Posted By: Madness

Cylinder wall thickness?? - 09/19/12 12:08 AM

What is considered minimum for cylinder wall thickness on a 470 low deck stroker, no nitrious,

7.1" rod? I have a block that's betwen .133" & .153" on the minor thrust on #8 cycl. .157" on #2 minor thrust. .169" On #1 major thrust.

Rest of block is .188" to .259"

Posted By: Thumperdart

Re: Cylinder wall thickness?? - 09/19/12 01:14 AM

My low #`s weren`t much better than yours and had one cyl. was .110 non thrust............thrust were all over bet. .154 low and .288. Twelve plus years later and one bore and hone later, it`s still going strong.

Posted By: Jwilli500

Re: Cylinder wall thickness?? - 09/19/12 05:45 AM

Sounds ta bit long huh. I dont guess I've seen a .92 CH Piston before...

Quote:

7.1 rod in a low deck?

Posted By: BradH

Re: Cylinder wall thickness?? - 09/19/12 03:24 PM

Looks thin to me... I'd look for another block w/ some more beef in the cylinders.

Posted By: Thumperdart

Re: Cylinder wall thickness?? - 09/19/12 04:32 PM

I remember reading that one of the bigger builders out there shot for no less than .100 on major thrust side up to around 600 hp. Been there done that and have been fine...........

