Moparts

when is a torque strap necessary?

Posted By: pettyblue440

when is a torque strap necessary? - 01/22/12 08:19 PM

what hp or et does a torque strap make a difference? carin question is a 450 hp b body with auto and stock tires. thanks, jon

Posted By: Locomotion

Re: when is a torque strap necessary? - 01/22/12 08:56 PM

Basically, any time you put the pedal to the floor regardless of engine. OEM rubber eventually pounds out and the replacement rubber can only be worse. Depending on what k-member you have, poly spool mounts or Magnum Mounts (or something like that (sandwich style), would work well. But adding a strap is never a bad idea.

Posted By: HEMIFRED

Re: when is a torque strap necessary? - 01/23/12 01:45 AM

moreso when it's as footbraker

Posted By: Jeepmon

Re: when is a torque strap necessary? - 01/23/12 02:25 AM

It my 73, which is just a little 500hp small block, we are constantly breaking the drivers side motor mount.. I would guess at least 1 per year with the amount we street drive and race...

I've made a little torque strap using a hardware store turnbuckle set up and the motor mounts no longer breaks..

Posted By: B_Body_Bob

Re: when is a torque strap necessary? - 01/23/12 02:31 AM

Somebody around here told me to try a solid on the driver's side and rubber on the passenger that way the solid takes up the shock but the rubber keeps it from vibrating the whole car. Worked OK in the last street car I had set up that way.

Posted By: 67Satty

Re: when is a torque strap necessary? - 01/23/12 02:59 AM

I made my driver's side motor mount into a semi-solid but drilling through it and putting in some grade eight bolts and nuts. It can compress a little but it can't go the other way from engine torque. That's the idea anyway.

Posted By: prochargedhemi

Re: when is a torque strap necessary? - 01/23/12 03:14 AM

Posted By: Ari440

Re: when is a torque strap necessary? - 01/23/12 03:27 AM

Quote:

