Posted By: allmopar

feeler guage and ring gap - 04/02/12 09:15 PM

I am filing my rings and and checking the gap in the cylinder bore.

What is the proper way to check the ring gap with a feeler guage. Find the right thickness guage that has a smooth fit by itself in the gap or use your finger to gently push the guage into the gap. If you push the guage into the gap with your finger you can get the next thicker size guage to fit into the gap.

Posted By: Thumperdart

Re: feeler guage and ring gap - 04/02/12 09:34 PM

I don`t get all caught up in the resistance it takes and the same w/setting the valves. I go for a fairly snug feel w/out killing my fingers and making the job harder than it needs to be. What`s a .001 diff anyhow.

Posted By: rickraw

Re: feeler guage and ring gap - 04/02/12 09:40 PM

u want the ring about 1" down in the bore with snug feeler fit.

Posted By: Al_Alguire

Re: feeler guage and ring gap - 04/02/12 09:40 PM

I agree with Dom, dont overthink it. Consistency is more important in the way you do it rather than how tight the feeler gauge is.

Posted By: 440lebaron

Re: feeler guage and ring gap - 04/02/12 09:58 PM

6 people will get 7

differant readings, like they said keep it simple

Posted By: Crizila

Re: feeler guage and ring gap - 04/03/12 01:32 AM

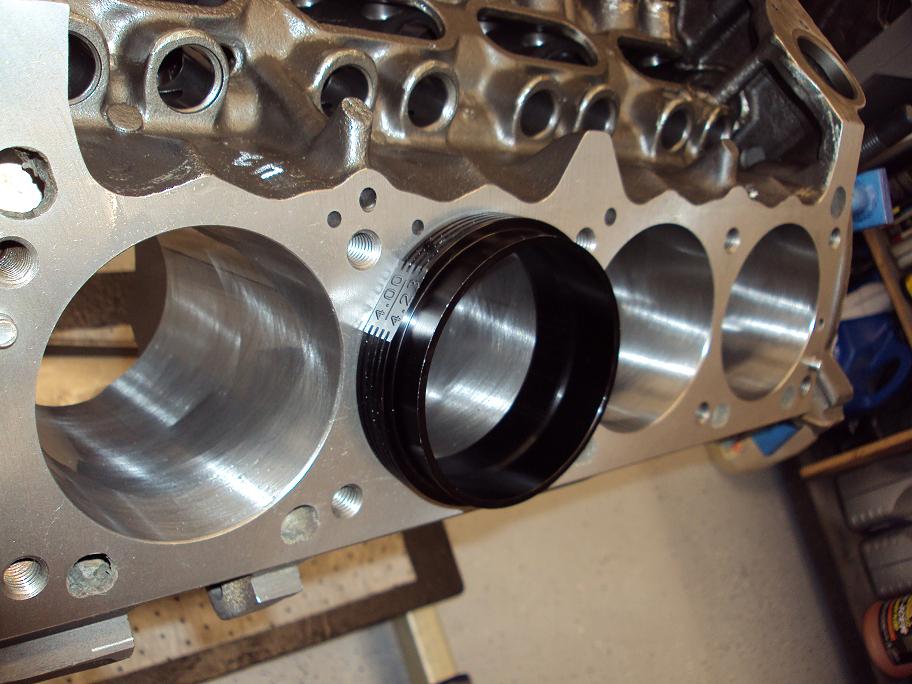

I would suggest investing in a ring squaring tool though - if you want real good consistancy with your measurements.

Posted By: allmopar

Re: feeler guage and ring gap - 04/03/12 02:28 AM

Thanks guys for the tips,

Consistancy and medium pressure with the guage.

I am using a piston upside down with a ring in the 2nd groove to push the ring in the cylinder straight.

Posted By: pittsburghracer

Re: feeler guage and ring gap - 04/03/12 03:57 AM

I bought one of these and really like the way it works. My son Matt was using it tonight fitting the rings for his new engine.

http://www.summitracing.com/parts/SME-906002/

Posted By: 70Cuda383

Re: feeler guage and ring gap - 04/03/12 02:26 PM

apparently you do want a "snug" fit to know the accurate size of the gap. I always used a "smooth" feel. I can drop the feeler gauge in, it doens't wiggle side to side at all, and I can slide it up and down against the cylinder wall, through the gap, and it "glides" through.

when I talked to the tech guy at KB, he told me that my gaps would actually be a bit bigger than what I was measuring because of how I was measuring.

oh well. too big on ring gaps are better than too small. Plus, I think I've seen some write ups from different builders online who say that they've noticed no loss in Hp with as much as a .060" ring gap

... just some drag is all I do

... just some drag is all I do

differant readings, like they said keep it simple

differant readings, like they said keep it simple

.005 to big is way better than .0005 to small when it comes to ring gaps

.005 to big is way better than .0005 to small when it comes to ring gaps

. I use a ring squaring tool made by PRC. I like it cause I can reach through the middle and actually pull the ring up against the tool to make sure it is square to the bore.

. I use a ring squaring tool made by PRC. I like it cause I can reach through the middle and actually pull the ring up against the tool to make sure it is square to the bore.