Posted By: Madness

Re: Cylinder wall thickness?? - 09/19/12 05:35 PM

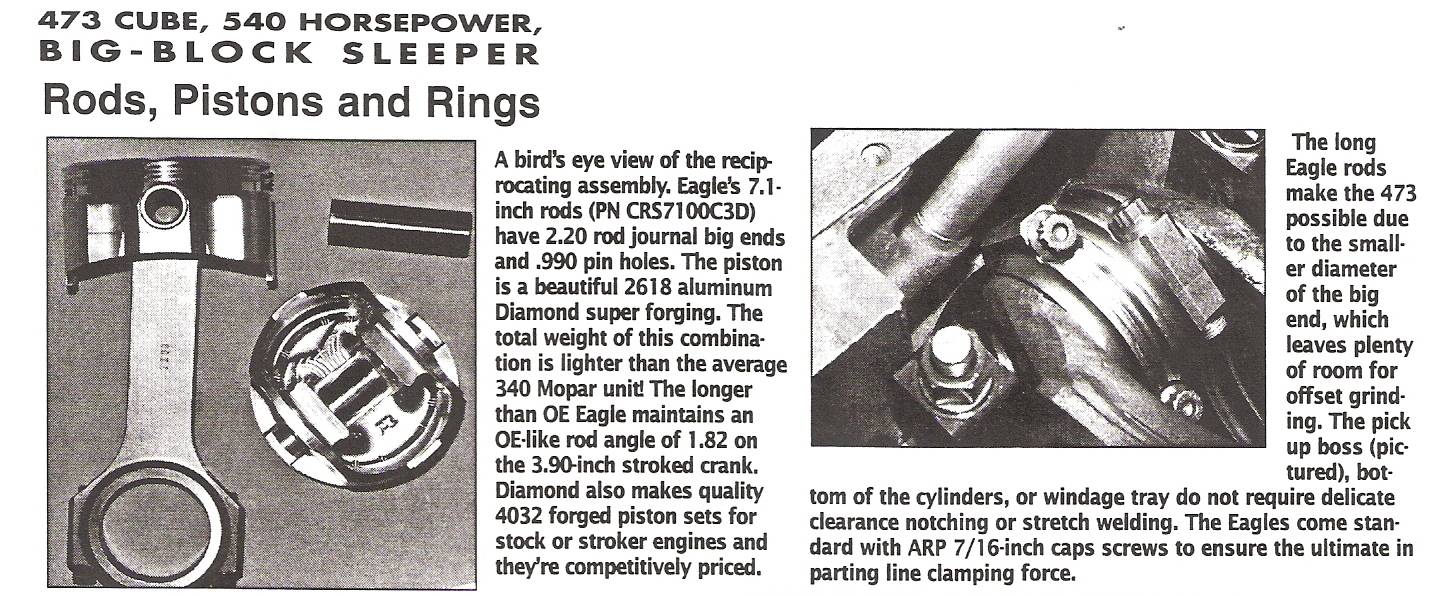

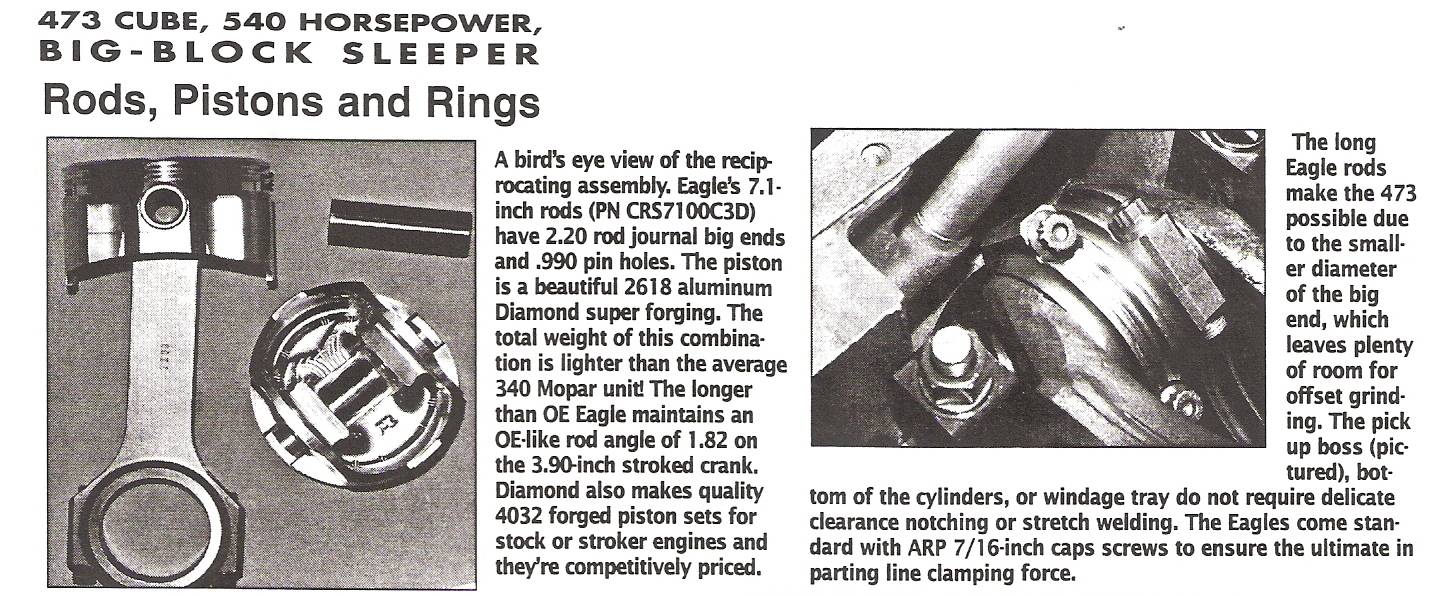

It appears you guys are correct & I am wrong on the 7.1" rod. I just called Diamond & Randy said they couldn't fit the ring stack in that C.H. I was getting my info from an old High Performance Mopar magazine article (July 2000, P.53) written by Frank Licari. He goes on about the 7.1 rod (#CRS7100C3D) & a dished Diamond 2618 piston w/ .990" pin. Said it gave a rod angle of 1.82 on the 3.90" stroke.

Years ago I was ordering a set of pistons from Diamond for my 470. I mentioned I intended to add a small nitrous kit, & they talked me into using a 6.7 rod so they could move the ring stack down out of the heat. My pins are into the oil ring grooves using bridges.

