What hp motor and VFD did you use?

- used a lower end lenze 15hp drive with a generic 7.6 hp motor that I machined down on small lathe to make the pulley fit.

-'ve done a pile of projects with single phase to three phase conversions, fans pumps,augers,etc and I found that to make it work, the vfd has to be rated for double the size of the motor nameplate to make last.

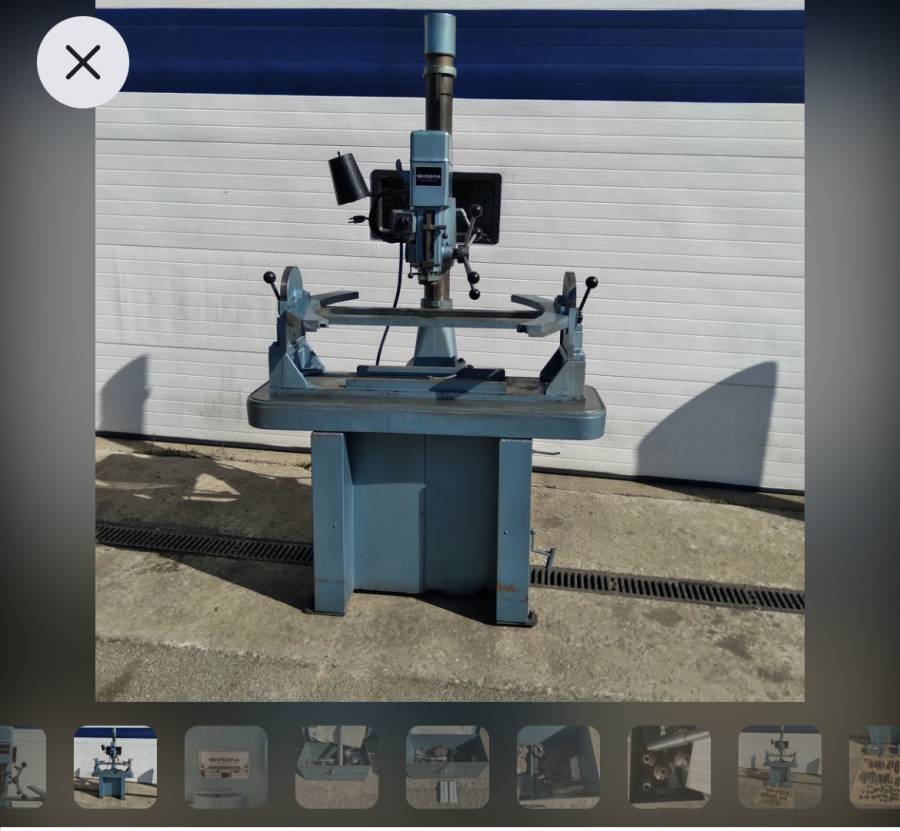

Another one I did in my own shop that was neat, its a jet drillpress I was given. It had a good quality quill and chuck, but a dinky motor that would stall on larger bits. I took a surplus 3 phase motor I had from an air conditioner, 1.0 hp and put it on a vfd.now the cool thing about the smaller vfd's is that you power them with 115v single phase and make 208v 3phase. On the drill press, now I have infinite speed control, soft start, and reverse for LH drill bits.

The lathe electrical is gutted, the vfd replaces all the contactos.