open arms for this stuff since it can very well address a problem ALOT of Mopar guys didnt even know they had, me included. But when you piss a guy off, over trivial BS and hes gone, hes gone. OK guys back to posting your trophies and dyno results of your bracket engines.

Posted By: Crizila

Re: Rocker Geometry Measurements - 10/28/13 06:29 PM

Quote:

Quote:

Mike, How about us Magnum guys that are using rocker studs?

The magnum guys have it easy, so to speak. You can correct geometry by altering the pushrod length, but drastic changes get dicey. You need to offset the rocker when large changes are made and that makes studs a real pain in the moon crease. (Or use rockers with a different fulcrum length)

Checks in the mail  - and your expert opinion is:

- and your expert opinion is:

Posted By: Crizila

Re: Rocker Geometry Measurements - 10/28/13 06:30 PM

on the base circle

Posted By: Crizila

Re: Rocker Geometry Measurements - 10/28/13 06:31 PM

on the nose

Posted By: Hemi Allstate

Re: Rocker Geometry Measurements - 10/28/13 06:57 PM

Quote:

Quote:

Quote:

In your picture, the bottom of the spring is not centered. doesn't that skew the math?

Seriously?????

From the original post: Quote:

Be sure the square is resting on top of the rocker shaft and the blade is on the same angle as the valve stem.

The picture is a reference to show how to position the square to take the measurement. The spring is an outer from a triple setup that gives a clear view of the square resting against the spring without interference from the retainer. Obviously that spring won't locate on the spring step in the head. Do you really find that troubling or do you just like trying to bust my chops? I'm trying to find ways to help Mopar guys, not tear down others.

Yes, there's a couple of things I find troubling. when you said; Quote:

Be sure the square is resting on top of the rocker shaft and the blade is on the same angle as the valve stem. (See Photo)

Clearly the square is NOT on the same angle as the valve stem. If it was, the measurement would be different. If you're not careful enough to post a picture that shows things correctly, what other shortcuts will be next?

The other troubling thing is that your post is just a thinly veiled FOR SALE add to get people to call you and buy some kit. If you really wanted to help people you'd just post your formula so people can check to see if they have a problem. If they do, maybe they'll call you. Sorry, but your whole approach looks more like a snake oil salesman tactic as opposed to someone who's really trying to help.

Google = http://houston.craigslist.org/pts/4099405039.html

Posted By: onig

Re: Rocker Geometry Measurements - 10/28/13 06:58 PM

Quote:

on the nose

The head stud is in the way of the valve, but looks like the rocker needs to be raised.

Onig

Posted By: HotRodDave

Re: Rocker Geometry Measurements - 10/28/13 08:04 PM

Quote:

Quote:

on the nose

The head stud is in the way of the valve, but looks like the rocker needs to be raised.

Onig

Longer pushrods are needed but may cause the rocker to push on the side of the valve stem tip instead of the center, that would require filling the bolt hole and re-drilling it further towards the cam. Or you could offset drill and tap the hole to a bigger size stud

Of course all that makes the PR angle worse than it already is

Posted By: Performance Only

Re: Rocker Geometry Measurements - 10/28/13 09:34 PM

Quote:

Quote:

Quote:

on the nose

The head stud is in the way of the valve, but looks like the rocker needs to be raised.

Onig

Longer pushrods are needed but may cause the rocker to push on the side of the valve stem tip instead of the center, that would require filling the bolt hole and re-drilling it further towards the cam. Or you could offset drill and tap the hole to a bigger size stud

Of course all that makes the PR angle worse than it already is

Just measure the width of the sweep pattern, that'll tell you if the geometry is correct. If it's less than .600 lift it should be less than .025 on the sweep. The closer to the center of the valve the sweep is, the better off you are, but it doesn't have to be perfectly in the center to have good geometry.

Posted By: tsanchez

Re: Rocker Geometry Measurements - 10/28/13 09:42 PM

Quote:

Quote:

Quote:

Quote:

on the nose

The head stud is in the way of the valve, but looks like the rocker needs to be raised.

Onig

Longer pushrods are needed but may cause the rocker to push on the side of the valve stem tip instead of the center, that would require filling the bolt hole and re-drilling it further towards the cam. Or you could offset drill and tap the hole to a bigger size stud

Of course all that makes the PR angle worse than it already is

Just measure the width of the sweep pattern, that'll tell you if the geometry is correct. If it's less than .600 lift it should be less than .025 on the sweep. The closer to the center of the valve the sweep is, the better off you are, but it doesn't have to be perfectly in the center to have good geometry.

This^^^ Is correct.

Posted By: Hot 340

Re: Rocker Geometry Measurements - 10/28/13 09:55 PM

Man you guys are like a bunch of old women sometimes. Who cares if he has a product? Same with every other machine shop owner who frequents here. Good grief.

Posted By: WHITEDART

Re: Rocker Geometry Measurements - 10/28/13 10:15 PM

this is his testing tool in less you have this you will have to call him

http://www.dotcom-monitor.com/blog/wp-content/uploads/2010/08/gross.jpg he is just trying to help us get out our wallet

Posted By: sam64

Re: Rocker Geometry Measurements - 10/29/13 12:20 AM

and if one of the IN people on here said they used it you all would have your wallets out.

Posted By: skrews

Re: Rocker Geometry Measurements - 10/29/13 03:55 AM

Quote:

and if one of the IN people on here said they used it you all would have your wallets out.

Quoted for the truth.

Posted By: Crizila

Re: Rocker Geometry Measurements - 10/29/13 03:59 AM

Quote:

and if one of the IN people on here said they used it you all would have your wallets out.

Obviously I didn't use it  .

.

Posted By: Mopar-Al

Re: Rocker Geometry Measurements - 10/29/13 04:15 AM

Well then, is it time for our 10 oclock college course? We havent even learned how much his product costs yet. He is a salesman and in the wrong area of the site. Bottom line is, what he has been saying is what we pretty much know. If your rocker assembly is messed up bad, something will break and fail, but for only 19.95 there is a cure for that.

It is rarely that this area has a soliciter selling a product. And if they do, the product sells itself and not pushed. So you B3 angels stay put and be ready for your next lesson.

Posted By: MPerry

Re: Rocker Geometry Measurements - 10/29/13 11:33 AM

shaft .870

roller tip .500

lift with 1.5 ratio .622

using 1.6 rockers

measurement according to picture .208

Posted By: 80fbody

Re: Rocker Geometry Measurements - 10/29/13 12:36 PM

With all the different rocker lengths as AndyF has pointed out, a custom fix does seem like a great idea. As long as it's cost effective versus milling stands or buying another set of rockers.