Now I'm really confused. May be one of those articles where the motor was never really put together. I know there have been several articles written by a local machinist & our local GM parts dept. about wild Chevy combinations, complete with pictures, that never were assembled. Sold lots of parts, though.

Posted By: dogdays

Re: Cylinder wall thickness?? - 09/19/12 08:12 PM

9.980 - 7.100" = 2.880" for 1/2 of stroke plus compression height.

The smallest compression height with which I am familiar is 1.000" in some smallblock engines, pushing the envelope, like a 4" crank and 6" rod in a chevy 350.

So you take your 2.880 and subtract 1" = 1.880"

2 x 1.880 = 3.76" stroke.

This is an undoable package unless you are going to use 0.927" or smaller diameter pins. Anyway, there's no need to because you don't need that long a rod in a B engine.

Spend the few bucks it takes to buy Streetwize's engine book. I believe he likes the 6.535 bigblock chevy + 0.400" rod in a B engine.

I have really backed off my "long rods are best" ideas after seeing short rod engines with really big heads taking the Enginemasters competitions. I know Smokey is dead and unable to defend his theory, but I think that late engines are showing us that shorter rod ratios are practically better, to the point that the B rod 451 looks better than the RB rod 451 for everyday use. John Kaase would be the leader on this rethink.

As for cylinder wall thickness, if you have a new World block you may see 0.300" walls, but on an OEM Mopar bigblock you'll be lucky to see 0.200" on all 8 holes, anywhere.

If you can keep the major thrust to 0.170" and never go below 0.100" on any portion of any hole, it should be OK. A few years ago a major builder looked at a number of 400 blocks and found that most of them had 7 good holes and one that needed sleeving. I have read accounts here of a "cold weather" 400 block that had a cylinder with less than 0.090" on one bore, with the bore standard sized.

It was traditional to think that Mopar blocks were hell for stout and cylinder walls were no problem, but that was before sonic checking became affordable. Now we can see how bad the castings really were!

That's analagous to the new thinking about heads that has come from having flowbenches on every streetcorner. Now we know how bad those B/RB heads really were.

Also about 10 years ago it surprised everyone to see that a mostly stock 440 really did make about 325 hp. Before there was a dyno in every garage, it was easy to imagine much more.......

The good old days are now!

R.

Posted By: Madness

Re: Cylinder wall thickness?? - 09/20/12 09:14 PM

I was after the longest rod possible without getting into the oil ring groove. I hoped to lessen the side loading on the thrust side of the cylinder walls.

For kicks, here is a copy of a couple of pics & text from the article I mentioned.

Posted By: dogdays

Re: Cylinder wall thickness?? - 09/20/12 10:43 PM

Doing the math, that's a compression height of 0.930"!

subtract half the pin diameter and the top edge of the pin is 0.435" from the top of the piston.. Print out the photo and scale the picture. We know the pin diameter is almost exactly an inch.

Any way you slice it, that's a very short piston.

R.

Posted By: jafr

Re: Cylinder wall thickness?? - 09/22/12 12:13 AM

looking at the picture it looks like the pin is up to the top of the oil ring land and using a .043 top and second ring.

It tested like yours

It tested like yours  I would use yours with no fill in a hot second

I would use yours with no fill in a hot second It made 612 HP to start with on CA pump gas with ported big valve 906 iron heads

It made 612 HP to start with on CA pump gas with ported big valve 906 iron heads  Now it is 518 C.I. making 725 HP now on Oregon pump gas, still no fill

Now it is 518 C.I. making 725 HP now on Oregon pump gas, still no fill  I did buy and have the Mopar ductile iron main caps and ARP main studs installed to start with, I wish they where stil availble

I did buy and have the Mopar ductile iron main caps and ARP main studs installed to start with, I wish they where stil availble

Sounds ta bit long huh. I dont guess I've seen a .92 CH Piston before...

Sounds ta bit long huh. I dont guess I've seen a .92 CH Piston before... Can you say super lightweight pistons

Can you say super lightweight pistons