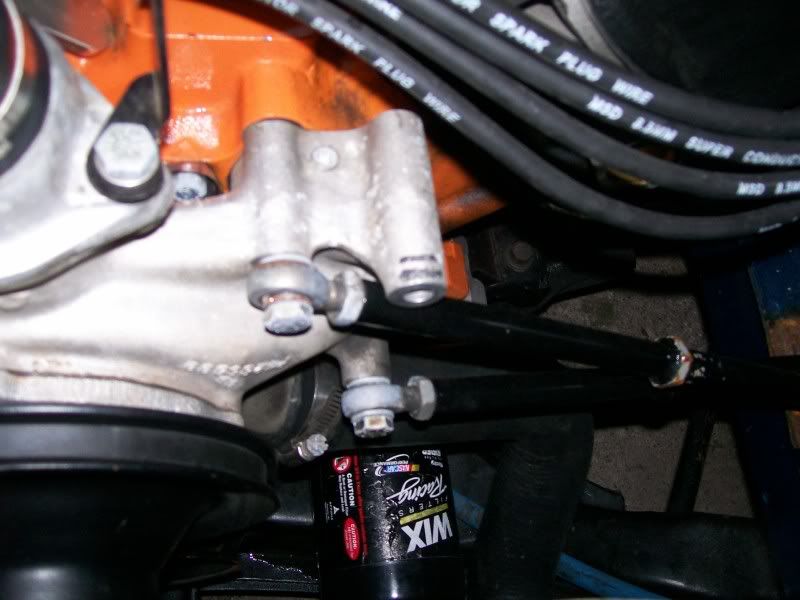

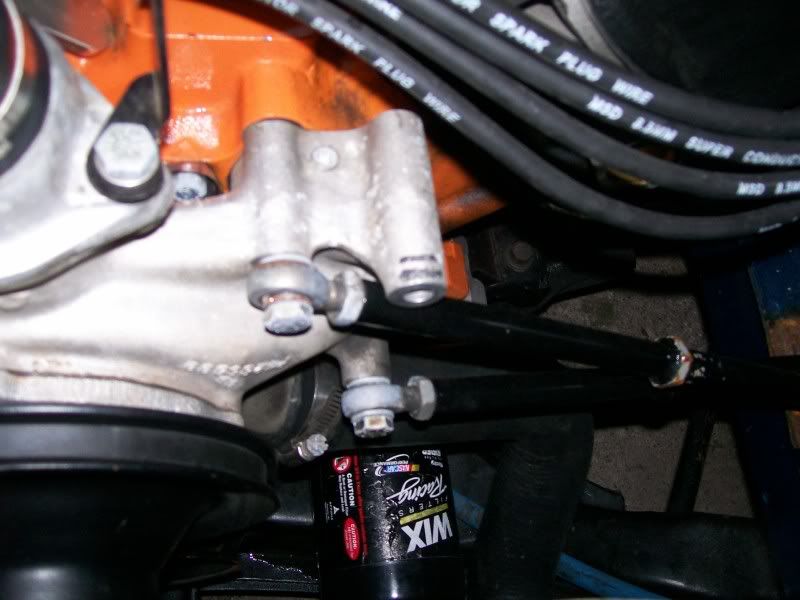

i think a strap is always necessary whenever your not worried about the looks of the engine compartment. this is my design and its hidden pretty well by the battery and tray. now obviously it doesn't work with power steering but gives you an idea. I don't like mounting off the boss on the front of block as it "could" cause distortion in that cylinder, both of these cars have stock rubber mounts. been like this for 5-6 years now and no trouble

here it is in my 68 b-body

where can someone get a strap like that one ?

very nice !

Posted By: prochargedhemi

Re: when is a torque strap necessary? - 01/23/12 04:09 AM

i made those ones. its pretty basic really. a couple heim ends, some aluminum bar stock/steel stock or tube, and 8 inches of 1/4x2 plate. obviously you will need someone to drill/tap the rods left and right hand to thread the heims into but other than that its DIY stuff

Posted By: B1duster

Re: when is a torque strap necessary? - 01/23/12 05:41 AM

A piece of chain with a little slack from a motor mount block bolt to the K frame works great. Went 9s with rubber mounts.

Posted By: polyspheric

Re: when is a torque strap necessary? *DELETED* - 01/23/12 05:44 AM

Post deleted by polyspheric

Posted By: prochargedhemi

Re: when is a torque strap necessary? - 01/23/12 04:50 PM

Quote:

Sorry, not trying to be Mr. Wizard here, but this needs to be said.

The quality of the parts and the installation is not possible to evaluate from here, let's agree that they were well chosen and have held up well.

What I find troubling is the position of the mounts.

The only resistance it offers to forward and back motion is the angle built into the Heim joints - and they're not designed to take any thrust that way. If you had significant motion (another mount fails, etc.) the Heims would go out of range and fail.

Vertical movement of the block is zero, since the 2 links form a triangle. If either link were removed, or both links mounted at different heights separately, the block could rise and fall with some side motion. It would resist rotation (torquing) but not efficiently.

Side to side movement of the block is zero. If it tried to go right, the links are in tension - good, no harm. If it tries to go left, at least 1 link is in compression and will bend.

The only block motion that is both controlled and safe now is an angle rotating the entire block around the fender mount. This is opposite the way the block will move under power.

In short, the hardware is fine, but the relationships are not helping you.

In order to resist engine rotation, the link must always be in tension (pulling down on the left side, or up on the right), never at 90° to the expected force.

Its worked fine for my 790hp rig. Ive seen faster cars with less. if you don't like it don't use it, it was posted for an example.

Posted By: maximum entropy

Re: when is a torque strap necessary? - 01/23/12 05:09 PM

Quote:

Sorry, not trying to be Mr. Wizard here, but this needs to be said.

The quality of the parts and the installation is not possible to evaluate from here, let's agree that they were well chosen and have held up well.

What I find troubling is the position of the mounts.

The only resistance it offers to forward and back motion is the angle built into the Heim joints - and they're not designed to take any thrust that way. If you had significant motion (another mount fails, etc.) the Heims would go out of range and fail.

Vertical movement of the block is zero, since the 2 links form a triangle. If either link were removed, or both links mounted at different heights separately, the block could rise and fall with some side motion. It would resist rotation (torquing) but not efficiently.

Side to side movement of the block is zero. If it tried to go right, the links are in tension - good, no harm. If it tries to go left, at least 1 link is in compression and will bend.

The only block motion that is both controlled and safe now is an angle rotating the entire block around the fender mount. This is opposite the way the block will move under power.

In short, the hardware is fine, but the relationships are not helping you.

In order to resist engine rotation, the link must always be in tension (pulling down on the left side, or up on the right), never at 90° to the expected force.

you said what i was thinking. the rod should be tangential to the crank axis. i'm sure it works, but that doesn't make it optimal. i had a solid strap running down the the driver's side to the k member, rubber on the passenger side. it took me about a half an hour to fab up, and worked great.