He's definitely ruffled a few feathers but there's plenty others doing similar. I can't count how many posts there's been a reference to installing a certain girdle on our big blocks in order to live.

Posted By: 408Dust

Re: Rocker Geometry Measurements - 10/29/13 01:12 PM

Quote:

BR can you tell us who you are and a little back ground? are you here to sell something? just curious

You know it's not the same person that cracked your X block when installing lifter bore bushings.

Posted By: RAMM

Re: Rocker Geometry Measurements - 10/29/13 01:28 PM

Quote:

Quote:

BR can you tell us who you are and a little back ground? are you here to sell something? just curious

You know it's not the same person that cracked your X block when installing lifter bore bushings.

What? J.Rob

Posted By: Stanton

Re: Rocker Geometry Measurements - 10/29/13 02:58 PM

Quote:

I think the formula is his and he wants to keep it that way. Who can blame him? Sounds like he wants your measurements when and if you call him so he can use his formula to either have a solution or tell you your junk isnt to far off to worry about. I understand where everyone is coming from but I also dont like to see a guy who may possibly know his s$%t get thrown under the bus over a picture of a measurement. Education isnt free here in America last I checked. I for one an open arms for this stuff since it can very well address a problem ALOT of Mopar guys didnt even know they had, me included. But when you piss a guy off, over trivial BS and hes gone, hes gone. OK guys back to posting your trophies and dyno results of your bracket engines.

Very well said!

Yes, the OP is trying to sell his product but that in itself is "help". As for his "secret formula", why should he post it? He's protecting himself, how many businesses do you know that give away their formulas or manufacturing processes?

If the math is so simple then someone else should be able to figure it out and post it. And why isn't someone else making these parts? Hmmm, maybe its not so simple after all!

FWIW I have actually seen his product first hand (he was at Carlisle in July) and its not just a set of shims to move the shafts up or down, they also move the shafts laterally (which as far as I could tell also required work on the shafts). I thought he had an excellent product and the price was reasonable.

Posted By: GTX MATT

Re: Rocker Geometry Measurements - 10/29/13 03:25 PM

Quote:

I thought he had an excellent product and the price was reasonable.

I spoke with Mike recently as I know my geometry is much less than optimal. The kit looks very nice and the price was very reasonable I thought. The formula is part of the service he is offering for this fee. You take some measurements, send him the numbers, and he uses it to figure out how he needs to machine this shim/spacer/whatever you want to call it so that it will move your rocker shaft to the correct location. If he gave the formula away its all that much easier for an off-shore company to just start making them in a one size fits all kit and will get most people close enough, undercut his price by 50 bucks, and then you'll all be on here complaining that nothing is made in the USA, and that Mike was offering a good service custom making these kits for only 50 bucks more but got ran out of town by the dreaded outsourcers.

Additionally theres been a few threads relating to this topic recently that Mike posted on and was asked for more information regarding correct geometry, so maybe he thought it was relevant?

Posted By: BradH

Re: Rocker Geometry Measurements - 10/29/13 03:29 PM

Quick comments:

1. OP seems to be mixing tech w/ marketing on what is supposed to be a tech-only forum. He should probably have posted under New Products.

2. I have no problems w/ his solution approach and have come up w/ similar fixes (band-aids?) for my own stuff, even if I don't agree 100% w/ his methodology.

3. I can't stand bolts for holding down aluminum heads rocker shafts and would look for quality studs long enough to work, instead.

4. I'd like to know if the poster who says he saw the OP at Carlisle recalls the $$$ for the kits? It bothers me that no prices have been mentioned, but that ties back to point #1 on where IMO this should have been posted... with prices.

Posted By: Crizila

Re: Rocker Geometry Measurements - 10/29/13 03:47 PM

Quote:

Quote:

I thought he had an excellent product and the price was reasonable.

I spoke with Mike recently as I know my geometry is much less than optimal. The kit looks very nice and the price was very reasonable I thought. The formula is part of the service he is offering for this fee. You take some measurements, send him the numbers, and he uses it to figure out how he needs to machine this shim/spacer/whatever you want to call it so that it will move your rocker shaft to the correct location. If he gave the formula away its all that much easier for an off-shore company to just start making them in a one size fits all kit and will get most people close enough, undercut his price by 50 bucks, and then you'll all be on here complaining that nothing is made in the USA, and that Mike was offering a good service custom making these kits for only 50 bucks more but got ran out of town by the dreaded outsourcers.

Additionally theres been a few threads relating to this topic recently that Mike posted on and was asked for more information regarding correct geometry, so maybe he thought it was relevant?

plus new posters aren't exactly welcomed with open arms on this site.

plus new posters aren't exactly welcomed with open arms on this site.

Posted By: BradH

Re: Rocker Geometry Measurements - 10/29/13 03:50 PM

Quote:

... new posters aren't exactly welcomed with open arms on this site.

And more than a few of the old posters have bailed on this place due to changes in attitude & tendencies for other posters to go into "attack mode" over subjects they either don't necessarily understand or agree with.

Posted By: jamesc

Re: Rocker Geometry Measurements - 10/29/13 04:24 PM

Quote:

3. I can't stand bolts for holding down aluminum heads rocker shafts and would look for quality studs long enough to work, instead.

i can't for the life of me understand why people use bolts here. all you need to do is figure the length needed and order them from ARP or there are vendors that sell kits with studs and superior hold downs to the stock stamped stuff

personally i would NEVER use bolts in an aluminum head and only consider it with an iron head. i've seen so many damaged threads from people cranking down valve gear and it's a PITA to fix half azz properly

Posted By: Quicktree

Re: Rocker Geometry Measurements - 10/29/13 04:26 PM

Quote:

Quote:

BR can you tell us who you are and a little back ground? are you here to sell something? just curious

You know it's not the same person that cracked your X block when installing lifter bore bushings.

it was repaired with 100% guarantee. that has nothing to do with this situation. I like to know a little about some one when they come here with so called help.

Posted By: Mopar-Al

Re: Rocker Geometry Measurements - 10/29/13 05:52 PM

Quote:

Quick comments:

1. OP seems to be mixing tech w/ marketing on what is supposed to be a tech-only forum. He should probably have posted under New Products.

2. I have no problems w/ his solution approach and have come up w/ similar fixes (band-aids?) for my own stuff, even if I don't agree 100% w/ his methodology.

3. I can't stand bolts for holding down aluminum heads rocker shafts and would look for quality studs long enough to work, instead.

4. I'd like to know if the poster who says he saw the OP at Carlisle recalls the $$$ for the kits? It bothers me that no prices have been mentioned, but that ties back to point #1 on where IMO this should have been posted... with prices.

