How many hours/miles on that 3406E ?

In the 1980s it was the repeated failures of $27,000 CAT turbochargers on 992 front end loaders that gave me heartburn.

$27K back then would be $90K today.

Years later when reading WW-II history I learned that turbochargers were a huge headache on aviation engines.

The first time it croaked was Jan 2018 at 750k, dropped a liner. Cut a corner I should have went around on the inframe when I only replaced 2 injectors. 8 months later it split an injector tip and smoked #2 piston and liner. June 2020 it broke the crank.

Currently has 1.1 million on it.

My buddy has a 5EK series that lost an injector tip at 1.1 million. That overhaul has 1.6 million and counting.

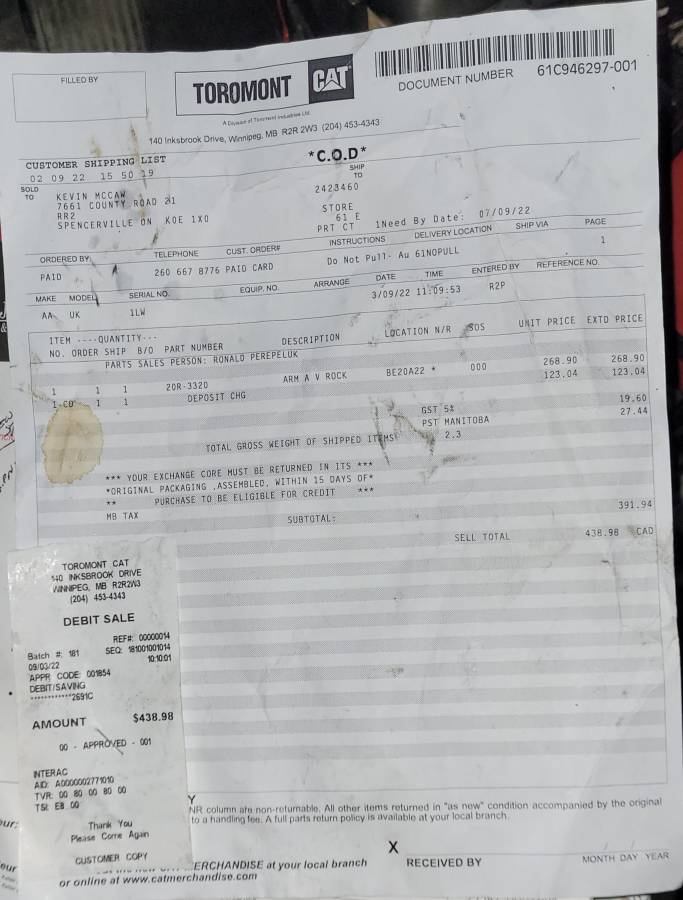

Kevin

.jpg)