Posted By: StealthWedge67

Dodged a bullet; vibration found - not good (w/ pics) - 01/05/13 03:09 AM

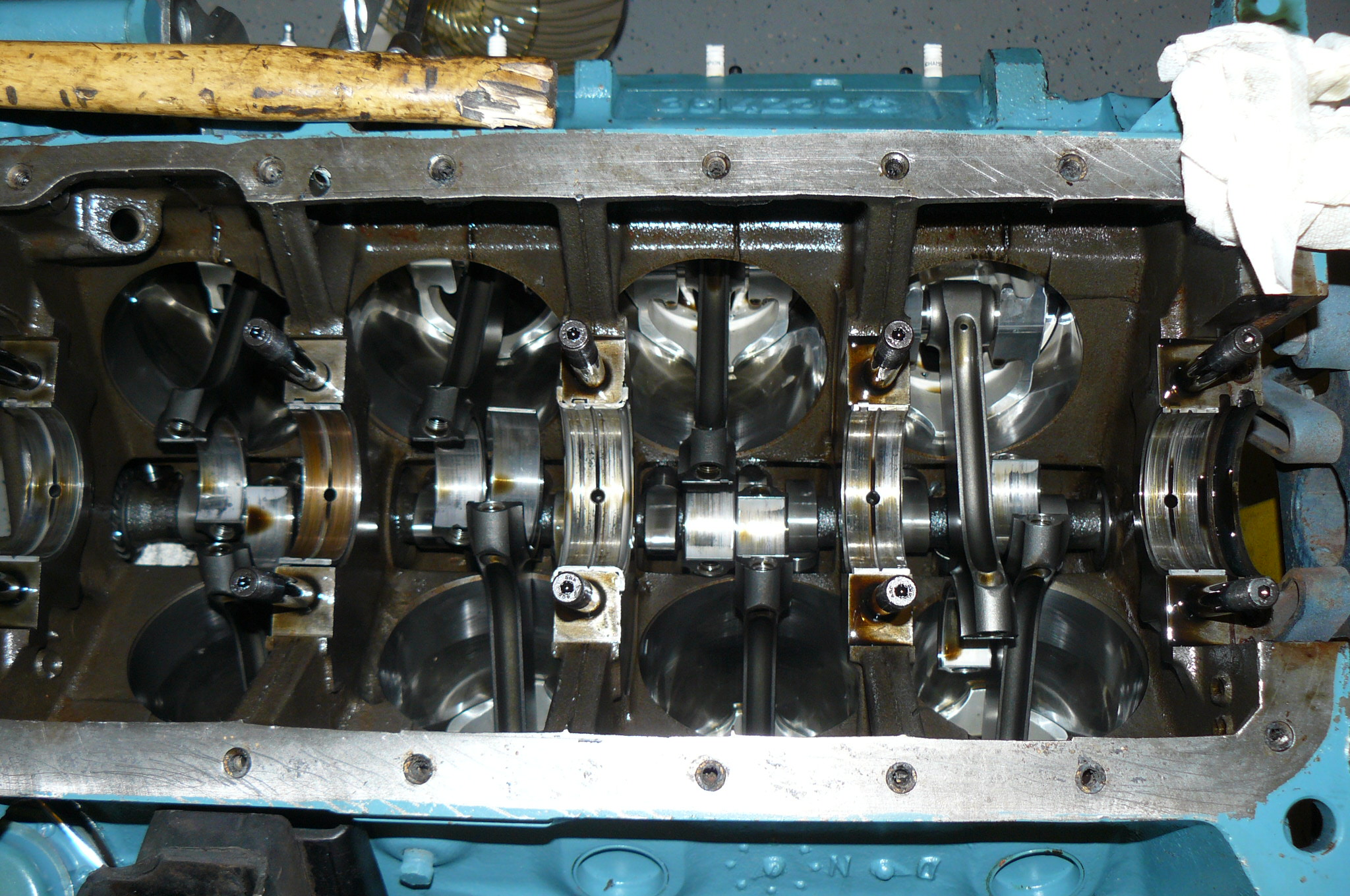

Well, I think I've found the source of my vibration. Question now is: Where do I go from here? Some of you may remember, Motor developed a vibration after I had a converter baloon, and the flexplate bolts smacked the pan rail. Visually, I see no issues with the main webbing. Pics below are of the main bearing issue I've found. All the bearings look bad to me for a 3 year old, 5000 mile motor, probobly a result of the vibration that looks to be related to the #2 main, which is obviously fried, and it would appear that I shut 'er down just in time!

Weird thing is the bearing no longer fits in the saddle correctly. Both at the saddle and cap, the bearing will rock back & forth. When I pulled caps and the crank, all bearings stayed in place except #2. Cap half stayed with the crank when I lifted the cap, and saddle side did the same when I lifted the crank.

The mainline of this block was honed, and the crank was turned down from RB dia. to std. B dimensions (413 crank). bearings are cleavite P series. Motor always showed about 40 lbs of oil pressure at warm idle, and 60 while running from day one, and never changed a bit up until I tore it down.

My plan is to have the crank magged and checked out completely and see where that takes me.

Thoughts from you guys?????

Weird thing is the bearing no longer fits in the saddle correctly. Both at the saddle and cap, the bearing will rock back & forth. When I pulled caps and the crank, all bearings stayed in place except #2. Cap half stayed with the crank when I lifted the cap, and saddle side did the same when I lifted the crank.

The mainline of this block was honed, and the crank was turned down from RB dia. to std. B dimensions (413 crank). bearings are cleavite P series. Motor always showed about 40 lbs of oil pressure at warm idle, and 60 while running from day one, and never changed a bit up until I tore it down.

My plan is to have the crank magged and checked out completely and see where that takes me.

Thoughts from you guys?????

Measure the actual lobe lift on all lobes, easier to do in a lathe

Measure the actual lobe lift on all lobes, easier to do in a lathe  The very first motor I put together after a minor overhaul did the same thing as yours looks, my camshaft went flat do to me being yuong and dumb, used lifters on a used cam

The very first motor I put together after a minor overhaul did the same thing as yours looks, my camshaft went flat do to me being yuong and dumb, used lifters on a used cam

BTW, I've done worst since then like breaking a rod in the lights on my original numbers matching block in my 1963 M.W. 415 HP stocker

BTW, I've done worst since then like breaking a rod in the lights on my original numbers matching block in my 1963 M.W. 415 HP stocker

buddy did it once and the bearings started looked to like that after a short break in he found the debris in his oil filter check then pulled the pan had to pull his motor back out.

buddy did it once and the bearings started looked to like that after a short break in he found the debris in his oil filter check then pulled the pan had to pull his motor back out.

drop it back in and dial O the mains and see whats up

drop it back in and dial O the mains and see whats up