^^^^^^

this

On his craigslist adds he doesn't give any price info either.

I am not out to stalk this guy, so don't take it that way, Brad said it better than I could. Mixing sales and Tech. There are other areas to do that.

It just feels like a forsale add with no prices to me. That in itself annoys most anybody that is on a budget. Lots of people here are polishing their trophies and such as been said, without have this option.

Posted By: Stanton

Re: Rocker Geometry Measurements - 10/29/13 06:42 PM

Quote:

4. I'd like to know if the poster who says he saw the OP at Carlisle recalls the $$$ for the kits? It bothers me that no prices have been mentioned, but that ties back to point #1 on where IMO this should have been posted... with prices.

I don't recall the price. I recall seeing the product, getting the complete lowdown and thinking it was reasonably priced.

If you want the price, ask the OP. He might have been giving me a smokin' deal cuz I'm such a nice guy!

Posted By: 72Swinger

Re: Rocker Geometry Measurements - 10/29/13 07:02 PM

How about you guys that are

b@#$%in like church ladies just call him yourself?

Posted By: GTX MATT

Re: Rocker Geometry Measurements - 10/29/13 07:52 PM

Quote:

How about you guys that are [Email]b@#$%in[/Email] like church ladies just call him yourself?

Exactly, hes only a PM away. I don't want to post the price he gave me because maybe he doesn't want them advertised because it'd be that much easier for someone to figure out how to price it and cut out a piece of his market share. That said I don't see how he could possibly sell them any cheaper and have it be worth his while.

Posted By: BradH

Re: Rocker Geometry Measurements - 10/29/13 08:03 PM

Quote:

... He might have been giving me a smokin' deal cuz I'm such a nice guy!

Oh, well... then I'm screwed.

Posted By: tboomer

Re: Rocker Geometry Measurements - 10/29/13 09:17 PM

If he has a good idea and a good product he should make a post here about it. Then we can move it to the hot deals section for all to see it.

Posted By: Crizila

Re: Rocker Geometry Measurements - 10/29/13 09:21 PM

Quote:

If he has a good idea and a good product he should make a post here about it. Then we can move it to the hot deals section for all to see it.

Posted By: Quicktree

Re: Rocker Geometry Measurements - 10/29/13 09:31 PM

heck i would just like him to introduce himself

Posted By: all spooled up

Re: Rocker Geometry Measurements - 10/29/13 11:49 PM

Posted By: Quicktree

Re: Rocker Geometry Measurements - 10/30/13 12:01 AM

Quote:

chased off a nuter one

well if he is not man enough to stick around and explain a few things no big loss.

Posted By: WHITEDART

Re: Rocker Geometry Measurements - 10/30/13 12:51 AM

Quote:

Quote:

chased off a nuter one

well if he is not man enough to stick around and explain a few things no big loss.

Posted By: Sport440

Re: Rocker Geometry Measurements - 10/30/13 01:25 AM

Quote:

Here are the measurement and spec instructions, required for calculating correct geometry, that so many of you have requested.

1. Distance between the top of the rocker shaft and the top of the valve stem. Measure the distance between the combination square and the tip of the valve stem using a caliper, feeler gages, or other accurate measuring device. Be sure the square is resting on top of the rocker shaft and the blade is on the same angle as the valve stem. (See Photo)

2. Diameter of the rocker shaft and the roller tip of the rocker arm.

3. Rocker ratio being used.

4. Valve lift from cam card w/ 1.5 ratio rocker, or just lobe lift.

With these measurements and specs, you can contact me and I can let you know if correction is necessary, and supply you with the appropriate kit to make it perfect, guaranteed.

As always, I am happy to answer questions. I like questions.

Im not here to scare anybody.

But I believe the above requested info isnt enough to figure out anybodys rocker geometry.

IMO, one would also need to know the relationship between the "Roller tip and the Rockers body", along with the variable pushrod side of that Rocker.

As in, at a 90* angle to the valve is the roller center in the rocker body parrallel with the shafts center or is it offset up or down from that center.

Without knowing that, IMO, A absolute Geometry cant be figured out. Would I be correct??

Also, is absolute geometry really needed, for most purposes Im going to assume the rocker manufactures have it really close to begin with.

No doubt IMO, a really tight sweep of the roller tip is a good indicater of good geometry.

Posted By: Stanton

Re: Rocker Geometry Measurements - 10/30/13 02:04 AM

Quote:

Also, is absolute geometry really needed, for most purposes Im going to assume the rocker manufactures have it really close to begin with.

Really ?!?! You were sounding pretty smart for a while there but you've just dispelled that notion.

Posted By: sam64

Re: Rocker Geometry Measurements - 10/30/13 02:05 AM

uh then why does andy f show so many differences in manufactures difference in design?do your research first.

Posted By: Sport440

Re: Rocker Geometry Measurements - 10/30/13 02:18 AM

Quote:

Quote:

Also, is absolute geometry really needed, for most purposes Im going to assume the rocker manufactures have it really close to begin with.

Really ?!?! You were sounding pretty smart for a while there but you've just dispelled that notion.

I hear you, but Im referring to the word "Absolute" Im sure many of us dont have it with our rocker arm/shaft/valve combos.

Posted By: AndyF

Re: Rocker Geometry Measurements - 10/30/13 03:09 AM

I think that most of the mfgs do a decent job figuring out the rocker arm geometry. The problem is that they don't tell people what the assumptions are behind the designs. Some rocker arms are designed to be stock replacements, some as race parts, some for stock heads, etc.

I spent my own money years ago to buy one rocker arm from every mfg possible so I could do my own measurements. I gradually figured out which arms worked with which heads and what lift ranges but it was a bit of a painful process.

I used to sell these rocker sweep tools. They do a good job of providing an engine builder with an actual number for the sweep. Without an actual measurement you're just kind of guessing at the results of a geometry change.

I've looked at the system that the OP sells and it doesn't make any sense to me. Maybe it works, maybe it doesn't. I'm not going to buy one to test out. I'll let someone else do that job. I've tested enough parts over the years!

Posted By: rowin4

Re: Rocker Geometry Measurements - 10/30/13 05:35 AM

Looking at the add pictures that he has on craigslist, it seems that the heads need machining for the shims to be installed. Looks like the shims themselves are ground offset in the picture to correct the geometry., but the heads need machining to do that as you can't put that thick of a shim under the shaft without splitting the shaft mount. Or you could use a smaller shaft, but that would require special rockers to replace the ones that are off. As for the bolt /studs in aluminum heads, I bought my ARP rocker shaft studs from Magnum for my Edelbrock RPM's 440 heads.

