I'm no expert on cams either Since I run a roughly similar combo I feel somewhat qualified to comment though. Mine's an Ed headed 496,

243@.050 .55" lift cam, 108 cl, manual transmission, MP single plane intake, 3.23 rear and 25" tire. It's a little tender launching but does fine with practice. It will accelerate cleanly in high gear from 1200 RPM with part throttle but still may buck a little if I try to run it steady at say 1500. In that situation, I just pull the next gear. With a 30" tire it would possibly be too "tender".

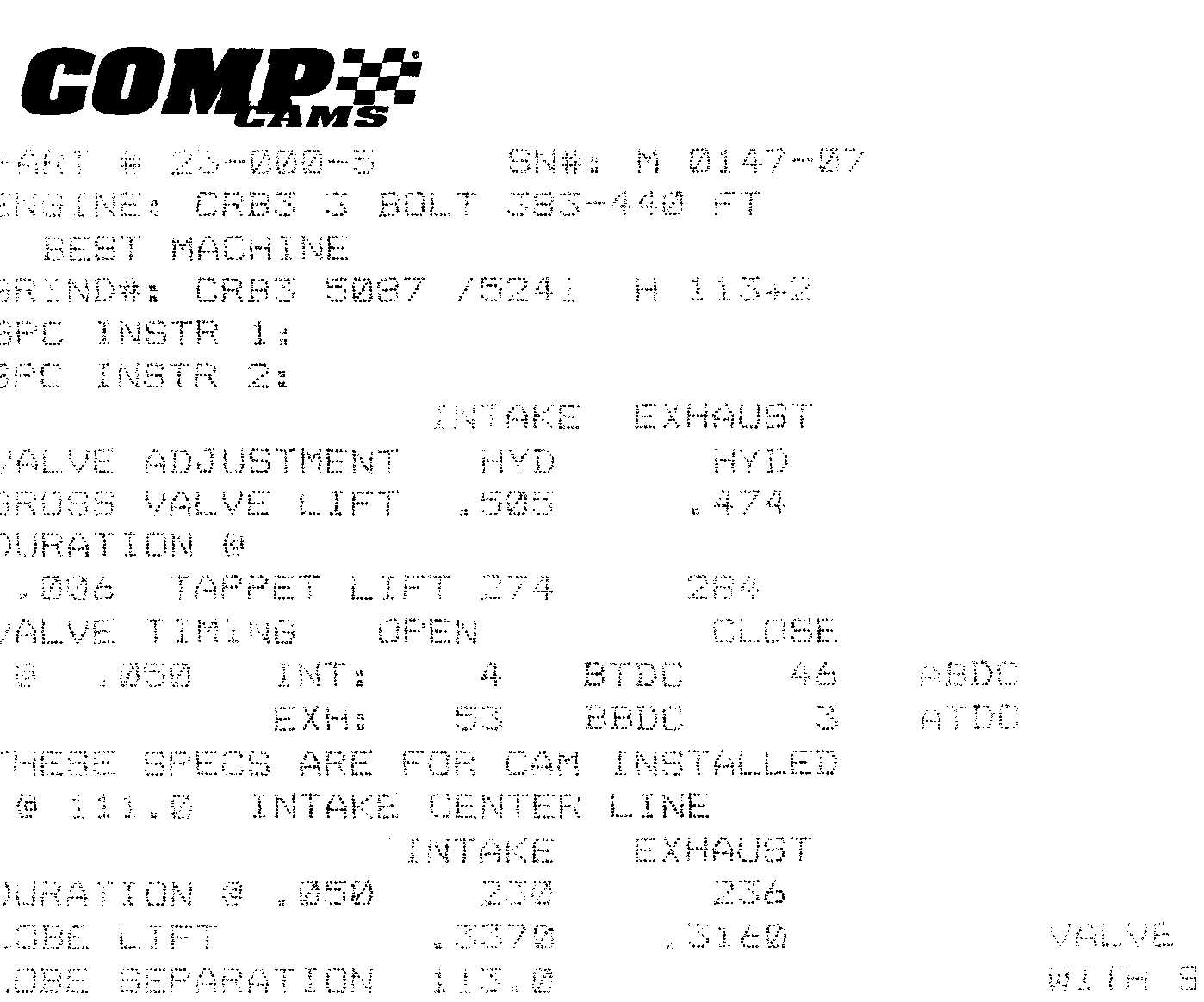

With 10:1 (true measured) compression you may be limited in reducing cam duration much as you can run into detonation problems. You are doing well not to have problems now. Also, I think there is a good chance you can get it smoothed out without a cam change or at least without a lower duration cam with the suggestions posted above and one or two more. If you do change cams a wider LSA with about the same duration would be in the right direction. Advancing is worth a try; a lot of the rest is tuning so if you are going to advance it, start with that first. Surging at low RPM may be the result of a lean mixture, excessive advance and/or a big tight CL cam. A dual plane intake should help. Getting it to behave in the 1200-2000 range also takes a lot of tuning. I'm a little surprised reducing spark advance to 5 degrees helped... most moderatly performance cammed strokers like 15-20 initial. It makes me wonder if the rest of the timing curve is off somehow. I'd suggest an initial timing of 15 degrees and a slow advance to 34 degrees at 2800-3000 RPM. Add or re-connect the vacuum advance after you get it smoothed out without vacuum. Vacuum advance will help the engine burn clean and improve fuel economy if you can get it sorted out. The carb likley will need tuning and I'm not a carb guy, mine's EFI and has taken a lot of fiddling to get it to behave reasonably well at low RPM. 750 is a bit small for a 500" engine but may be ideal for your application to help response and low RPM drivability. A vacuum secondary carb is usually considered more street friendly than a DP. It would be worth looking for somebody in your area that's good at tuning carbs.

If all of that helps, but doesn't quite get there, a step or two up in rear gear will help. 3.55 isn't much of a change so 3.7x may be the best bet with 30" tires.

Good luck!

If you feel you must change the camshaft just call Tim @ bullet cams. I have given up giving cam suggestions,just too many guru's on the interweb.

If you feel you must change the camshaft just call Tim @ bullet cams. I have given up giving cam suggestions,just too many guru's on the interweb.