Posted By: 67Satty

Re: when is a torque strap necessary? - 01/23/12 05:27 PM

Here's a link to making the rubber insulator into a semi-solid mount:

http://www.dodgecharger.com/forum/index.php?topic=13216.0;all

Posted By: HEMIFRED

Re: when is a torque strap necessary? - 01/23/12 09:30 PM

for years only a chain was attached whick allow a certain degree of movement and luxury of the rubber mounts . when the motor starts to move to far the chain stops it all.

that might be to simple for many here but it works 100%

Posted By: dirtybee

Re: when is a torque strap necessary? - 01/24/12 12:19 AM

that's what i use, a chain from my sway bar bracket to the boss on the front of the block, works great because you still have the 2 rubber mounts but there's no way the engine can break loose. that is a good point about the cylinder distortion though, i may change to the upper water pump bolt hole. cheap and easy and quite necessary on any 440 in my opinion. when i bought my 70 coronet in 2001 it had a really tired 440 AND a busted drivers side mount.

Posted By: Exit1965

Re: when is a torque strap necessary? - 01/24/12 05:48 AM

I cut a chain link in half, welded it to the K member, then run a turnbuckle up to the block from there. Simple design, easy to do, cheap.

Posted By: polyspheric

Re: when is a torque strap necessary? - 01/24/12 06:13 AM

This is the point where I mention that whenever some expert (and he must be an expert - he's got 790 hp) takes a technical comment as a personal insult, my interest in assisting anyone goes down 1 notch.

I've seen faster cars with less upside down, too.

Posted By: prochargedhemi

Re: when is a torque strap necessary? - 01/24/12 11:34 AM

Quote:

This is the point where I mention that whenever some expert (and he must be an expert - he's got 790 hp) takes a technical comment as a personal insult, my interest in assisting anyone goes down 1 notch.

I've seen faster cars with less upside down, too.

i never claimed to be an expert. It worked for me, like i stated. It is shown for example, as stated. I didn't take it personally at first but by the looks of it you are trying to take it in that direction. Enjoy

Posted By: Max Wedge Savoy

Re: when is a torque strap necessary? - 01/24/12 12:54 PM

Why is everyone busting his sack?!?! He posted an example that has worked for him. As stated, if you don't like it, don't use it!

Posted By: Dodgeguy101

Re: when is a torque strap necessary? - 01/24/12 01:34 PM

Quote:

for years only a chain was attached whick allow a certain degree of movement and luxury of the rubber mounts . when the motor starts to move to far the chain stops it all.

that might be to simple for many here but it works 100%

I have to agree, just a poor farm boy, but a chain and turnbuckle works.

Posted By: dangina

Re: when is a torque strap necessary? - 01/28/12 08:07 AM

Quote:

for years only a chain was attached whick allow a certain degree of movement and luxury of the rubber mounts . when the motor starts to move to far the chain stops it all.

that might be to simple for many here but it works 100%

Quote:

I cut a chain link in half, welded it to the K member, then run a turnbuckle up to the block from there. Simple design, easy to do, cheap.

any pics?

Posted By: Bad340fish

Re: when is a torque strap necessary? - 01/28/12 02:29 PM

I used to run a chain on mine. Now I just welded up a stock mount. I am thinking of going back to tHe chain though. Any concern with running it to an aluminum head?(that's why I switched)

Posted By: 383man

Re: when is a torque strap necessary? - 01/28/12 06:19 PM

I use a solid mount on the drivers side with a chain for back-up. Ron

Posted By: Exit1965

Re: when is a torque strap necessary? - 01/28/12 07:00 PM

Quote:

Quote:

for years only a chain was attached whick allow a certain degree of movement and luxury of the rubber mounts . when the motor starts to move to far the chain stops it all.

that might be to simple for many here but it works 100%

Quote:

I cut a chain link in half, welded it to the K member, then run a turnbuckle up to the block from there. Simple design, easy to do, cheap.

any pics?

Good thing you asked for pics. Turns out I later welded an "ear" to the side of the motor mount tower on the Kmember. The cut chain is still welded there (there is a zip tie holding some cooler lines) but I see that I didn't like the fact that it was forward of the point where the turnbuckle mounted to the engine.

So the ear on the side of the motor mount tower makes more of a straight line to the motor and that's what I use.

Posted By: cjs69mope

Re: when is a torque strap necessary? - 01/28/12 07:34 PM

I prefer to use a moroso solid on the drivers side only.

But my car is a 4speed and i don't want the risk of blowing out a clutch linkage during a power shift run.

Also i drill out the hole for the long bolt to run a hardware store 5/8 x 4" long bolt because that is the size of the k frame hole and i want zero movement i have seen engines move up on the k and stay crooked even though the bolt was tight . Works great and the vibration is not bad even driving on the street .