Posted By: onig

Re: Rocker Geometry Measurements - 10/30/13 12:59 PM

This topic is very interesting as I am going through this process with a Pontiac stud rocker system. I have been doing some research to understand the theory.

The kit that B3RE sells will work. Those "shims/spacers" are machined to raise the shaft up the required amount to achieve the 90* angle to the valve at half lift. He also can move the shaft to the inside or outside if needed. From what I know each kit is custom made to your application from the specs that you give him.

I think that a lot of people will change rockers and not check for proper geometry. I used to think that proper geometry was having the roller centered on the valve, but not any more after looking into this somewhat.

Onig

Posted By: Quicktree

Re: Rocker Geometry Measurements - 10/30/13 01:55 PM

Quote:

This topic is very interesting as I am going through this process with a Pontiac stud rocker system. I have been doing some research to understand the theory.

The kit that B3RE sells will work. Those "shims/spacers" are machined to raise the shaft up the required amount to achieve the 90* angle to the valve at half lift. He also can move the shaft to the inside or outside if needed. From what I know each kit is custom made to your application from the specs that you give him.

I think that a lot of people will change rockers and not check for proper geometry. I used to think that proper geometry was having the roller centered on the valve, but not any more after looking into this somewhat.

Onig

I think everyone will agree with that. a different approach would have went over a lot better.

Posted By: CHAPPER

Re: Rocker Geometry Measurements - 10/30/13 02:20 PM

Quote:

heck i would just like him to introduce himself

Maybe you should try one of the online dating sites,,,he's not the only guy out there.

Posted By: max_maniac

Re: Rocker Geometry Measurements - 10/30/13 02:56 PM

Quote:

Quote:

heck i would just like him to introduce himself

Maybe you should try one of the online dating sites,,,he's not the only guy out there.

Posted By: Stanton

Re: Rocker Geometry Measurements - 10/30/13 03:08 PM

Quote:

Quote:

heck i would just like him to introduce himself

Maybe you should try one of the online dating sites,,,he's not the only guy out there.

LMAO !!!

Posted By: Quicktree

Re: Rocker Geometry Measurements - 10/30/13 04:14 PM

Quote:

Quote:

heck i would just like him to introduce himself

Maybe you should try one of the online dating sites,,,he's not the only guy out there.

I am sure your homo friends will get a laugh out of that

Posted By: 408Dust

Re: Rocker Geometry Measurements - 10/30/13 09:39 PM

I am sure your homo friends will get a laugh out of that

Thought you Obama supporters were OK with that stuff

Posted By: Crizila

Re: Rocker Geometry Measurements - 10/31/13 12:16 AM

Quote:

Quote:

Quote:

Also, is absolute geometry really needed, for most purposes Im going to assume the rocker manufactures have it really close to begin with.

Really ?!?! You were sounding pretty smart for a while there but you've just dispelled that notion.

I hear you, but Im referring to the word "Absolute" Im sure many of us dont have it with our rocker arm/shaft/valve combos.

Like everything else in our hobby, there is rarely an absolute right way. It usually involves a trade-off of some kind. In this case, the trade-off seems to involve centering the roller on the valve tip, which often does not lead to "perfect" valve train geometry. Due to the smaller contact patch with roller tip rockers ( verses scrub type rockers ), I personally am willing to sacrifice "some" geometry to be able to get the largest roller tip contact patch ( middle of valve stem). This also helps in the valve stem wear dept. On the down side I am probably sacrificing some area under the curve.

Posted By: HotRodDave

Re: Rocker Geometry Measurements - 10/31/13 12:20 AM

Maybe some of you guys should look at that guys kit, it moves the shaft up to correct geometry and back to center the contact patch, the only compromise I see is the PR geometry will get worse, not a big deal on a BB but a SB is already bad. Of course a W2 is worstest yet and they can rev good so

Posted By: Quicktree

Re: Rocker Geometry Measurements - 10/31/13 12:23 AM

never been a fan of shimming the rocker shaft and never had any issues with geometry. are they perfect probably not but I don't really care.

Posted By: Crizila

Re: Rocker Geometry Measurements - 10/31/13 12:31 AM

Quote:

Maybe some of you guys should look at that guys kit, it moves the shaft up to correct geometry and back to center the contact patch, the only compromise I see is the PR geometry will get worse, not a big deal on a BB but a SB is already bad. Of course a W2 is worstest yet and they can rev good so

That's fine if you are running shafts, but I'm running rocker studs and off-set drilling them aint happening.

Posted By: AndyF

Re: Rocker Geometry Measurements - 10/31/13 03:20 AM

Quote:

Maybe some of you guys should look at that guys kit, it moves the shaft up to correct geometry and back to center the contact patch, the only compromise I see is the PR geometry will get worse, not a big deal on a BB but a SB is already bad. Of course a W2 is worstest yet and they can rev good so

The CAD drawings I've done say the shaft has to move down to correct geometry with a high lift cam. Moving the shaft up makes things worse on every simulation that I've run.

Posted By: B G Racing

Re: Rocker Geometry Measurements - 10/31/13 12:18 PM

We think this post needs to start over and maybe this guy can provide us with more detailed information on how his kits can correct common issues, and after we understand how it works, then he won't have to do a sales pitch, we will be ringing his phone off the hook.

I know it would be of interest to us since we spend so much time on valvetrain corrections and end up with different fixes that are a priority for each build.

I hope he comes back and helps us and himself by educating us on his method and product.

Posted By: onig

Re: Rocker Geometry Measurements - 10/31/13 01:32 PM

Quote:

Quote:

The CAD drawings I've done say the shaft has to move down to correct geometry with a high lift cam. Moving the shaft up makes things worse on every simulation that I've run.

Andy,

Have you done this with the rocker shaft pedestals.

I am guessing that you machined the pedestals down some; yes?

Also what are you considering high lift cams, 700, 800, 900?

Thanks

Onig

Posted By: dannysbee

Re: Rocker Geometry Measurements - 10/31/13 04:16 PM

Andy I agree with you, with increased lift rocker shaft would have to be lowered assuming geometry is optimized before the additionial lift is added. I can also see how the rocker would need to be raised to compensate for the relocation of the contact point by adding the roller. This is what I have learned from these discussions Bottom line is there is only one location that is optimum for each type rocker, ratio and lift combination. The by product of your effort will be a rocker that is centered on the valve stem when the valve is on the seat and at full lift. What is acceptable other than being in this blue printed location I have no idea. Thanks to the OP for starting the discussion.

Posted By: Quicktree

Re: Rocker Geometry Measurements - 10/31/13 04:33 PM

Quote:

We think this post needs to start over and maybe this guy can provide us with more detailed information on how his kits can correct common issues, and after we understand how it works, then he won't have to do a sales pitch, we will be ringing his phone off the hook.

I know it would be of interest to us since we spend so much time on valvetrain corrections and end up with different fixes that are a priority for each build.

I hope he comes back and helps us and himself by educating us on his method and product.

heck that makes to much sense

Posted By: B G Racing

Re: Rocker Geometry Measurements - 10/31/13 05:50 PM

Quote:

Quote:

We think this post needs to start over and maybe this guy can provide us with more detailed information on how his kits can correct common issues, and after we understand how it works, then he won't have to do a sales pitch, we will be ringing his phone off the hook.

I know it would be of interest to us since we spend so much time on valvetrain corrections and end up with different fixes that are a priority for each build.

I hope he comes back and helps us and himself by educating us on his method and product.

heck that makes to much sense

Sorry ,Tony I was think out loud again.I keep my mind/mouth closed from now on.

Posted By: SuperStock68Dart

Re: Rocker Geometry Measurements - 10/31/13 05:51 PM

Quote:

Quote:

Maybe some of you guys should look at that guys kit, it moves the shaft up to correct geometry and back to center the contact patch, the only compromise I see is the PR geometry will get worse, not a big deal on a BB but a SB is already bad. Of course a W2 is worstest yet and they can rev good so

The CAD drawings I've done say the shaft has to move down to correct geometry with a high lift cam. Moving the shaft up makes things worse on every simulation that I've run.

Posted By: BradH

Re: Rocker Geometry Measurements - 10/31/13 05:57 PM

Quote:

Quote:

Maybe some of you guys should look at that guys kit, it moves the shaft up to correct geometry and back to center the contact patch, the only compromise I see is the PR geometry will get worse, not a big deal on a BB but a SB is already bad. Of course a W2 is worstest yet and they can rev good so

The CAD drawings I've done say the shaft has to move down to correct geometry with a high lift cam. Moving the shaft up makes things worse on every simulation that I've run.

FWIW, my Stage VIs required raising the shafts to get the geometry straightened out + lash caps, along w/ test-fitting a variety of rocker arms to come up w/ a combination that actually worked correctly. From what I've heard, that wasn't typical for most Stage VIs, but it's what was required with my particular set.

I think the approach required depends on the application, the particular parts used, and the rocker geometry results (e.g. Jim Miller's Mid-Lift design vs. Jesel's theory) you're looking to achieve.

Posted By: B G Racing

Re: Rocker Geometry Measurements - 10/31/13 06:04 PM

We have seen rockers that need to be raised,lowered,moved toward the intake side and to the exhaust side.

Posted By: Performance Only

Re: Rocker Geometry Measurements - 10/31/13 06:27 PM

Then add some .100" length valves (or longer) in the mix and there's a whole host of geometry issues created. The actual geometry itself is pretty basic. achieving it is the hard part.

Posted By: dannysbee

Re: Rocker Geometry Measurements - 10/31/13 06:45 PM

Brad I would like to see an engine with one theory applied on one head and the other theory on the other. Then check the lift at the valve to see which achieves the most lift at the valve. One thing for sure the set up that has the rocker 90 degrees in relation to the valve at mid lift will have the least amount of scrub.

Posted By: BradH

Re: Rocker Geometry Measurements - 10/31/13 08:09 PM

I played around with this stuff years ago looking to see what happened when I set up the valve train to achieve different end goals. It's not just a "peak lift thing"; you can also measure differences in net duration at various points across the lift curve, as well as variations in the scrub patterns and where in the lift curve the majority of the scrubbing takes place.

Now, if you asked me what my findings were... I can't tell you where those notes ended up, nor would I claim my "testing" was precise enough to make any specific claims one way or the other.

I will say that the final configuration I worked out for those Stage VIs resulted in a nicely centered sweep across the valve tip that was somewhere in the .050-.060" width range over .600" lift. It followed Jim Miller's Mid-Lift concept, rather than Jesel's, and the guides showed basically no wear after about 5K miles when I sent the heads back to Dwayne Porter to be touched up.

Posted By: AndyF

Re: Rocker Geometry Measurements - 10/31/13 09:03 PM

Quote:

Brad I would like to see an engine with one theory applied on one head and the other theory on the other. Then check the lift at the valve to see which achieves the most lift at the valve. One thing for sure the set up that has the rocker 90 degrees in relation to the valve at mid lift will have the least amount of scrub.

Mid lift provides the least amount of scrub. Low point (2/3 lift) gives you the least amount of scrub under load. That is, the scrub occurs while the load is low and then when the load is high there is very little scrubbing action.

I think most of the serious valve train designers migrated to the low pivot point design a number of years back. The math is fairly complicated but if you put the rocker arm perpendicular to the valve stem at 2/3 lift you're in the ballpark. The scrub pattern is larger than with the mid-lift design, but the sideways force applied to the valve goes down.

Posted By: cudaman1969

Re: Rocker Geometry Measurements - 10/31/13 09:28 PM

I wouldn't hesitate to say these last two posts are over the heads of 95% of the readers of this discussion. Oh yeah wher's my free stuff.

Posted By: mickm

Re: Rocker Geometry Measurements - 10/31/13 09:33 PM

Quote:

I wouldn't hesitate to say these last two posts are over the heads of 95% of the readers of this discussion. Oh yeah wher's my free stuff.

not sure why that's important.

are they over my head? more or less. but i still read them and learn from them, and even if i don't completely get it, it still either expands my knowledge of the subject or enables me to understand things in a little more detail the next time i read or discuss these concepts.

Posted By: cudaman1969

Re: Rocker Geometry Measurements - 10/31/13 10:10 PM

Why that's important? If a guys got a bullet in him I could remove it and sew him up but I would rather let a doctor do it right and PAY him. The man obviously has a service to offer that's complicated and most couldn't get it right. It's called capitalism. Every part of the engine has to be bought, why not this? Or just let him give it away?

Posted By: mickm

Re: Rocker Geometry Measurements - 10/31/13 10:38 PM

ok, i get what you are saying, just wasn't clear from the first post...

Posted By: Performance Only

Re: Rocker Geometry Measurements - 10/31/13 10:47 PM

Quote:

Why that's important? If a guys got a bullet in him I could remove it and sew him up but I would rather let a doctor do it right and PAY him. The man obviously has a service to offer that's complicated and most couldn't get it right. It's called capitalism. Every part of the engine has to be bought, why not this? Or just let him give it away?

Like Ted the moderator said, the OP should put up a post offering his kit and his service. It'll ultimately end up in a different forum but it will get the word out he has something to offer for those that want or need it.

Posted By: AndyF

Re: Rocker Geometry Measurements - 10/31/13 10:59 PM

Quote:

I wouldn't hesitate to say these last two posts are over the heads of 95% of the readers of this discussion. Oh yeah wher's my free stuff.

The concept would be easier to communicate if I took the time to post a picture. Or better yet, a short video would fully explain it in just a few frames.

I first read about the low pivot concept in a GM engine book years ago. The author didn't explain it fully but it sounded interesting. Years later I finally sat down at the CAD terminal and figured it out. The math is too complex for me so I solved the equation graphically. What you're trying to do is to solve the smallest product of load and scrub. When the valve is closed the load is small so you allow a lot of scrub. When the valve is full lift you're at max load so that is when you want zero scrub.

When you solve the equation you end up with the rocker arm perpendicular to the valve stem at about 2/3 of lift. This is below the mid-point theory which is more popular. The mid-lift approach is a simple approach that works pretty well in most applications. But if you're setting up something with 800 or 900 lbs on the nose then you might want to minimize the scrub under load.

Posted By: mickm

Re: Rocker Geometry Measurements - 10/31/13 11:56 PM

Quote:

The concept would be easier to communicate if I took the time to post a picture. Or better yet, a short video would fully explain it in just a few frames.

I first read about the low pivot concept in a GM engine book years ago. The author didn't explain it fully but it sounded interesting. Years later I finally sat down at the CAD terminal and figured it out. The math is too complex for me so I solved the equation graphically. What you're trying to do is to solve the smallest product of load and scrub. When the valve is closed the load is small so you allow a lot of scrub. When the valve is full lift you're at max load so that is when you want zero scrub.

When you solve the equation you end up with the rocker arm perpendicular to the valve stem at about 2/3 of lift. This is below the mid-point theory which is more popular. The mid-lift approach is a simple approach that works pretty well in most applications. But if you're setting up something with 800 or 900 lbs on the nose then you might want to minimize the scrub under load.

yup, that makes it perfectly clear! thanks!

Posted By: Performance Only

Re: Rocker Geometry Measurements - 10/31/13 11:59 PM

Quote:

Quote:

I wouldn't hesitate to say these last two posts are over the heads of 95% of the readers of this discussion. Oh yeah wher's my free stuff.

The concept would be easier to communicate if I took the time to post a picture. Or better yet, a short video would fully explain it in just a few frames.

I first read about the low pivot concept in a GM engine book years ago. The author didn't explain it fully but it sounded interesting. Years later I finally sat down at the CAD terminal and figured it out. The math is too complex for me so I solved the equation graphically. What you're trying to do is to solve the smallest product of load and scrub. When the valve is closed the load is small so you allow a lot of scrub. When the valve is full lift you're at max load so that is when you want zero scrub.

When you solve the equation you end up with the rocker arm perpendicular to the valve stem at about 2/3 of lift. This is below the mid-point theory which is more popular. The mid-lift approach is a simple approach that works pretty well in most applications. But if you're setting up something with 800 or 900 lbs on the nose then you might want to minimize the scrub under load.

Basically the 2/3 method is "almost" what we end up with on the blown alky motors that have around 450 lbs on the seat and 1250-1400 (depending on combo) actual over the nose.

Posted By: cudaman1969

Re: Rocker Geometry Measurements - 11/01/13 12:21 AM

I rest my case. It's been enjoyable.

3416 watched

2 understand

Posted By: Crizila

Re: Rocker Geometry Measurements - 11/01/13 12:42 AM

Quote:

Quote:

Brad I would like to see an engine with one theory applied on one head and the other theory on the other. Then check the lift at the valve to see which achieves the most lift at the valve. One thing for sure the set up that has the rocker 90 degrees in relation to the valve at mid lift will have the least amount of scrub.

Mid lift provides the least amount of scrub. Low point (2/3 lift) gives you the least amount of scrub under load. That is, the scrub occurs while the load is low and then when the load is high there is very little scrubbing action.

I think most of the serious valve train designers migrated to the low pivot point design a number of years back. The math is fairly complicated but if you put the rocker arm perpendicular to the valve stem at 2/3 lift you're in the ballpark. The scrub pattern is larger than with the mid-lift design, but the sideways force applied to the valve goes down.

- try reading the book "Valve Gear design" by Michael Turkish, 1946, Eaton corporation. Turkish was a mathematician who worked for Eaton - and Eaton was a tier one supplier to GM - and probably a lot of other automotive OEM's. Yes, the math is well over my head, but pretty much as you alluded to verses the common 50/50 rocker arm arrangement ( 90* at mid lift) that most use today. My brother ( much smarter than I ) has done extensive research in this area also. I was able to grasp about 75% of what he sent me on the subject. Yes, it is a complicated subject and unfortunately, a lot that has been written about it has been written by people working for magazines trying to sell you a product ( those pretty gold anodized aluminum roller tip rocker arms with your initials stamped on them

- try reading the book "Valve Gear design" by Michael Turkish, 1946, Eaton corporation. Turkish was a mathematician who worked for Eaton - and Eaton was a tier one supplier to GM - and probably a lot of other automotive OEM's. Yes, the math is well over my head, but pretty much as you alluded to verses the common 50/50 rocker arm arrangement ( 90* at mid lift) that most use today. My brother ( much smarter than I ) has done extensive research in this area also. I was able to grasp about 75% of what he sent me on the subject. Yes, it is a complicated subject and unfortunately, a lot that has been written about it has been written by people working for magazines trying to sell you a product ( those pretty gold anodized aluminum roller tip rocker arms with your initials stamped on them  ). So, since this thread has turned in to "who's the smartest", Could I see a show of hands of those with the title of "Mathematician".

). So, since this thread has turned in to "who's the smartest", Could I see a show of hands of those with the title of "Mathematician".  - I won't be raising mine

- I won't be raising mine  .

.

Posted By: HotRodDave

Re: Rocker Geometry Measurements - 11/01/13 01:11 AM

The only math class I ever did good in was geometry so I can follow along with all the geometric theory part very well but still have a couple questions about the real world.

So is the effect of scrub really more important than valve lift/timing effects on the power/reliability of normal street/strip engines with roller rockers? Seems scrub would not be very important with a roller tip as it would be with a sliding type rocker tip, within reason of course.

Maybe say in a lift limited class where your valve opens to max lift for more than just a degree or two, would you want to set it up so it is perpendicular to the valve at max lift where the ratio is the highest?

Posted By: 67_Satellite

Re: Rocker Geometry Measurements - 11/01/13 01:40 AM

And you know only 2 understand?How??

Posted By: cudaman1969

Re: Rocker Geometry Measurements - 11/01/13 02:28 AM

I'm sorry, three, i'm not in that group, I'm past the point where I need to know it all. Good day

Posted By: 72Swinger

Re: Rocker Geometry Measurements - 11/01/13 03:34 AM

Keep talking about it now that you run off the guy willing to give this thing a remedy. Contempt prior to conviction....

Posted By: Stanton

Re: Rocker Geometry Measurements - 11/01/13 03:38 AM

Quote:

Seems scrub would not be very important with a roller tip as it would be with a sliding type rocker tip, within reason of course.

Actually I think it would be the opposite. With a roller rocker the roller is round (obviously) and the pivot is fixed so you will definitely have scrub.

On the other hand a sliding type rocker could have its tip ground in an eccentric so that although there is still the friction, the contact point could be maintained at the very center of the valve tip. Never seen one like it but definitely a possibility!

Posted By: dannysbee

Re: Rocker Geometry Measurements - 11/01/13 04:56 AM

Dave with the rocker position you are suggesting the scrub would be double what it is with the rocker perpendicular to the valve at mid lift.

Posted By: CompWedgeEngines

Re: Rocker Geometry Measurements - 11/01/13 04:29 PM

Although I can only understand about 10% of the 20 different simulations going on here....I am shocked now after reading this that anyones engines even make it safely down the track three times.....I think we are being " theorized" to death on this one. In my world....there is idealology....and reality.....I often choose only one.....please carry on....

and for the record, I do realize what the OP was trying to do, unfortunately the presentation fell short. He was addressing an issue that can be a problem for sure. Now how you handle it, thats a different cat to skin.

My question would be, what is the IMMEDIATE catastrophic result of setting up a valvetrain with well known principles that work, with a realistic degree of engineering and geometry, that would be considered adequate?

Posted By: BradH

Re: Rocker Geometry Measurements - 11/01/13 05:03 PM

Quote:

... In my world....there is idealology....and reality.....I often choose only one...

I often get caught between the two (like an "Outer Limits" episode) and the end result is my junk never gets back together to see if I can even make those three passes down the track.

Posted By: jamesc

Re: Rocker Geometry Measurements - 11/01/13 05:30 PM

Quote:

Although I can only understand about 10% of the 20 different simulations going on here....I am shocked now after reading this that anyones engines even make it safely down the track three times.....I think we are being " theorized" to death on this one. In my world....there is idealology....and reality.....I often choose only one.....please carry on....

and for the record, I do realize what the OP was trying to do, unfortunately the presentation fell short. He was addressing an issue that can be a problem for sure. Now how you handle it, thats a different cat to skin.

My question would be, what is the IMMEDIATE catastrophic result of setting up a valvetrain with well known principles that work, with a realistic degree of engineering and geometry, that would be considered adequate?

agreed especially the last paragraph and was my basic point when i commented on another thread. does it make a difference, yes but unless something is out in left field there are bigger concerns. i've said it before personally i think people get carried away with the whole valve train geometry thing. unless it's completely wacked i would focus more effort on other aspects of the engine but that's just me

Posted By: dartman366

Re: Rocker Geometry Measurements - 11/01/13 05:37 PM

I have been reading this post and remembering the day in which my engine builder explained all the rocker geometry stuff to me. thats why I have not gotten into the mix of opinions that seem's to have gotten a little out of hand at times, seems like some feel the op has some ulterior motive here, I see it as he has a service to offer and it isn't free as there is no free lunch,,he may of come off as a little defensive but after being on this site for the time I have, you learn to be a little thick skinned,it also seems to me that anyone that gets on this site that knows anything ends up getting critiqued to death and some just decide to leave so not to deal with it,,,I don't blame the OP but his presentation may of been a little brash for some, the rest of us just overlook that trait and move on.

Posted By: dannysbee

Re: Rocker Geometry Measurements - 11/01/13 05:42 PM

Quote:

Although I can only understand about 10% of the 20 different simulations going on here....I am shocked now after reading this that anyones engines even make it safely down the track three times.....I think we are being " theorized" to death on this one. In my world....there is idealology....and reality.....I often choose only one.....please carry on....

and for the record, I do realize what the OP was trying to do, unfortunately the presentation fell short. He was addressing an issue that can be a problem for sure. Now how you handle it, thats a different cat to skin.

My question would be, what is the IMMEDIATE catastrophic result of setting up a valvetrain with well known principles that work, with a realistic degree of engineering and geometry, that would be considered adequate?

Todd I understand what you are saying. In my case I don't have cast in place rocker stands and my stands will have to be made. I would like them to be as close to the idea height as possible. I am just trying to be an educated consumer.

Posted By: CompWedgeEngines

Re: Rocker Geometry Measurements - 11/01/13 06:28 PM

Understand 100% Danny. Nothing wrong with that at all.

it really all comes downt o how much time and money someone is willing to spend to " fix" their issue. Everyone will accept a different level of " right". Thats why my last paragraph.

I just did a 500" BBC and it had ProComp heads. To do them right, I would have had to start all over, re-machine the pads, reset the angles, and techinically re-locate the rocker stud locations, if I wanted it to be " right".As it was I had to play around and get Dart psuhrod guides and change a few other things to get them useable. There is no way in he** a guy with Pro Comp heads is going to spend that money for his street car. A Pro Comp head is like a all out race head, in the fact that nothing fits....lol...so there we have it, a cheap offshore head, vs a high dollar aftermarket race head. At times, there is no difference.They both need work.Heck, most of the Chevy guys think valve train " geometry" is just selecting the proper length pushrod!~

Most guys are fine with what I stated at the end of my other post. Good mechanical skills and reference to accepted standards will work for most everyone.

I like to refer to the old W2 offset rocker stands and offset rocker shafts to remember, people have been trying to adress this in Mopar sfor a very very long time. Milling the rocker support pads and starting with a new square block of aluminum works pretty well.When you think of it, thats all very simple math. All of this changes based on the rocker centerline to roller tip. Then add the height of a taller valve...it goes on and on. Go back to the accepted prinicpals I spoke of , and they all work, and dont wear out parts at a alarming rate, at least that I have every expierenced.

Posted By: RT540

Re: Rocker Geometry Measurements - 11/01/13 06:32 PM

Quote:

Quote:

Maybe some of you guys should look at that guys kit, it moves the shaft up to correct geometry and back to center the contact patch, the only compromise I see is the PR geometry will get worse, not a big deal on a BB but a SB is already bad. Of course a W2 is worstest yet and they can rev good so

The CAD drawings I've done say the shaft has to move down to correct geometry with a high lift cam. Moving the shaft up makes things worse on every simulation that I've run.

If you have a perfect sweep with a .600 lift cam, and then change to a .800 lift cam, the wheel will move closer to the rocker shaft at full lift.

I agree, the shaft needs to go down. I moved my T&D 1.8 sep. shaft setup down 1.2mm and still got more scrub after the wheel starts to roll back( against the rockers shafts).

Posted By: dartman366

Re: Rocker Geometry Measurements - 11/01/13 06:55 PM

Quote:

Quote:

Quote:

Maybe some of you guys should look at that guys kit, it moves the shaft up to correct geometry and back to center the contact patch, the only compromise I see is the PR geometry will get worse, not a big deal on a BB but a SB is already bad. Of course a W2 is worstest yet and they can rev good so

The CAD drawings I've done say the shaft has to move down to correct geometry with a high lift cam. Moving the shaft up makes things worse on every simulation that I've run.

If you have a perfect sweep with a .600 lift cam, and then change to a .800 lift cam, the wheel will move closer to the rocker shaft at full lift.

I agree, the shaft needs to go down. I moved my T&D 1.8 sep. shaft setup down 1.2mm and still got more scrub after the wheel starts to roll back( against the rockers shafts).

I know when I went to the TD rockers they sent a gage to set my rocker stand height, they will also tell you that X amount lower or higher lift then you correct height by a determined amount, my machinist went by this system and the geometry was spot on, now this is on the paired rocker system that uses the mounting bar that is bolted to the head's

Posted By: B3RE

Re: Rocker Geometry Measurements - 11/01/13 11:13 PM

I'm Baaaaaack! Hoohooaahaahaah!

Ok, now I'm serious again.

First, I would like to apologize to anyone who thought I came across with an attitude. I certainly didn't want to anger anyone, although I admit, when the name calling started, my dander started to "get up". I'll try not to let it get to me anymore.

I don't have a lot of time to spend on the forum, so unfortunately I don't know all of the rules for posting. This post was meant to provide information requested by members from other threads I posted on, discussing valvetrain geometry. It was NOT meant to be a sales pitch to anyone. I did ask a moderator how to post on New Products, once the "pup" (as my daughter says it) hit the fan, but I have yet to get a response.

I was thinking the post wouldn't get any responses and some members might miss it so I contacted each one personally to let them know I posted the info. Whew, I never expected it to turn into a roast, 'specially since I'm no celebrity.

I will go through the thread post by post and try to answer evryone's questions and concerns as best I can. If I start getting a 'tude, somebody give me an emoticon backhand.

Thanks,

Posted By: CompWedgeEngines

Re: Rocker Geometry Measurements - 11/01/13 11:22 PM

Mike,

Just one thing....if you and Quicktree DO go on a date, make sure he pays.Last time , he did the old, " must have left my wallet in my other pants" thing to me, and then proceeded to " run out of gas" on the way home.....after a long night, he left me cold, shaken , and emotionally tattered....

.....he screamed something to me as he drove away....all I could make out was something about some pinhead angle or something like that....maybe it was pinion...I dunno..

Disclaimer: This is a valid attempt to inject some mild humor into a thread that has gone horribly awry. These are not the comments nor an official statement from the site, the owner or any of its affiliates. While reading this, or any other thread on Moparts' Unlawful Racing section, please remember to drink responsibly.

Posted By: B3RE

Re: Rocker Geometry Measurements - 11/01/13 11:25 PM

Quote:

Checks in the mail  - and your expert opinion is:

- and your expert opinion is:

Without actual measurements, it is almost, if not completely impossible to determine geometry. My suggestion would be to look at an old Lunati catalog for setting up stud type rockers. I have it somewhere and if I get the time, I'll look it up and post it for you.

Posted By: B3RE

Re: Rocker Geometry Measurements - 11/01/13 11:28 PM

[quote

Google =

http://houston.craigslist.org/pts/4099405039.html

Yup, I sell them on CL, as well as other locations.

Posted By: B3RE

Re: Rocker Geometry Measurements - 11/01/13 11:32 PM

Quote:

this is his testing tool in less you have this you will have to call him http://www.dotcom-monitor.com/blog/wp-content/uploads/2010/08/gross.jpg he is just trying to help us get out our wallet

How did you find this pic?!!! That's a "Top Secret Rocket Scientist" laboratory photo.

How did you find this pic?!!! That's a "Top Secret Rocket Scientist" laboratory photo.

Posted By: Quicktree

Re: Rocker Geometry Measurements - 11/01/13 11:36 PM

Quote:

Mike,

Just one thing....if you and Quicktree DO go on a date, make sure he pays.Last time , he did the old, " must have left my wallet in my other pants" thing to me, and then proceeded to " run out of gas" on the way home.....after a long night, he left me cold, shaken , and emotionally tattered....  .....he screamed something to me as he drove away....all I could make out was something about some pinhead angle or something like that....maybe it was pinion...I dunno..

.....he screamed something to me as he drove away....all I could make out was something about some pinhead angle or something like that....maybe it was pinion...I dunno..

Disclaimer: This is a valid attempt to inject some mild humor into a thread that has gone horribly awry. These are not the comments nor an official statement from the site, the owner or any of its affiliates. While reading this, or any other thread on Moparts' Unlawful Racing section, please remember to drink responsibly.

I am going to piss on your leg when I meet you

Posted By: B3RE

Re: Rocker Geometry Measurements - 11/01/13 11:40 PM

Quote:

Well then, is it time for our 10 oclock college course?

Ever wonder why it's usually 10 o'clock or so when I post. 14-16 hr workdays are not uncommon for me. Oh yeah, college courses aren't free, so where's my money.

Posted By: B3RE

Re: Rocker Geometry Measurements - 11/01/13 11:47 PM

Quote:

Quote:

Quote:

I thought he had an excellent product and the price was reasonable.

I spoke with Mike recently as I know my geometry is much less than optimal. The kit looks very nice and the price was very reasonable I thought. The formula is part of the service he is offering for this fee. You take some measurements, send him the numbers, and he uses it to figure out how he needs to machine this shim/spacer/whatever you want to call it so that it will move your rocker shaft to the correct location. If he gave the formula away its all that much easier for an off-shore company to just start making them in a one size fits all kit and will get most people close enough, undercut his price by 50 bucks, and then you'll all be on here complaining that nothing is made in the USA, and that Mike was offering a good service custom making these kits for only 50 bucks more but got ran out of town by the dreaded outsourcers.

Additionally theres been a few threads relating to this topic recently that Mike posted on and was asked for more information regarding correct geometry, so maybe he thought it was relevant?

plus new posters aren't exactly welcomed with open arms on this site.

plus new posters aren't exactly welcomed with open arms on this site.